Method for increasing tapping quantity of converter

A converter and steel scrap technology, which is applied in the manufacture of converters, etc., can solve the problems of affecting the production rhythm and efficiency of the converter, affecting the steel output of the converter, and being smaller than the scrap steel, so as to improve the heat utilization efficiency, reduce the amount of scrap steel added and join accidents, The effect of speeding up the pace of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

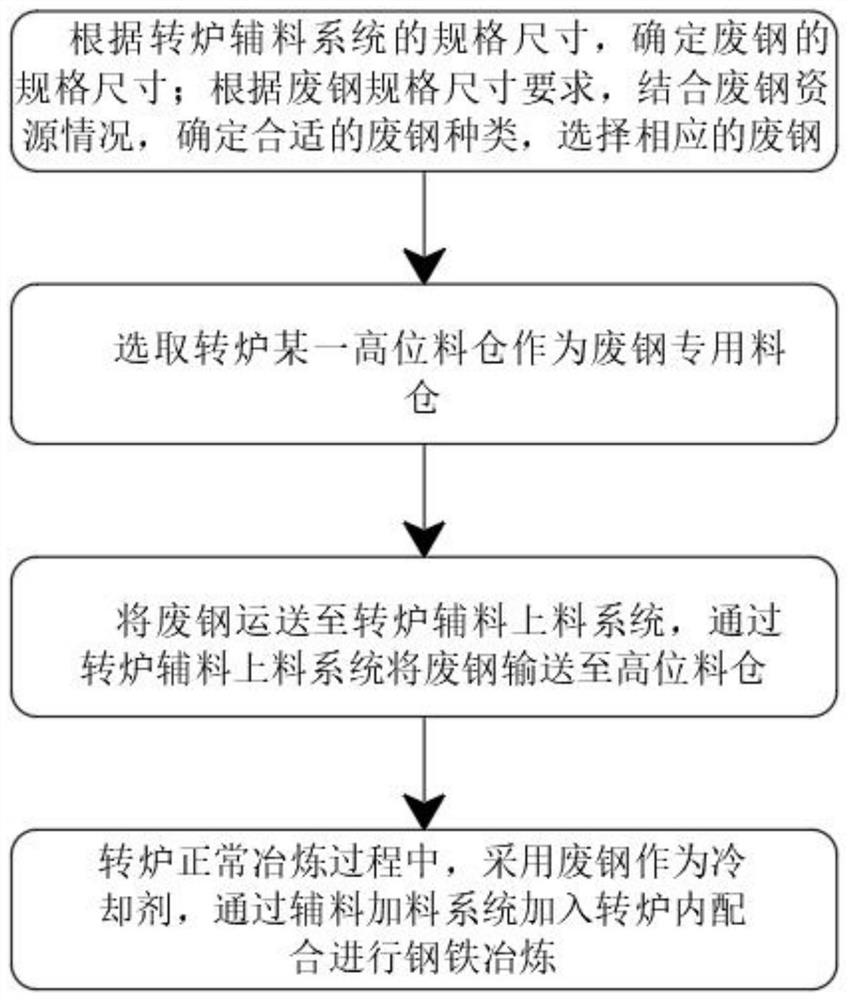

[0027] The present embodiment provides a kind of method that improves the steel output of converter, as figure 1 As shown, the specific steps are as follows:

[0028] (S1), select steel scrap

[0029] According to the specification and size of converter auxiliary material system, determine the specification and size of scrap steel;

[0030] According to the specification and size requirements of scrap steel, combined with the situation of scrap steel resources, determine the appropriate type of scrap steel, and select the corresponding scrap steel;

[0031] (S2), select the silo

[0032] Select a high-level silo of the converter as a special silo for scrap steel;

[0033] (S3), conveying scrap steel

[0034] Transport the steel scrap to the auxiliary material feeding system of the converter, and transport the steel scrap to the high-level silo through the auxiliary material feeding system of the converter;

[0035] (S4), adding steel scrap

[0036] During the normal smel...

Embodiment

[0058] Scrap material type: crushed scrap steel, the recovery rate is about 92%;

[0059] Steel grades for smelting: general carbon and low alloy steel grades without special requirements;

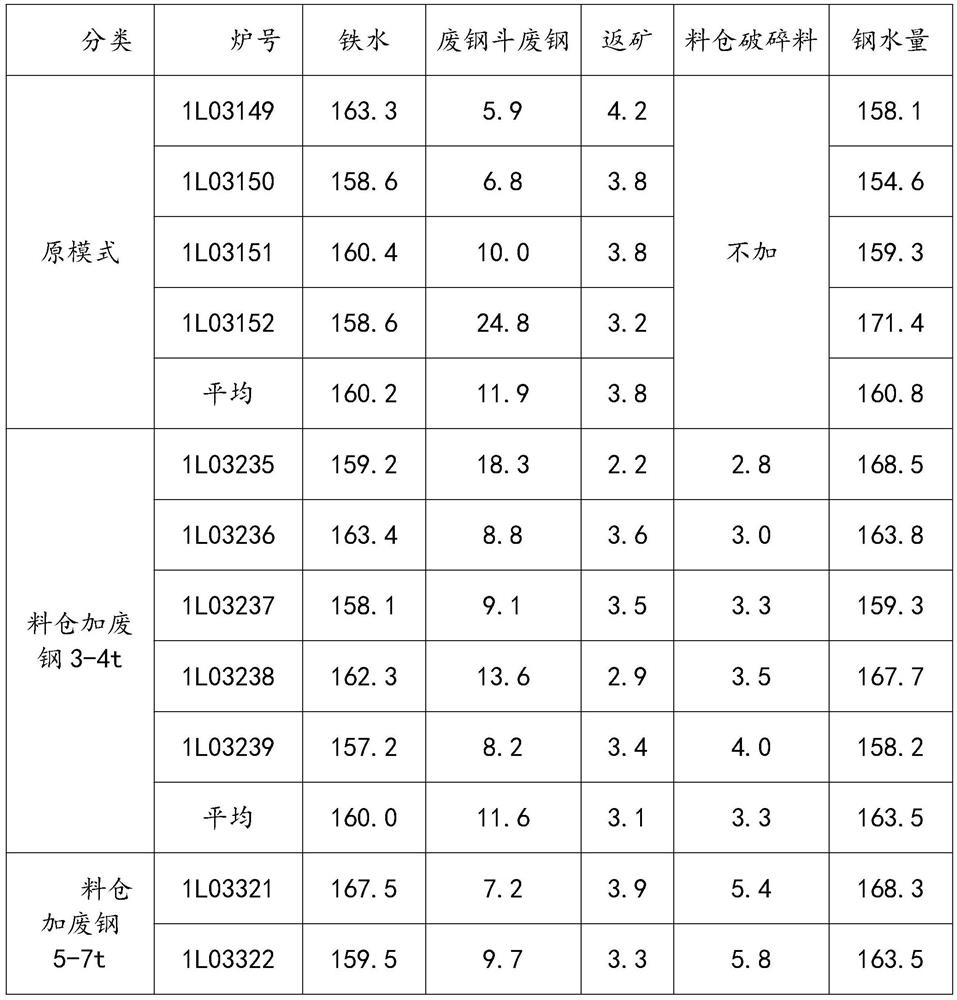

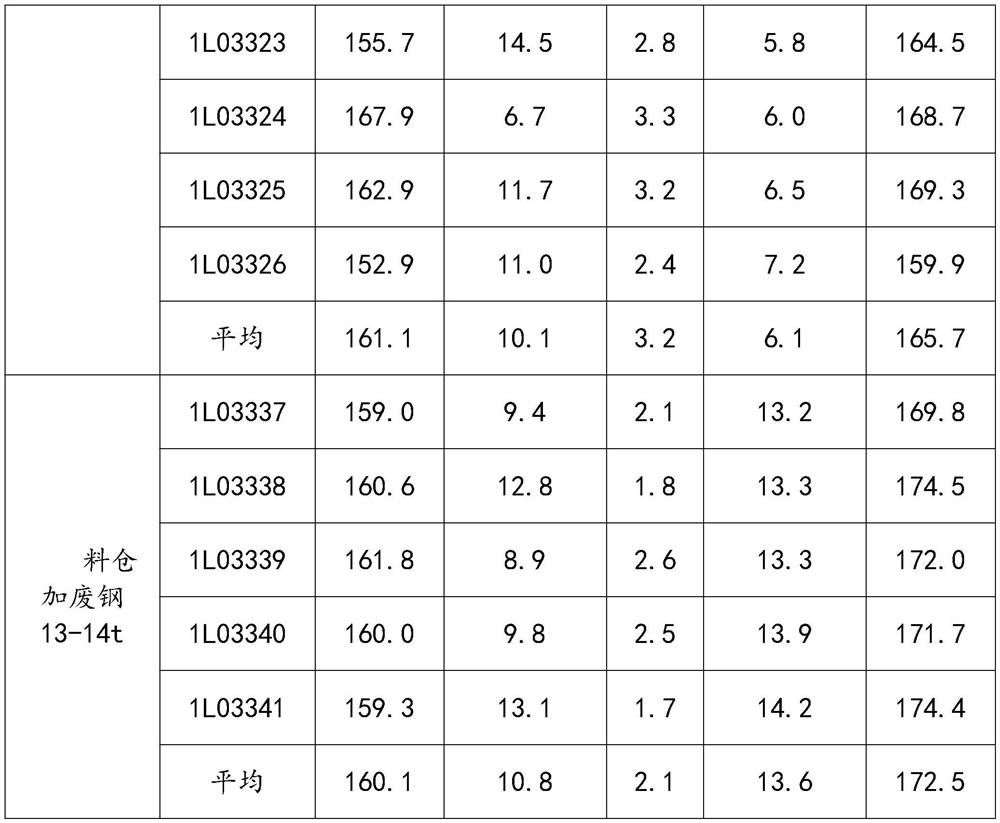

[0060] Original smelting mode: 160 tons of molten iron + scrap steel hopper plus 10 tons of scrap steel + coolant (return to ore)

[0061] Silo plus scrap mode: 160 tons of molten iron + scrap hopper plus 10 tons of scrap + scrap in silo + a small amount of coolant (return to ore).

[0062]The specific embodiment data is shown in the following table 1. The scrap steel is added through the high-level silo, and the addition amount is respectively 3.3 tons / furnace, 6.1t / furnace, and 13.6t / furnace, and the tapping amount increases respectively 2.6t / furnace, 4.8t / furnace, 11.6t / furnace, with the increase of crushing material addition, under the condition that the loading amount (the total amount of "hot metal + scrap steel bucket scrap steel" added) remains unchanged, the tapping amount increa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com