External-stretching-beam buried column base construction for reducing height of bearing table and construction method

A technology of overhanging beams and column feet, which is applied in the direction of basic structure engineering, columns, pier columns, etc., can solve the problems of large cap height, inconvenient construction, waste, etc., and achieve shortened construction period, reduced construction difficulty, and high cap height. Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

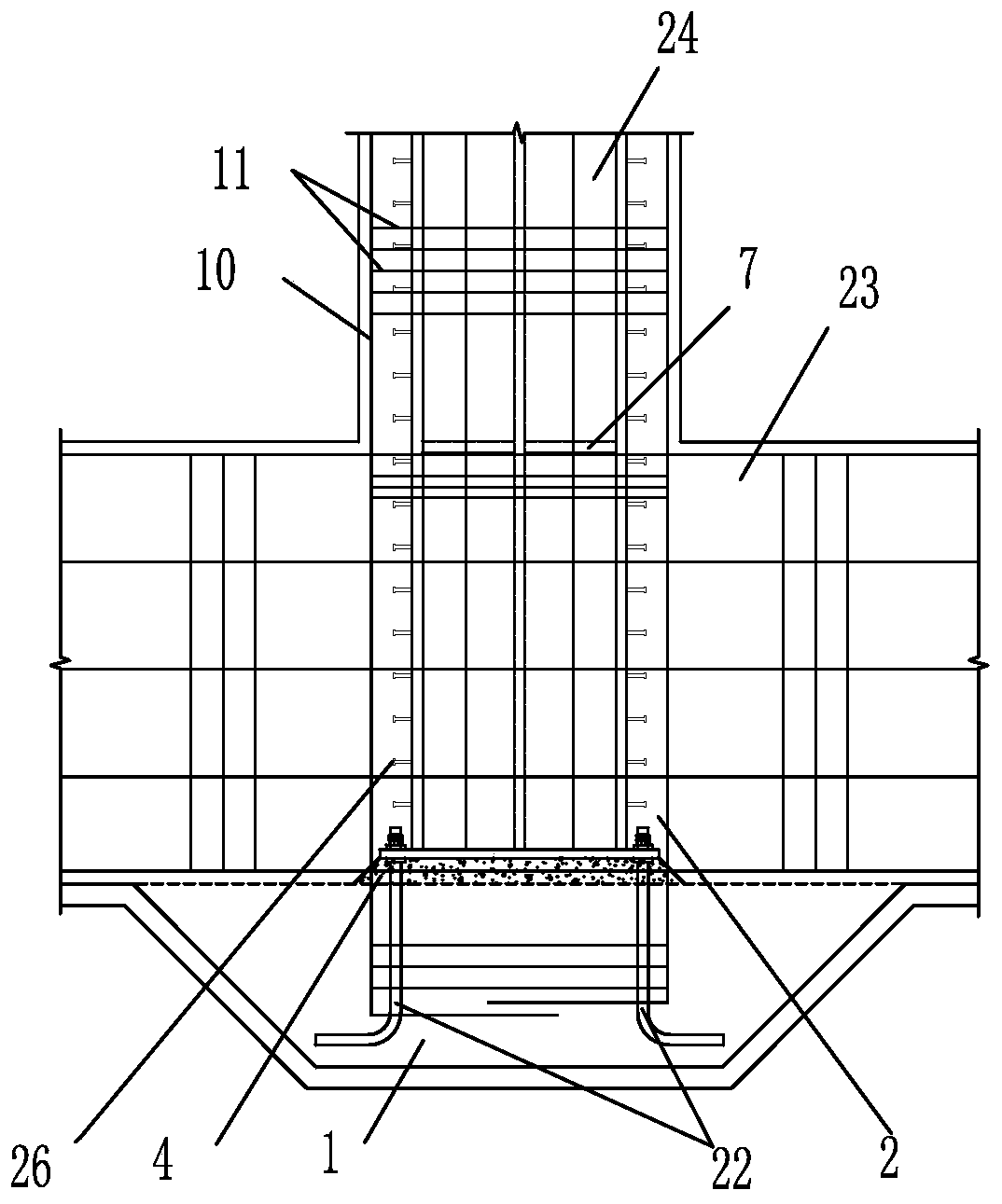

[0092] The land used for a depot in a certain place is in an irregular rectangle, 950m long from north to south, and 440m wide from east to west; the land area is about 28.01 hectares. The parking and train inspection depot, joint maintenance depot, throat area and surrounding roads in the site adopt an overall sinking scheme of 5.0m. Non-residential buildings such as office or commercial buildings will be developed on top of the depot storage area and throat area. The entire storage area, throat area and access section line are planned to be divided into 10 structural units. Among them, section 3 of the joint maintenance depot, section 4 of the parking train inspection depot, and part of the frame columns of the throat area 5 and 6 adopt steel-steel concrete members, and the throat area 7 adopts steel pipe concrete members. Pillar node. Here is an example of a steel-concrete frame column at a in area 4 of the parking and train inspection depot, see Figure 6(a1), Figure 6(a2)...

Embodiment 2

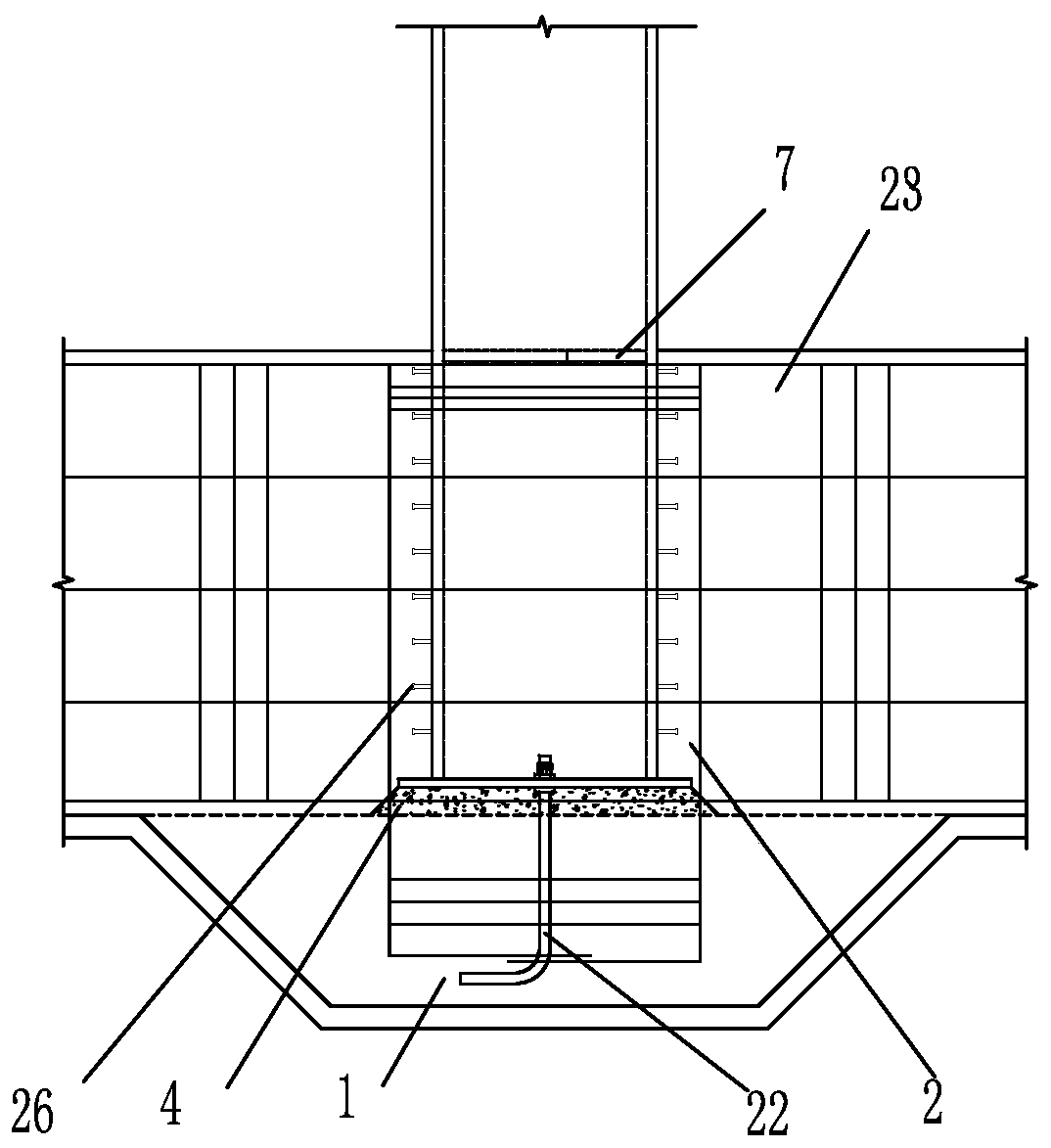

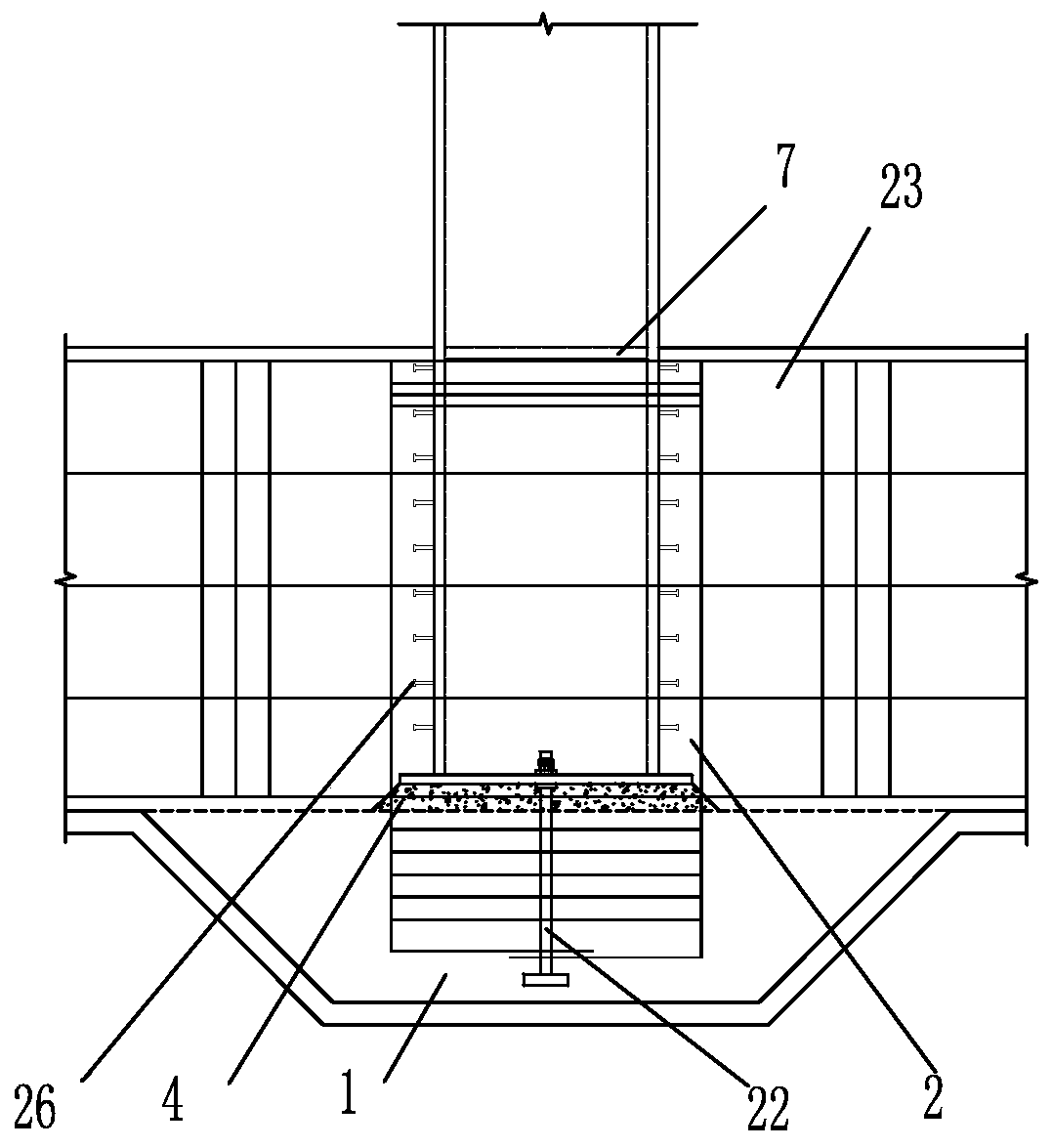

[0100] The west side of a certain depot area is the throat area, the central part is the joint inspection depot and the application depot (a two-story car depot is developed above the depot); the east and north sides are the turning line, and the south side of the depot is the test line; the east side The living area is between the turning line and the storage area. Residential buildings will be developed on top of the depot reservoir area, and the entire reservoir area and throat area are planned to be divided into 17 structural units. The frame columns of the combined maintenance warehouses A1-1, A1-2, A2-1, A2-2, A3-1, and A3-2 are partly steel concrete members, and the embedded column foot nodes are designed according to the method of the present invention. Here is an example of the steel concrete frame column foot joint at A2-1 area a of the joint maintenance depot, see Figure 7(a1) , 7(a2) ; 1 example of steel concrete frame column foot joint at b in area A2-2, see Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com