Patents

Literature

63results about How to "Increase the content of MgO" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Slag adjusting and furnace protecting method for controlling rising of converter bottom and furnace wall slag deposition

InactiveCN102127612AIncrease the content of MgOImprove furnace protection effectManufacturing convertersSteelmakingSludge

The invention belongs to the technical field of steelmaking and provides a slag adjusting and slag splashing furnace protecting method for controlling rising of a converter bottom and furnace wall slag deposition, solving the problems that the effective volume is reduced and the center of gravity of a furnace body shifts as slag stacked at the converter bottom rises and slag deposits at the lining of the furnace wall when the traditional slag splashing furnace protecting process is adopted. The method provided by the invention is characterized by adopting a two-step slag adjusting method, primary slag adjusting is carried out before molten steel is tapped, a boric sludge-magnesia slag adjusting agent is added into a furnace to reduce the viscosity of the slag, slag deposition at the lining of the unilateral furnace wall and slagging at the converter bottom in the tapping process can be prevented, the slag remaining and no steel remaining operation is adopted in the follow-up tapping process; and secondary slag adjusting is carried out after tapping, namely a magnesia carbon slag adjusting agent (coke powder and material containing magnesium oxide) is added into the slag remained in the furnace, and then the slag splashing slag protecting process is carried out. By adopting the method provided by the invention, the rising of the converter bottom and thickening of slag depositedon the furnace wall can be controlled, the thickness uniformity of the furnace wall can be guaranteed, and the slag splashing furnace protecting effect is obviously improved, thus the service life ofthe lining of a converter can be greatly prolonged.

Owner:JIANGSU UNIV

Magnesium binder used for pellet and preparation method and addition method thereof

InactiveCN102719662AIncrease the content of MgOImprove metallurgical performance indicatorsPass rateUltimate tensile strength

The invention provides a magnesium binder used for a pellet and a preparation method and an addition method thereof. The preparation method comprises: adding 30-35% of magnesite powder having a passing rate more than 80% through a 320 mesh, 40-55% of bentonite and 12-15% of active lime into a mixer; mixing a mixture above while adding 3-5% of sodium carbonate; and pulling the mixture out and airing the mixture for 7-9h to get a finished product. The addition method comprises adding the binder to a surface of a pellet mixture on a material conveying belt according to a preset weight of the binder that should be conveyed of a unit time and a unit length and based on a ratio by weight from 2.5% to 4.5%. Pellet MgO can be improved by 1-2%, mechanical strength of the pellet can be improved by 1-2%, and an initial softening temperature can be improved by 100-150 DEG C with the magnesium binder added into the pellet mixture. Blast furnace output can be improved by about 5% and coke ratio can be reduced by 10 kg by the pellet using the binder in the invention.

Owner:ANGANG STEEL CO LTD

Lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and preparation method and application thereof

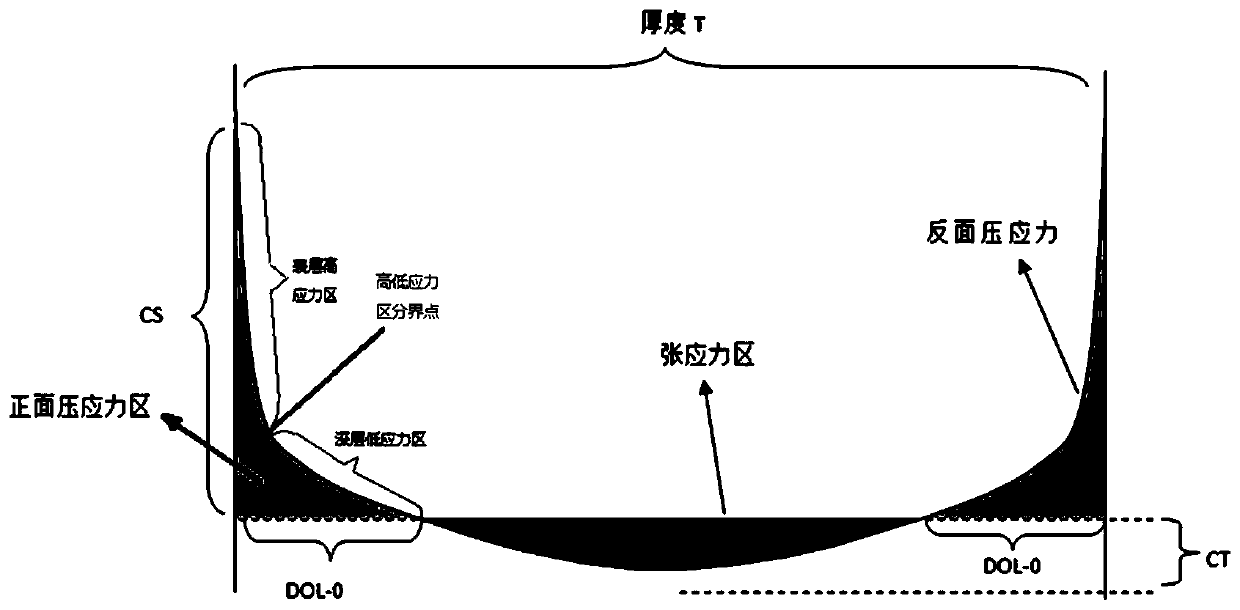

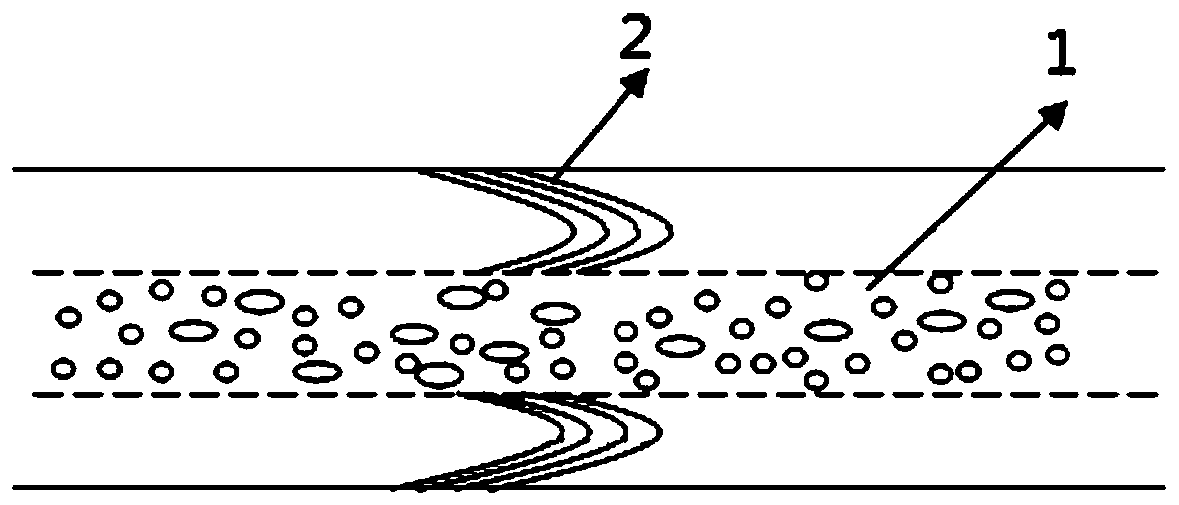

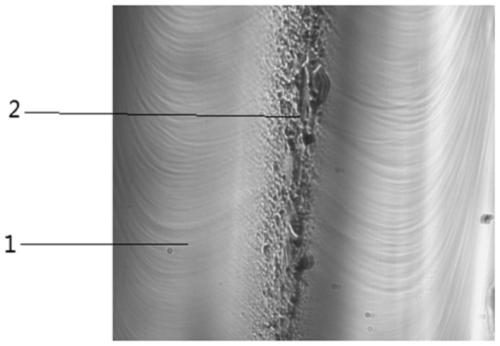

The invention discloses lithium aluminum silicon glass, lithium aluminum silicon chemically strengthened glass and a preparation method and application thereof. The molar content of oxide components contained in the lithium aluminum silicon glass satisfies the following relationship: the SiO2 content is at least 66.5 mol%, and the total amount of an alkali metal oxide usable for ion exchange is not more than 14 mol%; (Na2O+Li2O) / (SiO2+Al2O3) is 0.09-0.22; Na2O / Li2O is 0.4-1.2; MgO / SiO2 is 6%-18%; (Na2O+Li2O+0.3*MgO) / Al2O3 is 0.7-1.4; and 0.5%<P2O5+ZnO+SnO2+K2O+ZrO2+TiO2<7%. The lithium aluminum silicon chemically strengthened glass is formed by chemically strengthening the lithium aluminum silicon glass as basic glass.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD

Fireproof material for mending furnace as well as preparation method and using method thereof

The invention discloses a fireproof material for a mending furnace as well as a preparation method and a using method thereof. The fireproof material for the mending furnace comprises magnesia, magnesium powder, aluminium oxide, calcium oxide and sodium hexametaphosphate, wherein the total weight of the fireproof material for the mending furnace is used as a reference, the total content of the magnesia and the magnesium powder accounts for 80-90 percent by weight; the content of the aluminium oxide accounts for 3-7 percent by weight; the content of the calcium oxide accounts for 3-7 percent by weight; the content of the sodium hexametaphosphate accounts for 3-7 percent; and the main components of the magnesia and the magnesium powder are MgO. The fireproof material for the mending furnace is high in adhesive ratio, good in stickiness, solidification and hardness, and low in resilience value during mending; and therefore, a mending layer formed by the fireproof material for the mending furnace is good in anti-erosion performance and long in service life.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP +2

Electric furnace bottom ramming mass

The invention discloses an electric furnace bottom ramming mass. The electric furnace bottom ramming mass contains the following raw materials in percentage by weight: 20-40% of 5-3mm fused magnesite or high-purity magnesite aggregate, 10-25% of 3-1mm fused magnesite or high-purity magnesite aggregate, 15-25% of 1-0mm fused magnesite or high-purity magnesite aggregate and 20-30% of <88 mu m fused magnesite fine powder or high-purity magnesite fine powder. Brine, which accounts for 4-6 wt% of the raw materials, is also added as a binder. The raw materials for producing the ramming mass combined with the brine are stable and easy to store. The ramming mass production process is simple, and the product quality is easy to control. The ramming mass has high MgO content, low impurity content, high fire resistance and higher corrosion resistance, and the service life can be prolonged from more than two hundred times to more than five hundred times in the electric furnace use process.

Owner:河南竹林耐材有限公司

Flotation calcium-removing agent and method for magnesite

InactiveCN106345616ALower calcium levelsIncrease decalcification rateFlotationSodium silicateChemistry

The invention discloses a flotation calcium-removing agent and method for magnesite. Hydrochloric acid, sodium phosphate, dodecylamine, sodium hydroxide, sodium silicate, sodium hexametaphosphate, oleic acid and FZ-8 are taken as flotation calcium-removing agents, and different scientific and reasonable agent formula systems are adopted at different flotation stages, so that calcium content of the magnesite can be lowered effectively; meanwhile, a process flow of combining reverse flotation and positive flotation and adding flotation agents with a reasonable formula segmentally is adopted, so that the calcium content of the magnesite can be lowered effectively; as proved by detection, the MgO content of concentrated magnesite obtained by the flotation calcium-removing method is over 99 percent, the total impurity content is lower than 1.0 percent, and the CaO content is lower than 0.80 percent. By adopting the flotation calcium-removing agent and method, the calcium removal rate can be increased effectively, and the quality of the magnesite is improved; moreover, the method is easy and convenient to operate, is simple in process, has contribution to popularization, and has a considerable application prospect.

Owner:肃北镁弘科技有限公司

Fluoride-free environmental-friendly slag dilution solvent for electric furnace, converter and medium frequency furnace and preparation method of fluoride-free environmental-friendly slag dilution solvent

ActiveCN102747194AImprove liquidityExtended service lifeProcess efficiency improvementElectric arc furnaceSlag

The invention discloses a fluoride-free environmental-friendly slag dilution solvent for an electric furnace, a converter and a medium frequency furnace and a preparation method of the fluoride-free environmental-friendly slag dilution solvent. The fluoride-free environmental-friendly slag dilution solvent comprises the following components by mass: 5-20 percent of CaO, 30-70 percent of Al2O3, 10-30 percent of Fe2O3, 5-20 percent of MgO, 1-5 percent of borax and 1-5 percent of soda ash, wherein the borax and the soda ash are taken as additives. Compared with traditional slag dilution solvents, particularly when being used for smelting a special alloy steel grade, due to the characteristics of low melting point, good mobility, small surface tension and the like of the slag of the special alloy steel grade, the fluoride-free environmental-friendly slag dilution solvent ensures that slag has stronger capability of adsorbing rare metal oxide of vanadium oxide, titanium oxide, titanium nitride and the like in molten steel and supplies powerful guarantee for increasing the molten steel purity of the special alloy steel and reducing steel billet inclusion in subsequent continuous casting.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

Maintenance method for converter lining

InactiveCN102851430AIncrease the content of MgOHigh viscosityLinings repairManufacturing convertersSlagRepair material

The invention involves a maintenance method for the converter lining. The method is characterized in that: during the process of converter turndown for sampling, standing for tapping or taping, spray repair operation and / or manual feed repair operation is performed to the part of the furnace lining not covered by steel slag, and modification to the slag is not required to be performed during the slag splashing furnace maintenance process performed after tapping is finished. Compared with the prior art, the method has the advantageous effects that: a part of spray repair material or feed repair material adheres on the furnace lining, increases the thickness of the slag splashing layer, and has effect on furnace lining protection, and the rest spray repair material or feed repair material enters into the slag, is molten under the high temperature action of the slag; and since the spray repair material or feed repair material has higher MgO content, the slag viscosity can be remarkably increased, so that slag modification is not required to be performed during the slag splashing furnace maintenance process after the following tapping is finished, and under the condition that slag splashing furnace maintenance time is remarkably shortened, the slag splashing effect is still superior to that the modified slag not adopting the process, in addition, adoption of the process has no need of shutdown of the furnace, so that the converter operating rate can be remarkably improved.

Owner:ANGANG STEEL CO LTD

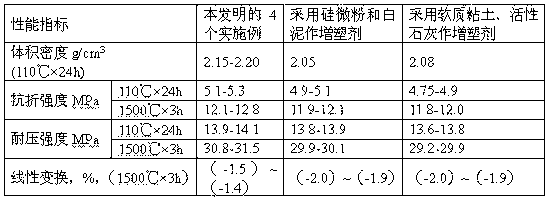

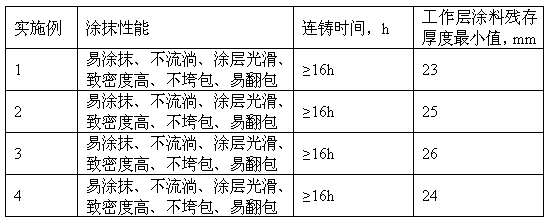

Continuous casting tundish working layer coating

The invention relates to the field of ferrous metallurgy technology and fireproof materials for ferrous metallurgy, in particular to a continuous casting tundish working layer coating. The invention has the following purposes: magnesite and boron mud are used as main base materials to invent a continuous casting tundish working layer magnesian coating without using silica powder, clay, active lime and other plasticizers, properties beneficial to a fireproof working layer, such as high MgO content, high fire resistance, high activity, high plasticity and the like, of the boron mud are fully utilized, and the boron mud is used for replacing the plasticizers used in the prior art, thus recycling the boron mud, improving the fire resistance, slag resistance and the like of the continuous casting tundish magnesian coating as well as prolonging the service life of the continuous casting tundish magnesian coating.

Owner:JIANGSU UNIV

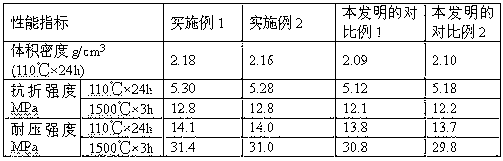

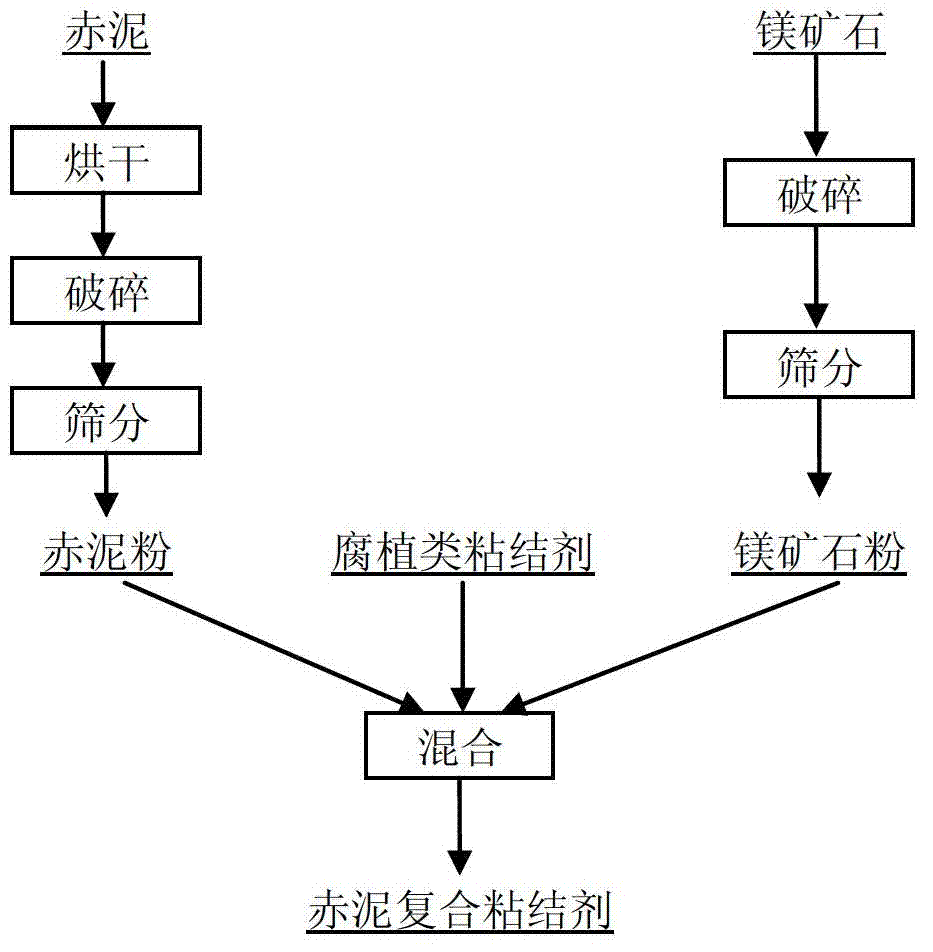

Red mud composite binder for oxidized pellets

The invention discloses red mud composite binder for oxidized pellets. The red mud composite binder is prepared by waste red mud of aluminum plants, magnesite stone and humus binder. The red mud composite binder has characteristics of good hydrophily, excellent binding effect, low price, high iron content and the like. The granularity of the red mud composite binder is smaller than 200 meshes, partial weight ratio is larger than or equal to 90%, and water content is smaller than or equal to 1%. Therefore, the red mud composite binder can partially or totally replace bentonite to be used for producing the oxidized pellets. Compared with the technology completely utilizing the bentonite to produce the oxidized pellets, production rates of pellet TFe, sinter TFe and an ironmaking system are all improved, and slag quantity of a blast furnace is reduced. Besides, the content of MgO in the pellets is increased, so that the thermodynamic property of the pellets is good, and operation of the blast furnace is facilitated.

Owner:LAIWU IRON & STEEL GRP

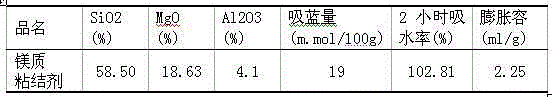

Preparation method of iron ore powder pelletized magnesian binding agent

A preparation method of an iron ore powder pelletized magnesian binding agent comprises the following processing steps that firstly, mixed adding is carried out, wherein, according to raw material ratio, 90%-95% of sepiolite and 5%-10% of magnesia are included, and according to the mass percent of the prepared chemical components, SiO2 is smaller than 60%, MgO is larger than 18%, Al2O3 ranges from 3% to 6%, the blue absorption power ranges from 18m.mol / 100g to 20m.mol / 100g, the two-hour water absorption rate ranges from 100% to 105%, the expansion capacity ranges from 2ml / g to 3ml / g, and after raw materials are prepared, a spiral stirrer or cylindrical mixer is used for full mixing; secondly, rough breaking is carried out, wherein a hammer type breaker or jaw type breaker is used for breaking a mixture of the sepiolite and the magnesia to be particles with the granularity smaller than 3 mm; and thirdly, grinding is carried out, wherein a raymond mill or medium-speed mill is used for continuously grinding the mixture broken to the particles with the granularity smaller than 3 mm in a fine manner to -200 meshes, and the occupation is above 95%. The magnesian binding agent is used for replacing bentonite and other efficient binding agents for producing, the pelletizing performance is greatly improved, the pressure of MgO is improved while the sintered ore is reduced, stability and the improvement of the quality of the sintered ore are facilitated, and the production process is simple.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Converter final slag thickening method

InactiveCN104531940AReduce FeO contentHigh yieldManufacturing convertersLime productionSlagLaboratory test

The invention discloses a converter final slag thickening method. The converter final slag thickening method includes the steps that firstly, after oxygen is blown for 10 minutes, gun pressing operation is conducted, in other words, the position of the gun is reduced by 200 mm, the oxygen pressure is kept between 0.75 MPa and 0.80 MPa, and duration is larger than 40 seconds; secondly, through a sampling laboratory test, and when the carbon content of molten steel is higher than the requirement of a smelting steel grade or the temperature of the molten steel is lower than the requirement of the smelting steel grade, reblowing treatment is conducted; thirdly, raw dolomite or lime is added so as to serve as a thickening material before steel is placed, and the addition amount of steel ranges from 2 kg / t to 5 kg / t. Through the optimization of converter end point gun pressing and reblowing, the FeO content of furnace slag is reduced, the metal yield is increased, the slag blocking success rate can be increased, the steel ladle slag amount is reduced, rephosphorization is reduced, the splashed slag furnace protecting effect can be improved, the furnace age can be prolonged, the slag amount requirement for slag residual operation is guaranteed, and lime consumption can be reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Ironmaking oxidized pellet additive

The invention discloses the globe group chemic additive used in the mine, it is the powder duplicating mix compound. The granularity exceeds 200 items, the team element (the weight percent): the adding adhesive is 30-50%; the adding oxygen activator is 10-25%; the intensifying reagent is 10-25%; the carrier is 30-50%. The produced additive has not Si, AL, K, Na element which are harmful for the piddling. It can replace fully the expanding moist soil in producing the ball and is need to depress the quality of the globe group mine, the request of the quality can be reached and exceeded with the adding of the 0.4-0.6% additive in the globe group material, the ability of the metallurgy under the high temperature in the globe group material can be improved highly. The function of the additive exceeds the function of the expanding moist soil highly.

Owner:刘虎生

LF furnace refining slag used for aluminum-controlled steel

InactiveCN101121953AIncrease alkalinityImprove refining effectProcess efficiency improvementAlkalinityCoesite

The invention discloses a refined slag of LF furnace used in aluminum steel, which is confected by bauxite, lime, dolomite, limestone and wollastonite. The weight percent of the chemical components of the invention is 60.23 to 67.54 CaO, 1.90 to 3.86 SiO2, 10.58 to 17.57 A12O3, 1.84 to 5.57 Mg, 0.09 to 0.23 H2O and 0.036 to 0.042 S and the rest is loss. Through adjusting to the weight of the ingredients of the refined slag, the invention provides the refined slag that can meet requirements of manufacturing aluminum steel in melting performance, foaming performance, viscosity, alkalinity, reduction performance, surface tension and conductivity and can manufacture the refined slag of refined steel liquid with good quality.

Owner:CHONGQING UNIV

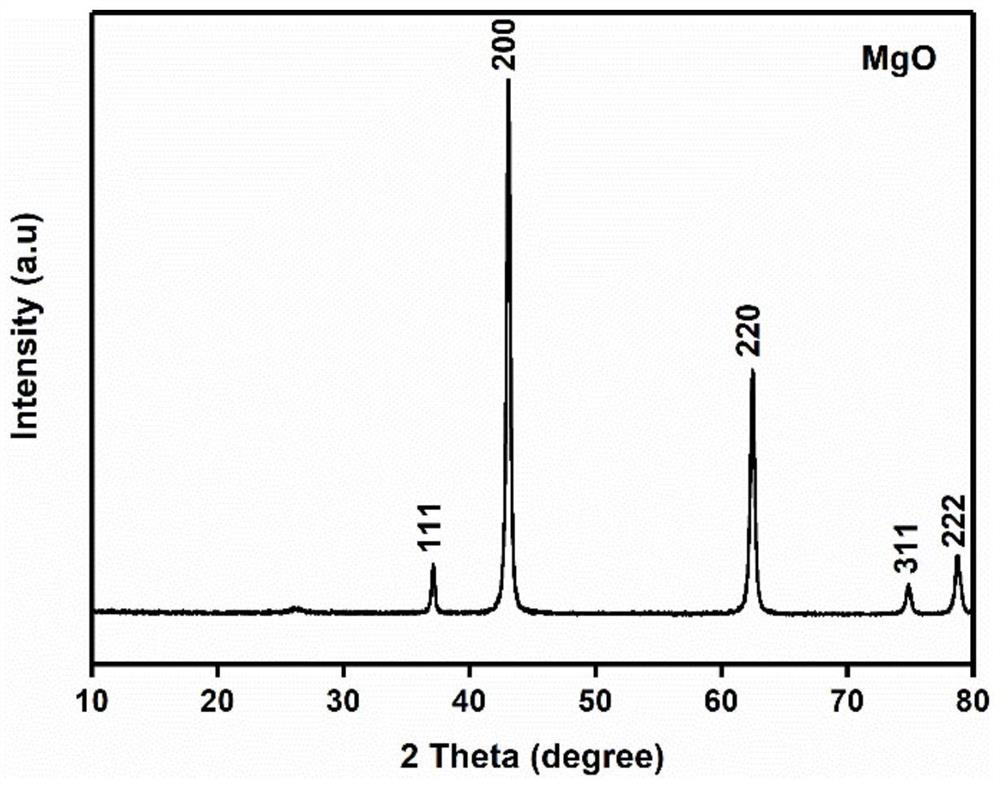

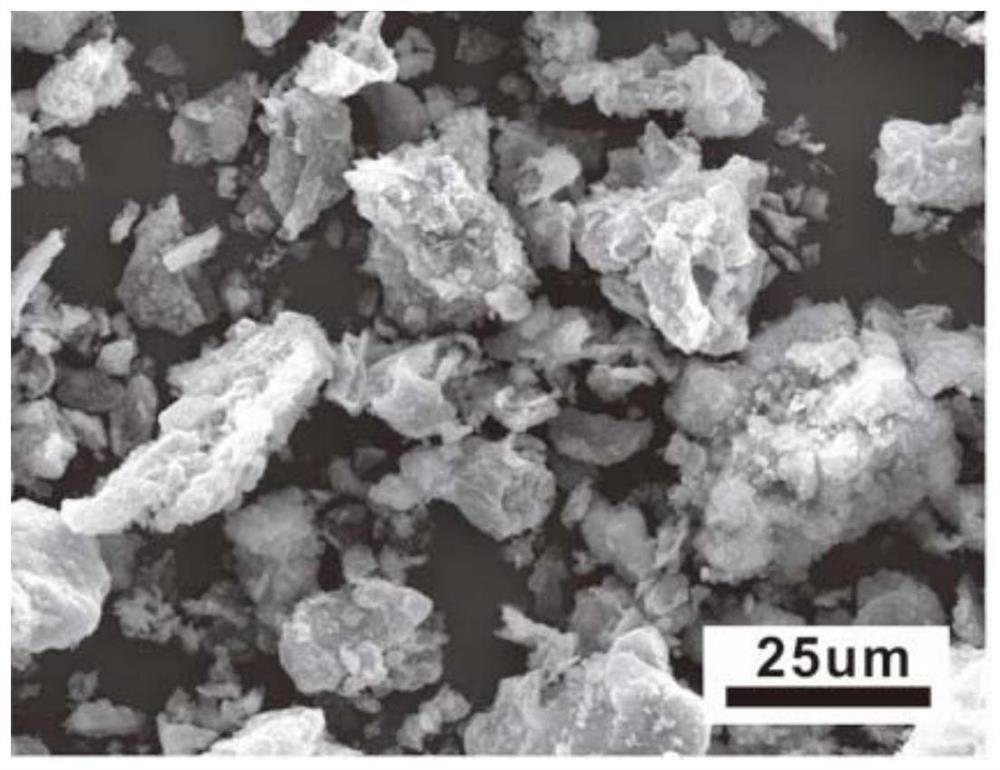

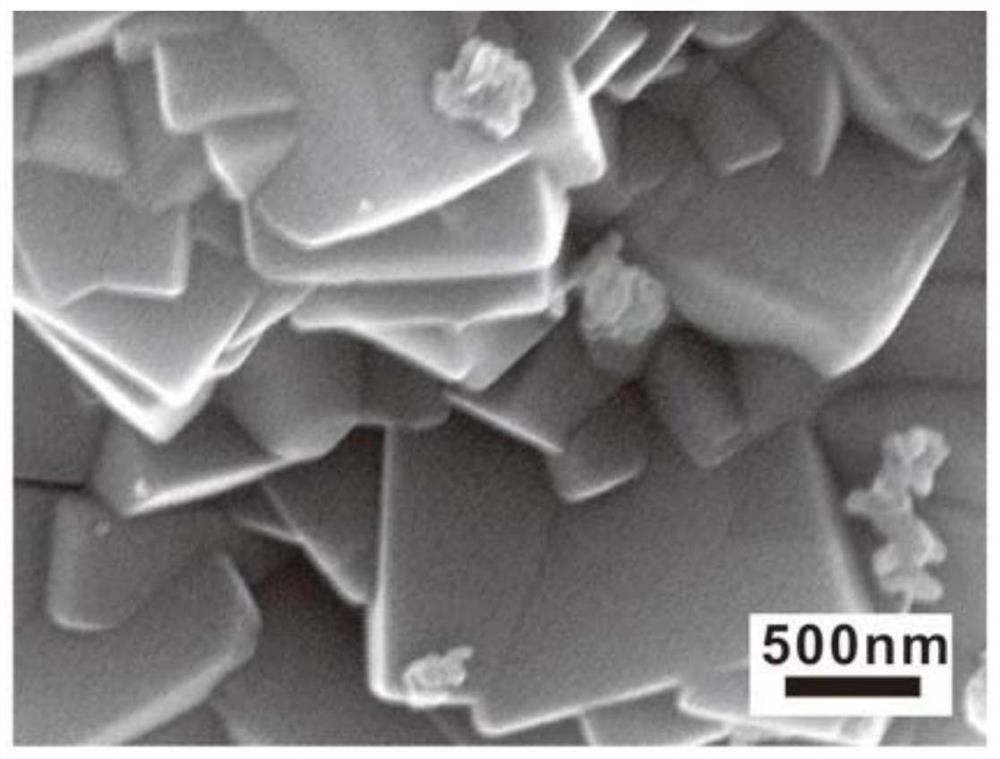

Purification process of high-purity magnesia

InactiveCN102774861ARational development and utilizationLess investmentSolid waste disposalMagnesiaTunnel kilnGranularity

The invention relates to a purification process of high-purity magnesia. The process comprises the following steps of: performing water washing by using tailings and discarded fine ores with granularity smaller than or equal to 10mm produced in a magnesite exploitation process; adding a little light burning MgO powder to the water washed tailings and discarded fine ores and mixing and pressing to obtain a blank; naturally drying the blank, and light burning the dried blank with a tunnel kiln and a back reflection kiln, and placing the light burned blank into a Raymond mill for fine grinding; at the same time, performing centrifugal air classification purification, and pressing the blank into balls by a dry ball press after fine grinding and purification; and after maintenance and drying, putting the balls into a super-high temperature heavy oil vertical kiln for sintering to obtain a high-purity magnesia product, wherein MgO content is larger than or equal to 97%, and the volume density is larger than or equal to 3.3.g / cm<3>. Compared with the prior art, the purification process of high-purity magnesia has the beneficial effect that the process has the characteristics of low investment, simple process and obvious purification effect, and resources are rationally exploited and utilized, thus the existing problem of shortage of special grade magnesite ore is solved, and the process is very worthy of being popularized and utilized in the industry of magnesia refractory raw material production.

Owner:海城三星矿业有限公司

Pellet magnesium composite binding agent and preparation method and application method thereof

The invention relates to a pellet magnesium composite binding agent and a preparation method and an application method thereof. The pellet magnesium composite binding agent consists of the following components in parts by weight: 0.1-0.3 part of organic high molecular materials, 0.1-0.3 part of thickening agent, and 99.5-99.7 parts of magnesium additive. Firstly, the organic high molecular material, the thickening agent and magnesite are uniformly mixed in proportion for cogrinding to obtain a semi-finished product; and then, the semi-finished product is uniformly mixed with caustic burned magnesia in proportion for cogrinding to obtain a finished product. When pellets are produced, the magnesium composite binding agent is added in iron concentrate powder to mix green balls for roasting to prepare finished pellets; and the adding quantity of the magnesium composite binding agent is 1.0-3.5 mass% of the adding quantity of the iron concentrate powder. The magnesium composite binding agent is adopted to replace a bentonite+magnesium additive form, so that the pellet quality is improved, the MgO content in the pellets is increased, the MgO content in sintered ores is reduced, the quality of the sintered ores and the quality of the pellets can be improved, and increment of the yield of a blast furnace and reduction of the energy consumption are finally realized.

Owner:ANSHAN ZHENGDA FURNACE CHARGE +1

Energy-saving high-strength microcrystalline glass and preparation method thereof

The invention relates to energy-saving high-strength microcrystalline glass and a preparation method thereof. The energy-saving high-strength microcrystalline glass solves the prior art problem of energy waste, and is prepared from 40-55wt% of SiO2, 21-45wt% of CaO, 16-30wt% of MgO, 0-3wt% of Al2O3, 1-8 or 0wt% of a nucleation agent and 0-2wt% of a flux or from 48-55wt% of SiO2, 23-26wt% of CaO, 15-18wt% of MgO, 0-6wt% of Al2O3, 0-8wt% of a nucleation agent and 0-1wt% of a flux by melting. The preparation method comprises the following steps of melting the above raw materials according to the above weight ratio to obtain a glass liquid, carrying out cooling and molding, feeding the molded glass into a roller kiln, carrying out nucleation and crystallization treatment at a low temperature for short time and then carrying out annealing treatment to obtain artificial jade or microcrystalline glass, or comprises when a nucleation agent use ratio is 0, melting the rest of the above raw materials to obtain a glass liquid, carrying out cooling and molding, and carrying out annealing treatment to obtain high-strength glass. The energy-saving high-strength microcrystalline glass has the advantages of low melting temperature, short crystallization time, good chemical, mechanical and electrical performances of the product, energy saving and low cost.

Owner:卢爱民

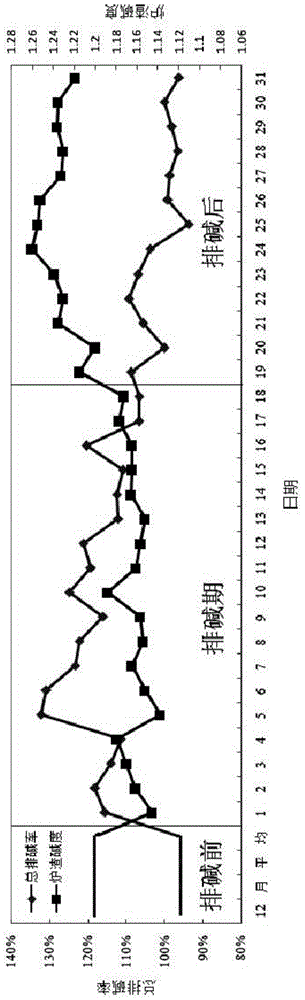

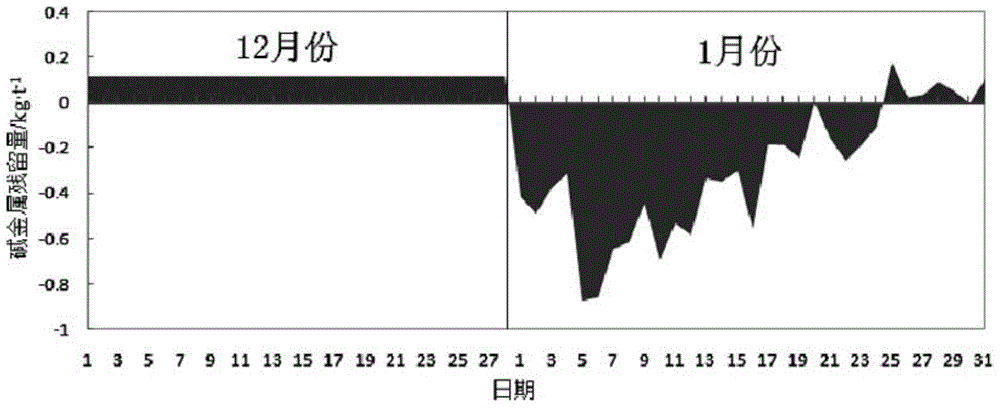

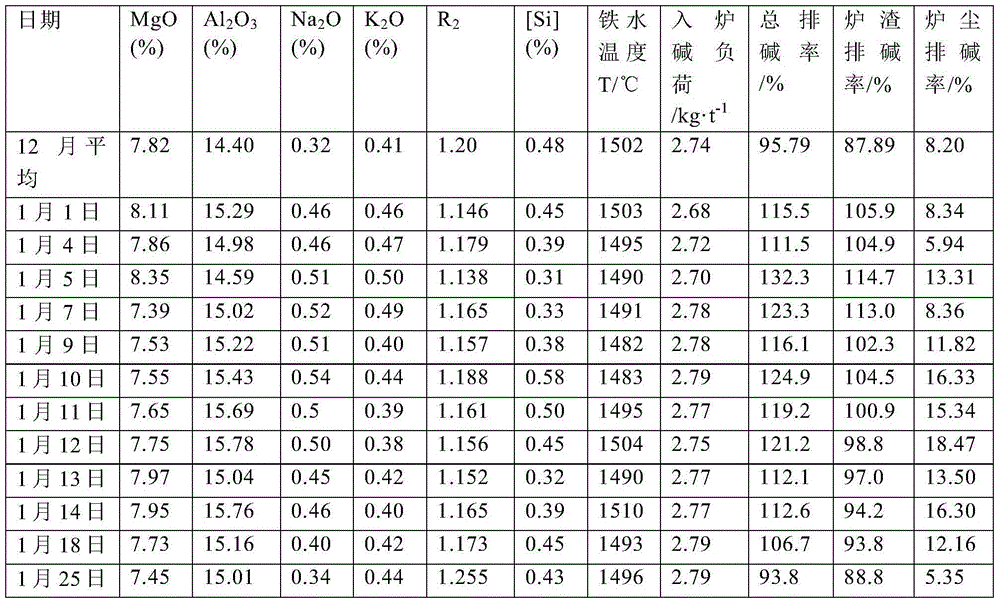

Method for reducing alkali metal enrichment in blast furnace

ActiveCN104152611ALow MgO contentIncrease the content of MgOBlast furnace detailsSlagAlkali metal oxide

The invention relates to a method for reducing alkali metal enrichment in a blast furnace. When loads of in-furnace alkali metal oxides are 2.8 to 3.0 kg / t, the blast furnace carries out alkali removing once in each quarter, and the alkali removing period ranges from 15 days to 20 days; in the alkali removing period, the MgO content in slag of the blast furnace is controlled to be 7% to 8%, and the binary basicity of the slag of the blast furnace is controlled not to be larger than 1.15; in the alkali removing period, the temperature of molten iron in the blast furnace is controlled to be 1490 DEG C to 1500 DEG C; the Si content in the molten iron is controlled to be 0.3 percent to 0.35 percent; the Ti content in the molten iron of the blast furnace is controlled to be 0.1 percent to 0.15 percent. The basicity of the slag of the blast furnace is controlled, components and the temperature of the molten iron of the blast furnace are adjusted cooperatively, the discharge rate of the alkali metal is improved, and the alkali metal enrichment is reduced.

Owner:BEIJING SHOUGANG CO LTD

Slagging method for electrosmelting

InactiveCN101824508AIncrease the content of MgOReduce erosionElectric furnaceLime productionSlagIron oxide

The invention relates to a slagging method of the field of metallurgy, in particular to a slagging method for electrosmelting. Slagging materials comprise three kinds of slagging assistant materials: bulk lime, bulk calcined dolomite and bagged lime, and a deoxidization furnace protective agent, wherein the bagged lime is distributed under waste steel and is added to an electrical furnace along with the waste steel; and the bulk lime and the bulk calcined dolomite are added to the electrical furnace by a charging system above the waste steel. The invention solves a series of problems of sparsity of electrosmelting slag, excessively high content of ferric oxide in the slag, high consumption of steel materials, serious furnace lining corrosion, substantial reduction of furnace age, sharp slag boiling in the early phase of blowing smelting, increase of slag quantity caused by a large quantity of flowing slag, high lime consumption and the like after the quantity of iron water is largely increased.

Owner:NANJING IRON & STEEL CO LTD

Method for controlling slag overflow in converter tapping process

ActiveCN112322824ALess foamIncrease the content of MgOManufacturing convertersSteelmakingProcess engineering

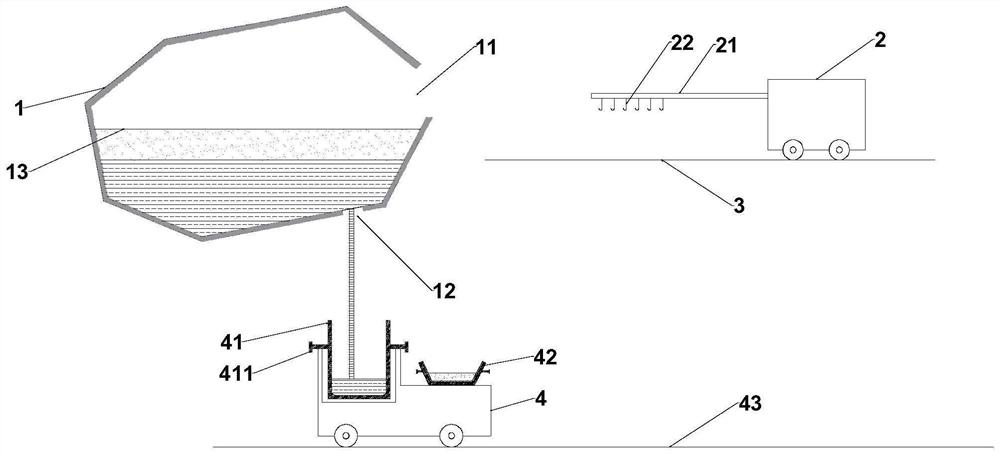

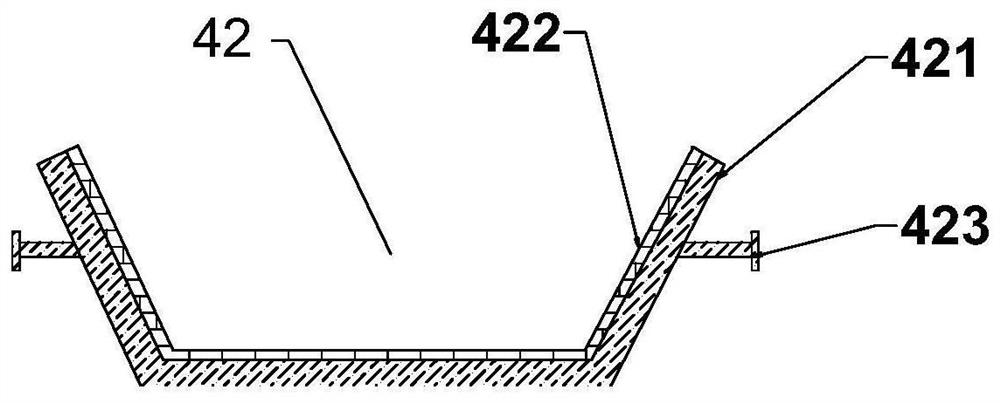

The invention belongs to the field of converter steelmaking systems, and relates to a method for controlling slag overflow in the converter tapping process. The method comprises the following steps that after converter blowing is finished, dolomite is added into a converter mouth through an overhead bunker; a converter oxygen lance is lowered to the position of 4 m, and high-pressure nitrogen is used for purging a slag surface for 20-30 seconds; after the slag surface is purged by the high-pressure nitrogen, the lance position of the oxygen lance is lifted, and the slag surface is purged for 10 seconds; and in the tapping process of a converter body, cooling slag pressing materials are added to the slag surface of a converter dispersedly through a cooling slag pressing material feeding vehicle right opposite to the converter mouth until tapping of the converter is finished. According to the method, slag overflow during steel tapping is controlled through the steps of adding the dolomite before steel tapping to reduce slag foaming, conducting gas purging for diluting the slag, adding the cooling slag pressing materials during steel tapping to press the slag and actively receiving the slag after slag overflow happens; and due to good slag overflow control, in the converter steel tapping process, the steps of forward pouring of the converter for temperature measurement, sampling and slag pouring can be omitted, the smelting time is saved by 2.5 minutes, and meanwhile, the production cost is reduced.

Owner:TIANJIN TIANGANG UNITED SPECIAL STEEL CO LTD

Low-cost blast furnace smelting method

InactiveCN106591524AQuality improvementAvoid pollutionTuyeresBlast furnace detailsGranularityBlast furnace smelting

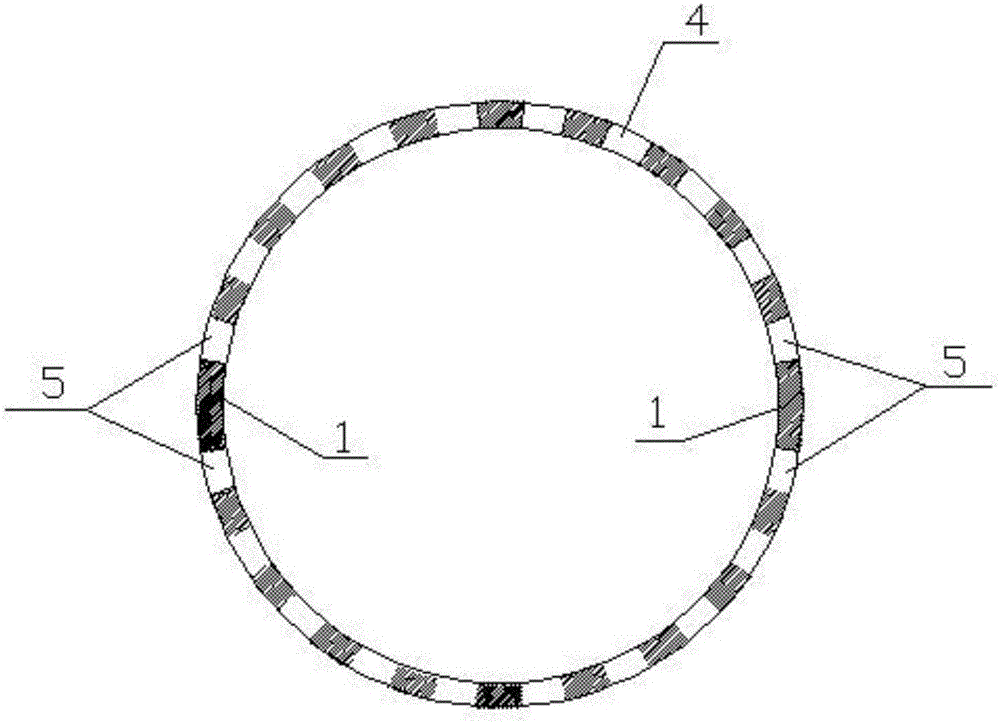

The invention discloses a low-cost blast furnace smelting method. The low-cost blast furnace smelting method comprises the steps that coke nut with the particle sizes ranging from 8 mm to 20 mm is added to sintered vanadium-titanium ores, small sintered vanadium-titanium ore cubes, vanadium-titanium pellets and pig iron, and an ore layer is formed through uniform mixing; and the coke and the ore layers are alternately fed into a blast furnace, so that an alternate layering structure of the ore layers and the coke layers is formed, wherein the coke is composed of high-strength coke and low-strength coke, and the high-strength coke comprises dry quenched coke. A hearth of the blast furnace comprises multiple tuyeres and two iron notches, wherein the two iron notches are symmetrical about the center axis of the hearth, the tuyeres are arranged above the iron notches and distributed circumferentially, the diameters of the tuyeres which are symmetrical about the center axis of the hearth are identical, and the diameters of the tuyeres located on the two sides of the iron notches are smaller than or equal to the diameters of the other tuyeres on the circumference. By the adoption of the low-cost blast furnace smelting method, the ventilation performance of blast furnace smelting is improved, the intensity of blast furnace smelting is improved, the fuel ratio is lowered, and the cost is lowered.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

Stainless steel smelting method for improving content of MgO in slag of gas oxygen refining converter and LF (ladle furnace)

ActiveCN102912085AIncrease the content of MgOReduce erosionManufacturing convertersProcess efficiency improvementSocial benefitsSlag

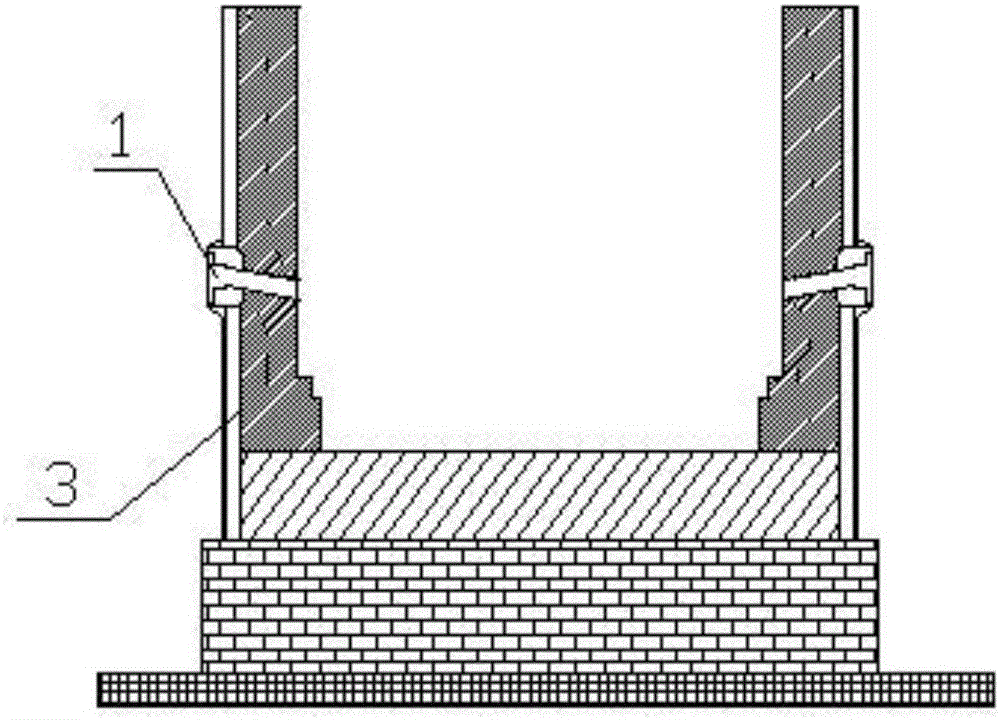

The invention discloses a stainless steel smelting method for improving the content of MgO in slag of a gas oxygen refining converter and an LF (ladle furnace). The method comprises the following steps: a, preparing a magnesium-calcium refractory material with particle size of 3-15mm and a magnesium-calcium refractory material with the particle size less than 3mm; b, adding the magnesium-calcium refractory material with the particle size of 3-15mm into the gas oxygen refining converter to serve as a bottom magnesium-calcium refractory material; adding the magnesium-calcium refractory material with the particle size of 3-15mm once more during the converting period I, so as to keep the content of MgO in the slag within 9-11%; c, during the smelting and slagging process of the refining LF, adding lime, a slagging agent and the magnesium-calcium refractory material with the particle size less than 3mm together, so as to control the content of MgO in the slag within 7-9%; and d, proceeding to the continuous casting procedure. The method disclosed by the invention can improve the content of MgO in the slag, at the same time, improves the content of CaO, reduces erosion to the furnace lining, and prolongs the furnace life of the converter as well as the ladle life of the LF. The method disclosed by the invention has low requirements on a crushing appliance, lowers the production cost, and has higher economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

Preparation method of super-efficient sewage dephosphorization adsorbent

ActiveCN111644148AHigh content of nano MgOGood removal effectOther chemical processesWater contaminantsSorbentPollution

The invention relates to a preparation method of a super-efficient sewage dephosphorization adsorbent, and belongs to the technical field of sewage treatment and adsorbents. According to the method, based on a reaction that magnesium metal is combusted in a carbon dioxide atmosphere, MgO crystals and amorphous carbon are generated at the same time simply and quickly in one step; the two substancesare uniformly combined in a nanometer scale, so that the formed magnesium-based nano composite carbon material can be used as the super-efficient sewage dephosphorization adsorbent. The adsorbent hasextremely fast adsorption kinetics, a wide pH application range and relatively strong impurity anion interference resistance, the adsorption capacity of the adsorbent to phosphorus in a solution is higher than 1000mg / g, and the efficient and rapid phosphorus removal effect can be achieved in actual sewage with various complex components. The method disclosed by the invention is simple to operate,short in preparation period and rich and cheap in raw material source, and the adsorbent has no toxicity to the environment, does not cause secondary pollution during preparation of the adsorbent andphosphorus removal application, and has a very good application prospect.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Magnesium-rich alkaline sliding plate brick and production method thereof

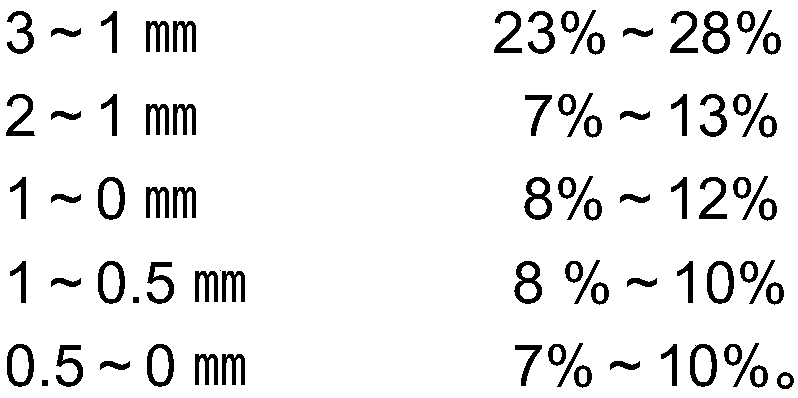

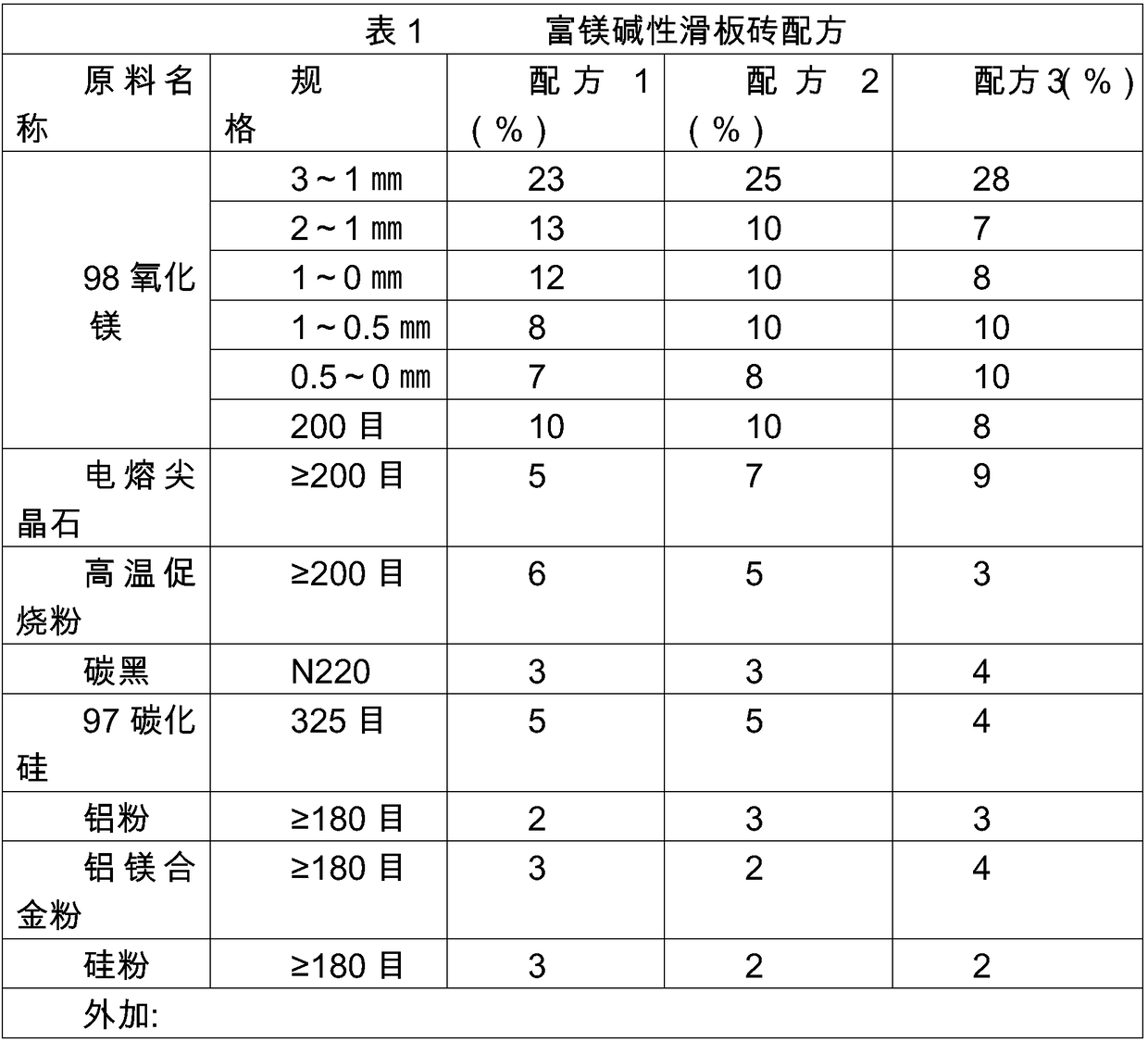

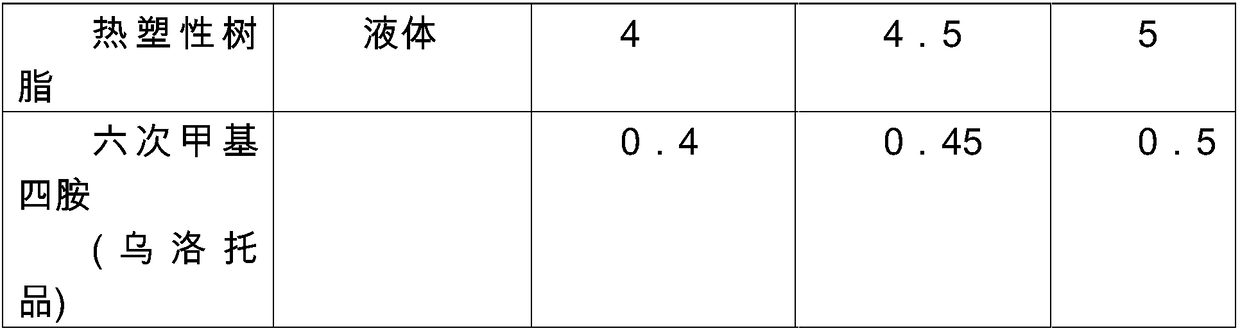

InactiveCN108409300AImprove densification performanceParticle Size Distribution Improvement and ControlBrickCombustion

The invention discloses a magnesium-rich alkaline sliding plate brick, comprising, by weight, 71-73% of 98 magnesium oxide, 5-9% of fused spinel, 3-6% of high-temperature combustion promoter powder, 3-4% of carbon black, 4-5% of 97 silicon carbide, 2-3% of aluminum powder, 2-4% of aluminum-magnesium alloy powder, and 2-3% of silicon powder, wherein all the components add up to 100% by weight, andalso comprising 4-5% of thermoplastic resin, and 0.4-0.5% of hexamethylenetetramine (urotropin). The invention is intended to provide a magnesium-rich alkaline sliding plate brick and a production method thereof to solve the problems that sliding plates in a steel plant have short lives, refractory steel has high consumption per ton, the cost needs to be reduced and resource waste needs to be reduced, and cost-reducing effect needs to be significant.

Owner:无锡市南方耐材有限公司

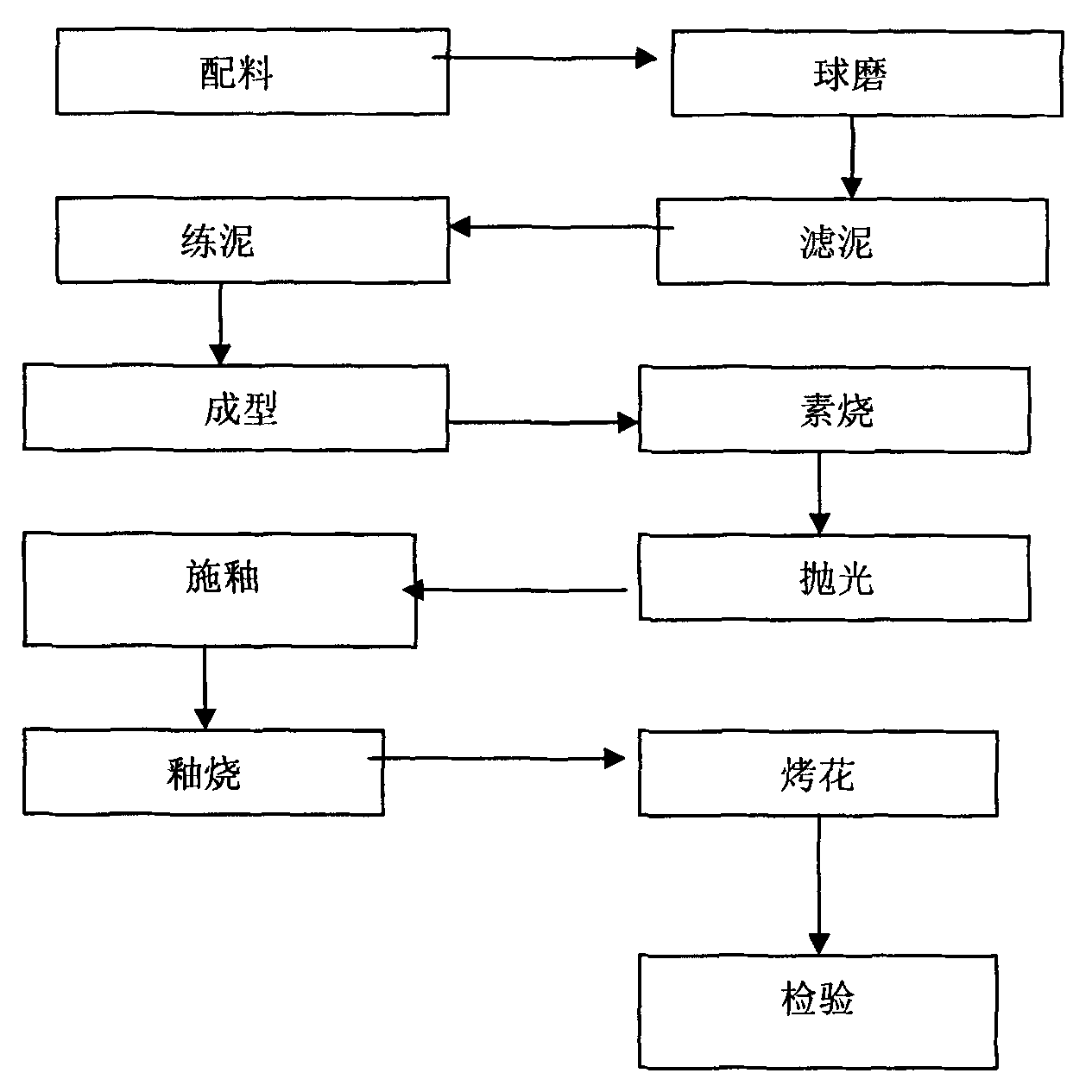

Method for preparing caring strengthened porcelain

InactiveCN101987790AProminent and significant technical effectsHigh viscosityClaywaresTalcBone china

The invention relates to a method for preparing caring strengthened porcelain. The method comprises the following steps of: (A) adding magnesium-rich clay into pug for later use and selecting a porcelain aging- and structural stress-resistant mineralizer for later use; (B) adding the pug and the mineralizer for later use into a blank; and (C) performing mixing, ball milling, pug filtering, pug milling, molding, biscuit firing, polishing, glazing, glaze firing, decoration firing and sorting in turn to prepare a strengthened porcelain product. Through the process, the barrier of industrializing household talc porcelain is broken through, the problem of formability of the blank is effectively solved, a firing range is broadened, the problems of later aging and the like are solved, and by adopting a process route for producing high-grade porcelain, the technology and process for manufacturing the caring strengthened porcelain achieve and exceed that for producing worldwide recognized high-grade bone china.

Owner:施永义

Iron ore pellet boron and magnesium composite bonder, and application and processing method of acid pellets

The invention provides an iron ore pellet boron and magnesium composite bonder, and application and a processing method of acid pellets. The bonder is in two types. According to one type, boron and magnesium iron ore powder resources rich in China are utilized, boron and magnesium iron ore powder with the B2O3 content being 3% or so and the MgO content being 40-50% or so are selected and mixed with 1-5% of carboxymethyl cellulose so that the boron and magnesium composite bonder can be obtained, According to the other type, MgO powder and B2O3 mixtures and carboxymethyl cellulose are compounded, the iron ore pellet boron and magnesium composite bonder is obtained, the content of MgO and the content of B2O3 are the same as those of the first type, and the MgO contained acid pellets are produced. By means of the bonder, the content of MgO in the acid pellets can be improved by 1-2.5%, the content of B2O3 in the acid pellets can be improved by 0.05-0.10%, the bonder can serve as a powdered iron pelletizing bonder and can also serve as acid pellet production additives, the content of the MgO is increased, the sintering temperature of the MgO acid pellets is not raised, and the purpose of producing the MgO contained acid pellets is achieved.

Owner:北京新佰奥科技有限公司

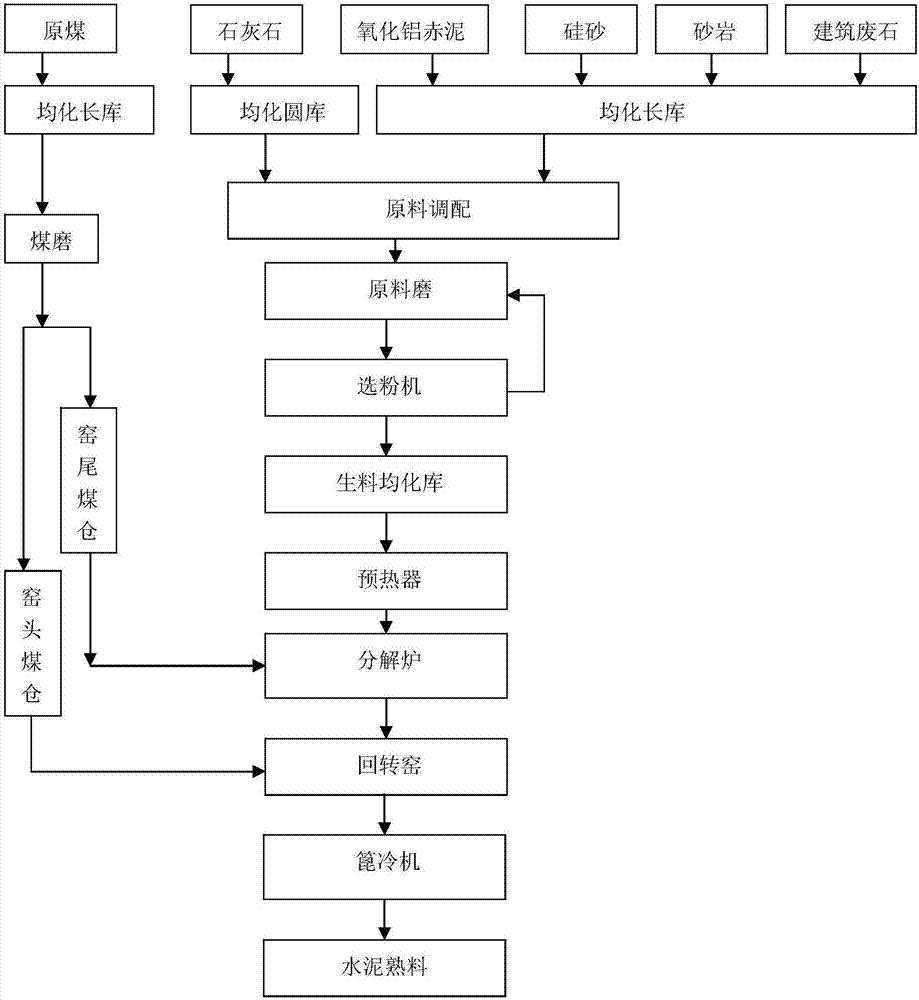

Cement clinker employing silica sand part instead of sandstone and preparation technology of cement clinker

ActiveCN107216055AAchieve control indicatorsImprove sintering qualityClinker productionRed mudToxic industrial waste

The invention relates to a cement clinker employing a silica sand part instead of sandstone. The cement clinker is prepared from the following raw materials in parts by weight: 87-90% of limestone, 2.7-3.0% of alumina red mud and 6-9% of silica sand, sandstone and construction waste rocks, wherein the mass ratio of the silica sand to the sandstone to the construction waste rocks is 1:3:1. A technology specifically comprises the following steps of carrying out burdening, homogenizing, grinding, powder selecting, preheating and decomposing, and finally carrying out high-temperature calcination and then cooling to obtain the cement clinker. By adopting the scheme of replacing the sandstone with the silica sand part to produce the cement clinker, the grindability of raw meal mill is improved; meanwhile, a lot of industrial waste silica sand and construction waste rocks are consumed, so that effective utilization of resources is achieved; the firing quality of the clinker is improved, the firing energy consumption of the clinker is further reduced and the production cost.

Owner:TIANJIN ZHENXING CEMENT

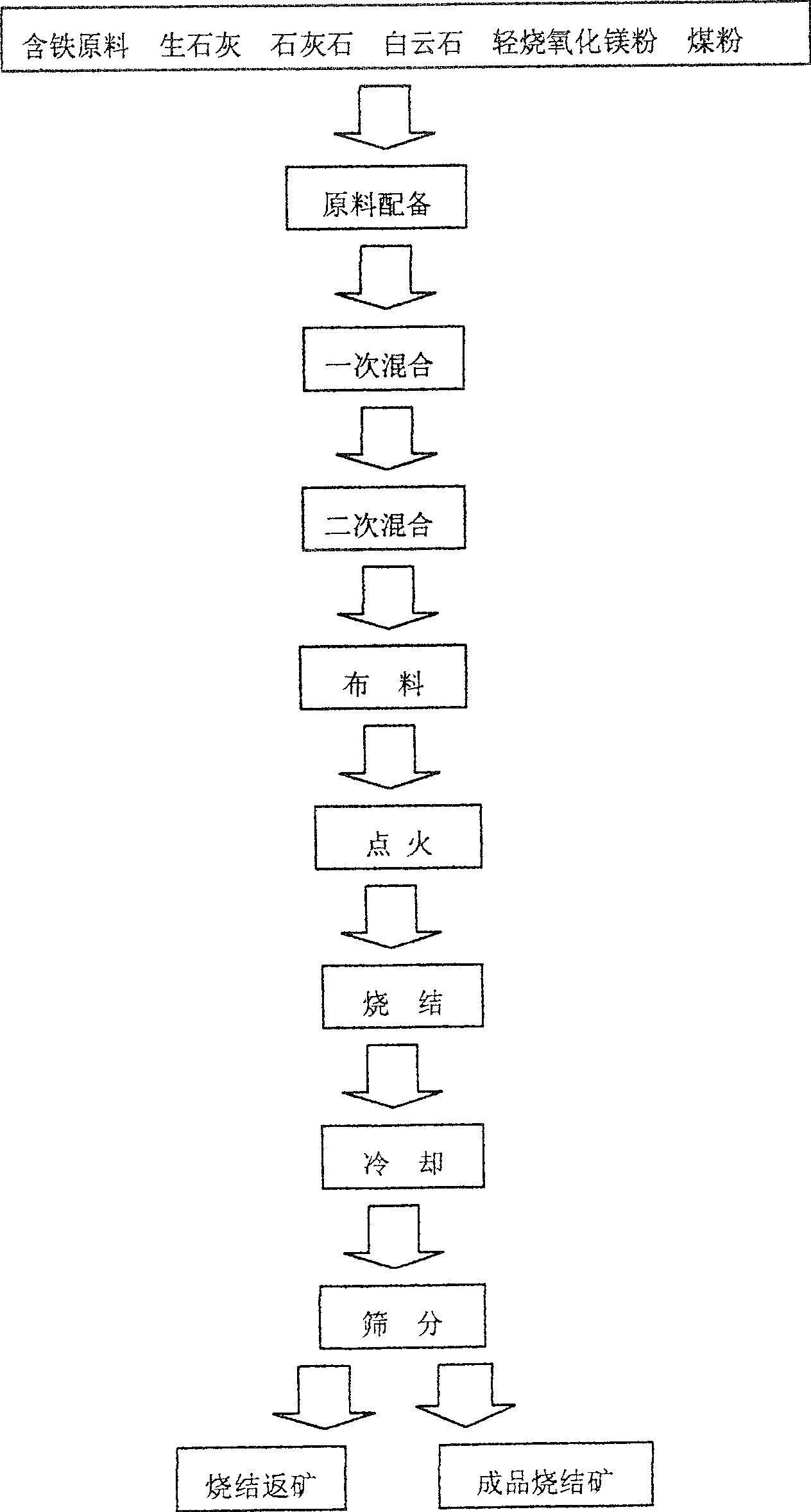

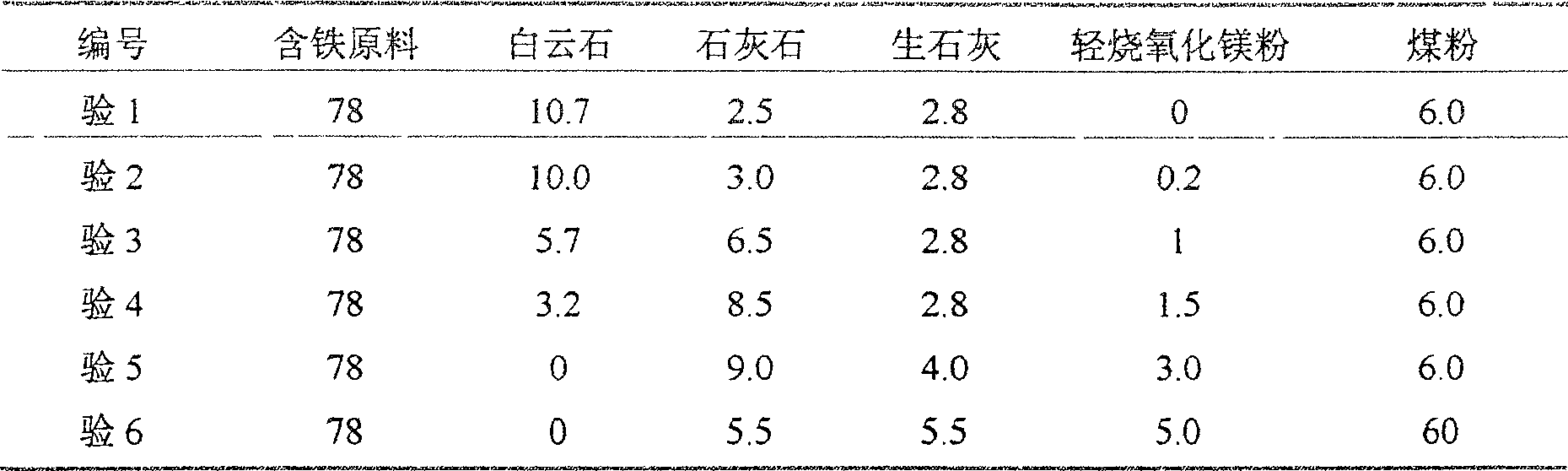

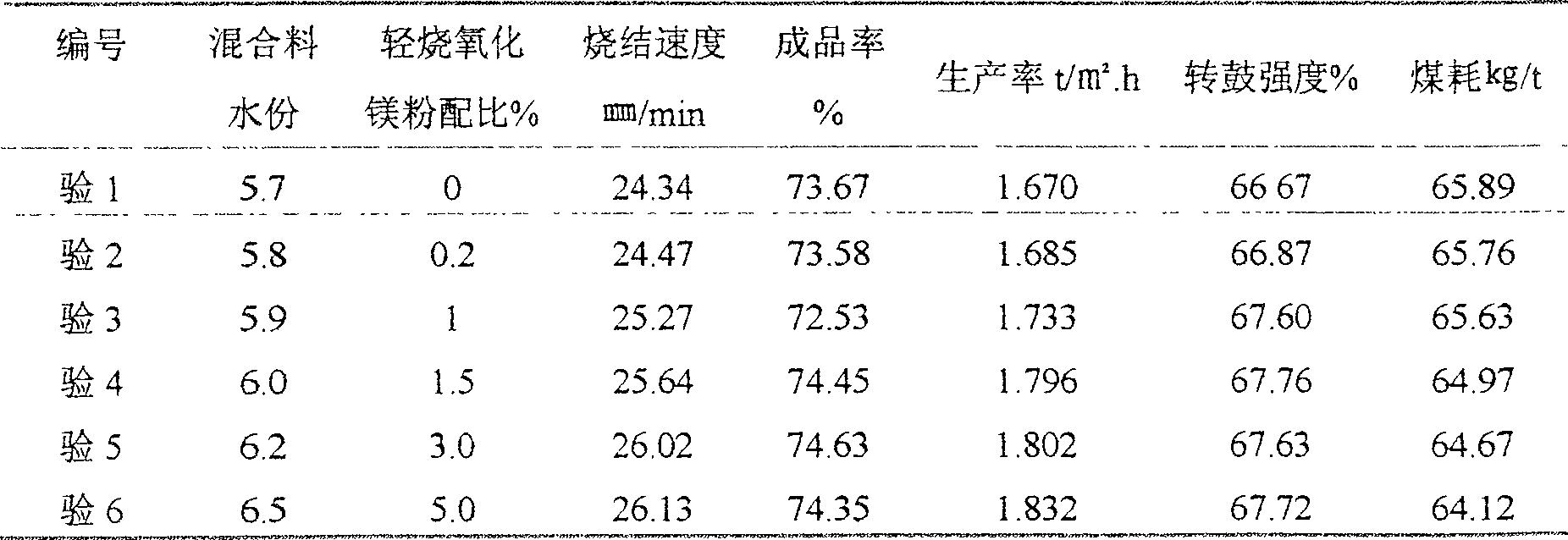

A sintered ore capable of improving viscosity of blast furnace slag and a preparation method thereof

The invention discloses a sintered ore and preparing method of improved blast furnace slag viscosity to solve bad fluidity of blast furnace slag with high Al2O3 in the present ferric ore, which comprises the following parts: 70-85% ferric material, 2-5% limestone, 0.2-5% light-burned magnesia powder and 3-8% coal dust or coke dust, wherein the alkalinity of CaO and SiO2 of sintering ore is 1.5-3.0 with TFe at 50-60% and MgO at 1.5-4.0%. The preparing method comprises the following steps: allocating raw materials; blending once and twice; distributing materials; igniting; sintering; cooling; sieving.

Owner:武钢集团有限公司 +1

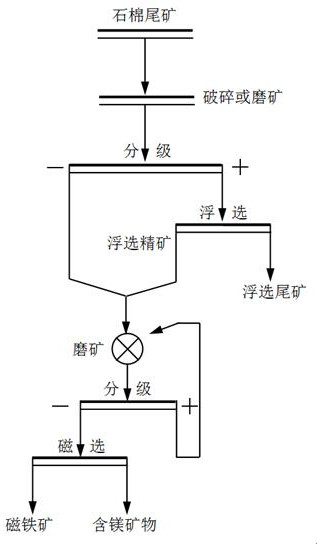

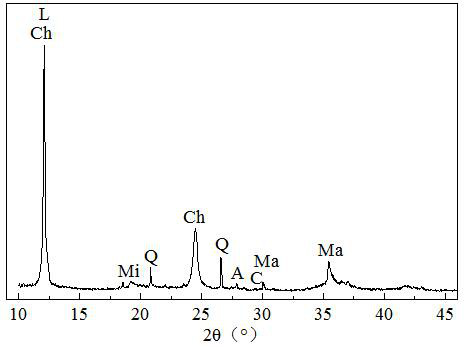

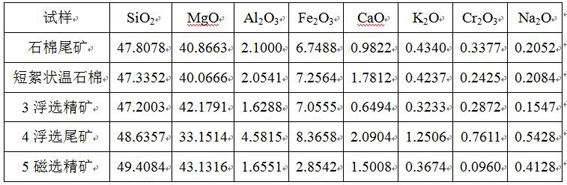

Method for enriching magnesium-containing minerals in asbestos tailings

PendingCN113083496AThe process steps are simpleEasy to operateSolid separationMechanical material recoveryFoaming agentMagnetite

The invention relates to a method for enriching magnesium-containing minerals in asbestos tailings. The method is characterized by comprising the steps of (1) crushing or grinding the asbestos tailings, and controlling the dissociation granularity to be -0.71mm; (2) controlling the graded cutting granularity to range from 0.105mm to 0.038mm, grading the crushed or ground asbestos tailings to obtain fine-fraction asbestos tailings and coarse-fraction asbestos tailings, and conducting flotation on the coarse-fraction asbestos tailings, wherein an inhibitor is modified carboxyl starch, and a collecting agent and foaming agent is an amphoteric collecting agent or a cationic collecting agent; and (3) grinding the fine-fraction asbestos tailings obtained through grading and flotation concentrate together to obtain minerals with the granularity of -0.105mm, conducting magnetic separation, and controlling the magnetic field intensity to be smaller than or equal to 4000Gs to obtain magnetite and the magnesium-containing minerals. The method has the beneficial effects that the process is simple and suitable for industrial production; and through a combined process, the magnesium-containing minerals in associated asbestos tailings such as serpentine, quartz, feldspar and magnetite can be effectively extracted, aluminum reduction and quartz removal are realized, and the grade of the magnesium-containing minerals is increased.

Owner:(CNBM) BENGBU DESIGN & RES INST FOR GLASS IND CO LTD

Stainless steel smelting method for improving content of MgO in slag of gas oxygen refining converter and LF (ladle furnace)

ActiveCN102912085BIncrease the content of MgOReduce erosionManufacturing convertersProcess efficiency improvementCalcium in biologySocial benefits

The invention discloses a stainless steel smelting method for improving the content of MgO in slag of a gas oxygen refining converter and an LF (ladle furnace). The method comprises the following steps: a, preparing a magnesium-calcium refractory material with particle size of 3-15mm and a magnesium-calcium refractory material with the particle size less than 3mm; b, adding the magnesium-calcium refractory material with the particle size of 3-15mm into the gas oxygen refining converter to serve as a bottom magnesium-calcium refractory material; adding the magnesium-calcium refractory material with the particle size of 3-15mm once more during the converting period I, so as to keep the content of MgO in the slag within 9-11%; c, during the smelting and slagging process of the refining LF, adding lime, a slagging agent and the magnesium-calcium refractory material with the particle size less than 3mm together, so as to control the content of MgO in the slag within 7-9%; and d, proceeding to the continuous casting procedure. The method disclosed by the invention can improve the content of MgO in the slag, at the same time, improves the content of CaO, reduces erosion to the furnace lining, and prolongs the furnace life of the converter as well as the ladle life of the LF. The method disclosed by the invention has low requirements on a crushing appliance, lowers the production cost, and has higher economic and social benefits.

Owner:SICHUAN JINGUANG IND GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com