Magnesium-rich alkaline sliding plate brick and production method thereof

A magnesium-rich alkaline, sliding brick technology, applied in the field of inorganic non-metallic refractory materials, can solve the problems of erosion, unable to achieve multiple continuous pouring, etc., and achieve the effect of improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

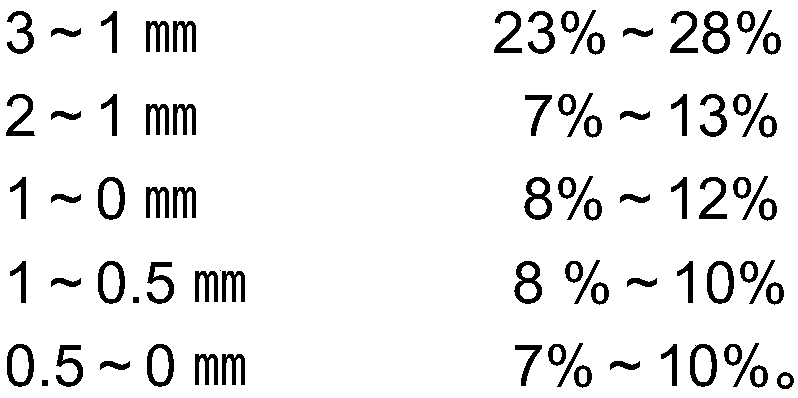

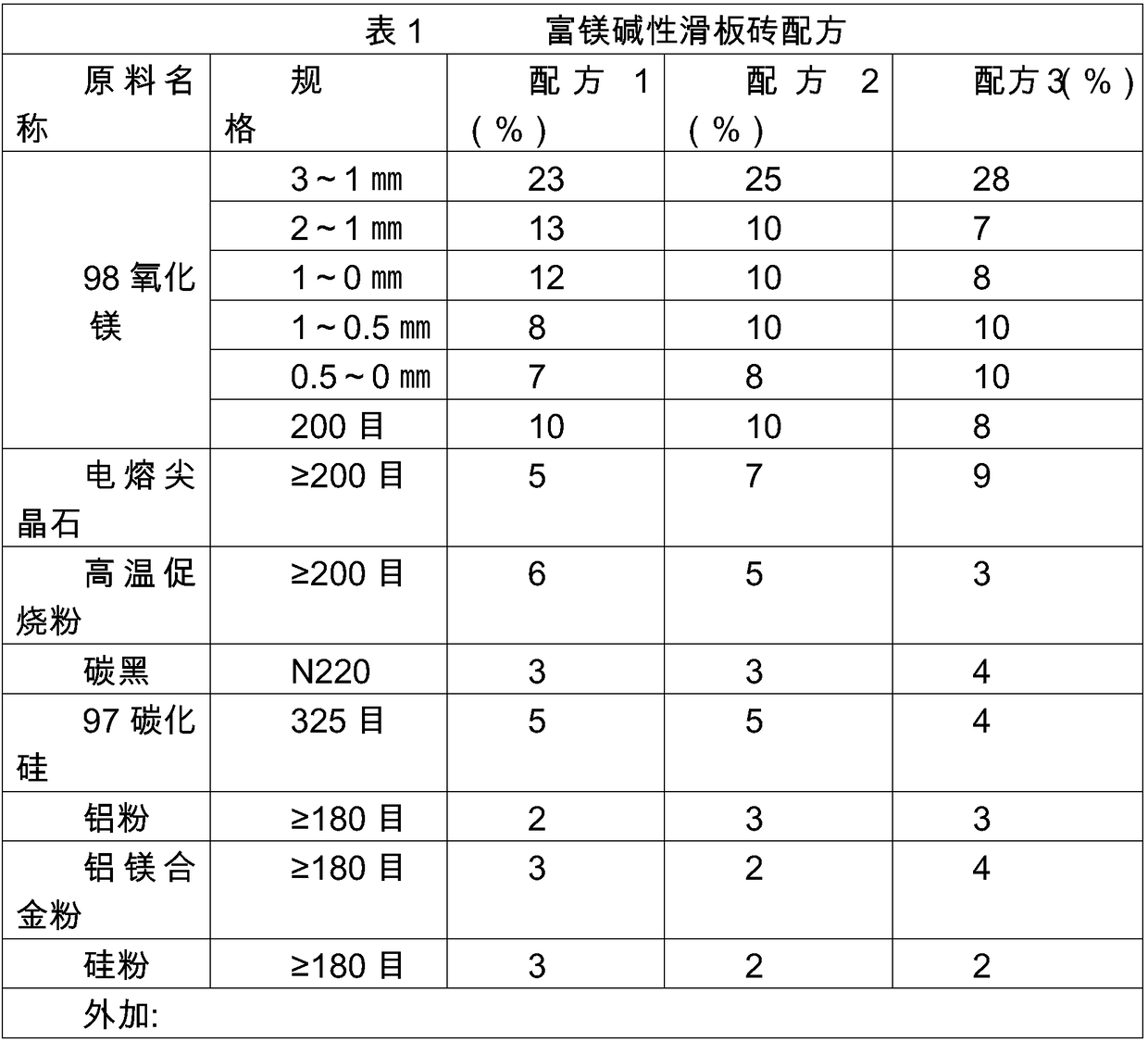

[0022] Raw material specifications are as follows:

[0023] 98 magnesia: MgO content ≥ 98%, fused spinel: Al 2 o 3 Content ≥ 72%, MgO content ≥ 21%, high temperature promoting powder: Al 2 o 3 content ≥ 70%, carbon black: C content ≥ 98%, 97 silicon carbide: SiC content ≥ 97%, aluminum powder: active aluminum Al content ≥ 98%, aluminum-magnesium alloy powder: Al content 50± 3%, active metal (Al+Mg) not less than 97.0%, silicon powder: Si content ≥ 97%, thermoplastic resin: carbon residue 45±4%, solid content 75-80%, viscosity 15000-18000mpa.

[0024] The basic production process of the invented product is as follows: according to the formula in Table 1, 98 magnesia carry out batching according to the formula in Table 1 after crushing and screening, add wet mill or high-speed kneader and mix for 3 to 6 minutes, add phenolic resin Binder, after mixing, add the following fine powder: 98 magnesia, fused spinel, high-temperature burning powder, carbon black, 97 silicon carbide,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com