Cement clinker employing silica sand part instead of sandstone and preparation technology of cement clinker

A technology for cement clinker and preparation process, which is applied in cement production, clinker production, etc. It can solve the problems of affecting the formation of clinker mineral components, affecting the quality of clinker, and high harmful components, so as to improve equipment production efficiency and beautify the ecology Environment, the effect of reducing the decomposition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

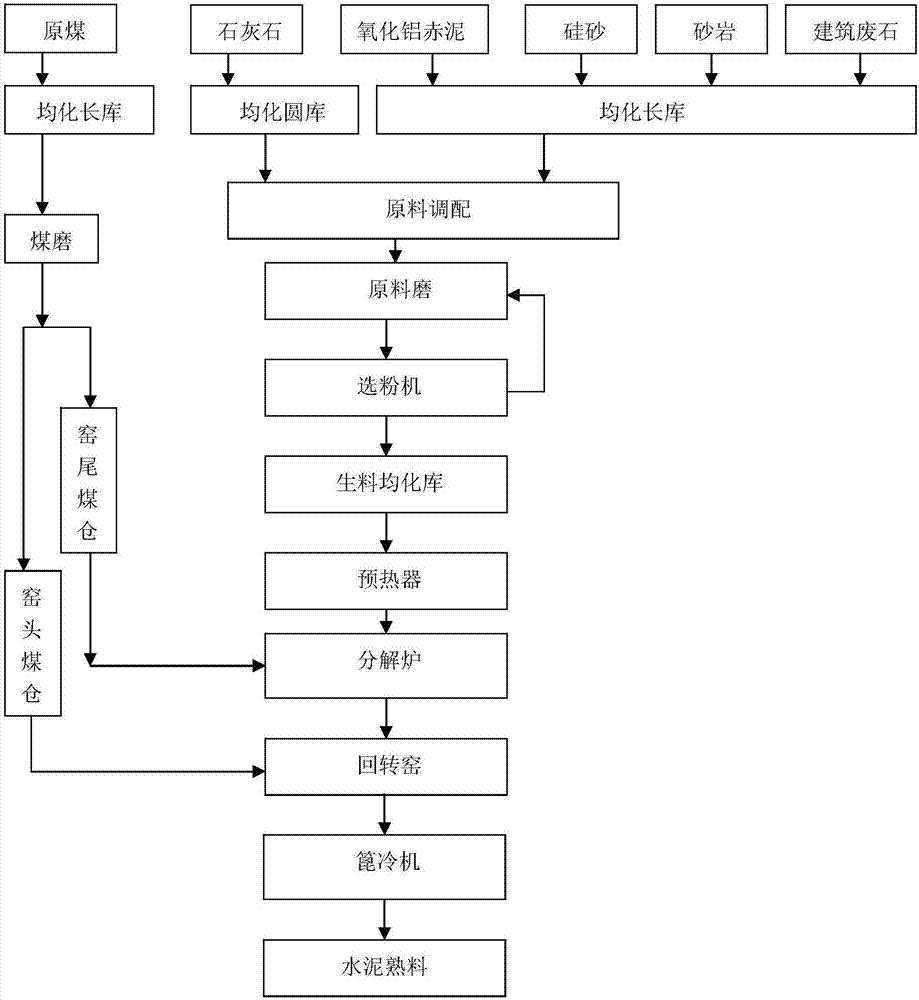

[0027] The method of utilizing silica sand to partially replace the cement clinker of sandstone, the specific steps are as follows:

[0028] 1) Homogenize the production raw materials limestone, alumina red mud, silica sand, sandstone, and construction waste rock respectively and store them in the homogenization warehouse.

[0029] 2) 88.86% of limestone, 2.7% of alumina red mud, 8.44% of silica sand + sandstone + construction waste rock, the mass ratio of silica sand: sandstone: construction waste rock is 1: 3: 1, and then feed it according to the weight ratio Grinding is carried out by the grinding system, and the moisture content of raw meal after grinding is controlled to be ≤1%, and the sieve residue of 80 μm raw meal is ≤14%, so as to obtain raw meal in the form of dry powder.

[0030] 3) The above-mentioned raw meal after grinding is imported into a powder separator for material selection, and the raw meal obtained after material selection is imported into a raw meal ho...

Embodiment 2

[0049] The method of utilizing silica sand to partially replace the cement clinker of sandstone, the specific steps are as follows:

[0050] 1) Homogenize the production raw materials limestone, alumina red mud, silica sand, sandstone, and construction waste rock respectively and store them in the homogenization warehouse.

[0051] 2) 89.80% of limestone, 2.7% of alumina red mud, 7.5% of silica sand + sandstone + construction waste rock, the mass ratio of silica sand: sandstone: construction waste rock is 1: 3: 1, and then feed it according to the weight ratio Grinding is carried out by the grinding system, and the moisture content of raw meal after grinding is controlled to be ≤1%, and the sieve residue of 80 μm raw meal is ≤14%, so as to obtain raw meal in the form of dry powder.

[0052] 3) The above-mentioned raw meal after grinding is imported into a powder separator for material selection, and the raw meal obtained after material selection is imported into a raw meal hom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com