Sintering mixture and application thereof

A technology for sintering mixtures and mixtures, applied in the field of sintering mixtures, which can solve the problems of reducing sintering production costs, agglomeration, clogging, etc., and achieve the effects of reducing workload, reducing production costs and increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

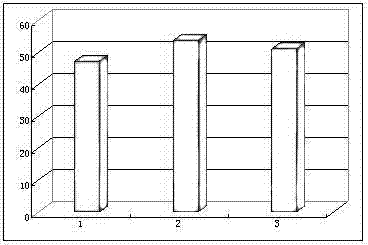

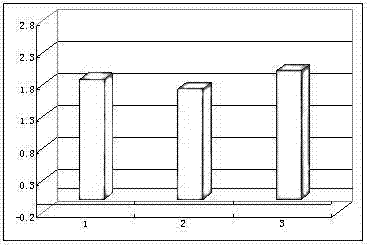

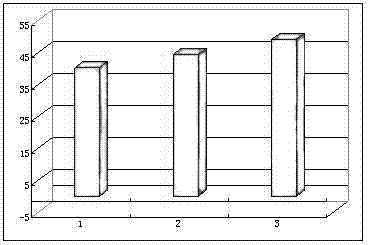

Embodiment 1

[0023] The mixture consists of the following components and parts by weight: 9 parts of quicklime, 1 part of dolomite, 4 parts of fuel, 81 parts of mixed ore powder, and 31 parts of returned ore; Quantity calculation, the weight ratio is coke powder: semi-coke = 7:3. Blue carbon has low heat generation. After adding Garland carbon, the temperature level in the high temperature area of the combustion zone will drop, and the liquid phase will be insufficiently formed, resulting in a dark red layer on the section, which will easily cause the tail section to be irregular. Uneven; the upper part of the material layer has insufficient liquid phase formation and poor agglomeration; the lower layer has better agglomeration, larger pores in the material layer, and local over-melting phenomenon, so the blue-coke ratio should not be too high during production.

[0024] The proportion of semi-coke particle size ≤ 3mm is controlled at 70-75%, and the proportion of semi-coke particle siz...

Embodiment 2

[0028] The mixture is composed of the following components and parts by weight: 12 parts of quicklime, 3 parts of dolomite, 6 parts of fuel, 84 parts of mixed mineral powder, and 34 parts of returned ore; Quantity calculation, the weight ratio is coke powder: semi-coke = 9:1. The proportion of semi-coke particle size ≤ 3mm is controlled at 70-75%, and the proportion of semi-coke particle size ≥ 5mm is less than 5%.

[0029] Weigh the above components and mix them evenly before sintering in the sintering equipment. The sintering thickness is ≥700mm, the ignition temperature is increased to 1170-1200℃, the water content of the mixture is 7.2±0.2%, and the proportion of the mixture particle size>3mm is controlled to be ≥70%. Sinter basicity ≥ 2.3 ± 0.1.

Embodiment 3

[0031] The mixture is composed of the following components and parts by weight: 9 parts of quicklime, 3 parts of dolomite, 6 parts of fuel, 84 parts of mixed mineral powder, and 31 parts of returned ore; the fuel is composed of coke powder and semi-coke. Quantity calculation, the weight ratio is coke powder: semi-coke = 3:1. The proportion of semi-coke particle size ≤ 3mm is controlled at 70-75%, and the proportion of semi-coke particle size ≥ 5mm is less than 5%.

[0032] The above components are weighed, mixed evenly, and then sintered in the sintering equipment, the sintering thickness is ≥700mm, and the ignition temperature is raised to 1170-1200°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com