A sintered ore capable of improving viscosity of blast furnace slag and a preparation method thereof

A blast furnace slag and sinter technology, which is applied in the field of sinter, can solve the problems of poor fluidity of blast furnace slag, achieve the effects of no deterioration of coal consumption index, simple and easy preparation method, and increase production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

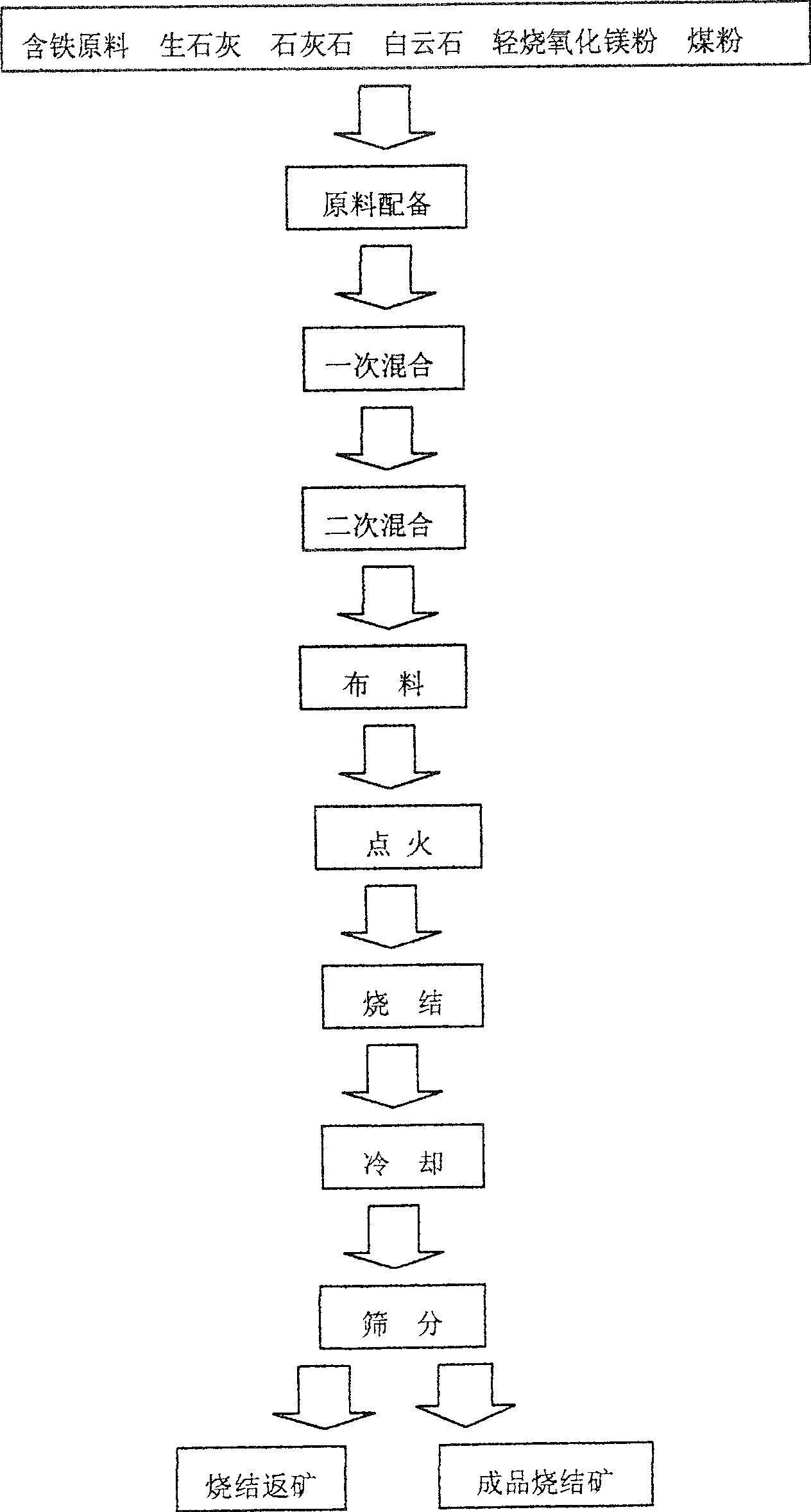

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0027] As shown in the figure, the sinter preparation process of the present invention is roughly divided into: raw material preparation → primary mixing → secondary mixing → distribution → ignition → sintering → cooling → screening and other stages. The specific operation steps are as follows:

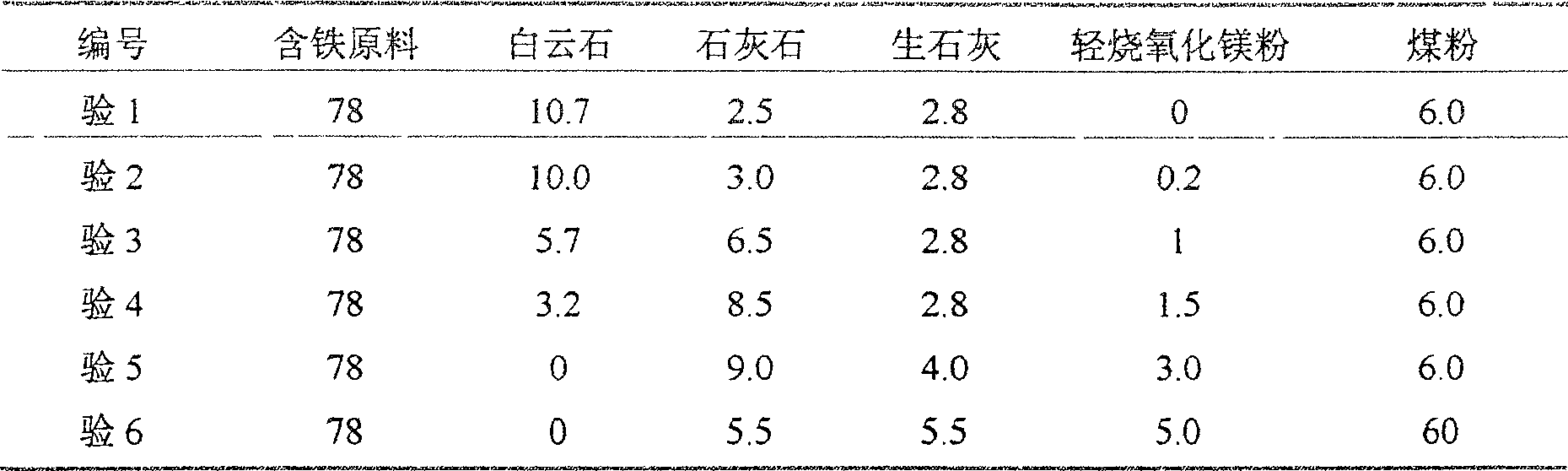

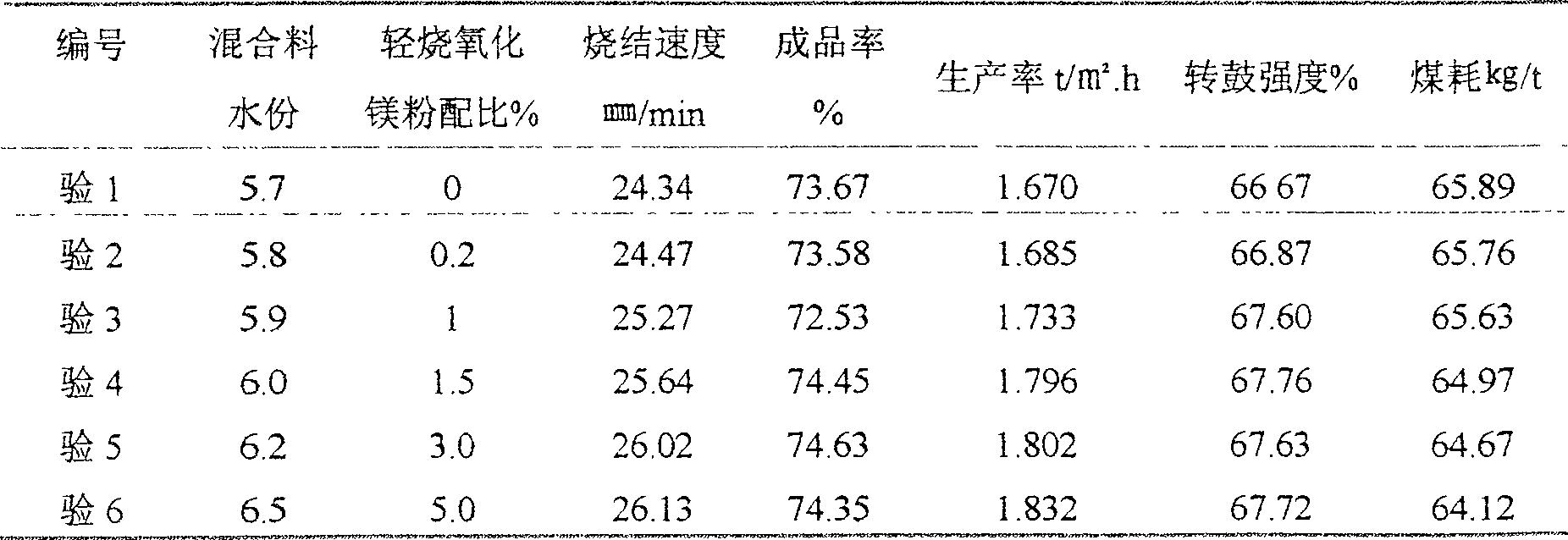

[0028]1) Raw material equipment: According to the specific requirements of the blast furnace for the basicity CaO / SiO2 and MgO content of the sintered ore, the finished sintered ore meets the basicity CaO / SiO2=1.5-3.0, the content of TFe is 50-60%, and the content of MgO is The index of 1.5-4.0%, in the weight ratio is 70-85% of iron-containing raw materials, 2-5% of quicklime, 0-8% of dolomite, 5-12% of limestone, 0.2-5% of light-burned magnesium oxide powder, coal In the range of 3% to 8% of coke powder or coke powder, the conventional calculation me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com