Method for enriching magnesium-containing minerals in asbestos tailings

A technology for asbestos tailings and minerals, applied in the field of mineral processing, can solve the problems of low grade and difficulty of magnesium-containing minerals, and achieve the effects of improving grade, easy operation and simple process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

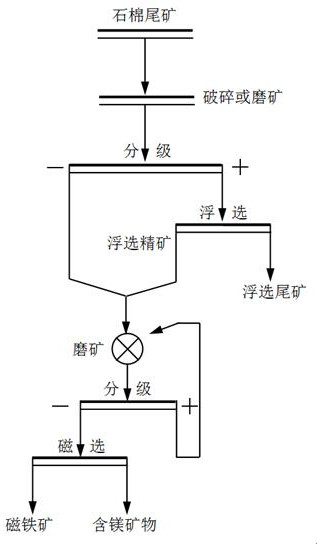

Method used

Image

Examples

Embodiment 1

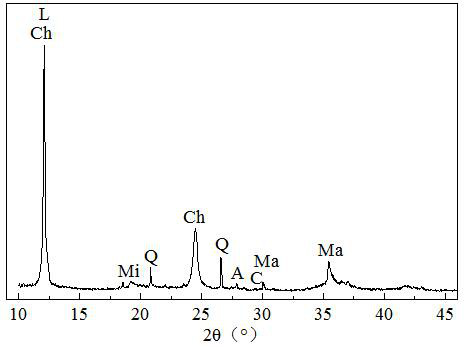

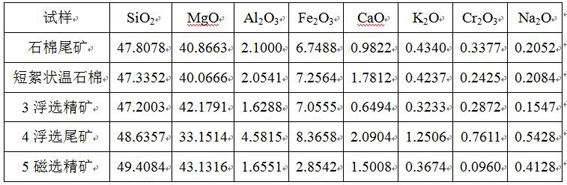

[0029] The main mineral phases of an asbestos tailings include serpentine (L), chrysotile (Ch), quartz (Q), magnetite (Ma), a small amount of albite (A), plagioclase (Mi), Calcite (C), etc., see its XRD pattern figure 2 , the specific composition is shown in the following table 1;

[0030] (1) Use a jaw crusher to crush asbestos tailings (the particle size composition is +8mm, 1.6%; 3~8mm, 90.3%; -3mm, 8.1%) to below 3mm, and use Φ200× for asbestos tailings below 3mm 240 type rod mill for grinding, the grinding medium is steel rod, weighing 13.2kg, the weight ratio of the grinding medium is Φ20mm: Φ16mm: Φ14mm=6.32kg: 4.36kg: 2.02kg; the ore feeding amount is 1.0kg / time; the grinding mass concentration 50%; the grinding time is 6 minutes; the particle size composition of asbestos tailings after grinding is +0.45mm content 1.5%, 0.105~0.45mm content 80.6%, -0.105mm content 17.9%;

[0031] (2) Use wet screening method to remove asbestos tailings after grinding to coarsely rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com