Method for preparing caring strengthened porcelain

A technology for strengthening porcelain and products, applied in the field of preparation of Kairui strengthened porcelain, can solve the problems of poor molding performance, hindering the development and industrialization of talc porcelain, and later aging, etc. Structural stress, effect of increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

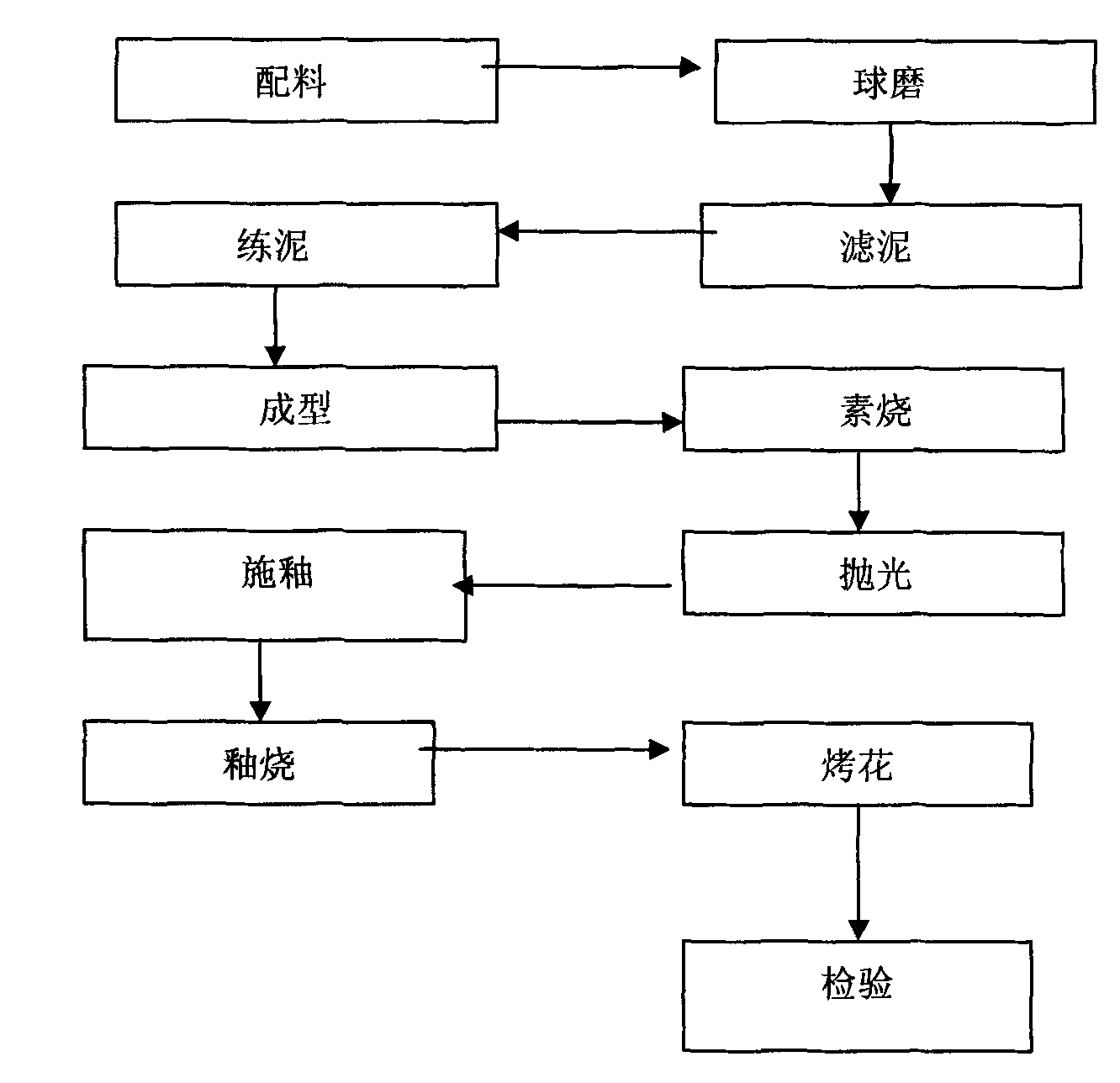

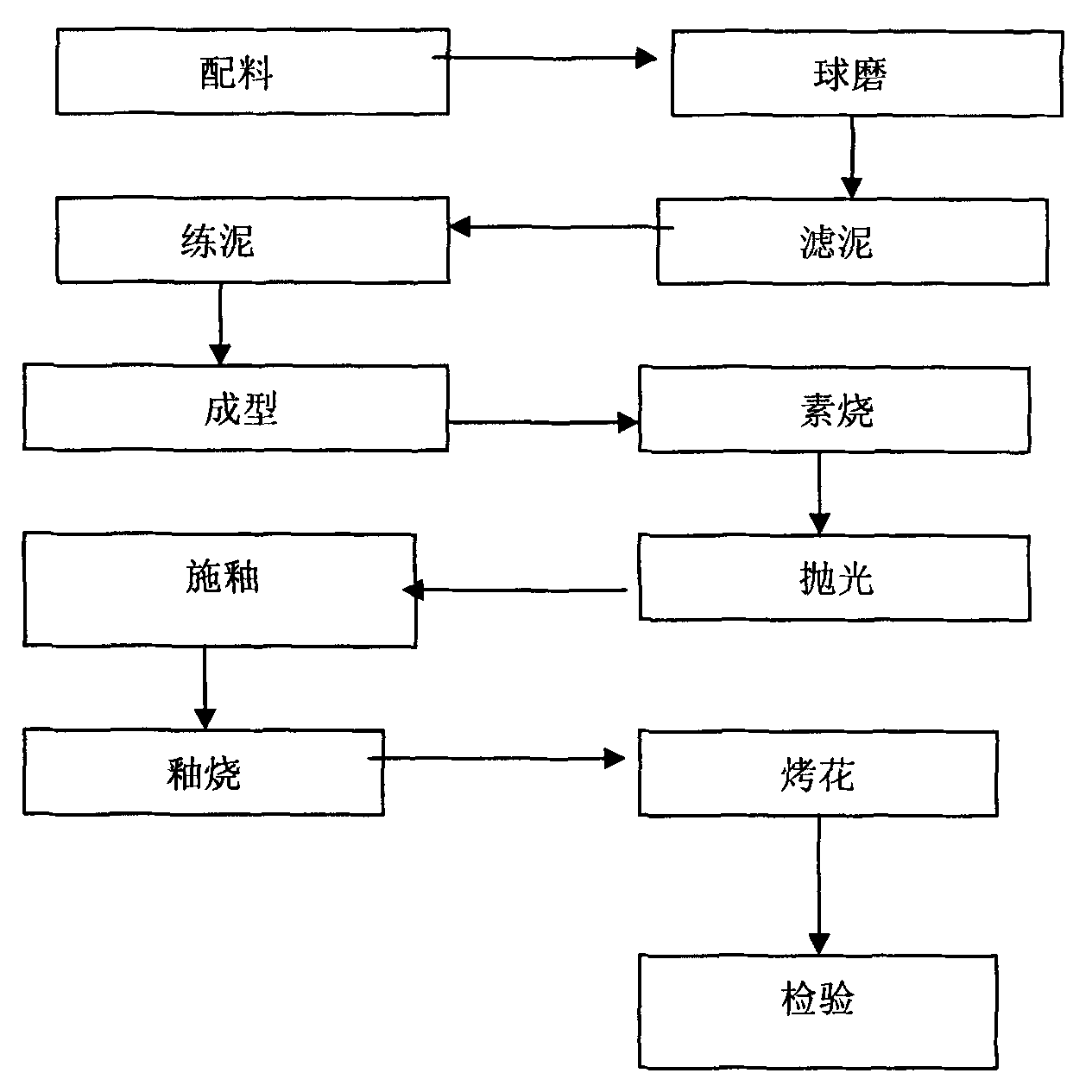

[0018] see figure 1 , when implementing the preparation method of Kaierui reinforced porcelain involved in the present invention, there are no more requirements for kiln equipment. Before operation, the steps of selecting and preparing materials should be carried out first. For example, magnesium-rich clay can be added to the mud for later use. Select a mineralizer for anti-porcelain aging and structural stress for backup; then add the spare mud and mineralizer to the billet; then proceed in sequence: batching-ball milling-filtering mud-refining mud-forming-bisque firing-polishing- The technical process of glazing-glazing firing-roasting-inspecting-intensifying porcelain products.

[0019] In order to obtain high-quality daily-use ceramics whose regularity and glaze smoothness of the product meet the bone china standard, and the large-scale product and positive mold relief molding process that can be realized in this method, in the above-mentioned flow process, it is necessary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com