Patents

Literature

35results about How to "Wide sintering range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High temperature sintering conductive silver paste for negative temperature coefficient (NTC) thermistor and preparation method thereof

ActiveCN103165222AReduce procurement costsReduce procurement cycleNegative temperature coefficient thermistorsNon-conductive material with dispersed conductive materialSlurryThermistor

The invention relates to high temperature sintering conductive silver paste for a negative temperature coefficient (NTC) thermistor and a preparation method of the high temperature sintering conductive silver paste for the NTC thermistor. The conductive silver paste comprises the following components, by weight: 72 parts to 85 parts of metal silver powder, 1 part to 10 parts of glass powder, 10 parts to 30 parts of organic carriers and 1 part to 10 parts of solvent. The mentioned materials are fully mixed in a blender mixer, and then are dispersed at high speed through a highs-peed dispersion machine, and even slurry is obtained. The slurry is grinded on a three-roller grinder, the fineness degree of the silver paste is controlled under 15 micrometers through the fine adjustment of idler wheels, the viscosity of the silver paste is 30 Pa.S to 50 Pa.S, and lead-free welding-resistance conductive silver paste for electrothermal film quartz glass tube electrical heating elements is prepared. Compared with the prior art, the high temperature sintering conductive silver paste for the NTC thermistor has the advantages of being low in cost, low in sintering temperature, wide in sintering range, strong in adhesive force and the like.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

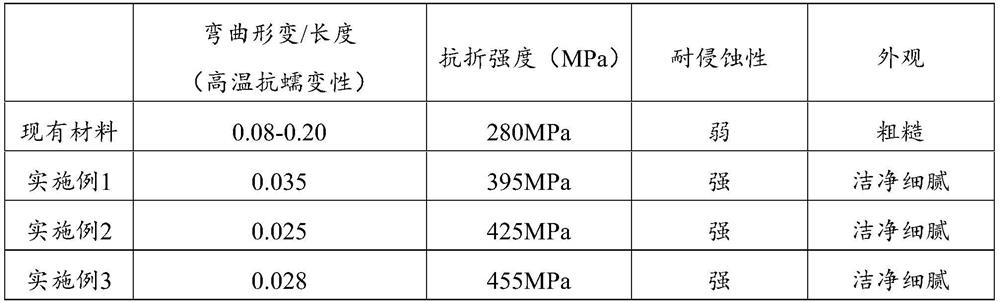

Reinforced ceramic prepared from common daily ceramic blanks and preparation method of reinforced ceramic

ActiveCN110028303ASmall coefficient of thermal expansionImprove mechanical properties and thermal stabilityClaywaresSodium silicateDecomposition

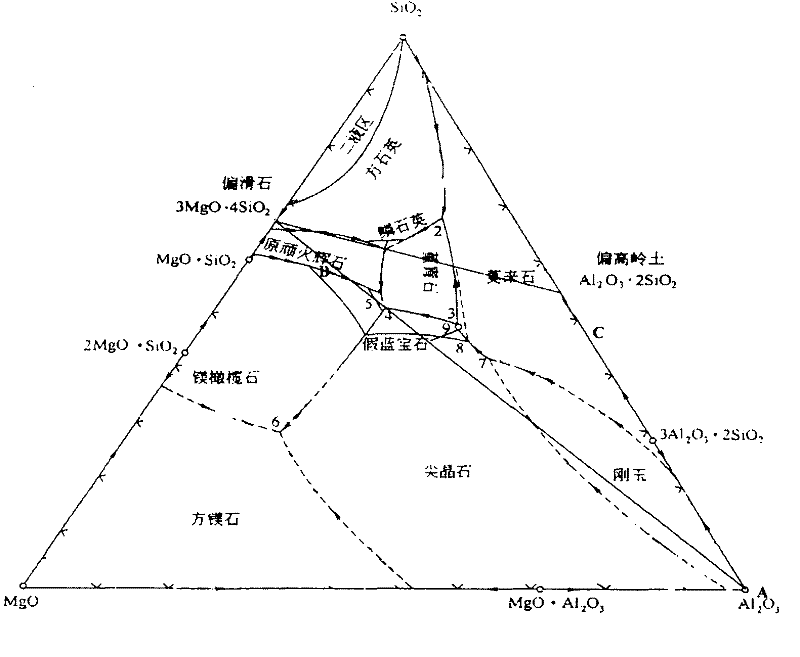

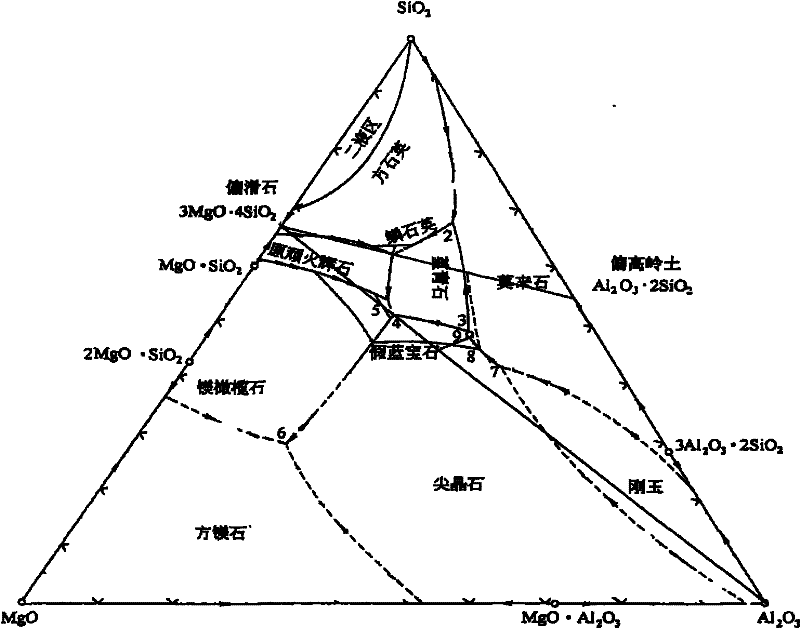

The invention relates to the technical field of daily ceramic preparation, and particularly relates to a reinforced ceramic prepared from common daily ceramic blanks and a preparation method of the reinforced ceramic. The reinforced ceramic is prepared from the following raw materials by mass: 85%-90% of daily ceramic blanks, 3%-10% of talc, 1%-3% of aluminum fluoride, 0-1% of titanium dioxide, 0-1% of vanadium pentoxide, 0-1% of lanthanum oxide and sodium silicate accounting for 5 per mill-8 per mill of the total mass of the raw materials. The reinforced ceramic provided by the invention is prepared by using the common daily ceramic blanks as main raw materials and adding a small amount of a reinforcing agent; the added talc can generate cordierite with aluminum oxide and silicon dioxidein clay to effectively reduce a thermal expansion coefficient of the ceramic blanks; the vanadium pentoxide or lanthanum oxide can promote decomposition of aluminum fluoride and activate with silicondioxide in the clay to form needle or whisker-like secondary mullite or form thermal shock-resistant aluminum titanate crystals with titanium dioxide at high temperature, thereby effectively improvingmechanical properties and thermal stability of the ceramic blanks.

Owner:WUHAN UNIV OF TECH +1

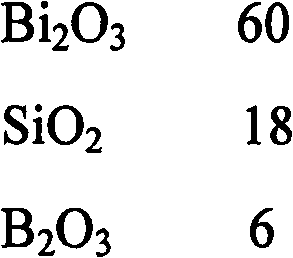

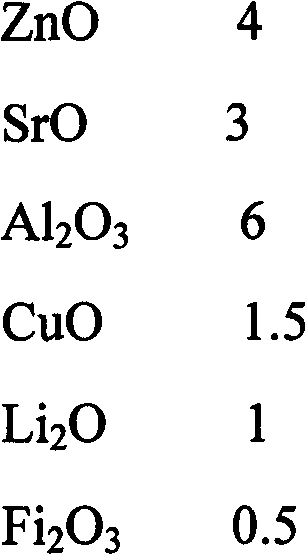

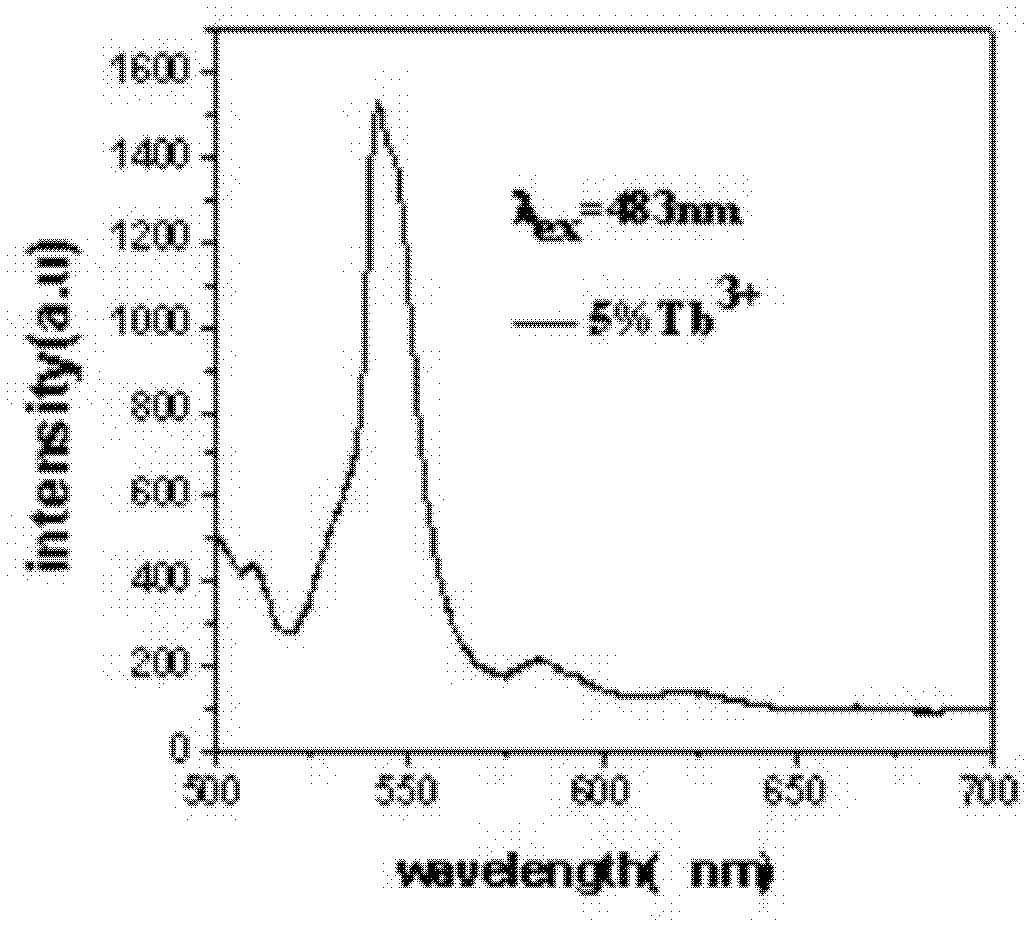

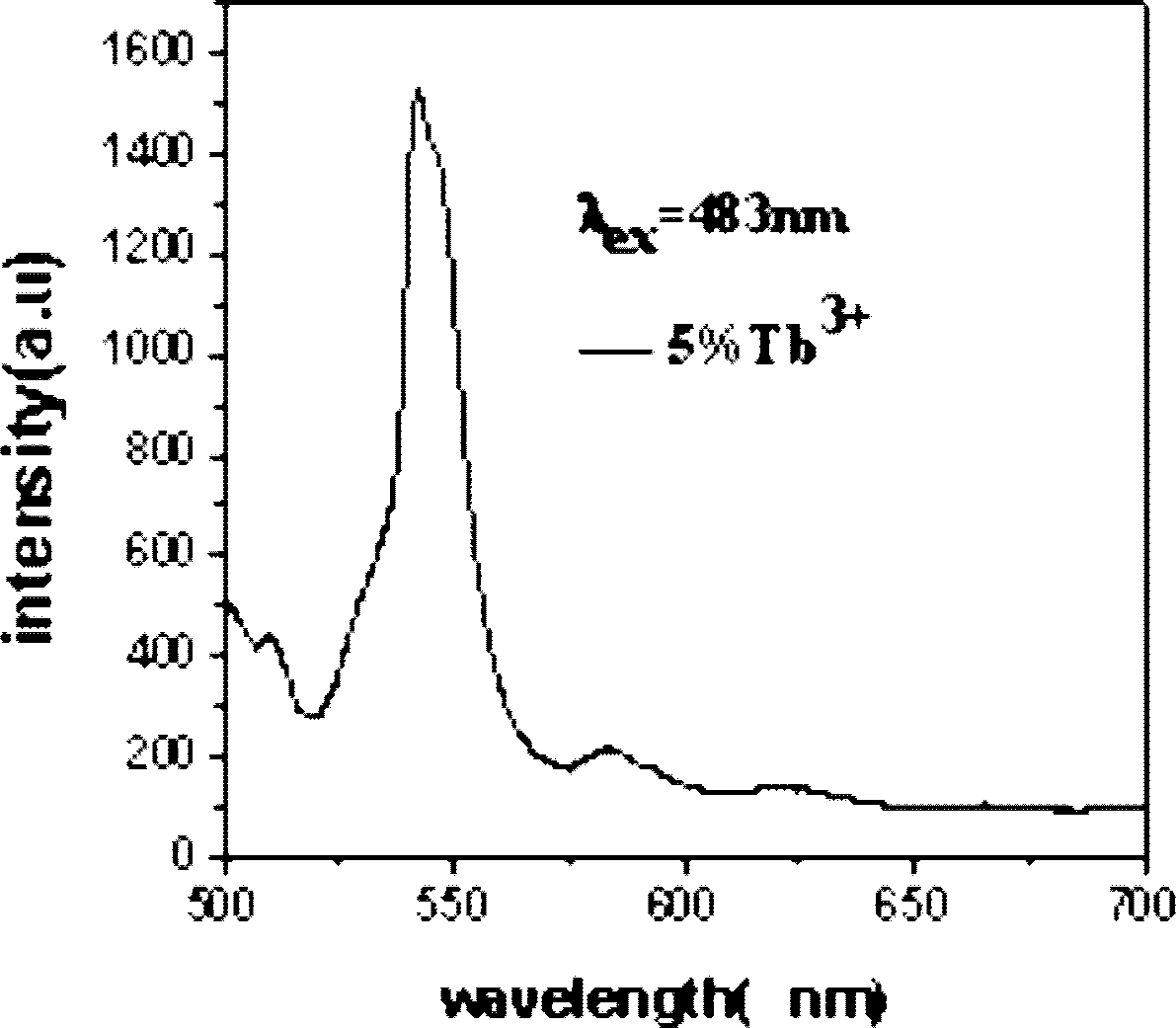

Yellow light-emitting low temperature co-fired ceramic material and preparation method thereof

The present invention relates to a calcium-boron-silicon based yellow light-emitting low temperature co-fired ceramic material synthesized through a Sol-Gel method, and a preparation method thereof. The doped activator in the ceramic material comprises one or two selected from Ce<3+> and Tb<3+>. The ceramic material comprises the following components, by mole, 15-20% of CaO, 60-70% of SiO2, 10-25% of B2O3, 1-9% of the activator ion and 1-9% of charge compensating agent ion. The material and the preparation method have the following advantages that: the luminous intensity is good, yellow lightwith a wavelength of about 541 nm can be emitted under the excitation of blue light with a wavelength of 460-490 nm; a LTCC substrate prepared from the material provided by the present invention can emit light under the excitation of a luminous chip, such that the LTCC substrate can be applicable for production of the LED lamp so as to simplify the production process, therefore, the ceramic material can be applicable for the field of white light LED, LTCC substrate materials and microelectronic packaging materials; the sintering temperature is low, the sintering temperature range is broad; the sintering shrinkage is controllable; the dielectric constant is adjustable and in a range of 3-7 (1 MHz), the dielectric loss is less than 0.002; the mechanical strength is high and the heat performance is good.

Owner:UNIV OF SCI & TECH BEIJING

Wide-range sintered glass ink for automobile laminated glass and preparation method of wide-range sintered glass ink

The invention discloses wide-range sintered glass ink for automobile laminated glass, which belongs to the technical field of ink materials, and comprises the following components in percentage by weight: acid-resistant glass powder, low-temperature glass powder, silver paste matched glass powder, copper-chromium melanin, varnish and a diluent. The invention also discloses a preparation method ofthe wide-range sintered glass ink for the automobile laminated glass, the ink prepared by the method does not contain harmful heavy metals such as lead and cadmium, meets ROHS10 and sustainable development requirements, and is non-toxic, harmless and pollution-free in the preparation process; the softening point of the ink is 450 to 530 DEG C; the thermal expansion coefficient is 60*10 <-7 > / DEG C-90*10<-7 > / DEG C, the Toyota acid-resisting time is longer than 8 h, the sintering temperature range is 520-720 DEG C, glass of different sizes and different curvatures can be covered, silver paste sintering can be matched, cracks are not generated, and the method can be used for forming front windshield laminated glass of cars, SUVs, middle buses and buses.

Owner:湖南衡义材料科技有限公司

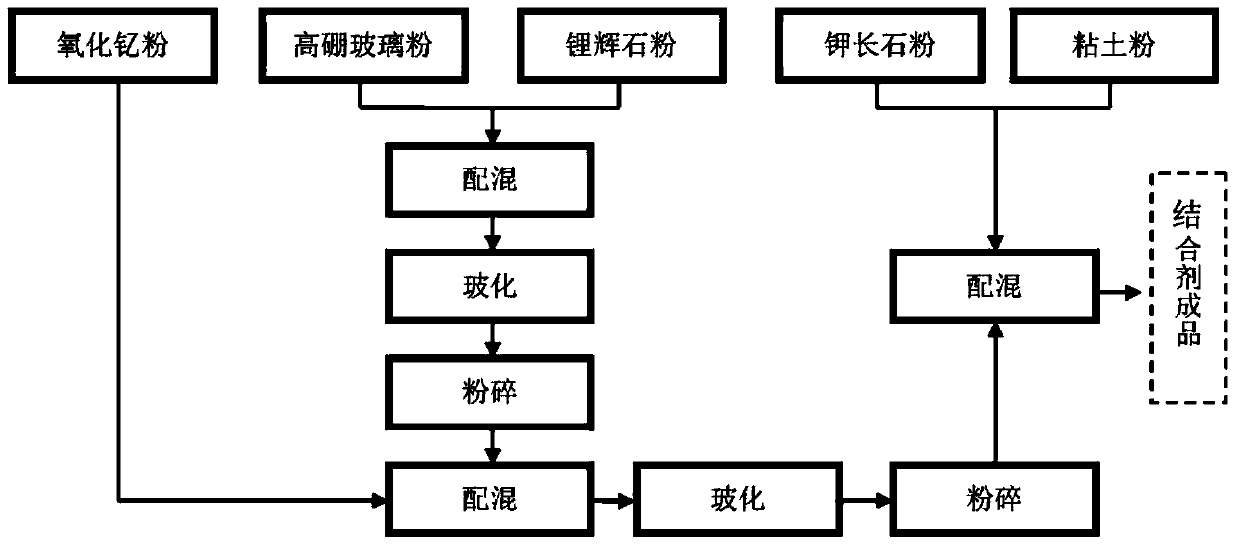

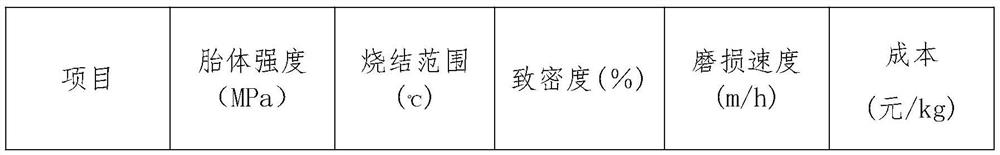

High-strength low-melting-point ceramic abrasive tool bonding agent and preparation method thereof

InactiveCN104191381ALow melting pointWide sintering rangeAbrasion apparatusGrinding devicesThermal energyPotassium

The invention discloses a high-strength low-melting-point ceramic abrasive tool bonding agent and a preparation method thereof. The high-strength low-melting-point ceramic abrasive tool bonding agent is made of, by weight, 20%-40% of high-boron glass powder, 15%-20% of clay powder, 40%-60% of potassium feldspar powder, 4%-15% of LiO2 powder and 0.1%-2% of Y2O3 powder. The ceramic abrasive tool bonding agent prepared according to the method has the advantages of low melting point, wide sintering range, proper liquidity, excellent high-temperature wettability, high mechanical strength and the like, the problems of low grinding capability, poor abrasion resistance, short service life and the like in grinding of difficult-to-machine materials such as tool steel, tough stainless steel, heat-resisting alloy steel and the like are solved, and utilization speed of the bonding agent is higher than 80m / s. Refractoriness of the bonding agent is only 780-860 DEG C and far lower than 1150 DEG C, and consequently thermal energy can be greatly reduced to save energy resources, and production efficiency is improved.

Owner:SUZHOU FAR EAST ABRASIVES

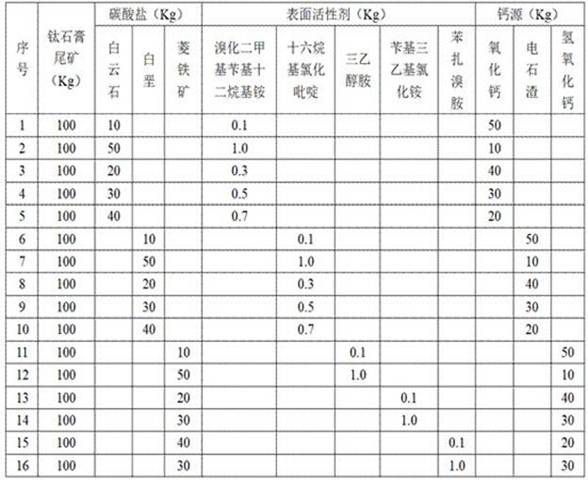

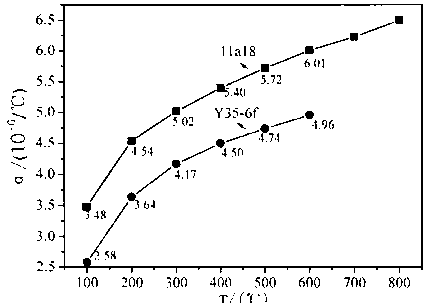

High-performance permanent magnet ferrite with extremely-low Hcj temperature coefficient and preparation method thereof

The invention relates to high-performance permanent magnet ferrite with an extremely-low Hcj temperature coefficient. A main phase molecular formula is SrxAyB1-x-yFezCnOm, wherein A is one or more of elements Ca, Ba and Pb; B is one or more of elements La, Bi and Y; C is one or more of elements Co, Zn, Ni, Cd, Mn, Cu and Cr; x, y, z, n and m represent a molar ratio, and the value taking ranges are that x is more than or equal to 0.1 but less than or equal to 0.6, y is more than or equal to 0.05 but less than or equal to 0.5, n is more than or equal to 0 but less than or equal to 0.3, z is more than or equal to 9.0 but less than or equal to 12, and m is more than or equal to 0.15 but less than or equal to 19. The permanent magnet ferrite provided by the invention can achieve high performance and has low Hcj temperature coefficient. According to a preparation method of the high-performance permanent magnet ferrite with the extremely-low Hcj temperature coefficients, a primary additive contains boric acid and ammonium bicarbonate, can promote the full generation of an M phase of the permanent magnet ferrite and plays a great role in promoting the magnetic property and the stability of the low Hcj temperature coefficient.

Owner:ANHUI SINOMAG TECH

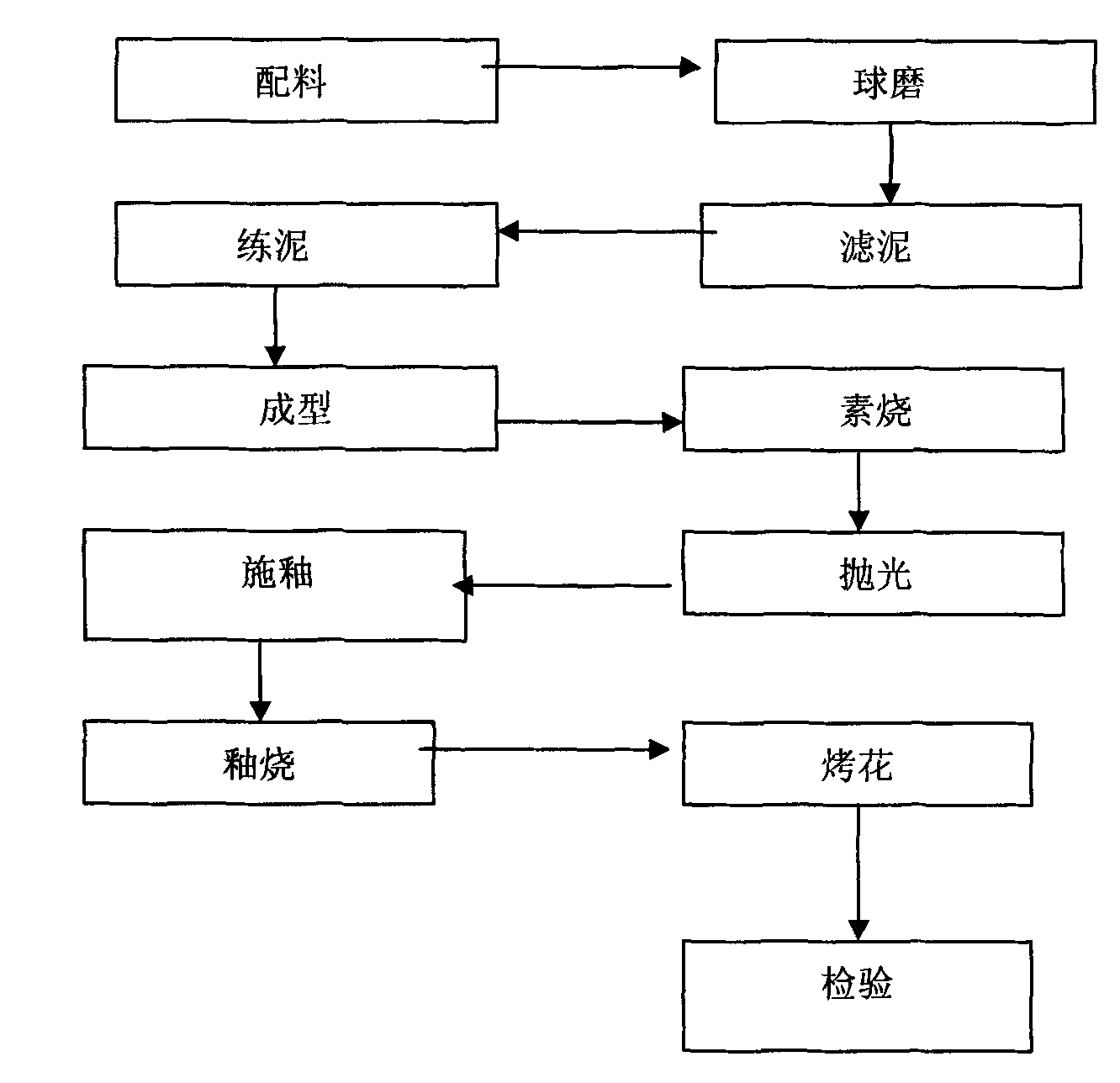

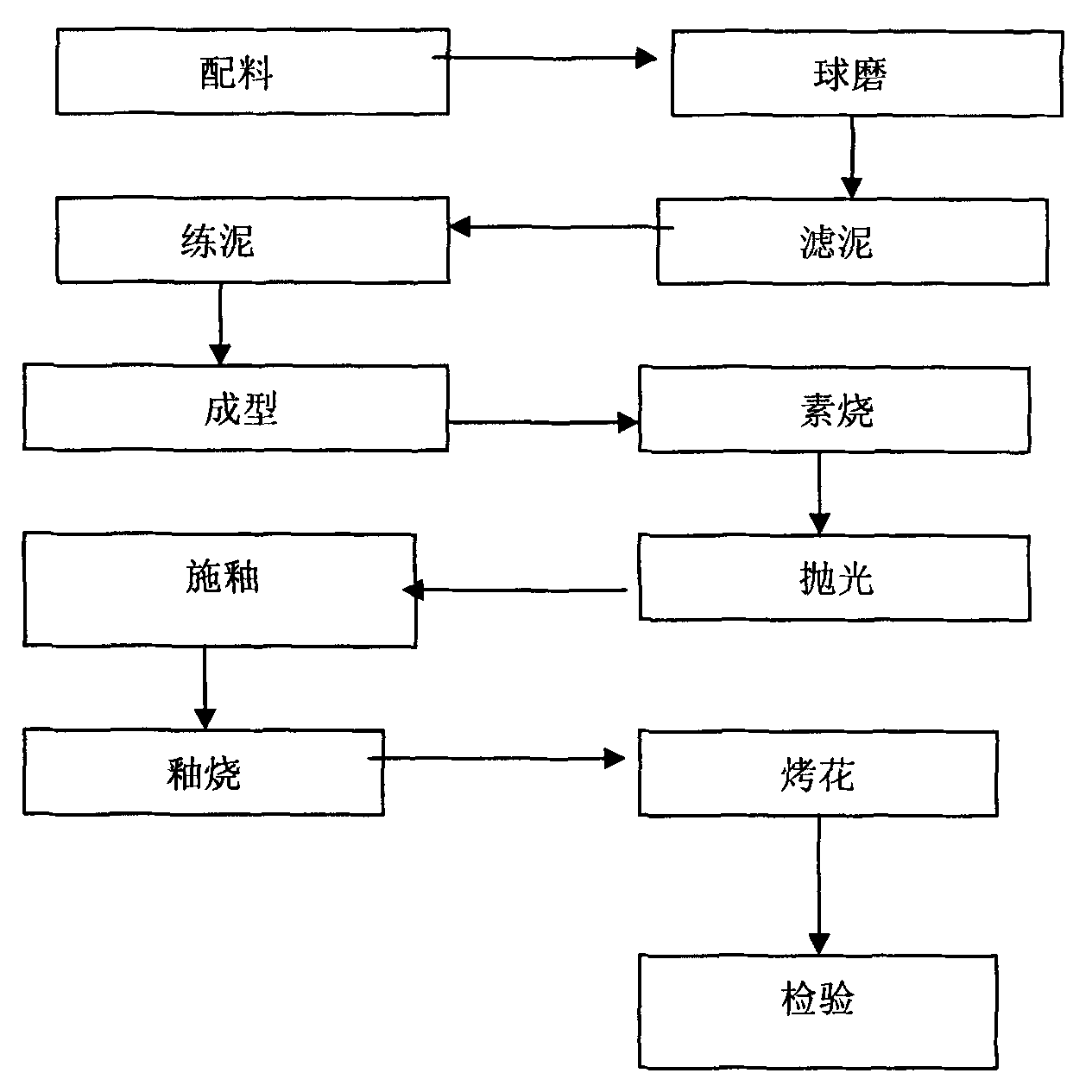

Method for preparing caring strengthened porcelain

InactiveCN101987790AProminent and significant technical effectsHigh viscosityClaywaresTalcBone china

The invention relates to a method for preparing caring strengthened porcelain. The method comprises the following steps of: (A) adding magnesium-rich clay into pug for later use and selecting a porcelain aging- and structural stress-resistant mineralizer for later use; (B) adding the pug and the mineralizer for later use into a blank; and (C) performing mixing, ball milling, pug filtering, pug milling, molding, biscuit firing, polishing, glazing, glaze firing, decoration firing and sorting in turn to prepare a strengthened porcelain product. Through the process, the barrier of industrializing household talc porcelain is broken through, the problem of formability of the blank is effectively solved, a firing range is broadened, the problems of later aging and the like are solved, and by adopting a process route for producing high-grade porcelain, the technology and process for manufacturing the caring strengthened porcelain achieve and exceed that for producing worldwide recognized high-grade bone china.

Owner:施永义

Low-temperature sintered medium-dielectric-constant microwave dielectric ceramic material and preparation method thereof

InactiveCN111517791AHas the advantage of energy savingImprove performanceDielectricDielectric permittivity

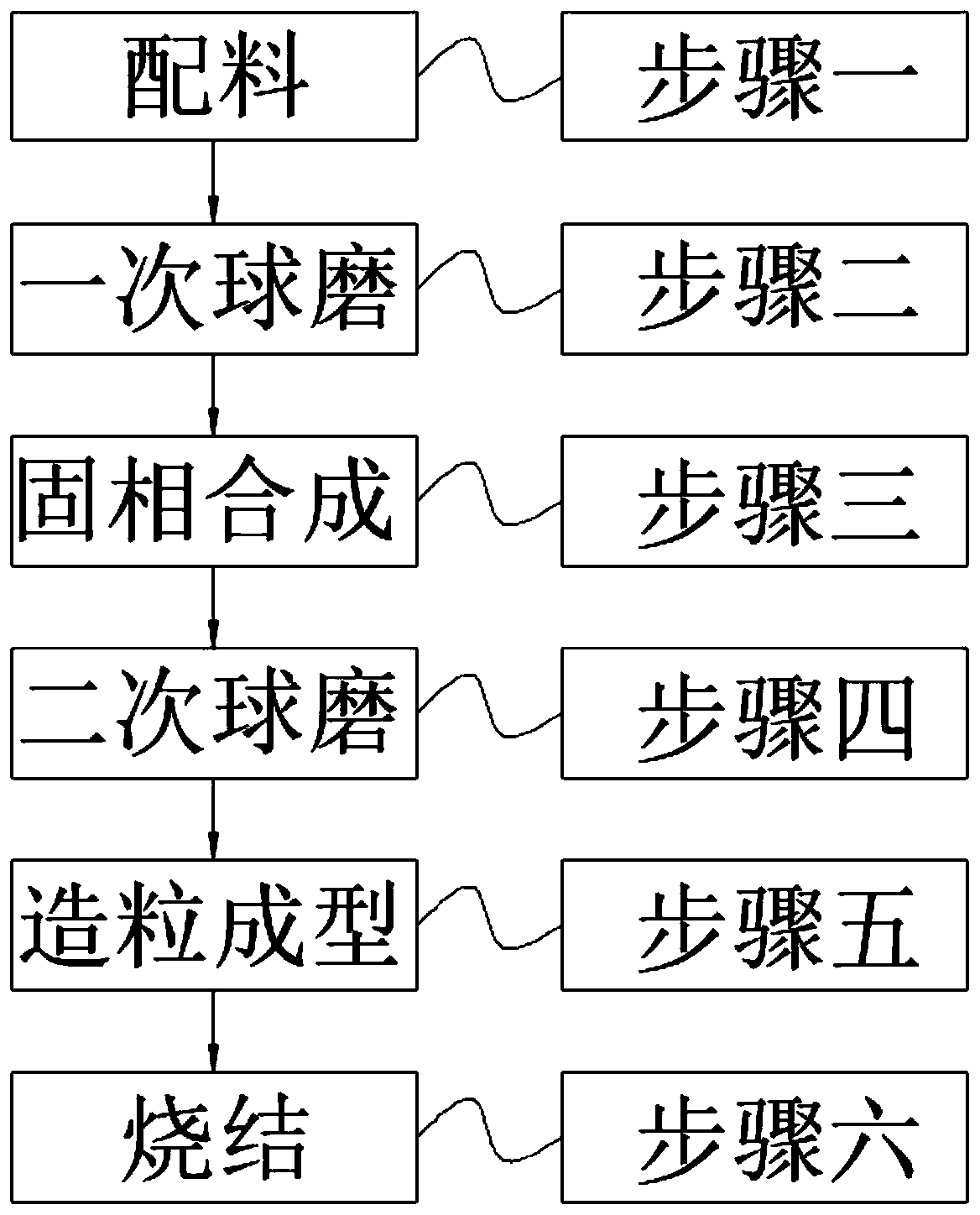

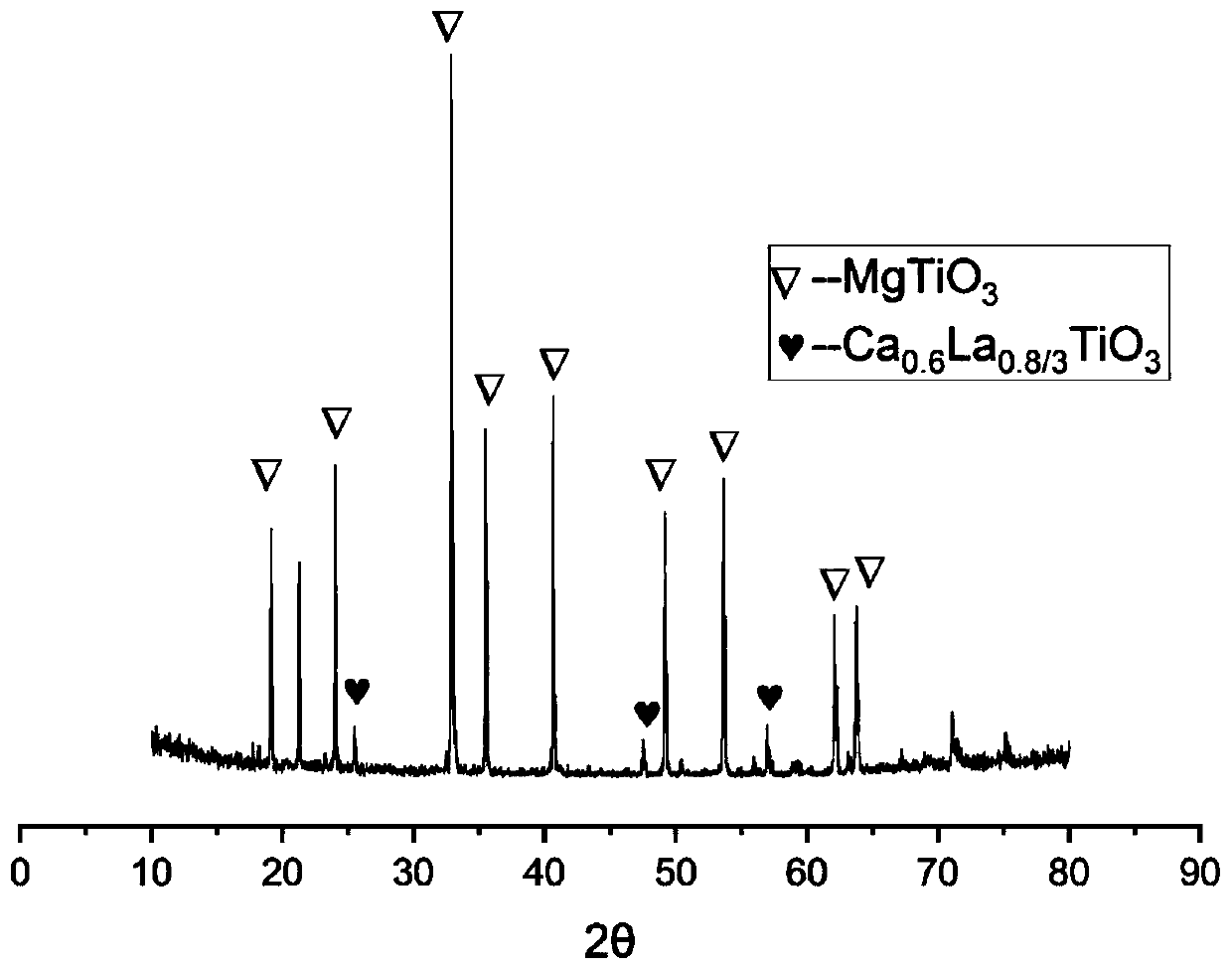

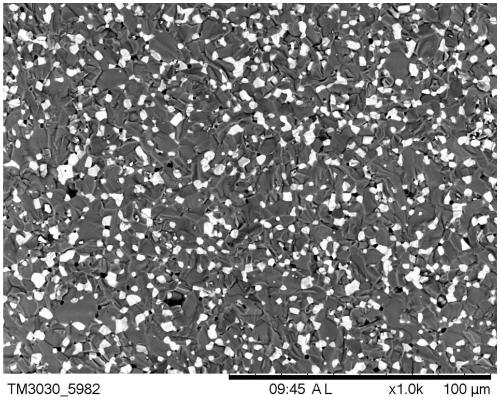

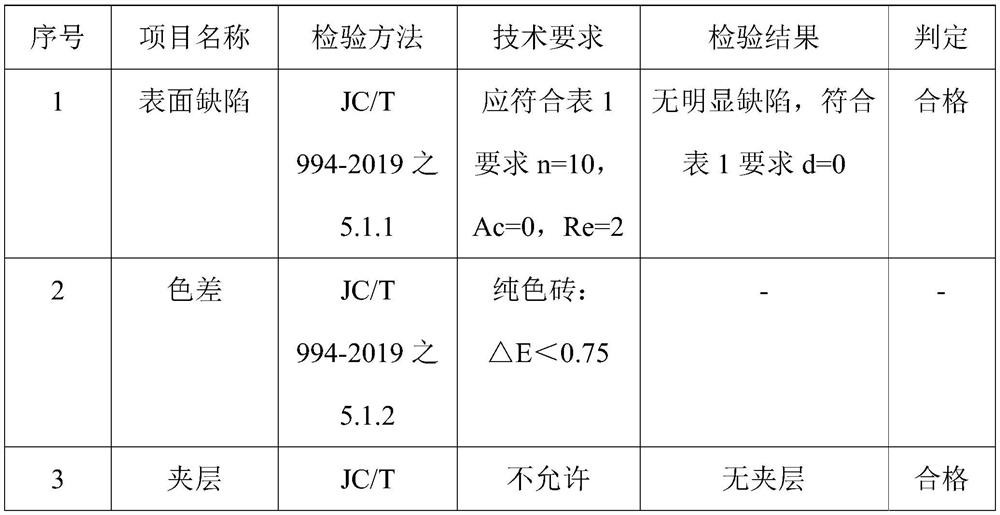

The invention discloses a low-temperature sintered medium-dielectric-constant microwave dielectric ceramic material and a preparation method thereof, the low-temperature sintered medium-dielectric-constant microwave dielectric ceramic material comprises a base material and an additive, and the preparation method of the low-temperature sintered medium-dielectric-constant microwave dielectric ceramic material comprises the following steps: step 1, burdening; 2, carrying out primary ball milling; step 3, performing solid-phase synthesis; 4, carrying out secondary ball milling; step 5, granulatingand molding; and step 6, sintering; the method comprises the following steps: step 1. MgO, TiO2, CaCO3 and La2O3 are used as raw materials; according to the invention, the sintering temperature of the traditional microwave-based ceramic is reduced; the microwave dielectric ceramic has the advantages of energy conservation, excellent performance, simple sintering condition, air sintering atmosphere, wide sintering range, high stability, greatly improved quality factor and great practical value, the raw materials are all domestic raw materials, the price is moderate, the formula does not contain heavy metals, and the microwave dielectric ceramic is environment-friendly and pollution-free.

Owner:福建溥昱电子科技有限公司

Wear-resistant microcrystal dry particles with soft light effect, preparation method thereof and ceramic tile

The invention discloses a wear-resistant microcrystal dry particle with a soft light effect, a preparation method thereof, and a ceramic tile. The wear-resistant microcrystal dry particle comprises the following components in percentage by weight: 55-65% of SiO2, 5-9% of Al2O3, 14-18% of CaO, 3.8-4.5% of ZnO, 3-5% of BaO, 3-6% of Na2O and 1-3% of B2O3. The microcrystalline dry particle can improve the glossiness of the surface of a product and improve the wear resistance of the product. The ceramic tile comprises a ceramic green body, the ceramic green body is sequentially provided with a glaze layer, a decorative layer and a wear-resistant microcrystalline layer from bottom to top, wherein the wear-resistant microcrystalline layer is prepared from the wear-resistant microcrystalline dry particles with the soft light effect. After high-temperature sintering, the wear-resistant microcrystalline layer presents a soft light effect, can protect ink jet patterns, and also presents soft light and semitransparent jade texture of natural stone, so that the aesthetic feeling and grade of the product are greatly improved, and the application range of the product is widened.

Owner:YANGXI BODE PRECISION IND BUILDING MATERIAL CO LTD

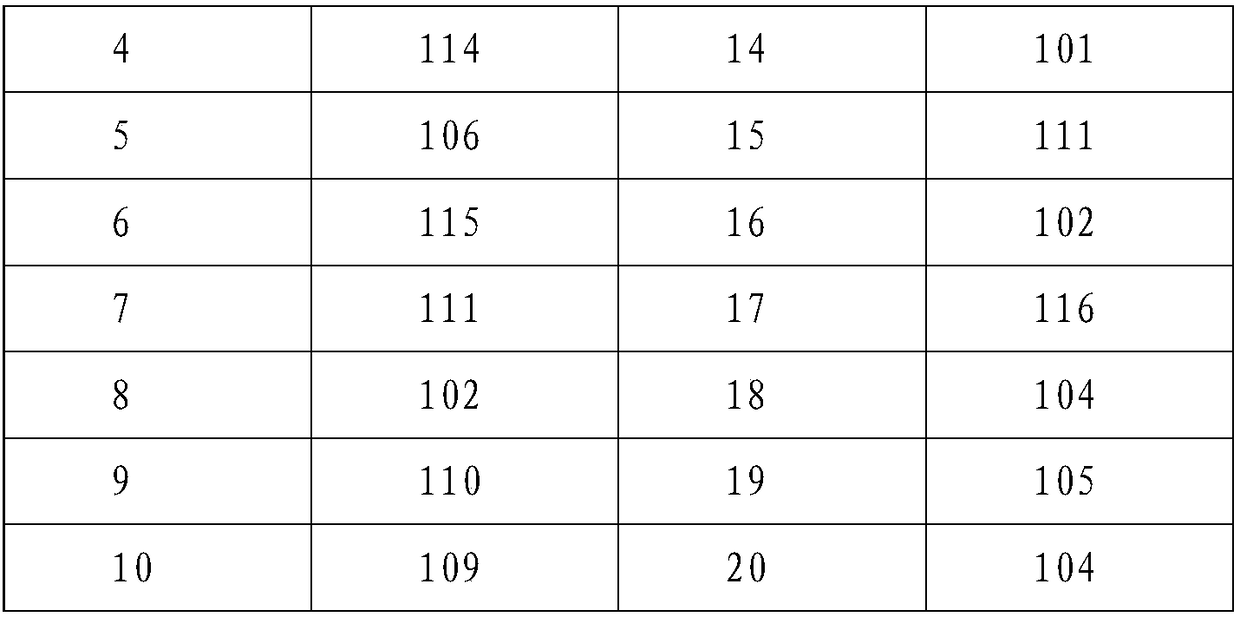

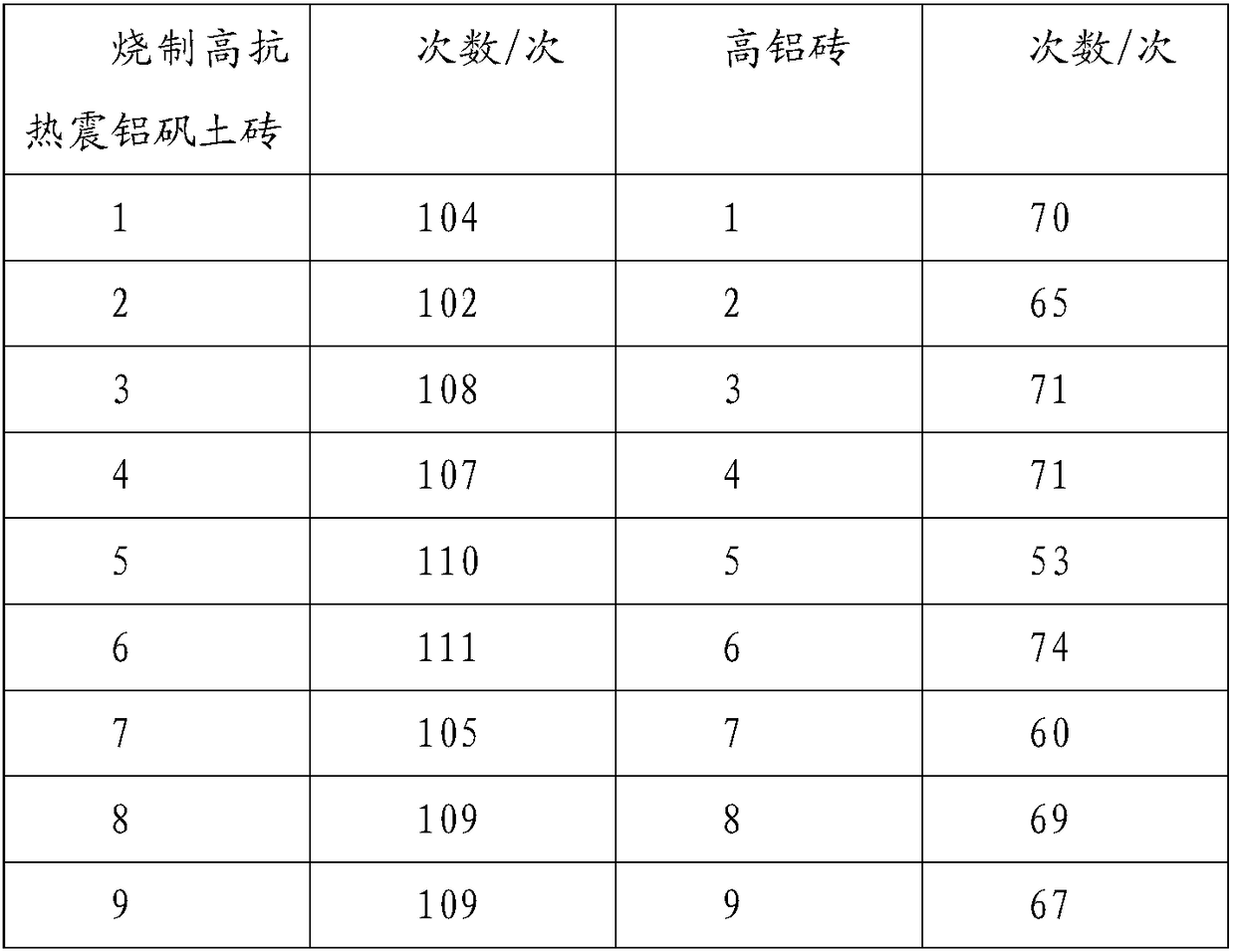

Sintered high thermal shock resistance bauxite brick, and production method thereof

The invention provides a sintered high thermal shock resistance bauxite brick, and a production method thereof, and belongs to the field of industrial kiln material. The sintered high thermal shock resistance bauxite brick comprises, by weight, 52 to 58 parts of high aluminium bauxite mixture, 15 to 20 parts of sillimanite powder, 8 to 12 parts of cordierite powder, 3 to 8 parts of aluminium oxidepowder, 10 to 15 parts of Guangxi white clay, 1 to 5 parts of zirconite powder, and 1 to 5 parts of silicon carbide fine powder. The production method comprises following steps: 1, mixing and stirring; 2, pressing and sintering; and 3, thermal insulation treatment. The production method is capable of improving the thermal shock resistance of the sintered high thermal shock resistance bauxite brick.

Owner:郑州凯翔耐火材料有限公司

Formula and production process of kaolin and white afrodite mixed powder

The invention relates to the technical field of mineral raw materials, and discloses a formula of kaolin and white afrodite mixed powder. The kaolin and white afrodite mixed powder comprises the following raw materials in percentage by weight: 70-85% of white afrodite and 15-30% of kaolin. According to the formula of the kaolin and white afrodite mixed powder and a production process of the kaolinand white afrodite mixed powder, the white afrodite is added, and the white afrodite is a silicon natural rock which is formed by binding quartz sand with silicate minerals. The white afrodite is extremely rich in mineral resources and is abundant in Sichuan, Hubei, Guangxi and the like, mining is convenient, price is low, cost is low, and high transportation cost can be avoided due to abundant production in many places, so that production cost of glass fibers can be reduced. The kaolin is added, and the kaolin is clay and clay rocks which are common in nature and are mainly composed of kaolinite clay minerals. Mixed glass fiber powder components of the kaolin and the white afrodite are very close to pyrophyllite, so that the formula provided by the invention can be used to replace an original formula comprising pyrophyllite powder for carrying out fiber drawing operation, so that the glass fiber drawing operation rate is improved, pyrophyllite resources are saved, and an active promotion effect of reducing cost of glass fiber raw materials is achieved.

Owner:重庆远嘉矿业有限公司

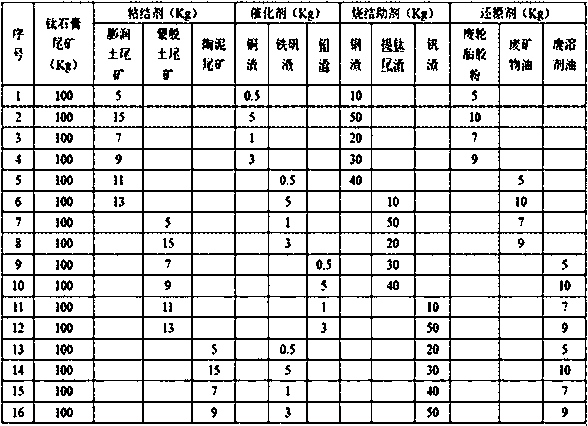

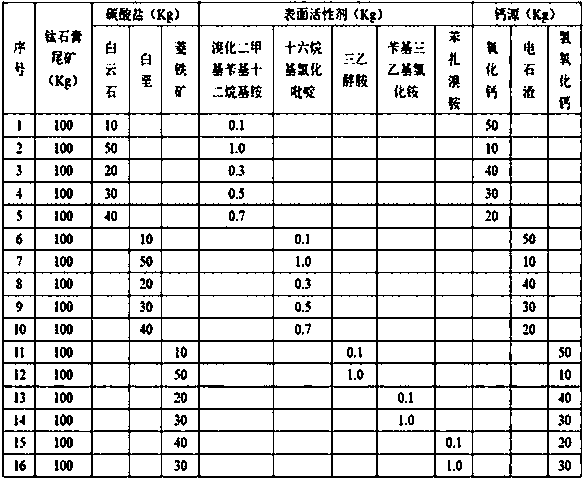

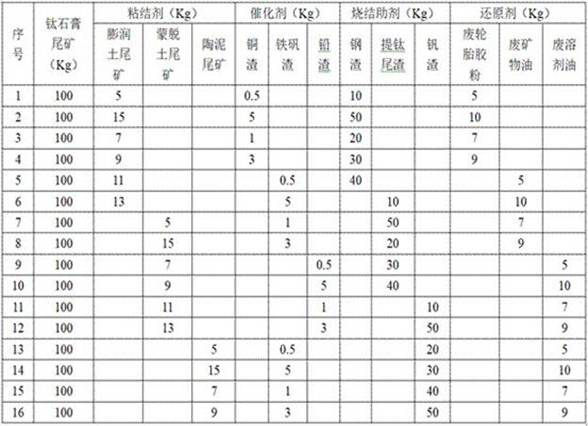

Method for preparing calcium ferrite from titanium-gypsum tailings

ActiveCN110372041AEfficient use ofEasy to controlIron compoundsProcess efficiency improvementCalciumSURFACTANT BLEND

The invention discloses a method for preparing calcium ferrite from titanium-gypsum tailings. Carbonate is added to titanium dioxide wastewater, filtration is conducted after reaction, after a surfactant is added to a filtrate, the filtrate is added to a calcium source to obtain titanium-gypsum slurry, and the titanium-gypsum tailings are obtained through physical separation; and after the titanium-gypsum tailings are aged, a binder, a catalyst, a sintering assistant and a reducing agent are added and mixed evenly to form a ball, and the calcium ferrite is obtained by reduction roasting. Compared with existing technical schemes, the method has the characteristics of being low in production cost, high in production efficiency and good in product quality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A kind of high-temperature sintered conductive silver paste for NTC thermistor and preparation method thereof

ActiveCN103165222BReduce procurement costsImprove adhesionNegative temperature coefficient thermistorsNon-conductive material with dispersed conductive materialSlurrySolvent

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Sintered heat-insulating brick and preparation method thereof

InactiveCN109665816AHigh utilization rate of solid wasteHigh strengthCeramic materials productionCeramicwareEnvironmental resistanceBrick

The invention discloses a sintered heat-insulating brick and a preparation method thereof. A green brick of the sintered heat-insulating brick comprises, by dry base weight, 50-90% of ash residue mixture, 10-30% of silica-alumina aggregate and 0-20% of hole forming material, the ash residue mixture comprises circulating fluidized bed ash residue and a heat correcting material, and doping amount ofthe heat correcting material is 0-20% of mass of the ash residue mixture. Doping amount of circulating fluidized bed ash in the sintered heat-insulating brick is 50-90%, other materials like furnaceslag, sawdust and rice hull ash used in a building block are industrial solid waste or byproducts, solid waste utilization rate is high, product quality is stable, each detection index of the sinteredheat-insulating brick produced by the method can reach national standard requirements, and the sintered heat-insulating brick has the advantages of high strength and high durability, meets environment-friendly, light-weight and energy-saving development direction of national wall materials and is an environment-friendly novel wall material.

Owner:梅州市梅县区金蔡建材厂

Preparation and application method of high whiteness, high light transmittance and high plasticity ceramic green mud

The invention relates to a preparation and application method of high whiteness, high light transmittance and high plasticity ceramic blank mud, which uses Linchuan talc, phlogopite, orthoclase and American fairy water as raw materials, and undergoes raw material pretreatment, batching, ball milling, Aged, sieved, iron-removed, dehydrated, and smelted to obtain a ceramic body slime with a plasticity index greater than 20, and the ceramic body mud has a whiteness greater than 84 after molding, drying, biscuit firing, water replenishment, glazing, and high-temperature firing. Ceramic products with light transmittance greater than 7.5% / 2mm. The invention adopts common mineral raw materials and chemical raw materials for specific proportioning, and modifies the Linchuan talc, so that the green body has high whiteness, strong light transmittance, good plasticity and wide sintering range, and can also make The green body will not be deformed when it is fired at a high temperature of 1240-1310°C. It solves the shortcomings of high difficulty in production, complex molding process and narrow firing temperature range of high-whiteness and high-transparency ceramics, so it has broad market prospects.

Owner:JINGDEZHEN CERAMIC UNIV

Wet process production technology for sintering cordierite

The invention relates to a wet process production technology for sintering cordierite. Coal gangue, a magnesium silica raw material, light roasting magnesia and cordierite chamotte are used as main raw materials; 60 to 80 percent of coal gangue, 8 to 20 percent of magnesium silica raw material, 10 to 20 percent of light roasting magnesia and 2 to 5 percent of cordierite chamotte are added into a container by weight percentage, then calcium lignosulphonate of which the weight is 0.1 to 0.5 percent that of the main raw materials and water of which the weight is 1.0 to 1.3 times that of the main raw materials are added, and mud a is obtained through grinding in a sealing manner; the sintering cordierite can be obtained through dehydrating, molding, drying and calcining of the mud a. The technology changes the traditional method for producing the sintering cordierite by adopting a dry method, the energy consumption of the technology is low, the volume density of the produced sintering cordierite product is greater than 2.0 g / cm<3>, and the quality is high.

Owner:SANMENXIA XINYANGSHAO SYNTHETIC MATERIALS

High-temperature creep-resistant ceramic material and preparation method thereof

The invention provides a preparation method of a high-temperature creep-resistant ceramic material, which comprises the following steps: S1, weighing 50-90 parts by weight of high-purity alpha-Al2O3 powder, 25-50 parts by weight of tabular corundum powder, 1-3 parts by weight of zirconium oxide powder and 0.5-1 part by weight of sintering aid, taking water as a solvent, adding a water-soluble dispersant, and carrying out ball milling to obtain slurry; s2, carrying out vacuum defoaming on the slurry, adding a catalyst and an initiator, uniformly stirring, injecting into a mold, curing, and demolding to obtain a green body; s3, drying the green body, softening, cutting into green sheets, and drying; and S4, sintering the dried blank sheet to obtain the ceramic material. The bulk density of the powder of the raw material components in different parts by weight is high, and the prepared ceramic material is a high-density material with high density and high hardness; and through mutual cooperation and distribution of the raw material components, bridge support of tabular corundum in a material system, and phase change toughening of alpha-Al2O3 and zirconium oxide in a high-temperature stage, and the prepared ceramic material has improved high-temperature creep resistance, breaking strength and erosion resistance, and is not easy to break and long in service life.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

A kind of strengthened porcelain prepared by using ordinary daily-use ceramic blank and its preparation method

The invention relates to the technical field of daily ceramic preparation, and particularly relates to a reinforced ceramic prepared from common daily ceramic blanks and a preparation method of the reinforced ceramic. The reinforced ceramic is prepared from the following raw materials by mass: 85%-90% of daily ceramic blanks, 3%-10% of talc, 1%-3% of aluminum fluoride, 0-1% of titanium dioxide, 0-1% of vanadium pentoxide, 0-1% of lanthanum oxide and sodium silicate accounting for 5 per mill-8 per mill of the total mass of the raw materials. The reinforced ceramic provided by the invention is prepared by using the common daily ceramic blanks as main raw materials and adding a small amount of a reinforcing agent; the added talc can generate cordierite with aluminum oxide and silicon dioxidein clay to effectively reduce a thermal expansion coefficient of the ceramic blanks; the vanadium pentoxide or lanthanum oxide can promote decomposition of aluminum fluoride and activate with silicondioxide in the clay to form needle or whisker-like secondary mullite or form thermal shock-resistant aluminum titanate crystals with titanium dioxide at high temperature, thereby effectively improvingmechanical properties and thermal stability of the ceramic blanks.

Owner:WUHAN UNIV OF TECH +1

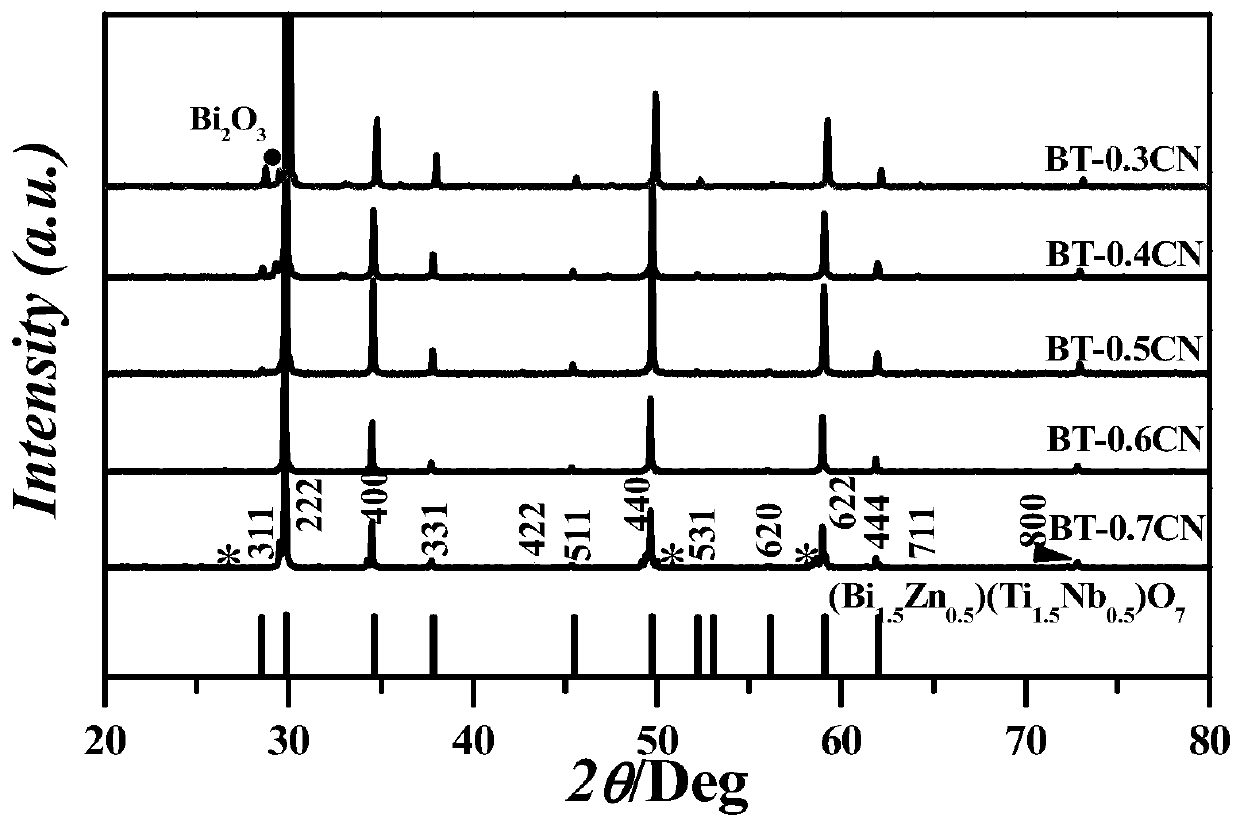

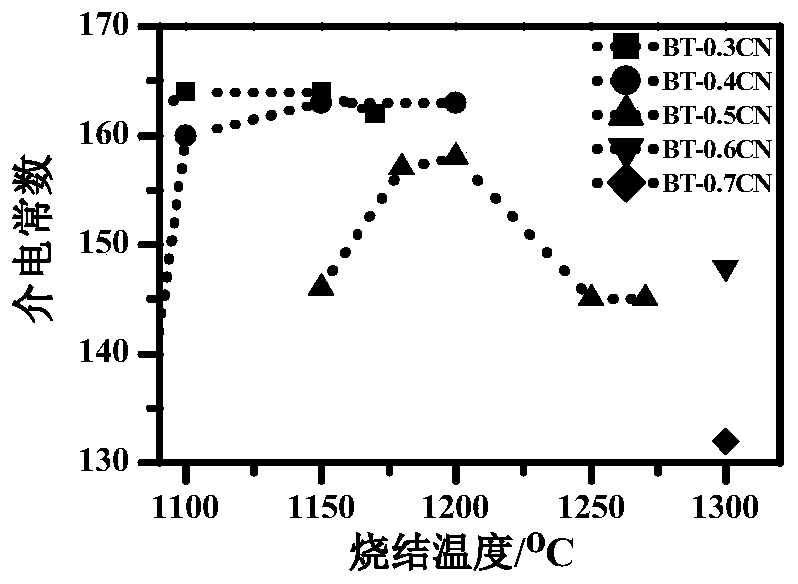

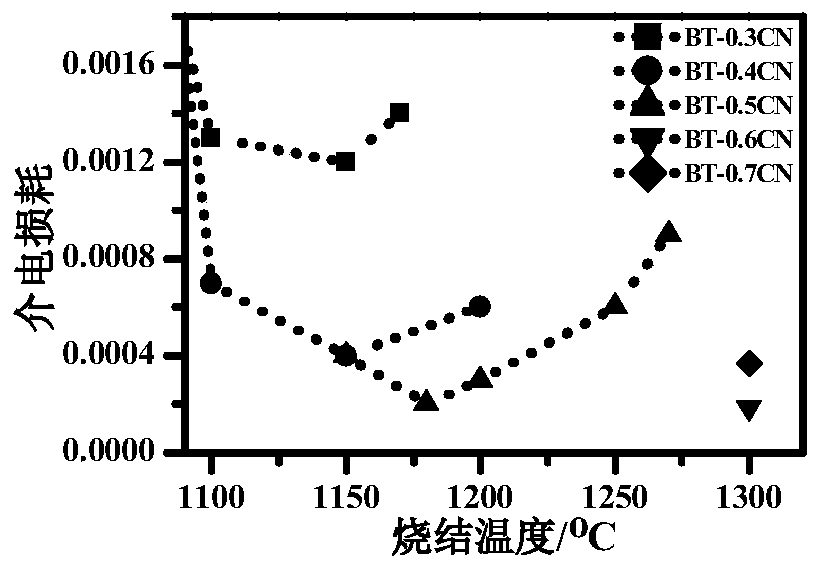

Preparation method of bismuth titanate-calcium niobate solid solution high-frequency dielectric ceramics

The invention discloses a preparation method of bismuth titanate-calcium niobate solid solution high-frequency dielectric ceramic. The preparation method aims at enabling the prepared bismuth titanate-calcium niobate solid solution high-frequency dielectric ceramic to have advantages of high dielectric constant, low dielectric loss, low sintering temperature and wide ceramic forming temperature range, and the ceramic is low in cost, environmentally friendly and pollution-free. The technical scheme adopted by the invention is as follows: 1) weighing raw materials according to the chemical metering ratio in (1-x)Bi2Ti2O7-xCa2Nb2O7; 2) subjecting the raw materials to ball milling, drying and then pre-synthesizing; 3) subjecting the pre-synthesized powder to coarse crushing, secondary ball milling and drying; 4) granulating the dried powder, and then pressing the dried powder into a thin round sheet blank; 5) performing high-temperature adhesive discharging on the thin round sheet blank, and naturally cooling the sheet blank; 6) subjecting the thin round sheet blank to sintering at high temperature and naturally cooling after high-temperature adhesive discharging is carried out.

Owner:XI AN JIAOTONG UNIV

A kind of method for preparing calcium ferrite from titanium gypsum tailings

ActiveCN110372041BEfficient use ofEasy to controlIron compoundsProcess efficiency improvementPtru catalystActive agent

This patent discloses a method for preparing calcium ferrite from titanium gypsum tailings. Add carbonate to titanium white wastewater, filter after the reaction, add surfactant to the filtrate, add calcium source for neutralization to obtain titanium gypsum slurry body, physical separation to obtain titanogypsum tailings; after aging, the titanogypsum tailings are added with binder, catalyst, sintering aid and reducing agent, mixed evenly, formed into balls, reduced and roasted to obtain calcium ferrite. Compared with the existing technical solutions, the method has the characteristics of low production cost, high production efficiency and good product quality.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Magnesian ceramic blank, magnesian ceramic and preparation method thereof

ActiveCN102786298BSmall coefficient of thermal expansionImprove thermal stabilitySodium BentoniteBall clay

The invention provides novel magnesian ceramic blank. The novel magnesian ceramic blank comprises, by weight percent, 60-70% of talcum, 20-25% of clay, 5-10% of feldspar, and 5-10% of alumina. The talcum is mixture of raw talcum and burnt talcum. The clay is mixture of kaolin, ball clay and bentonite. The invention further provides a preparation method of magnesian ceramic, and the magnesian ceramic prepared by the preparation method. The magnesian ceramic prepared by the magnesian ceramic blank, glaze and the preparation method is low in thermal expansion coefficient, and has improved thermal stability and formability. In addition, sintering range is wide, sintering temperature is low, and the risk of ceramic burst is lowered greatly.

Owner:HUNAN XIANFENG CERAMIC IND

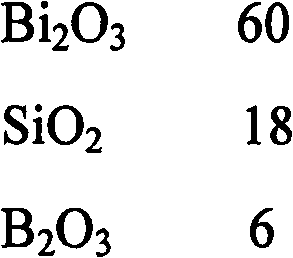

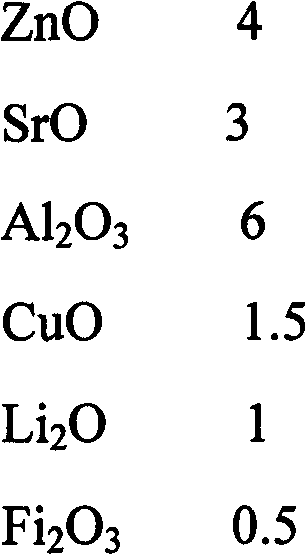

A lead free aluminum electrode slurry of PTC thermo-sensitive resistor and preparation method

InactiveCN101217067BAchieve lead-freeWon't fall offPositive temperature coefficient thermistorsMetal/alloy conductorsBarium titanateSlurry

The invention discloses a lead-free aluminum electrode paste for a PTC thermistor and the preparation method, the electrode paste is composed of the raw materials with the following parts by weight: 55 to 70 parts of aluminum powder, 10 to 20 parts of inorganic binder, 15 to 25 parts of organic binder and 2 to 4 parts of auxiliary; wherein, the organic binder is composed of 2 to 5 parts by weightof ethyl cellulose, 3 to 6 parts by weight of butyl carbitol, 15 to 23 parts by weight of butyl carbitol acetate, 2 to 4 parts by weight of benzyl alcohol, 60 to 70 parts by weight of terpineol, 0.5 to2 parts by weight of phenolic resin and 1 to 4 parts by weight of castor oil; and the auxiliary is composed of 30 to 50 parts by weight of Bi2O3 and 50 to 70 parts by weight of phosphorus red. The el ectrode paste can prepare the aluminum conductive paste by rolling, an aluminum electrode can be formed by screen printing and sintering on a doped barium titanate semiconductor substrate within therange of 630 plus or minus 20 DEG C, the electrode and the substrate form good ohmic contact, the adhesion is good, the aluminum membrane dose not shed, and the long-term placement of the electrode has no oxidation.

Owner:GUANGZHOU RUXING TECH DEV +1

Mid-lower-temperature sintering daily talc ceramic and production method thereof

The invention belongs to the technical field of daily ceramics, in particular to a mid-lower-temperature sintering daily talc ceramic and a production method thereof. The daily talc ceramic comprises the following chemical components: 58-63% of SiO2, 15-20% of Al2O3, 15-20% of MgO, 0.2-4% of K2O, 0.5-1% of Na2O, 0.1-2% of CaO and comprises the following components: 50-55% of talc, 25-30% of kaoline, 15-20% of feldspar and 2-5% of alumina. The daily talc ceramic has a sintering temperature range of 1180-1230 DEG C, uses great amounts of kaoline and feldspar, has the advantages of good molding performance, wide sintering range and low sintering temperature, overcomes the defects of difficult molding, difficult sintering and easy ceramic fracture of the traditional talc ceramic and is easy to popularize and apply.

Owner:JINGDEZHEN CERAMIC UNIV

Method for producing sulfoaluminate cement and iron sulfoaluminate cement

The invention provides a method for producing sulfoaluminate cement and iron sulfoaluminate cement; a shaft kiln is used for roasting sulfoaluminate cement clinker and iron sulfoaluminate cement clinker, and a new way is opened up for producing sulfate series and iron sulfoaluminate series special cement for shaft kiln cement plants in China under the condition of basically not increasing devices.

Owner:陈凤琴

Al based on azeotropic distillation 2 o 3 /zro 2 Composite ceramics and its preparation method and application

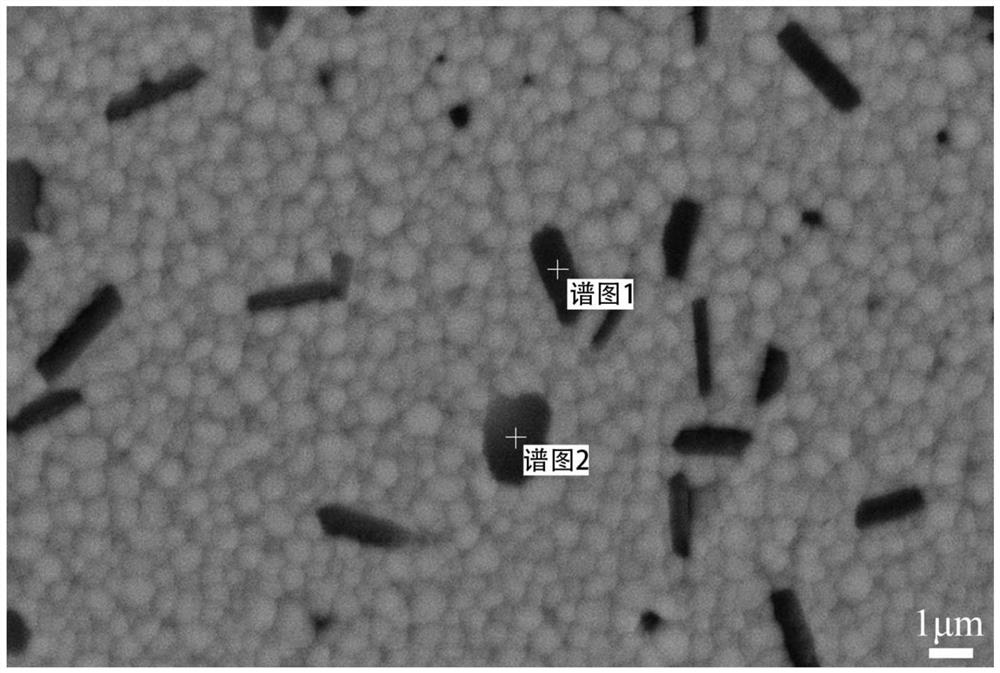

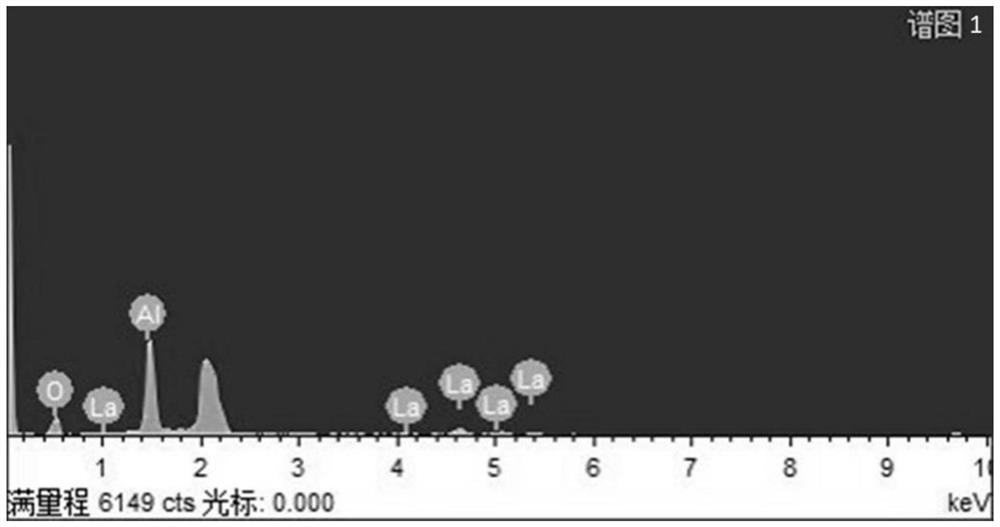

ActiveCN111620691BEvenly dispersedGood spherical shapeCeramic shaping apparatusTelephone set constructionsComposite ceramicPhysical chemistry

The invention discloses Al based on the azeotropic distillation method 2 o 3 / ZrO 2 Composite ceramics and their preparation methods and applications. The preparation method uses zirconium salts, yttrium salts, aluminum salts, and lanthanum salts as raw materials to prepare nano-scale composite powders by co-precipitation and azeotropic distillation. After molding, calcination and high-temperature sintering get Al 2 o 3 / ZrO 2 Composite ceramics. The composite powder obtained by the present invention is nano-scale, basically spherical, uniform in particle size distribution, and wide in sintering temperature range; ZrO 2 Al is dispersed in the matrix 2 o 3 Grains and long rods of LaAl grown in situ 11 o 18 At the same time, the mechanism of phase change toughening, particle toughening and whisker toughening is introduced to improve the fracture toughness, flexural strength and hardness of ceramic materials. The composite material also has good anti-aging performance, integrating good mechanical properties and high The stability is integrated, and it can be used for the ceramic backplane of 5G mobile phones. The preparation method is simple, easy to operate, and conducive to large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

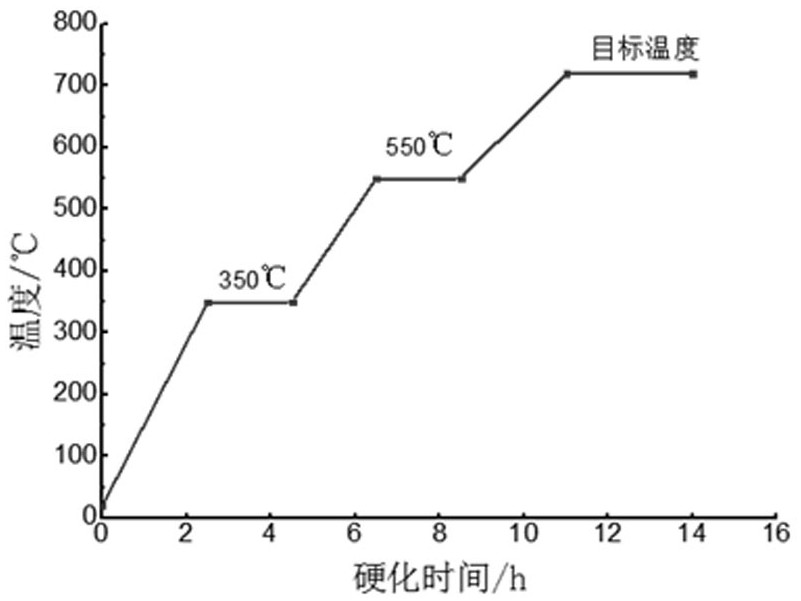

A mim316 sintering process

ActiveCN113547119BIncrease densitySolve the industry problem of low sintering hardnessNitrogen gasAustenite

Owner:东莞市华研新材料科技有限公司

Glass paste for thermal printing head and preparation method of glass paste

The invention relates to glass paste for a thermal printing head and a preparation method of the glass paste. The glass paste comprises the following components in percentage by weight: 70-75% of lead-free glass powder, 2-5% of an inorganic additive and 20-28% of an organic carrier. The lead-free glass powder comprises the following components in percentage by weight: 15%-40% of BaO, 10%-30% of CaO, 5%-50% of SiO2, 5%-15% of Al2O3, 5%-20% of SrO and 1%-5% of ZrO2; and the lead-free glass powder is subjected to heat treatment of roasting for 2-3 min within a temperature range of 760-780 DEG C.The method comprises the following steps: (1) dissolving the organic carrier; (2) preparing the glass paste; and (3) rolling the glass paste to finally obtain a product. Compared with the prior art, the method of the invention has the advantages of high initial particle melting temperature, high high-temperature fluidity, low viscosity, uniform particle size, small morphological difference, high bulk density, good high-temperature viscosity, high sintering power, difficulty in generating bubbles or pores and the like.

Owner:西安宏星电子浆料科技股份有限公司

Interlayer carcass material and preparation method of diamond tool bit

ActiveCN112238220ALow priceSmall specific surface areaTurbinesOther manufacturing equipments/toolsTool bitDiamond knife

The invention discloses an interlayer carcass material and a preparation method of a diamond tool bit, and belongs to the field of stone cutting. The interlayer carcass material comprises, in percentage by mass, 85-65% of Fe, 8-15% of Zn, 5-20% of Cu and 2-5% of ALSi. According to the preparation method, the interlayer carcass material, a first working layer mixture and a second working layer mixture are respectively loaded into corresponding hoppers; and the first working layer mixture is fed into a mold cavity, then the interlayer carcass material and the second working layer mixture are fedinto the mold cavity respectively and repeatedly, the pre-pressure every time is 50-100KG / cm<2> higher than the last pre-pressure, demolding and sintering are conducted, and the needed diamond tool bit is obtained. The interlayer carcass material has the advantages that coarse-grained elemental Fe powder is adopted, the powder is small in specific surface area and higher in oxidation resistance,and when the powder is applied to a multi-layer full-automatic cold press, the labor and material cost can be greatly reduced while the efficiency is improved, good sintering performance is kept, goodsintering density is obtained, good strength is obtained, and the material can effectively adapt to the abrasion speed of a tool bit working layer.

Owner:泉州众志金刚石工具有限公司

MIM316 sintering process

ActiveCN113547119AIncrease densitySolve the industry problem of low sintering hardnessNitrogen gasAustenite

The invention relates to the technical field of sintering, in particular to an MIM316 sintering process which comprises the following steps: firstly, carrying out vacuum sintering; filling low-pressure argon gas for sintering until the product becomes a compact layer; filling high-pressure nitrogen gas, applying auxiliary pressure during sintering, so that the product is further densified under the pressure, and argon gas is used for cooling. According to the MIM316 sintering process, the compactness of powder metallurgy sintering is improved, meanwhile, the industrial problem that the sintering hardness of the austenitic stainless steel is too low is solved. The MIM316 sintering process is suitable for sintering 316 stainless steel and other austenitic stainless steel such as 304, and is wide in sintering range.

Owner:东莞市华研新材料科技有限公司

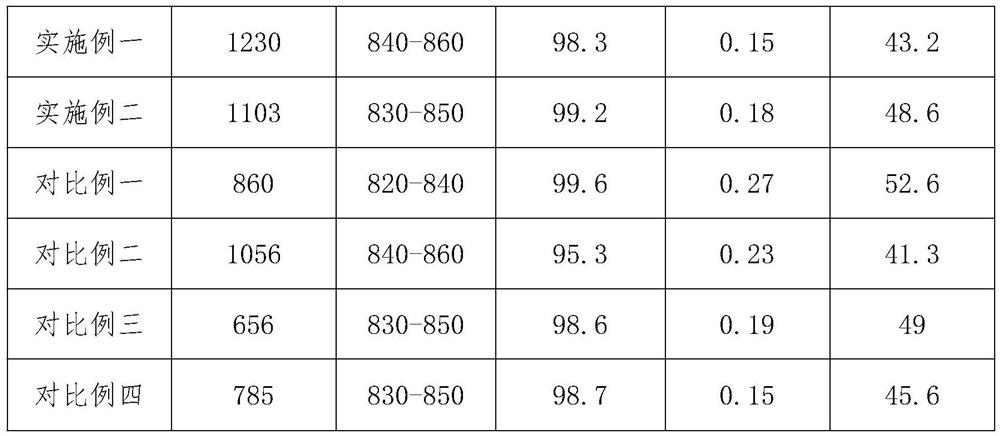

Vitrified bond end face grinding wheel for fine grinding of compressor sliding vane and preparation method thereof

ActiveCN112025565BHigh porosityEvenly distributedAbrasion apparatusGrinding devicesSurface finishMicrosphere

The invention discloses a special vitrified bond end face grinding wheel for precise grinding of compressor sliding vanes and a preparation method, using an aluminosilicate bond and adding ZrO 2 The glass network structure greatly improves the strength and holding force of the binder, and improves the life of the grinding wheel; at the same time, a small amount of rare earth oxide is added to increase the wetting performance of the binder, and at the same time, it also reduces the sintering temperature to achieve low-temperature sintering, which is convenient for mass production process control; Microspheres are used as a pore-forming agent to prepare a vitrified bonded end face grinding wheel for the fine grinding of compressor sliding vanes. It is easy to operate, convenient for mass production, easy to sinter and discharge without residue, and a high porosity can be obtained by adding grinding wheel raw materials at a lower mass percentage. The abrasive layer has uniform pore size and approximately circular shape, which can meet the high-precision finishing requirements of the workpiece. The double-end grinding wheel of the invention can realize the dimensional accuracy and surface smoothness requirements required by the finishing process.

Owner:江苏赛扬精工科技有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com