Method for preparing calcium ferrite from titanium-gypsum tailings

A technology of titanium gypsum and calcium ferrite, applied in chemical instruments and methods, iron compounds, improvement of process efficiency, etc., can solve the problems of difficult drying, high moisture content, low added value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific examples.

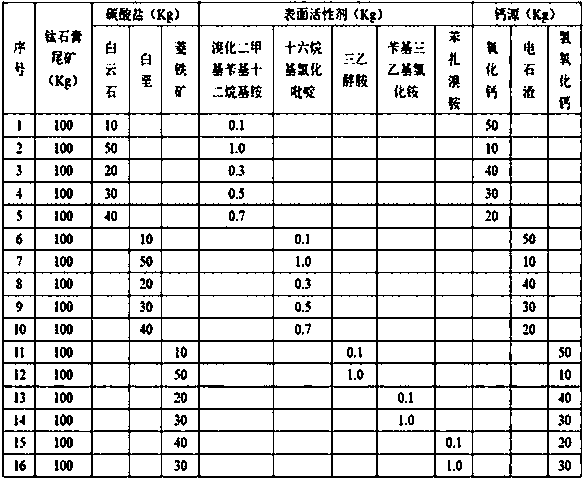

[0029] (1) Add carbonate to the titanium white wastewater, filter after the reaction, add surfactant to the filtrate, add calcium source for neutralization to obtain titanium gypsum slurry, and physically separate to obtain titanium gypsum tailings. The formulations of raw carbonate, surfactant and calcium source are shown in Table 1.

[0030] Table 1

[0031]

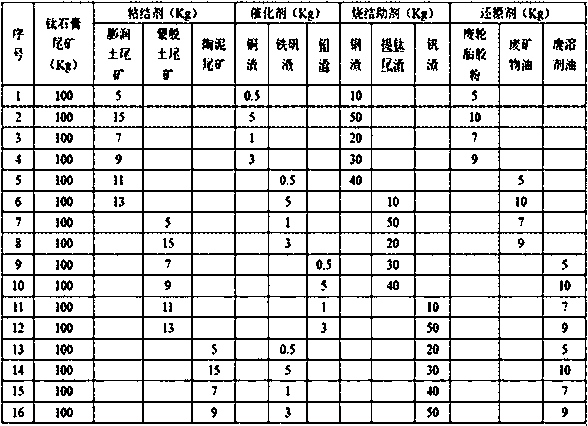

[0032] (2) After the titanogypsum tailings are aged, add binder, catalyst, sintering aid and reducing agent, mix evenly, form balls, reduce and roast to obtain calcium ferrite. The raw material formula is shown in Table 2.

[0033] Table 2

[0034]

[0035] It can be concluded from Examples 1 to 16 that the content of harmful elements in the obtained calcium ferrite meets the quality requirements of steelmaking raw materials, and can be used as a slagging agent for steelmaking.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com