Low-temperature sintered medium-dielectric-constant microwave dielectric ceramic material and preparation method thereof

A microwave dielectric ceramic and low-temperature sintering technology, which is applied in the field of electronic information functional ceramic materials, can solve the problems of high sintering temperature, excessive energy consumption of crystal grains, and narrow sintering range, and achieves simple sintering conditions, improved quality factor, and sintering range. wide effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

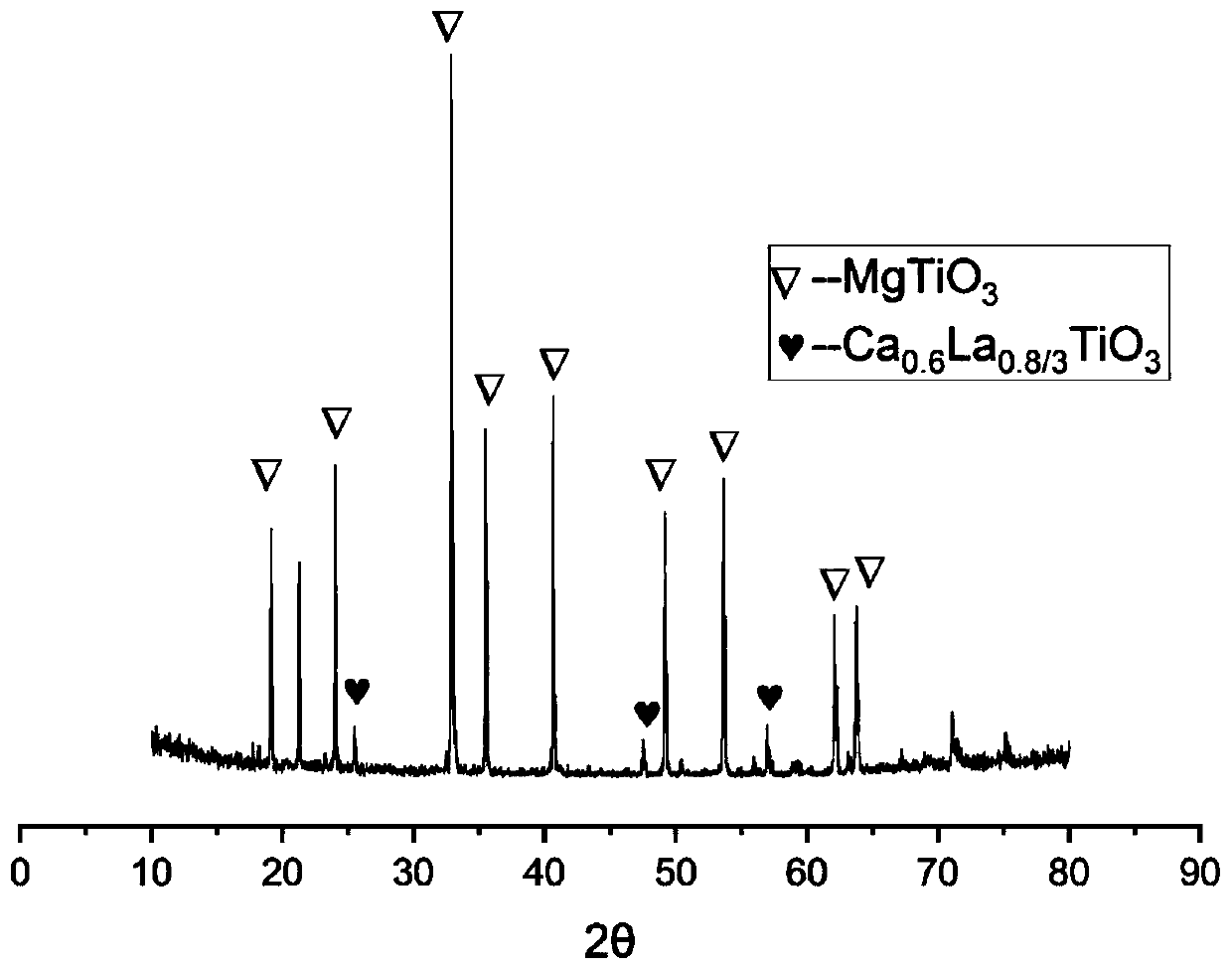

[0026] Low-temperature sintered medium dielectric constant microwave dielectric ceramic material, the formula includes: base material and additives, the base material is xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 , where x is 1.0; the additive is B 2 o 3、 SrO, MnO 2 and ZnO.

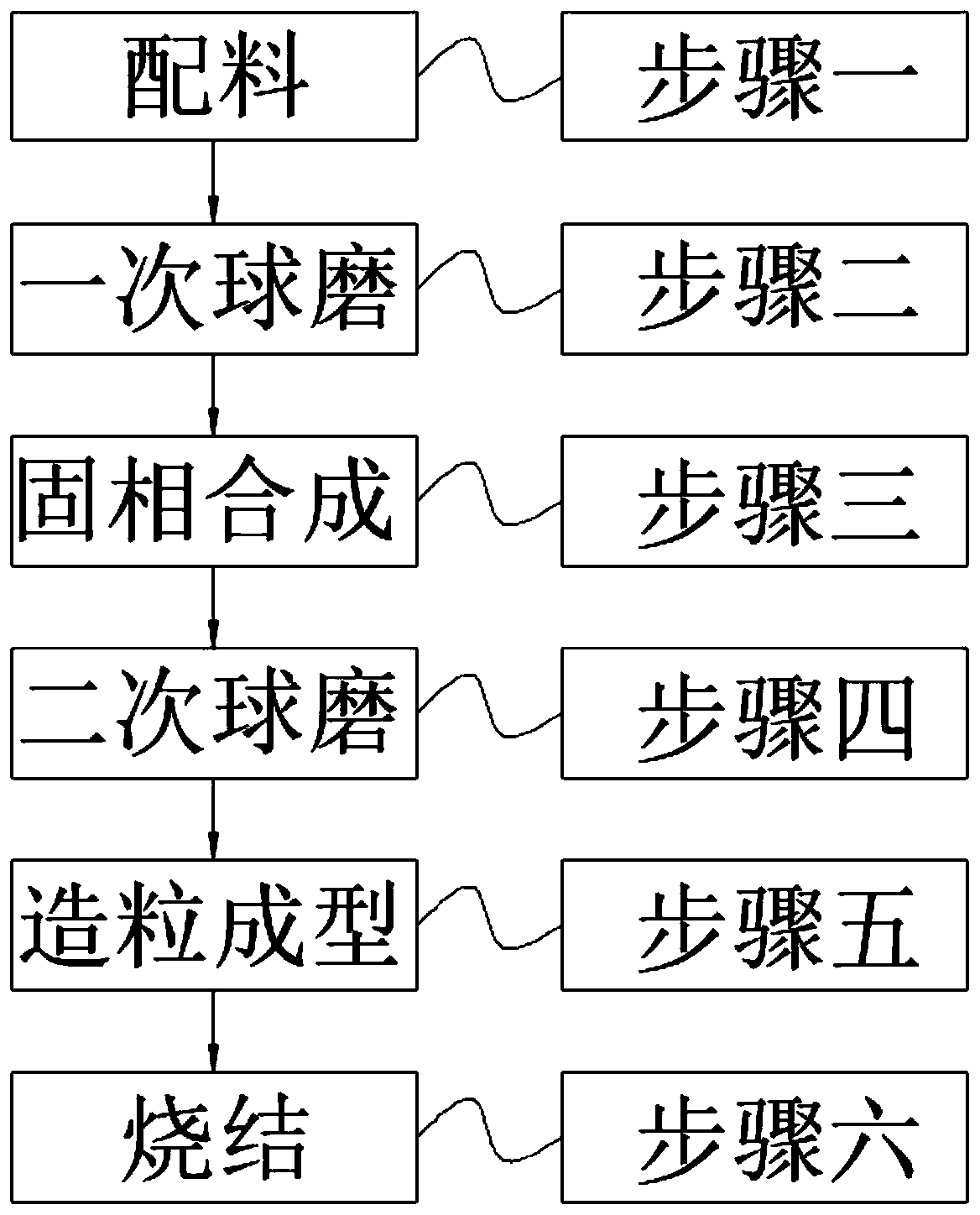

[0027] The preparation method of the dielectric constant microwave dielectric ceramic material in low-temperature sintering comprises the following steps: Step 1, batching; Step 2, primary ball milling; Step 3, solid phase synthesis; Step 4, secondary ball milling; Step 5, granulation; Sixth, sintering;

[0028] Wherein in above-mentioned step one, with MgO, TiO 2 , CaCO 3 and La 2 o 3 As raw material, according to the chemical formula xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 The molar ratio is carried out batching, wherein x is 1.0;

[0029] Wherein in the above step 2, the materials prepared in step 1 are mixed with deionized water for a ball milling process. The ball milling process is: ball mill...

Embodiment 2

[0035] Low-temperature sintered medium dielectric constant microwave dielectric ceramic material, the formula includes: base material and additives, the base material is xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 , where x is 0.9; the additive is B 2 o 3、 SrO, MnO 2 and ZnO.

[0036] The preparation method of the dielectric constant microwave dielectric ceramic material in low-temperature sintering comprises the following steps: Step 1, batching; Step 2, primary ball milling; Step 3, solid phase synthesis; Step 4, secondary ball milling; Step 5, granulation; Sixth, sintering;

[0037] Wherein in above-mentioned step one, with MgO, TiO 2 , CaCO3 and La 2 o 3 As raw material, according to the chemical formula xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 The molar ratio is carried out batching, wherein x is 0.9;

[0038] Wherein in the above step 2, the materials prepared in step 1 are mixed with deionized water for a ball milling process. The ball milling process is: ball millin...

Embodiment 3

[0044] Low-temperature sintered medium dielectric constant microwave dielectric ceramic material, the formula includes: base material and additives, the base material is xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 , where x is 0.8; the additive is B 2 o 3、 SrO, MnO 2 and ZnO.

[0045] The preparation method of the dielectric constant microwave dielectric ceramic material in low-temperature sintering comprises the following steps: Step 1, batching; Step 2, primary ball milling; Step 3, solid phase synthesis; Step 4, secondary ball milling; Step 5, granulation; Sixth, sintering;

[0046] Wherein in above-mentioned step one, with MgO, TiO 2 , CaCO 3 and La 2 o 3 As raw material, according to the chemical formula xMgTiO 3 -(1-x)Ca 0.6 La 0.8 / 3 TiO 3 The molar ratio is carried out batching, wherein x is 0.8;

[0047] Wherein in the above step 2, the materials prepared in step 1 are mixed with deionized water for a ball milling process. The ball milling process is: ball mill...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com