Process for extracting and concentrating dilute aqueous formaldehyde solution by using composite solvent

A composite solvent and process method technology, which is applied in the separation/purification of carbonyl compounds, chemical industry, sustainable manufacturing/processing, etc., can solve the weakly polar competitive chemical reaction of polycarbon alcohols, difficulty in finding extraction solvents, and solvent extraction effects. Reduction and other problems, to achieve the effect of stable and reliable product quality, enhanced extraction capacity, and low processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

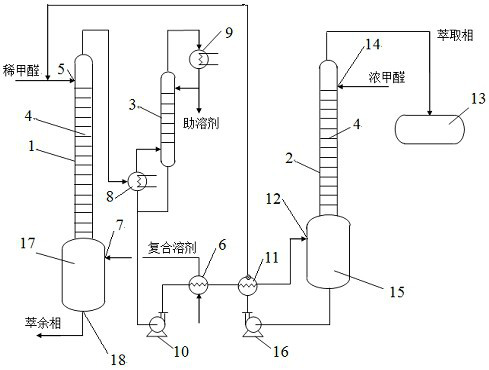

[0043] use figure 1 The extraction process, wherein the recovery extraction tower 1 and the concentration extraction tower 2 are all sieve tray towers containing 8 theoretical plates, and the precipitation rectification tower 3 has 8 theoretical plates and operates at normal pressure.

[0044] Dilute formaldehyde liquid at a temperature of 25°C (formaldehyde and water mass fractions are 8.0% and 92.0% respectively) enters the recovery extraction tower 1 from the top feed port 5 of the recovery extraction tower at a flow rate of 500kg / h; the composite solvent at a temperature of 25°C (Methanol and n-hexanol mass fractions are 15% and 85% respectively) After being heated, enter the recovery extraction tower 1 from the feed port 7 at the bottom of the recovery extraction tower with a flow rate of 900kg / h; the concentrated formaldehyde liquid (formaldehyde and water mass fractions are 44.0% and 56.0% respectively) into the concentrated extraction tower 2 from the concentrated extr...

Embodiment 2

[0049] use figure 1 The extraction process, equipment is identical with embodiment 1, normal pressure operation.

[0050] Dilute formaldehyde liquid at a temperature of 25°C (formaldehyde and water mass fractions are 12.5% and 87.5% respectively) enters the recovery extraction tower 1 from the feed inlet 5 at the top of the recovery extraction tower at a flow rate of 500kg / h; the composite solvent at a temperature of 25°C (Methanol and n-hexanol mass fractions are 8% and 92% respectively) After being heated, enter the recovery extraction tower 1 from the feed port 7 at the bottom of the recovery extraction tower with a flow rate of 1200kg / h; the concentrated formaldehyde liquid (formaldehyde and water mass fractions are 48.0% and 52.0% respectively) into the concentrated extraction tower 2 from the concentrated extraction tower top inlet 14 with a flow rate of 160kg / h.

[0051] After the operation is stable, the temperature of the recovery extraction tower 1 is 55-65°C, the...

Embodiment 3

[0055] use figure 1 The extraction process, equipment is identical with embodiment 1, normal pressure operation.

[0056] Dilute formaldehyde liquid at a temperature of 25°C (formaldehyde and water mass fractions are 5.0% and 95.0% respectively) enters the recovery extraction tower 1 from the feed inlet 5 at the top of the recovery extraction tower at a flow rate of 800kg / h; the composite solvent at a temperature of 25°C (Methanol and n-hexanol mass fractions are 12% and 88% respectively) After being heated, enter the recovery extraction tower 1 from the feed port 7 at the bottom of the recovery extraction tower with a flow rate of 900kg / h; and water mass fractions are 48.0% and 52.0% respectively) into the concentrated extraction tower 2 from the concentrated extraction tower top inlet 14 with a flow rate of 200kg / h.

[0057] After the operation is stable, the temperature of the recovery extraction tower 1 is 50-60°C, the temperature of the concentration extraction tower 2 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com