Mid-lower-temperature sintering daily talc ceramic and production method thereof

A technology of low-temperature sintering and talc porcelain, which is applied in the field of daily-use ceramics, can solve the problems of easy-fried porcelain, poor molding performance, and narrow sintering range, and achieves the effects of low sintering temperature, wide sintering range, and easy industrialization and application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

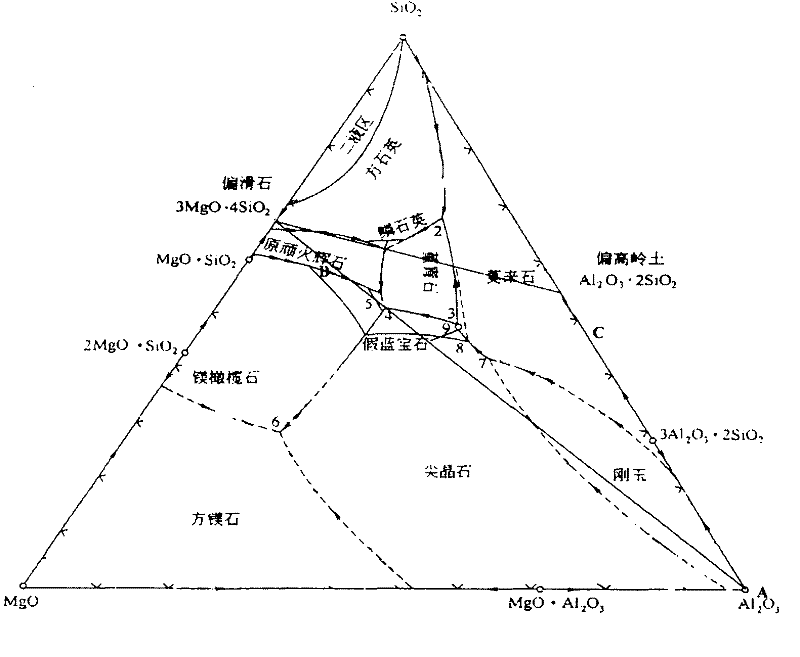

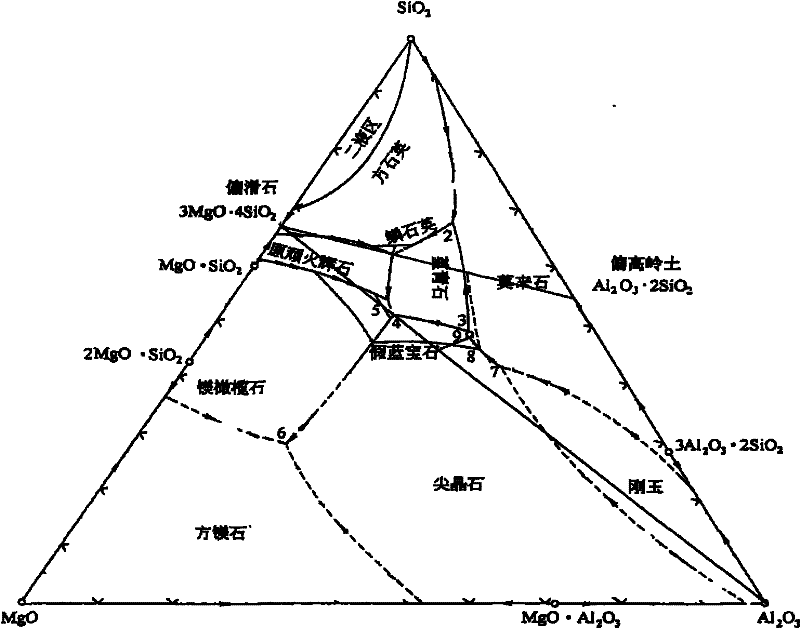

Method used

Image

Examples

Embodiment 1

[0017] Weigh the raw materials according to the billet formula: talc 53%, kaolin 27%, potassium feldspar 17%, alumina 3%, put the above raw materials into the ball mill, mix and ball mill to the required fineness (that is, the cumulative percentage of particles below 10 μm accounts for 90% or more), followed by sieving, iron removal, pressure filtration, mud refining, aging, molding, glazing, and then sintering at 1180°C to 1230°C to form porcelain. The blank chemical composition of the resulting product is: 61.61% SiO 2 , 16.14%Al 2 o 3 , 2.55%K 2 O, 0.66% Na 2 O, CaO 1.29%, MgO 17.59%, Fe 2 o 3 0.14%, TiO 2 0.02%.

Embodiment 2

[0019] Raw materials were weighed according to the billet formula: 50% talc, 26% kaolin, 20% potassium feldspar, 4% alumina, and the production process was the same as in Example 1. The blank chemical composition of the resulting product is: 61.19% SiO 2 , 17.29% Al 2 o 3 , 2.80%K 2 O, 0.75% Na 2 O, 1.23% CaO, 16.60% MgO, 0.14% Fe 2 o 3 , 0.02%TiO 2 .

Embodiment 3

[0021] Raw materials were weighed according to the billet formula: talc 55%, kaolin 28%, potassium feldspar 15%, alumina 2%, and its production process was the same as in Example 1. The blank chemical composition of the resulting product is: 62.09% SiO 2 , 15.15%Al 2 o 3 , 2.38%K 2 O, 0.61% Na 2 O, 1.34% CaO, 18.27% MgO, 0.15% Fe 2 o 3 , 0.02%TiO 2 .

[0022] The product performance that is made by above-mentioned each embodiment is as following table:

[0023] Example

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com