High-strength low-melting-point ceramic abrasive tool bonding agent and preparation method thereof

A manufacturing method and low melting point technology, applied in the manufacture of tools, abrasives, grinding devices, etc., can solve the problems of crystal size and structure damage, affecting the grinding performance of grinding wheels, weak wear resistance, etc., to reduce thermal energy, Good high temperature wetting performance and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

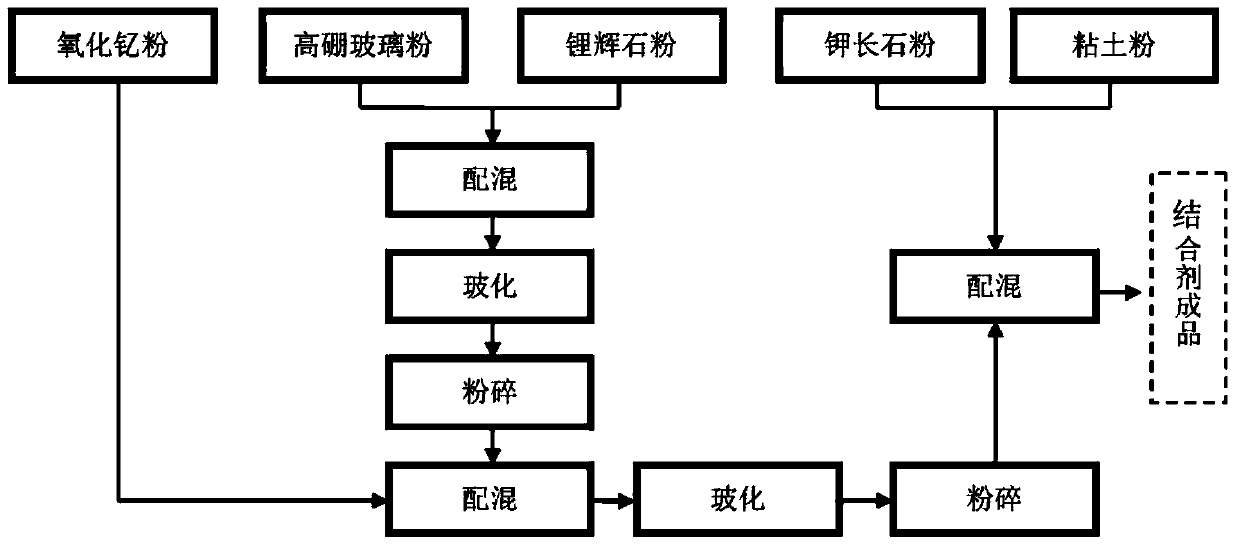

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

[0025] The present invention is based on clay-feldspar-high boron glass binder, and introduces Li 2 O and Y 2 o 3 and other trace elements, aiming to fully increase the strength and toughness of the binder, and reduce the refractoriness and melting point of the binder. At the same time, two vitrification processes are used to ensure the uniform structure of the binder.

[0026] The main chemical composition of clay-feldspar-high boron glass-based ceramic binder is: SiO 2 、Al 2 o 3 , Fe 2 o 3 , CaO, MgO, K 2 O, Na 2 O.B 2 o 3 , its refractoriness is greater than 1150°C, and it is only suitable for the manufacture of ceramic abrasive tools with a speed below 50m / s. In order to reduce the refractoriness of the binder and improve the strength and toughness of the bind...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com