Patents

Literature

148results about How to "Reduce silver content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

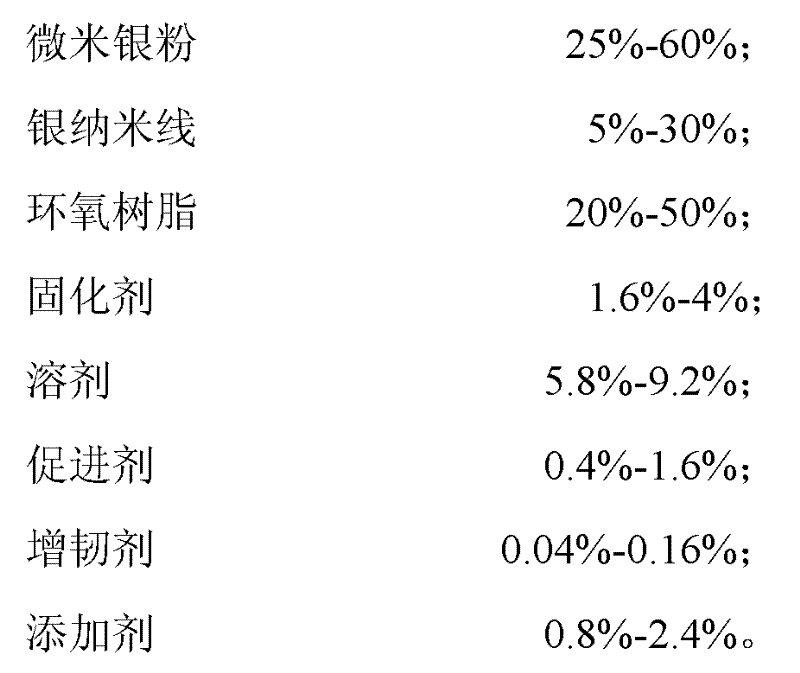

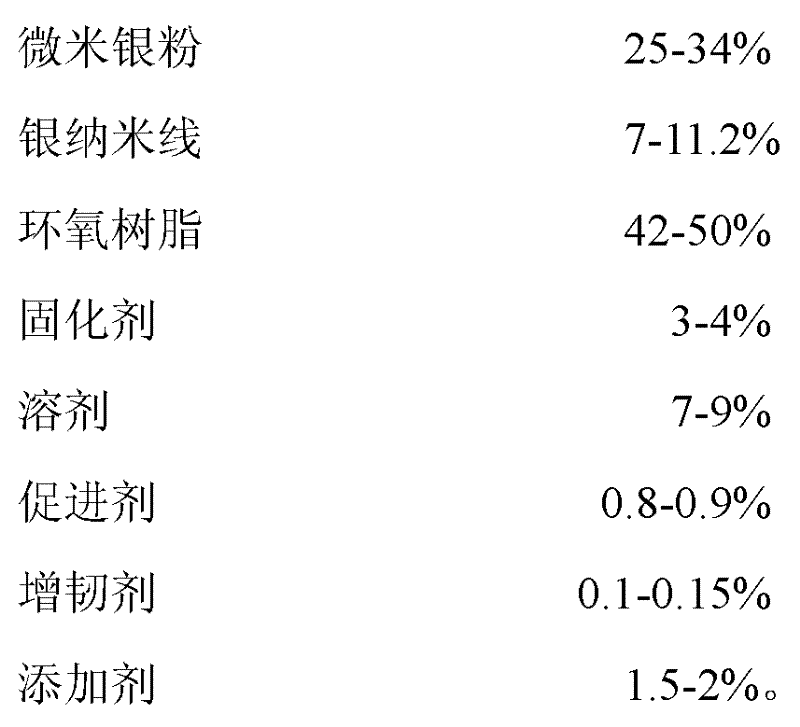

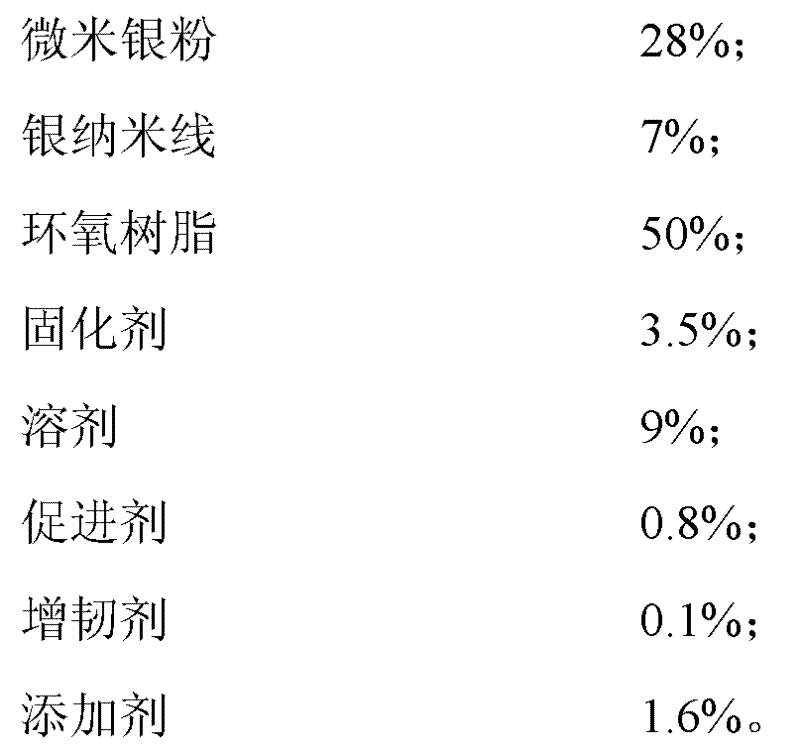

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

Preparation method of ultrasonic microarc oxidation silver-carrying antibiotic bioactive coating on magnesium and titanium surface

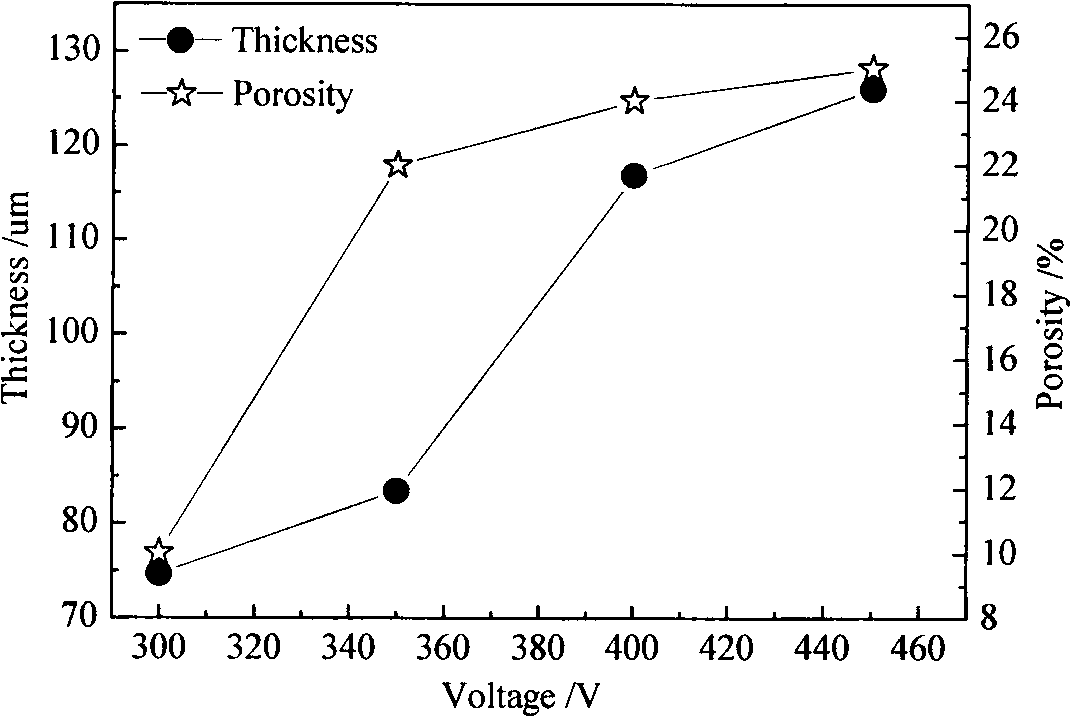

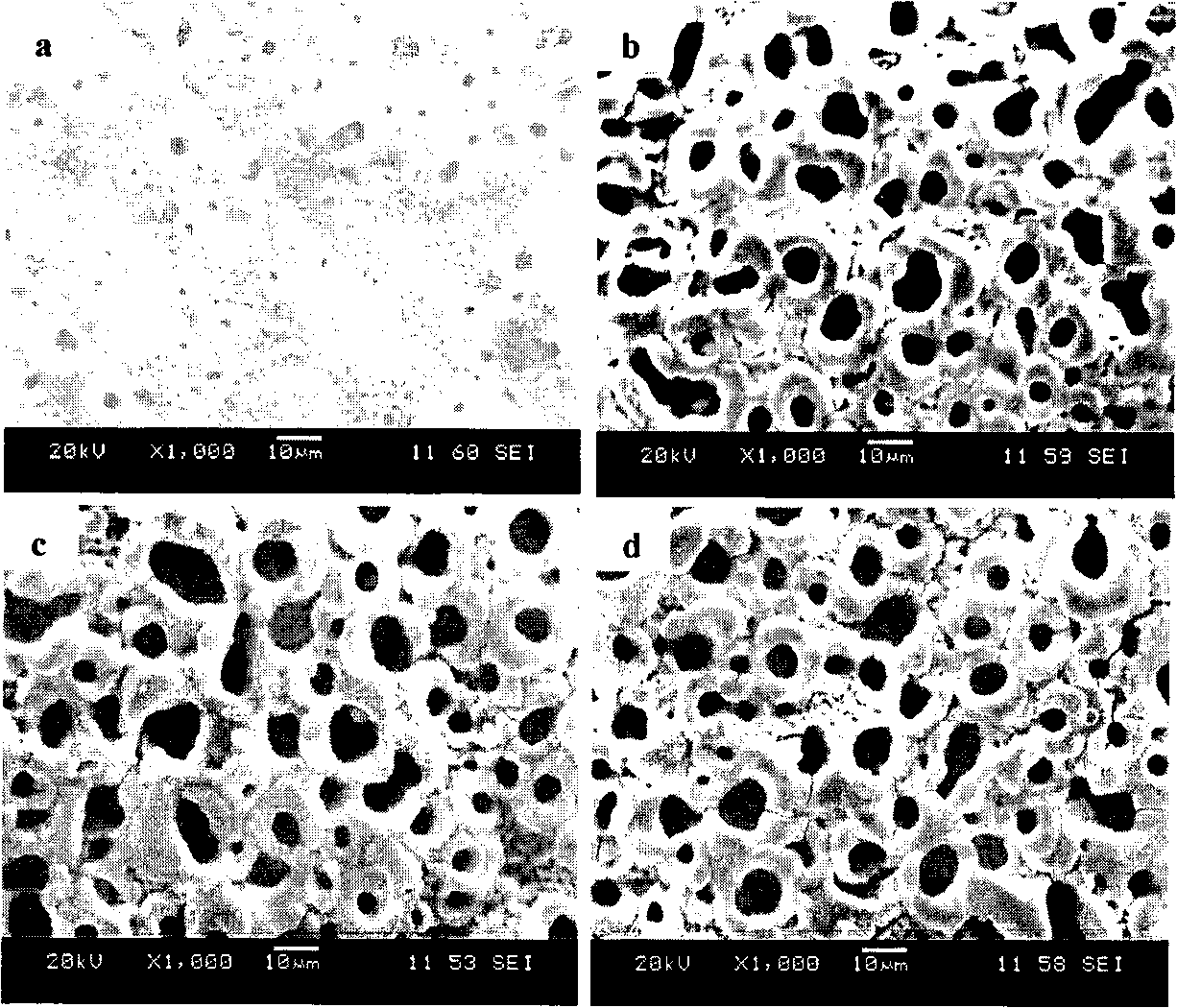

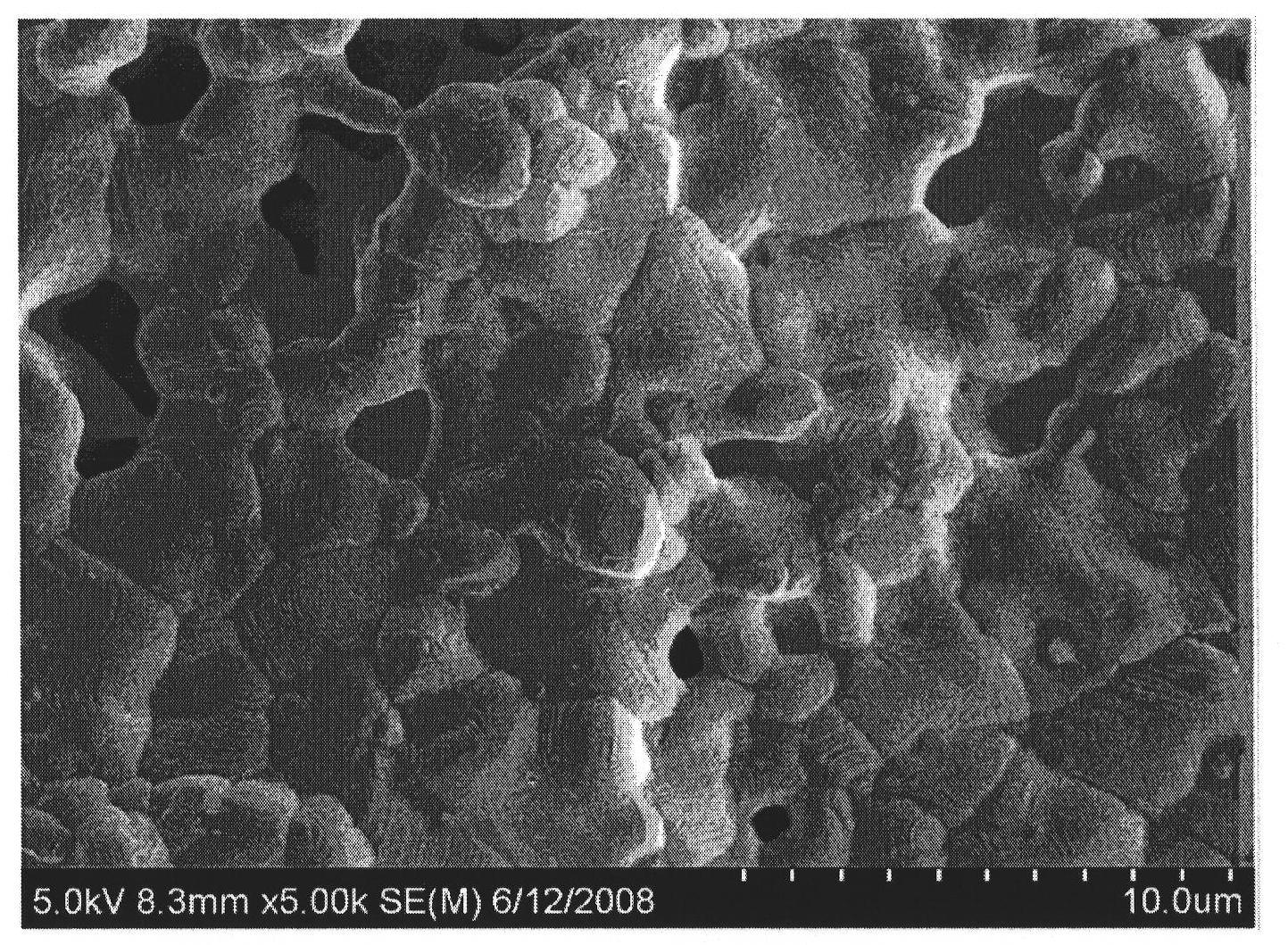

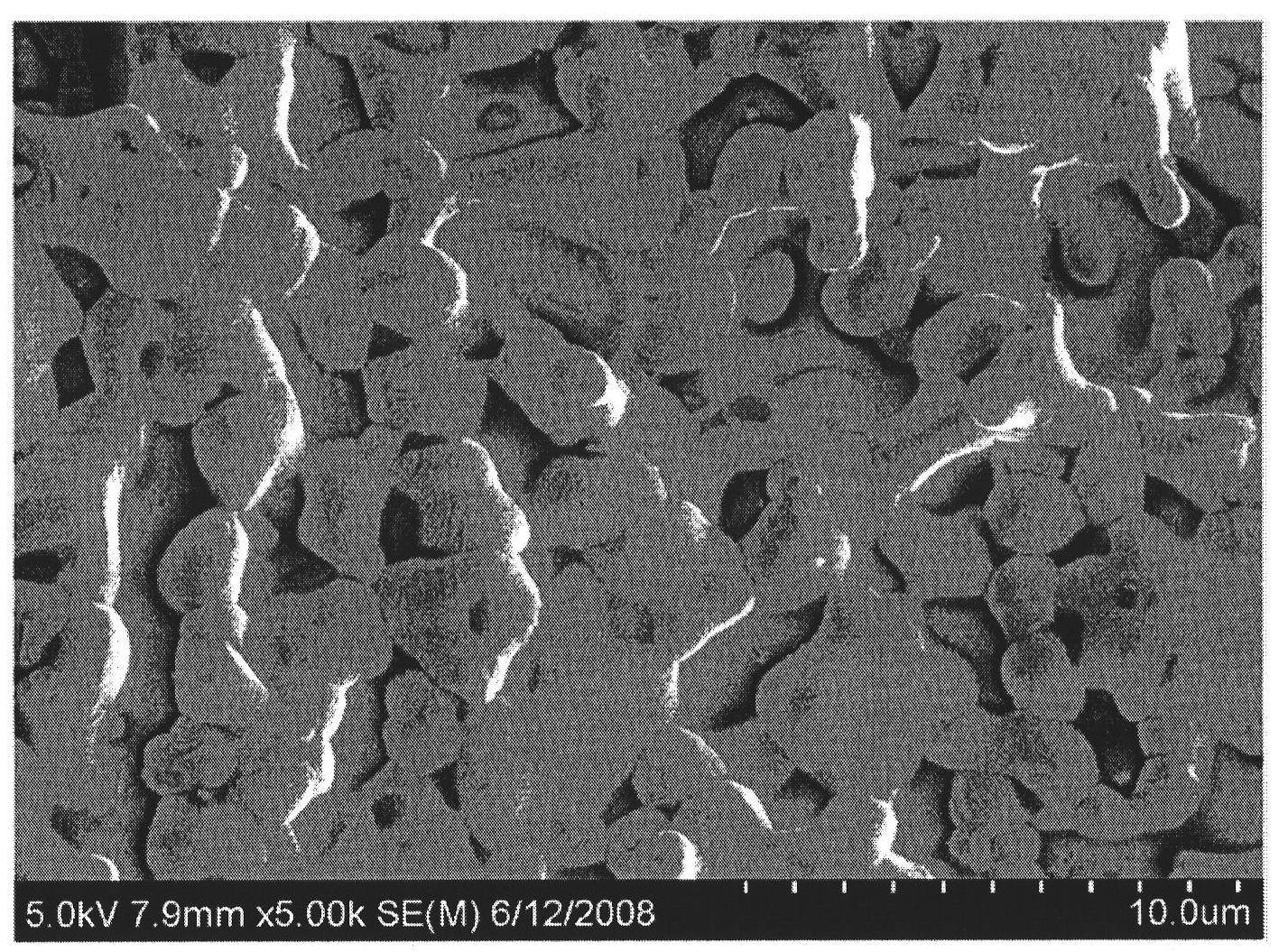

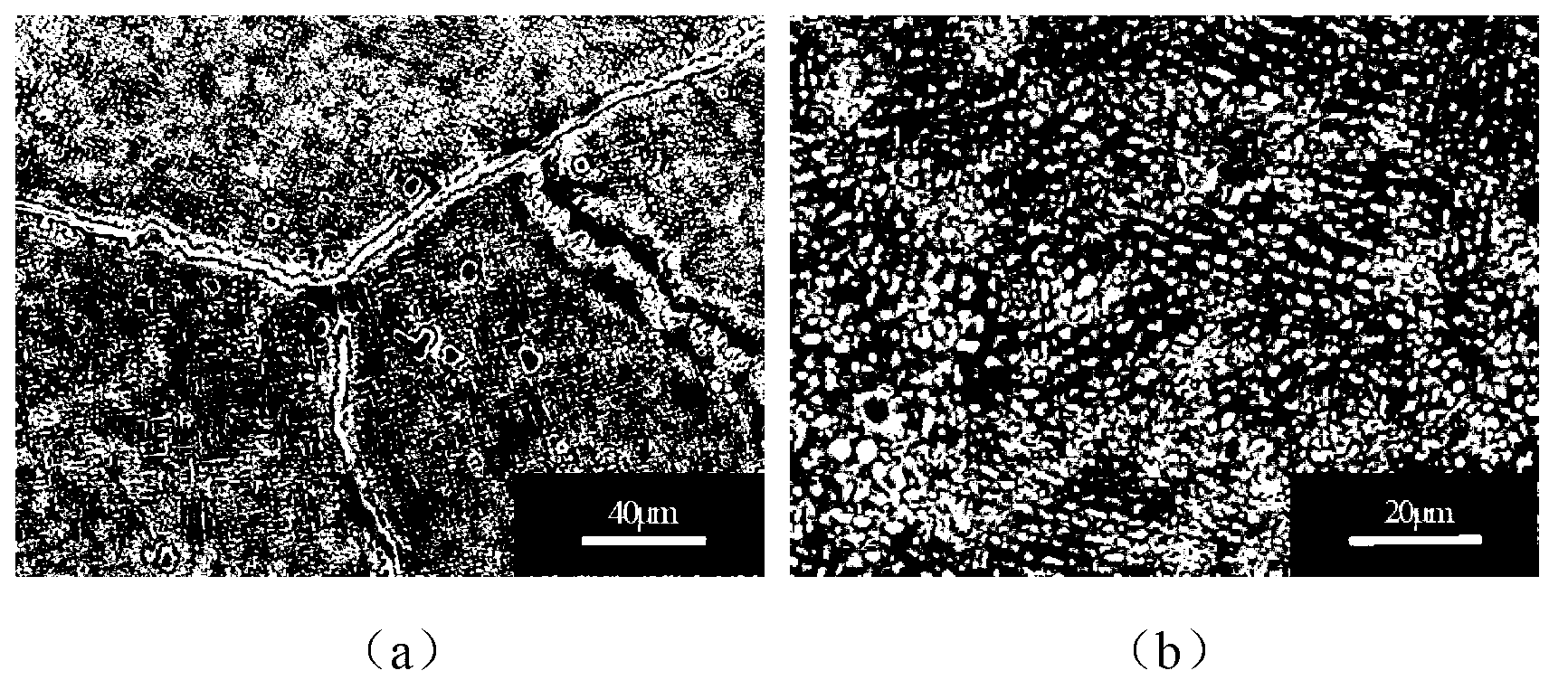

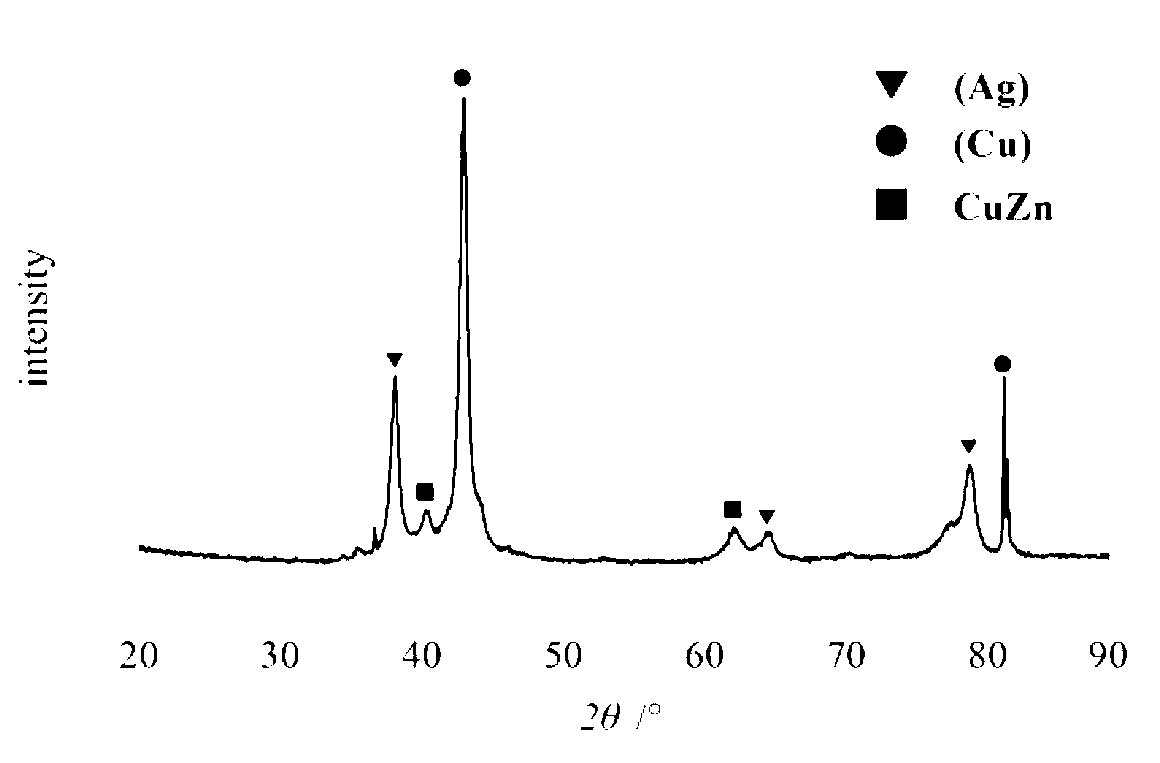

InactiveCN101899700AImprove corrosion resistanceGood resistance to friction and wear in human environmentAnodisationProsthesisPorosityPlasma electrolytic oxidation

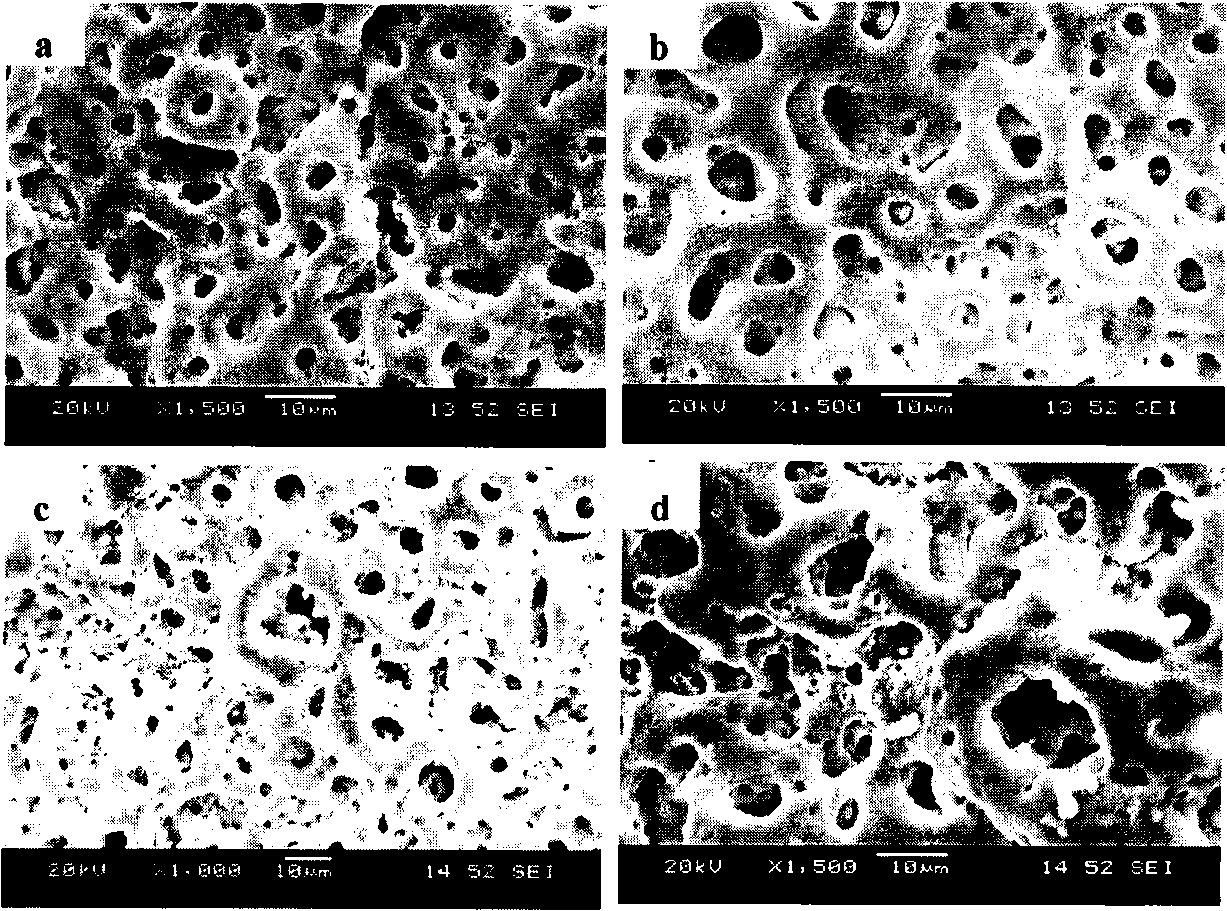

The invention relates to a new method for preparing an antibiotic bioactive coating material on the surface of titanium alloy and magnesium alloy by ultrasonic-microarc oxidation composite technology, which can be used for obtaining a biological coating material which is compact at the bottom layer and is porous at the surface layer, wherein Ca, P and Ag contained in the coating can improve the bioactivity and the corrosion resistance of magnesium and titanium, and reduce bacterial infection caused by implantation. The invention can meet the requirements of bearing bones of human beings for mechanical properties of implanted materials, and can overcome disadvantages of the traditional surface modification method for biologic materials. In the coating composite material, the coating thickness of titanium alloy is 50-85 mu m, the surface hole diameter is 4-25 mu m, the porosity is 20-30%, and the bonding strength between the coating and the matrix is 23-40 MPa. The coating thickness of magnesium alloy is 16-22 mu m, the surface hole diameter is 5-28 mu m, the porosity is 21-30%, and the bonding strength between the coating and the matrix is 8-20 MPa.

Owner:JIAMUSI UNIVERSITY

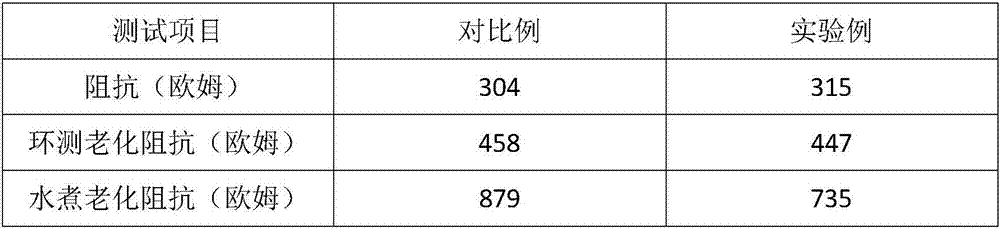

Mixed metal powder, preparation method, conductive silver pulp and use

ActiveCN106876000AReduce silver contentReduce manufacturing costTransportation and packagingMetal-working apparatusYttriumTungsten

The invention relates to the field of metal powder processing, and specifically relates to mixed metal powder, a preparation method, conductive silver pulp and a use. The mixed metal powder is of a core-shell structure, wherein the core material is a metal hydride, and the shell material is metal silver. The metal elements in the metal hydride include one or more selected from scandium, titanium, vanadium, chromium, manganese, iron, cobalt, nickel, copper, zinc, zirconium, hafnium, beryllium, tungsten, magnesium, yttrium, zirconium, niobium, molybdenum, technetium and cadmium. Compared with pure silver powder, the silver content in the mixed metal powder is much lower, and the production cost is reduced greatly. There is no significant difference between the impedance and adhesion of the conductive silver pulp prepared from the mixed metal powder and those of conductive silver pulp prepared from the traditional silver powder. The need of production practice is basically met.

Owner:湖南省国银新材料有限公司

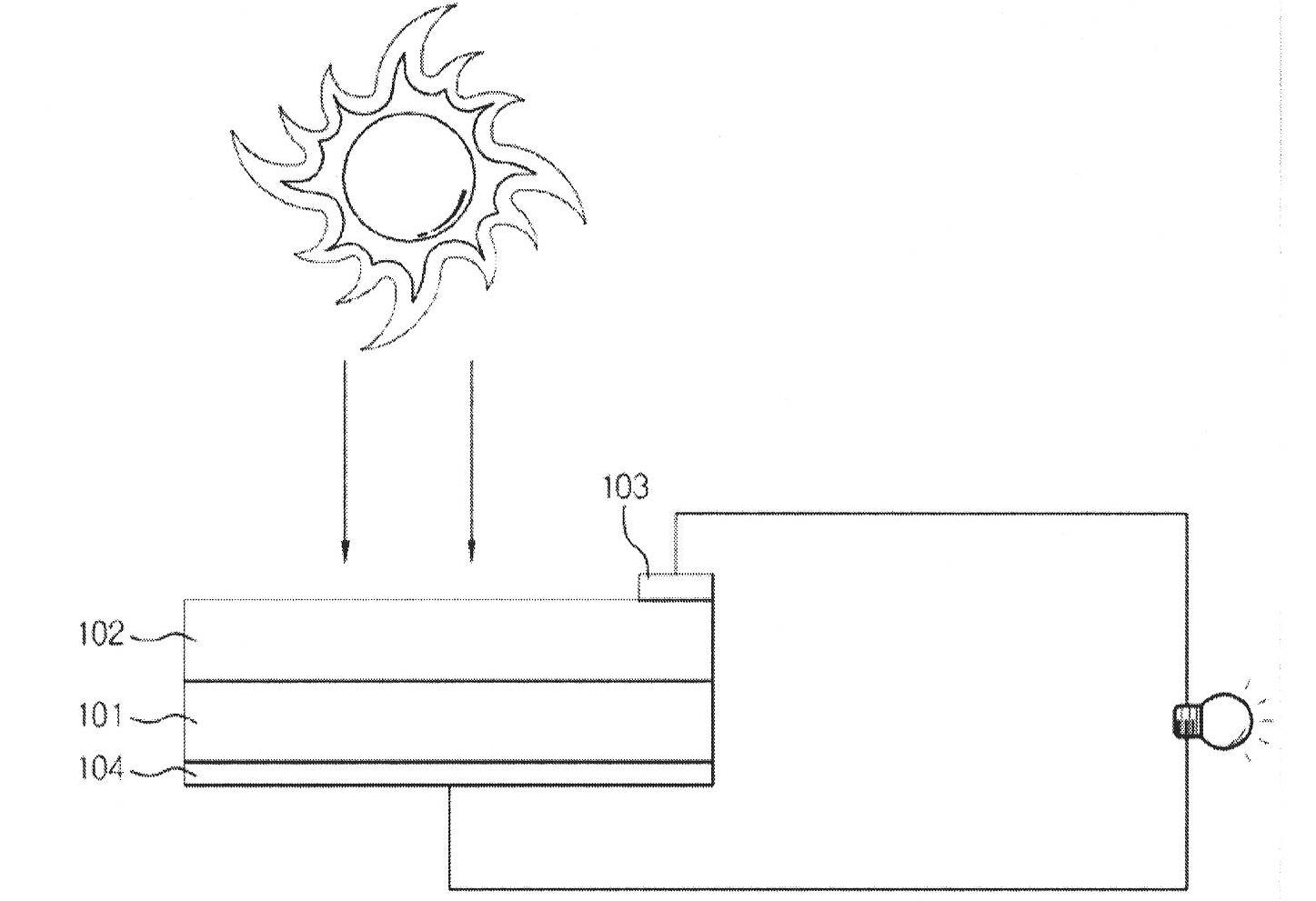

Conductive paste for solar battery

ActiveCN102237415AReduce the ratioDoes not affect electrical performanceNon-conductive material with dispersed conductive materialSemiconductor devicesScreen printingConductive paste

The invention belongs to the technical field of solar batteries and particularly discloses a conductive paste for a solar battery. The conductive paste comprises an organic carrier and solid powder dispersed in the organic carrier, wherein the solid powder comprises conductive silver powder and glass powder; the conductive silver powder is flaked silver powder; and the conductive silver powder accounts for 92 to 99 weight percent of the solid powder and accounts for 35 to 60 weight percent of the conductive paste. The conductive paste overcomes the prejudice of technicists in the field on lowsilver content and low electric performance, and higher electric performance can be achieved by reducing the silver content in the conductive paste; furthermore, the conductive paste for the solar battery has low silver content and moderate viscosity, and is favorable for screen printing, and attractive in appearance without sand holes, pinholes and the like after being sintered; compared with the common silver paste having higher silver content, the conductive paste has the advantage that the solar battery prepared from the conductive paste has high photoelectric conversion efficiency and the photoelectric conversion efficiency of a monocrystalline silicon piece is more than 17.50 percent.

Owner:BYD CO LTD

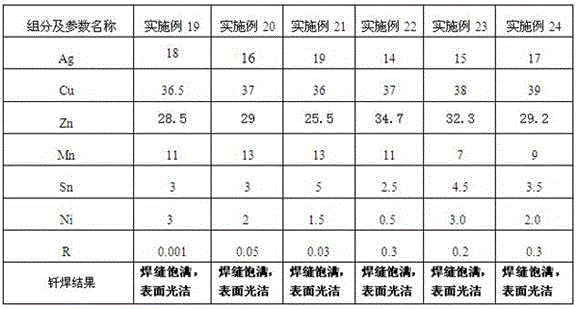

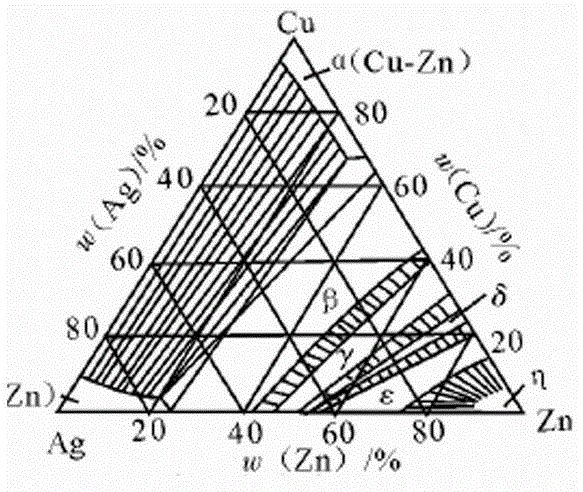

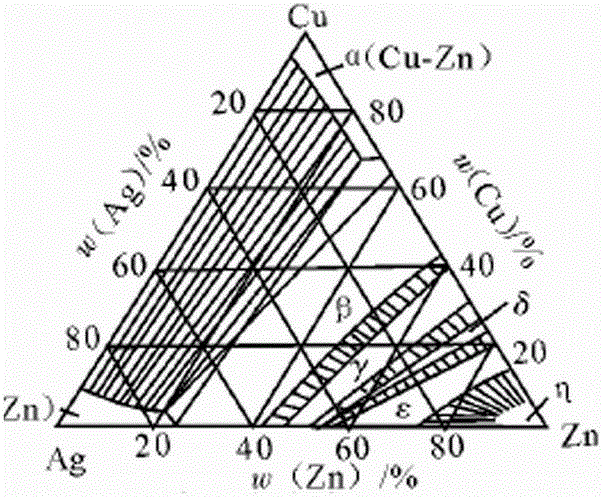

Cadmium-free and low-silver filler metal containing manganese and tin and production method of cadmium-free and low-silver filler metal

InactiveCN106077995AHigh strengthReduce silver contentWelding/cutting media/materialsSoldering mediaIntermediate frequencyCerium

The invention relates to cadmium-free and low-silver filler metal containing manganese and tin and a production method of the cadmium-free and low-silver filler metal, which are suitable for brazing copper alloys such as stainless steel, red copper and brass. The cadmium-free and low-silver filler metal is prepared from the following components in percentage by weight: 13 to 19 percent of Ag, 25.5 to 38 percent of Zn, 35 to 40 percent of Cu, 1.0 to 5.5 percent of Sn, 7 to 14 percent of Mn, 0.5 to 3.0 percent of Ni and 0.001 to 0.3 percent of trace element R, wherein the trace element R is prepared from one or more of lanthanum, cerium, silicon and antimony. The invention further provides the production method of the cadmium-free and low-silver filler metal containing the manganese and the tin. The production method comprises the following steps of adopting an intermediate frequency melting furnace to melt and cast; during melting, adding the components according to the sequence of Ag, Cu, Sn, Zn and Cu-Mn for melting; then adding a trace Cu-R alloy; finally, producing the cadmium-free and low-silver filler metal containing the manganese and the tin by techniques such as casting, saw stripping, extruding, drawing, forming and cleaning. The silver content of the cadmium-free and low-silver filler metal containing the manganese and the tin, disclosed by the invention, is lower than that of 20 percent of silver filler metal; the cadmium-free and low-silver filler metal containing the manganese and the tin does not contain cadmium element and is lower in melting temperature; and a multicomponent silver filler metal with good processing performance is used for brazing the red copper, the brass and the stainless steel.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

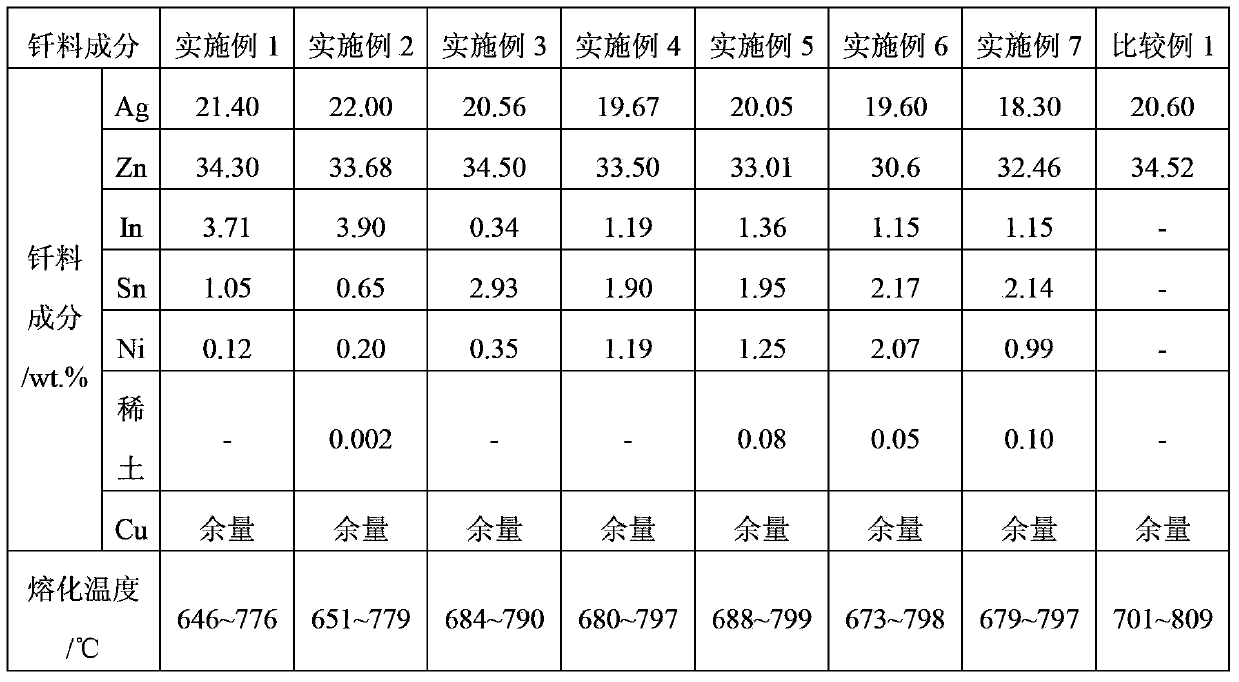

Silver solder for connecting brass and stainless steel

InactiveCN103418933ARight melting pointEasy to processWelding/cutting media/materialsSoldering mediaRare earthBrass

The invention relates to the technical field of welding materials, in particular to silver solder for connecting brass and stainless steel. The invention aims at overcoming the defects that existing solder for connecting the brass and the stainless steel is high in silver content and in welding cost, and providing the silver solder for connecting the brass and the stainless steel, wherein the silver solder is low in silver content and in welding cost, and non-cadmium silver solder containing more than 25wt.% of silver can be replaced by the silver solder for connecting the brass and the stainless steel. According to the technical scheme, the silver solder for connecting the brass and the stainless steel comprises components, by weight, 18-22 wt.% of Ag, 30-35wt.% of Zn, 0.3-4.5wt.% of In, 0.3-3.0wt.% of Sn, 0.1-2.5wt.% of Ni, 0.001-0.1wt.% of rare earth, and the balance Cu.

Owner:浙江信和科技股份有限公司

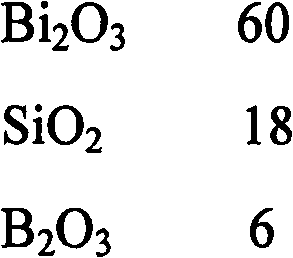

End-blocking slurry for flaky component

InactiveCN101728002AImprove process performanceAcid resistantConductive materialNon-conductive material with dispersed conductive materialElectrical conductorSlurry

The invention relates to an end-blocking slurry for a flaky component, which is prepared from the following raw materials in percentage by mass: 40 to 55 percent of silver powder, 4 to 15 percent of glass powder, 5 to 25 percent of inorganic filler and 20 to 40 percent of organic carrier, wherein the silver powder comprises the following silver powder in percentage by mass in the slurry: 25 to 40 percent of flaky silver powder and 15 to 30 percent of spherical silver powder. The end-blocking slurry has the advantages that: (1) the content of silver is low so as to reduce the cost of the slurry and improve the market competitiveness of the products, and 300 RMB can be saved in 1 kg of the slurry; (2) lead is not contained in the slurry, which is in favor of environmental protection; (3) a compact and flat conductor layer is formed at the end head of a substrate without pit and bulge after the processes of dipping the silver, drying and sintering, so the platability is good, the adhesive force is strong, and the glass is acid resistant. The slurry has good process use characteristics and is suitable to be used in the industries for generating the flaky components.

Owner:贵阳晶华电子材料有限公司

Conducting ink and preparation method thereof

The invention discloses conducting ink, which is prepared from the following ingredients in parts by mass: 35 to 55 parts of conducting filling materials, 20 to 30 parts of bonding agents, 9 to 21 parts of solvents and 2 to 5 parts of auxiliary agents, wherein the conducting filling materials comprise grapheme, flaky silver powder and ball-shaped silver powder; the grapheme accounts for 0.2 to 2 parts of the total amount of the conducting filling materials; the flaky silver powder accounts for 30 to 40 parts of the total amount of the conducting filling materials; the ball-shaped silver powder accounts for 5 to 15 parts of the total amount of the conducting filling materials. The invention also discloses a preparation method of the conducting ink. The method comprises the following steps of (1) bonding agent preparation; (2) grapheme precursor preparation; (3) crude pulp preparation; (4) grinding and filtering; (5) finished product obtaining. The preparation method has the advantages that the conducting performance and the anti-bending performance of the ink can be obviously improved; in addition, the characteristics of wide printing applicability, low conducting ink solid content and the like are realized.

Owner:DEYANG CARBONENE TECH

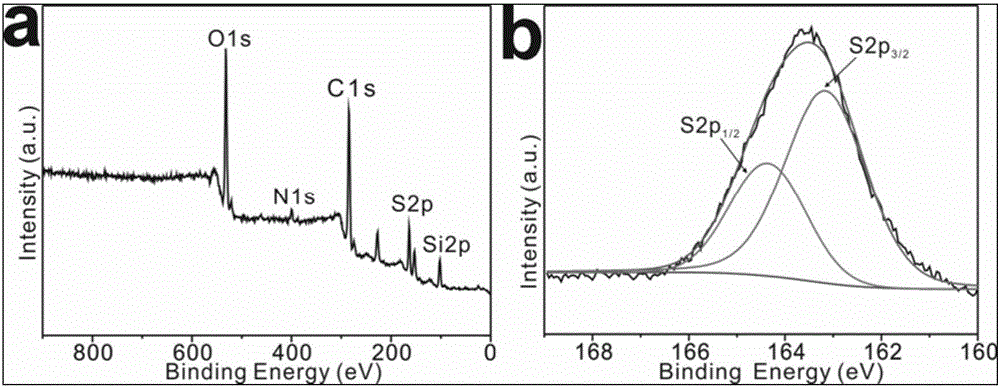

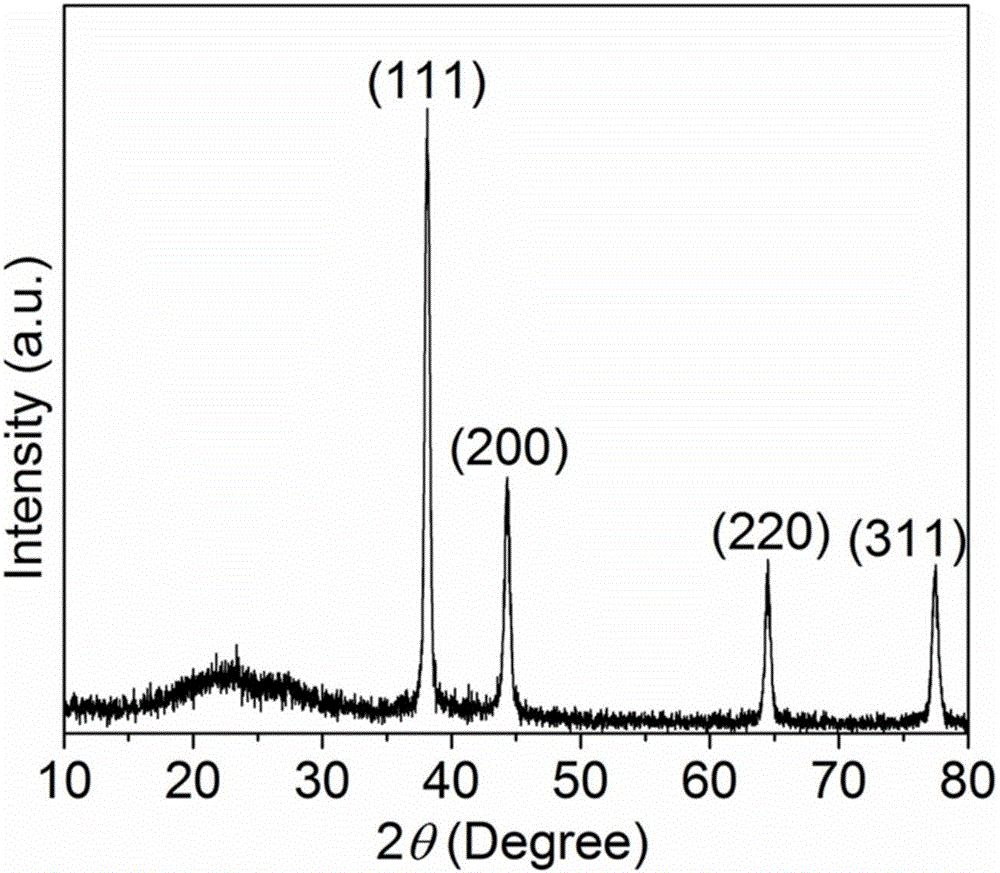

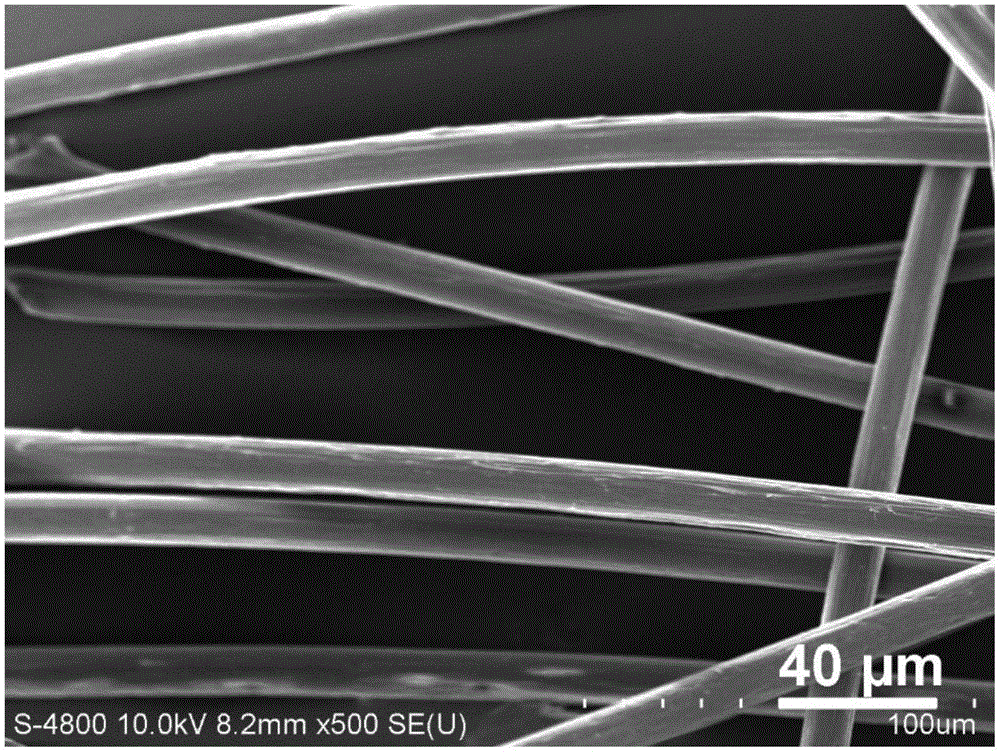

Chemical modification method for surface of aramid fiber and application of same in preparation of silver-coated aramid composite fiber

The invention relates to a chemical modification method for the surface of aramid fiber and application of the same in preparation of silver-coated aramid composite fiber. The chemical modification method comprises the following steps: 1) cleaning the surface of the aramid fiber and then carrying out pumping-filtration and drying; 2) placing the aramid fiber treated in the step 1) into a mixed solution of water and ethanol and adding a gamma-mercaptopropyltrimethoxysilane or gamma-mercaptopropyltriethoxysilane coupling agent and a catalyst so as to obtain a chemical modification solution; and 3) controlling reaction temperature and time for thiolation modification, and then successively carrying out pumping-filtering, washing and drying. Compared with the prior art, the invention has the following main advantages: the silver-coated aramid composite fiber prepared through the modification method has a uniform and compact silver shell, and the silver shell has low silver content, about 37.5 wt%; the silver-coated aramid composite fiber has excellent electrical performance and volume resistivity of 1.6*10<-4> omega.cm; bonding force between the aramid fiber and the silver shell is strong; and the method is simple in process, low in cost, environmentally friendly and easy for large-scale application.

Owner:WUHAN UNIV OF TECH

Low silver oxidation resistance active leadless solder

InactiveCN101214588AReduced activityImprove reliabilityWelding/cutting media/materialsSoldering mediaWettingWelding

A lower-Ag anti-oxidation lead-free solder relates to a lead-free solder. The invention solves the problems of high Ag content, high manufacture cost and poor wettability of the existing lead-free solder. The invention consists of the following components according to a weight percentage of 0.5 to 2.5 percent of Ag, 0.3 to 1.5 percent of Cu, 0.002 to 0.2 percent of P, 0.01 to 1.0 percent of Zn, 0.02 to 3.0 percent of Ti, 0.01 to 2.5 percent of Zr, 0.01 to 3.5 percent of Ni, 0.02 to 1.5 percent of mixed RE and the rest is Sn. Compared with the existing Sn-Ag-Cu solder under a same condition, the wetting angle of the lower-sliver anti-oxidation lead-free solder of the invention is reduced by 5 to 7 degrees, the anti-oxidation performance is improved by 14 to 20 percent and the creep strength is improved by 6 to 10 percent; thereby being able to acquire a joint with higher reliability from braze welding. The invention has the advantages of few Ag content and low manufacture cost.

Owner:HARBIN INST OF TECH

Cadmium-free silver filler containing lithium and niobium and production method thereof

ActiveCN101524793AImprove wettabilityGood spreadabilityWelding/cutting media/materialsSoldering mediaNiobiumMetallic materials

The invention belongs to the field of welding material, in particular relating to a cadmium-free silver filler containing lithium and niobium and a production method thereof; the chemical composition of the cadmium-free silver filler is as follows according to mass percent: 35.0%-40.0% of Cu, 42.0%-52.0% of Zn, 4.0%-6.0% of Sn, 0.001%-0.1% of Li, 0.001%-0.1% of Nb, and the balancing of Ag. In the invention, Nb and Li are added in sequence, so that the purity of the tissue of the silver filler can be obviously improved, thus improving the wettability and spreadability of the silver filler. The invention has low silver content, excellent braze welding performance, no toxic cadmium in the welded parts during welding or after welding, can replace Bag35CuZnCd brazing filler and Bag25CuZn brazing filler, and is applicable to braze welding for metal materials such as copper, brass, carbon steel, stainless steel, and nickel base alloy, etc.

Owner:JINHUA SANHUAN WELDING MATERIALS

Polybasic silver solder

ActiveCN103111770AReduce dosageImprove plasticityWelding/cutting media/materialsSoldering mediaRare-earth elementMetallurgy

The invention relates to polybasic silver solder characterized in that the polybasic silver solder comprises, by weight, 12-28% of Ag, 37-49% of Cu, 1.0-3.0% of In, 0.5-2.5% of Ni, 0.001-0.1% of rare earth elements and the balance Zn, wherein the polybasic silver solder contains little precious metal of silver, and the content of the silver is reduced by about 20% compared with high-silver solder such as Bag40CuZnSn. Therefore, production cost is greatly reduced, and use amount of the precious metal of the silver is saved.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

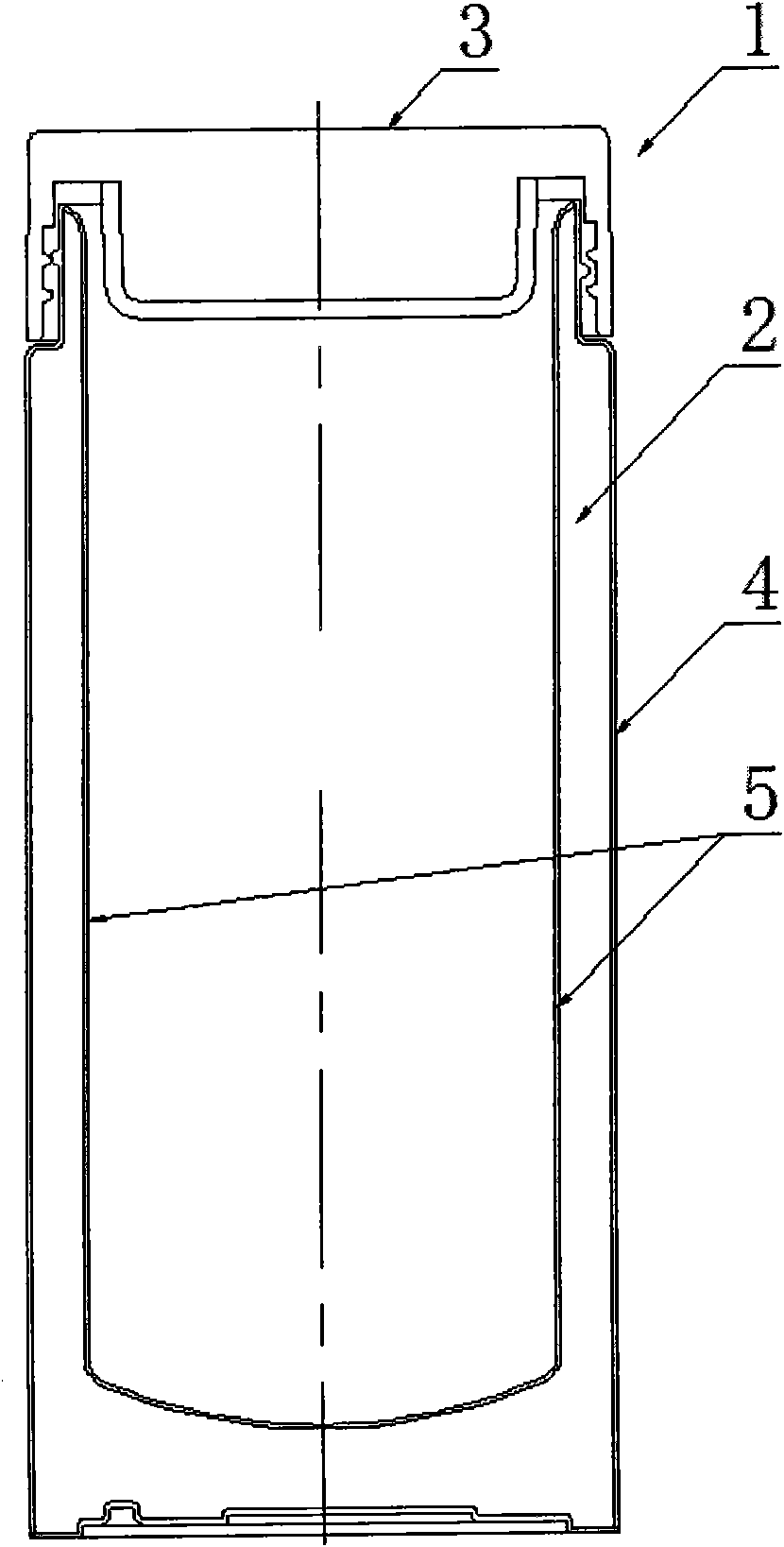

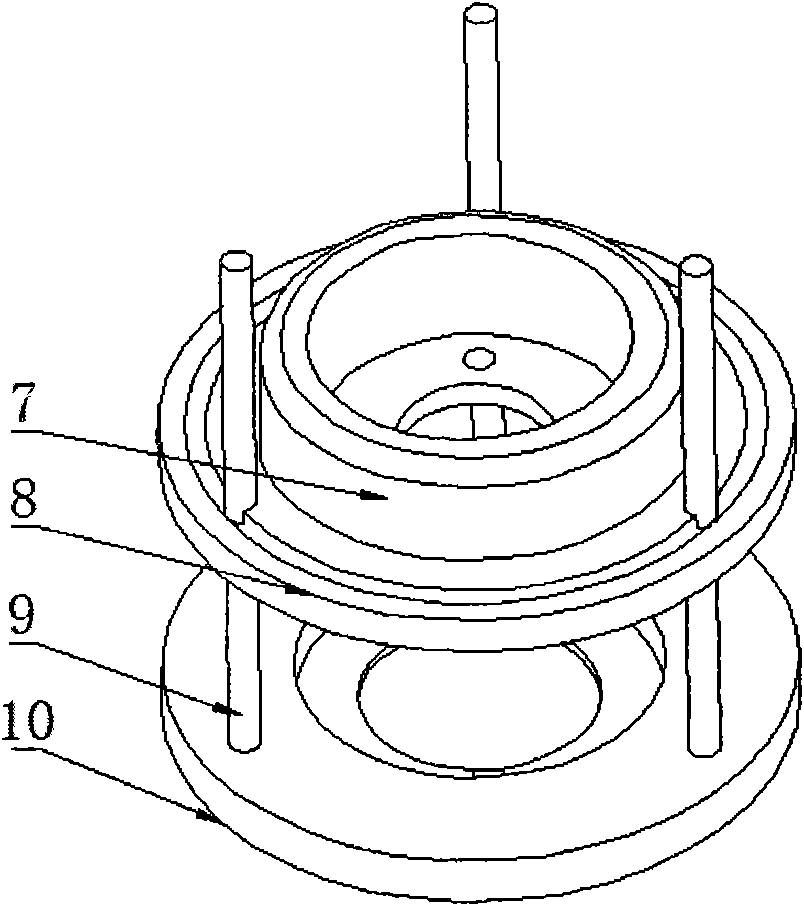

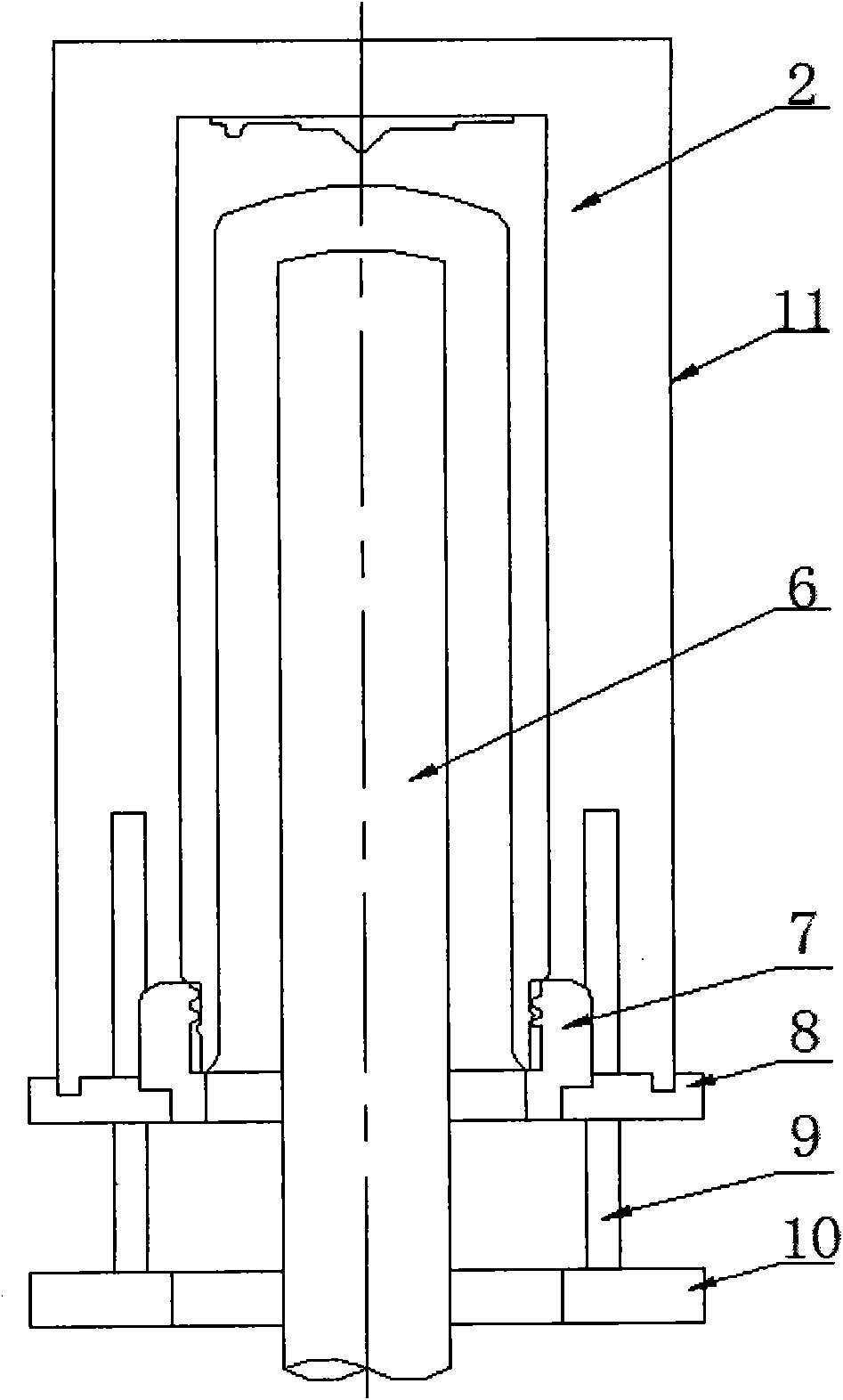

Nano silver antibacterial vacuum cup and processing technology thereof

ActiveCN102178426AReduce silver contentEnhanced inhibitory effectBiocideVacuum evaporation coatingPathogenic microorganismStaphylococcus aureus bacteria

The invention relates to a processing technology of a nano silver antibacterial vacuum cup, belongs to the fields of the manufacture technology for utensils for daily use and nano technology, and particularly relates to the technology of application of the nano technology to vacuum cups as the utensils for daily use. The nano silver antibacterial vacuum cup is characterized in that: a nano silver antibacterial film layer is evenly distributed, closely arranged and firmly pasted at the inner surface of a cup body. The manufacture process comprises the steps of: the formations of a shell, a cover and a base, and the silver plating manufacture of an inner container; the manufacture of the inner container comprises the following steps of: washing and drying a raw blank; washing and drying the inner surface of a cup container; washing an electrode; moving the cup container into a cup fixture in a vacuum room, and adjusting the positions of the inner surface of the cup container and the electrode; closing the vacuum room and vacuumizing stage by stage; and electrifying to sputter for vacuum plating. Advantageously, a vacuum cup with an antibacterial function is provided for markets. The vacuum cup has strong restraining and sterilizing functions to dozens of pathogenic microorganisms like colibacillus, Candida albicans, staphylococcus aureus and the like; and the vacuum cup is a quite practical home appliance.

Owner:JIANGSU XINUO INDAL

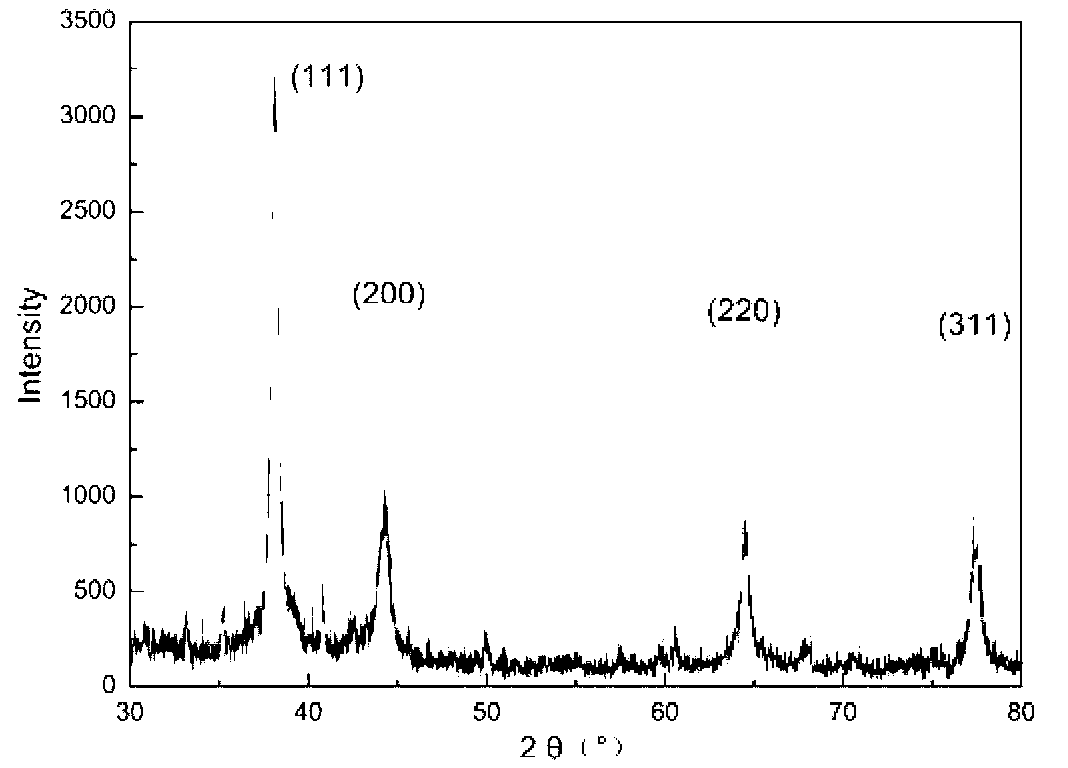

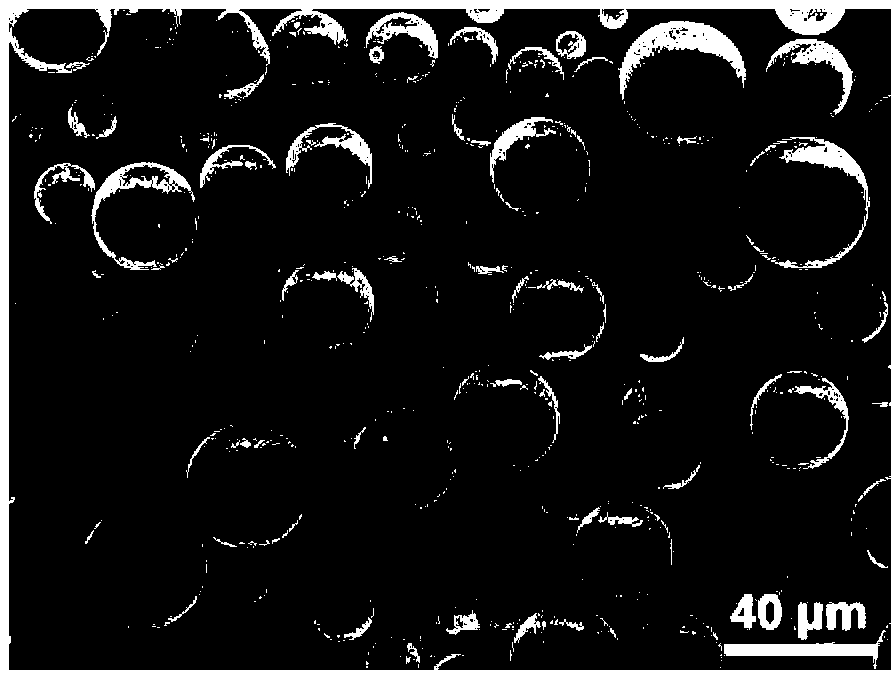

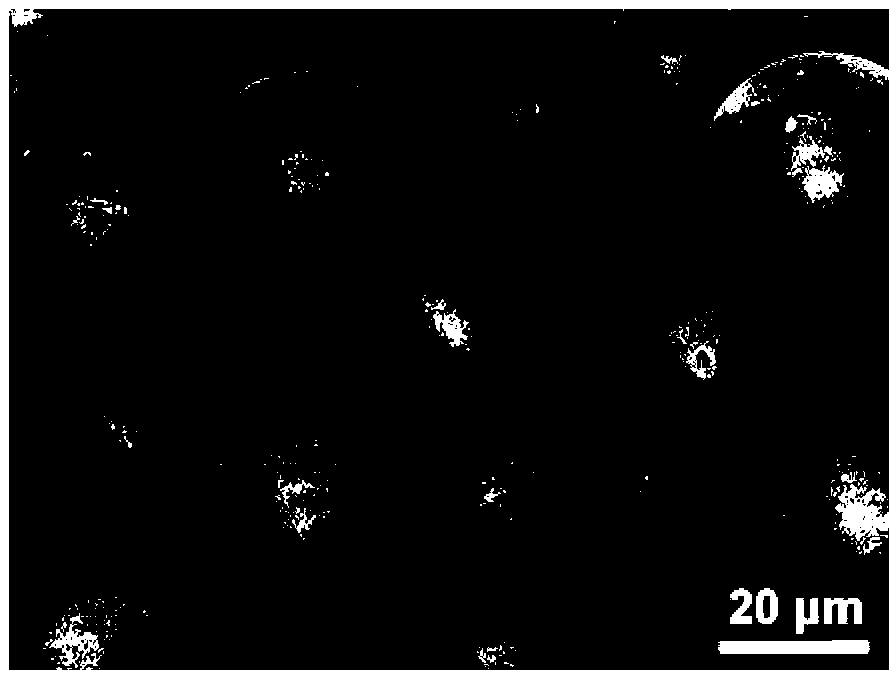

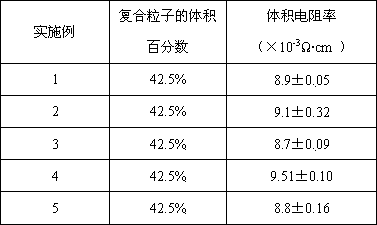

Preparation method of composite reducing agent liquid phase for conductive composite particles coated with silver shell layers

InactiveCN103341643AReduce silver contentLow costLiquid/solution decomposition chemical coatingGlass microsphereSalt solution

The invention relates to a preparation method of a composite reducing agent liquid phase for conductive composite particles coated with silver shell layers. According to the preparation method, a composite reducing agent solution constituted by a strong reducing agent and a weak reducing agent is adopted for reducing a silver salt solution to prepare the conductive composite particles coated with the silver shell layers in the presence of glass microspheres (GM) or SiO2 kernel particles subjected to surface chemical modification. The preparation method disclosed by the invention has the main advantages that the silver shell layers are dense and thin, the silver content is low, and the cost is low; the preparation method is easy to realize large-scale production. The preparation method disclosed by the invention has the advantages of simple preparation process, simple raw material composition, short preparation period and convenience in popularization and application.

Owner:WUHAN UNIV OF TECH

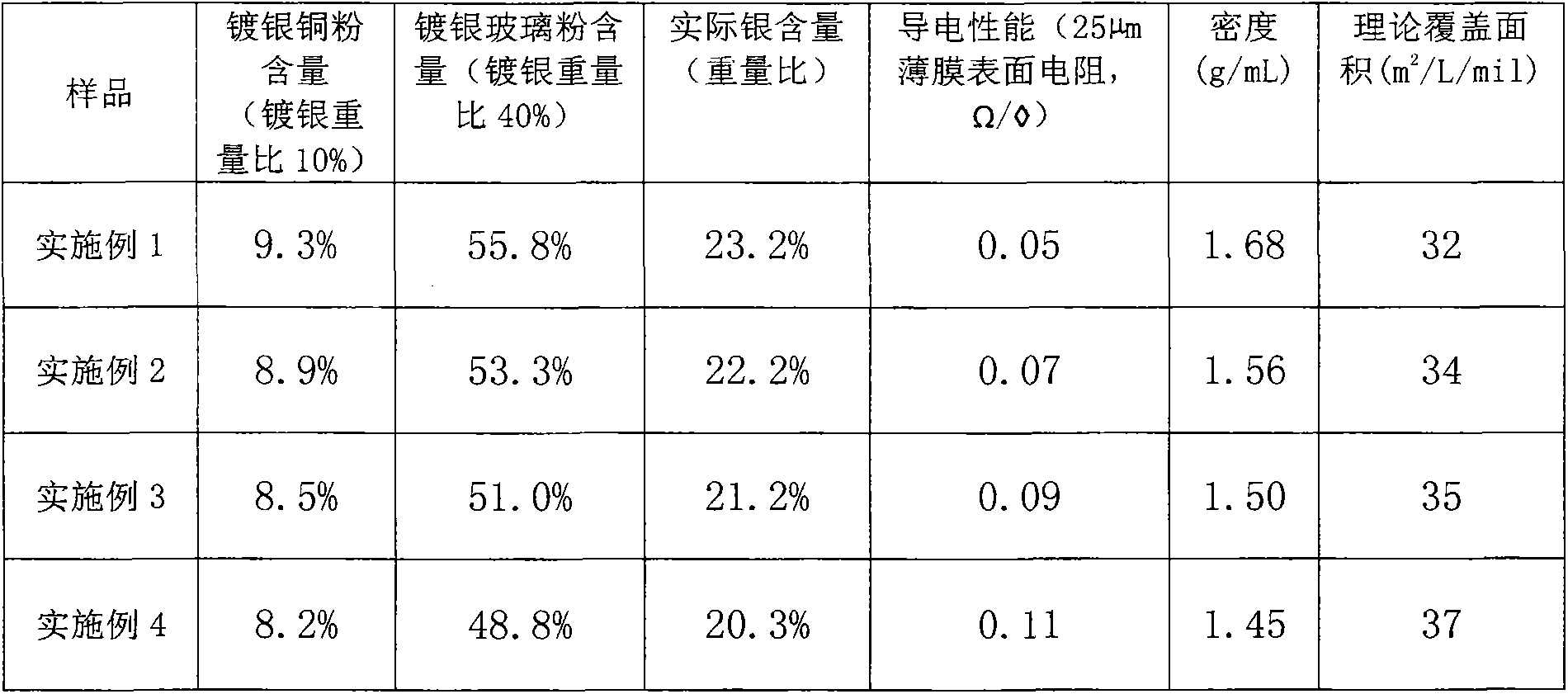

Low-silver-content composite conductive silver paste and preparation method thereof

InactiveCN104282356AGood electrical conductivityReduce manufacturing costNon-conductive material with dispersed conductive materialCable/conductor manufactureSpecific gravityImpressionability

The invention relates to a low-silver-content composite conductive silver paste and a preparation method thereof, and belongs to the technical field of electroconductive slurry. The low-silver-content composite conductive silver paste can be used for screen printing. At present, the conductive silver paste preparation technology in China is high in production cost, complex in preparation technology and the like. According to the low-silver-content composite conductive silver paste, silver-plated copper powder and silver-plated glass powder are adopted to replace pure silver powder, so that the production cost of the silver paste is effectively reduced; the mode that spherical particles and platy particles are combined is selected, so that the conductivity of the silver paste is improved; the silver-plated glass powder with the low specific density is adopted, so that the stability of the conductive silver paste is improved, and the storage life of the silver paste is prolonged. The problems existing in silver paste production at present in China are well solved, the sliver paste preparation technology is simple, the silver paste is good in conductivity and impressionability (including automatic and semi-automatic screen printing and the like), and high in adhesion capacity with various substrates such as a PET film, and has significant application value.

Owner:肖淑勇

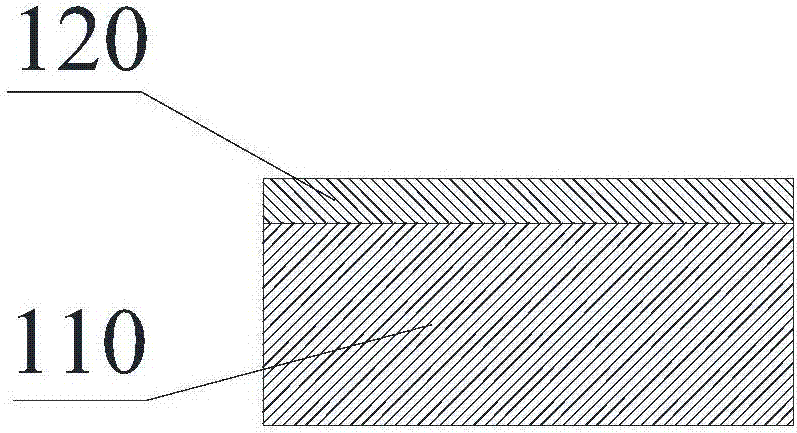

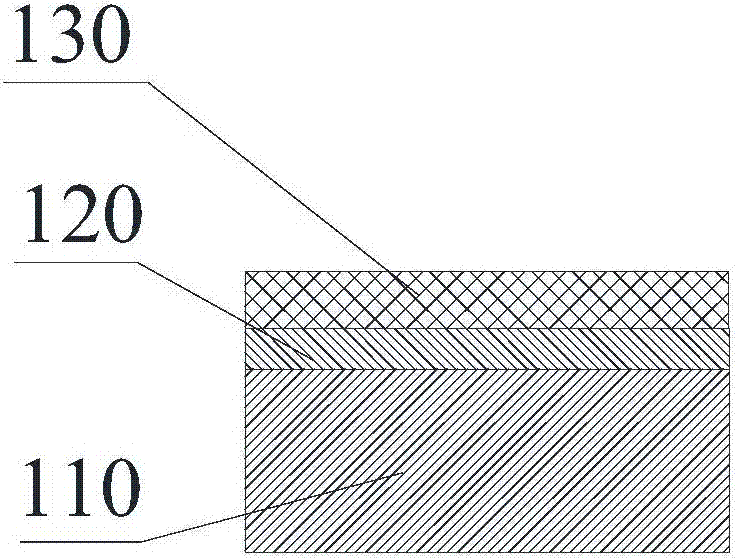

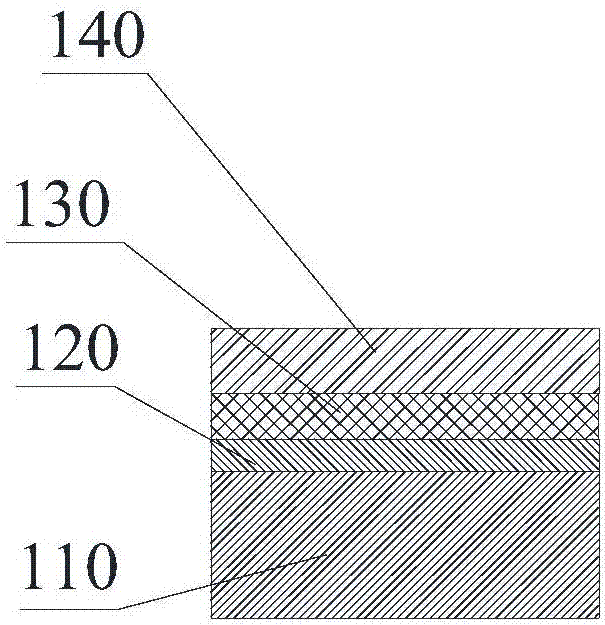

Manufacturing method of metal-ceramic composite substrate and composite substrate manufactured through manufacturing method

ActiveCN107546132ASmall electrical impedancePromote wettingSemiconductor/solid-state device detailsSolid-state devicesComposite substrateCopper foil

The invention discloses a manufacturing method of a metal-ceramic composite substrate and the composite substrate manufactured through the manufacturing method and belongs to the technical field of ceramic metallization. The manufacturing method comprises the following steps of forming a first brazing material layer on the surface of a ceramic substrate, wherein the first brazing material layer isa copper, silver and active metal brazing material layer; forming a second brazing material layer on the surface of the first brazing material layer, wherein the second brazing material layer is a copper and silver brazing material layer; forming a copper layer on the surface of the second brazing material layer; and sintering a metal-ceramic composite substrate precursor in vacuum. According tothe manufacturing method, an active metal in the first brazing material layer reacts with ceramic during vacuum sintering, so that the binding force is high and the thermal shock resistance is high. Copper and silver in the second brazing material layer are subjected to eutectic reaction with copper foil, so that the copper and the silver are tightly combined with the copper foil; and meanwhile, by adopting two brazing material layers, on one hand, the content of the silver is reduced and the cost is lower, and on the other hand, the content of the active metal is reduced, electrical impedanceis reduced and the metal-ceramic composite substrate is higher in high voltage resistance and high current resistance.

Owner:ZHEJIANG TC CERAMIC ELECTRONICS

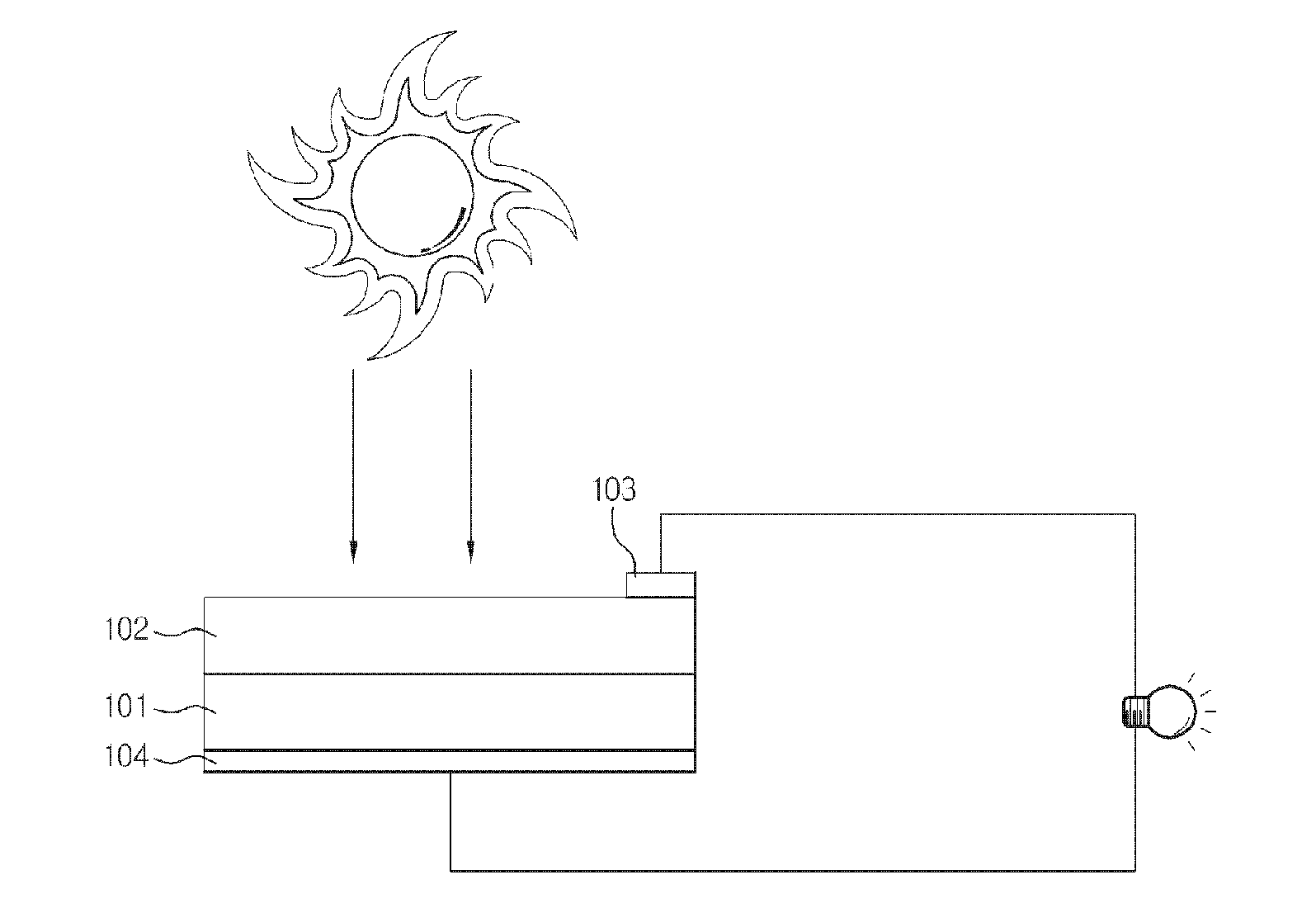

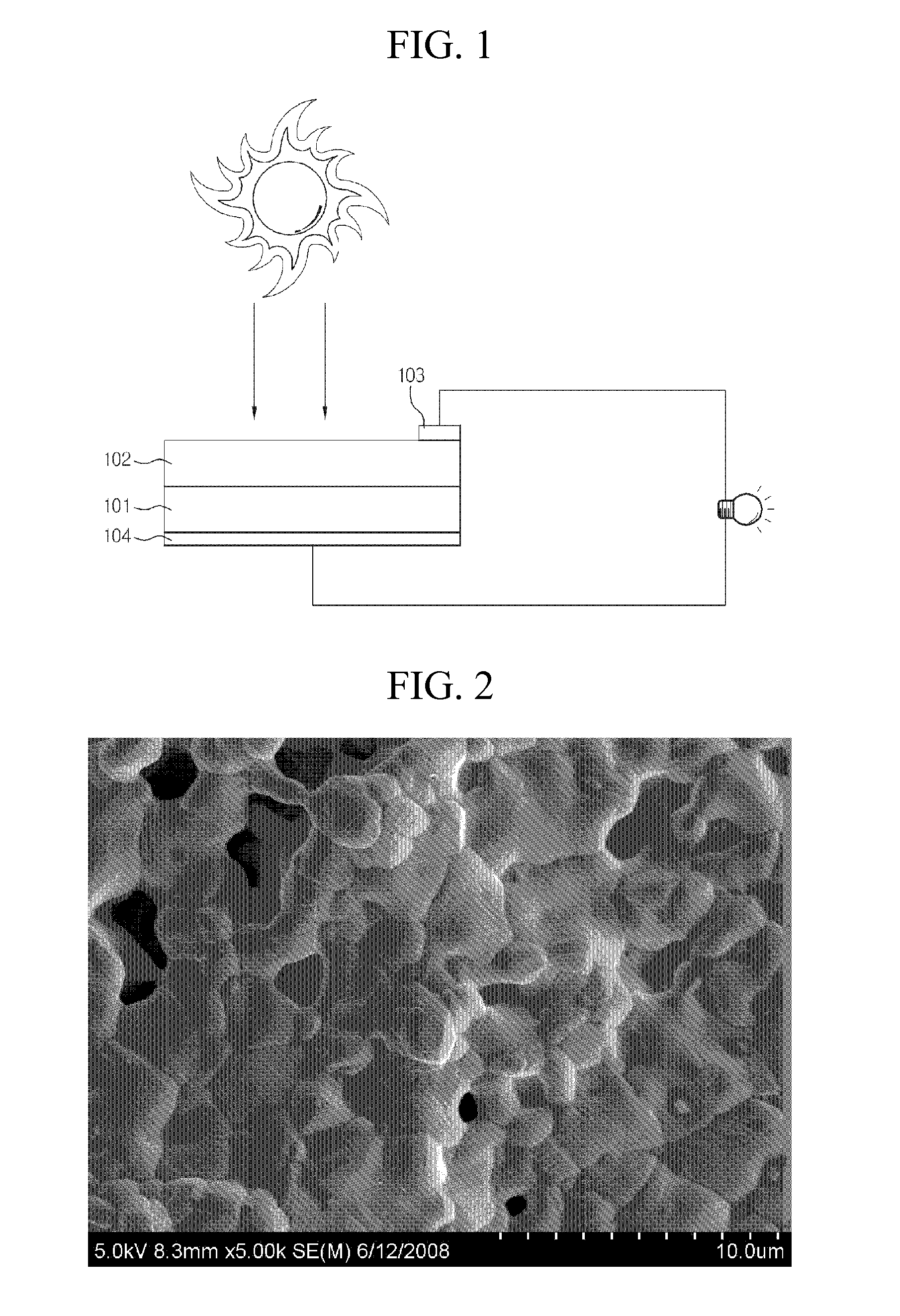

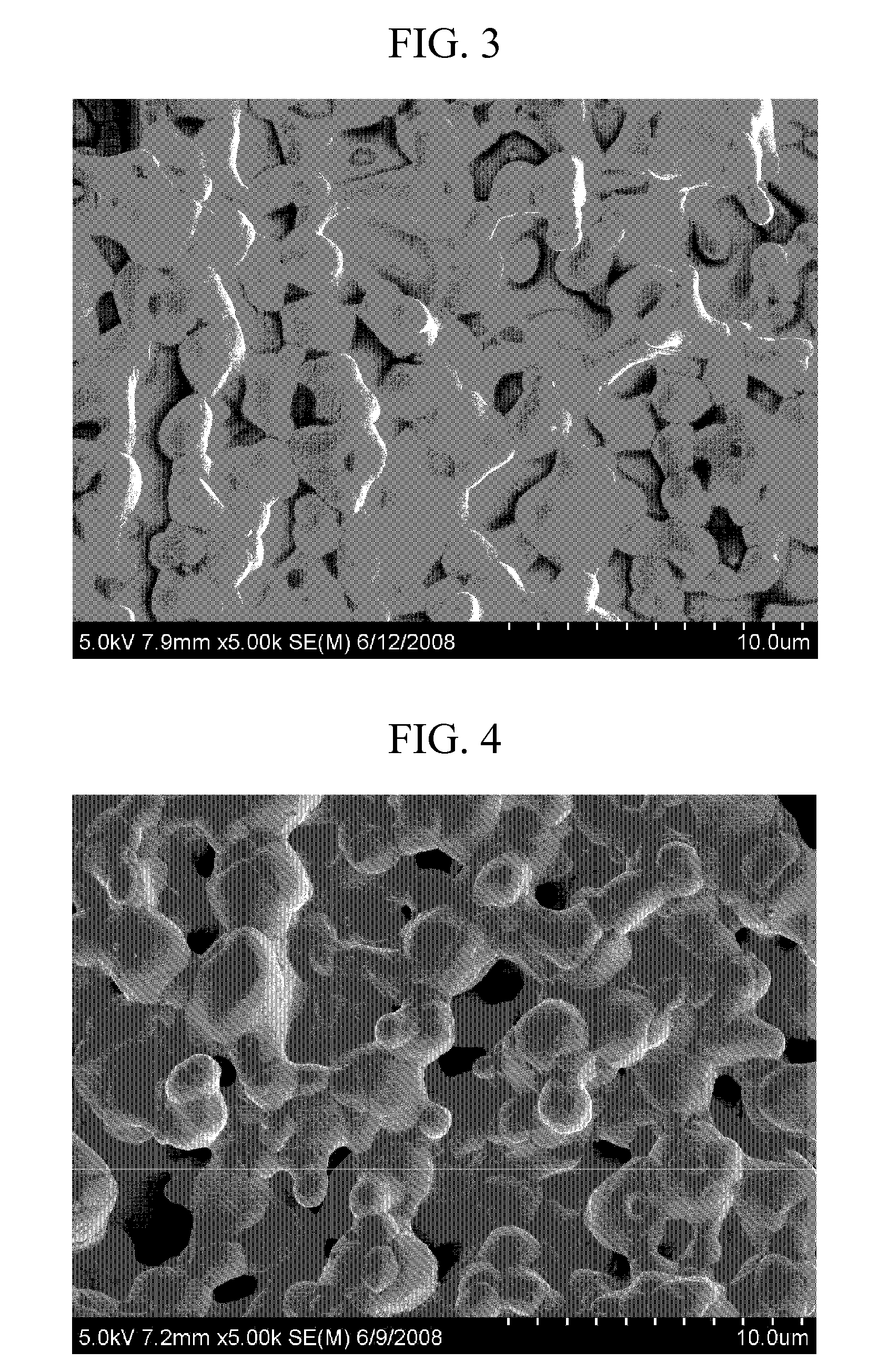

Metallic paste composition for formation of an electrode, and Ag-C composite electrodes and silicon solar cells using the same

InactiveCN102057443AReduce silver contentDoes not degrade electrical performanceNon-conductive material with dispersed conductive materialPhotovoltaic energy generationComposite electrodeFrit

The present invention relates to a metallic paste composition for formation of an electrode, and Ag-C composite electrodes and silicon solar cells using the same. The metallic paste composition for forming electrodes, comprises glass frit powder, silver powder and an organic binder further comprising a carbon-based material powder, wherein the carbon-based material is contained in an amount of not greater than 20 wt%, preferably not greater than 25 wt%, with respect to 100 wt% of the silver powder, and optionally, silver particles in the silver powder have an average particle diameter of not greater than 1 mm. Despite the relatively low silver content in the inventive metallic paste composition for formation of an electrode, electrical properties of the thus produced electrodes are not substantially degraded.

Owner:LG CHEM LTD

Novel tin-and-indium-containing multi-component cadmium-and-silver-free brazing filler metal

InactiveCN103056551ALow costImprove processing performanceWelding/cutting media/materialsSoldering mediaIndiumWetting

The invention discloses novel tin-and-indium-containing multi-component cadmium-and-silver-free brazing filler metal. The novel tin-and-indium-containing multi-component cadmium-and-silver-free brazing filler metal is characterized by comprising, by mass, 25.0%-26.0% of Ag, 36.0%-37.0% of Cu, 32.0%-34.0% of Zn, 1.0%-1.2% of In and the balance Sn. Silver content of the brazing filler metal is reduced by 5%, and cost is lowered. Solidus temperature is kept unchanged to be 701-713 DEG C, liquidus temperature is within the range of 720-730 DEG C and is decreased by 50 DEG C, and accordingly the interval between the solidus temperature and the liquidus temperature is decreased by 50 DEG C. In addition, wetting rate of the brazing filler metal on copper is increased by 0.5, microhardness is lowered by 50Hv, machinability is improved, and shearing strength of copper-copper brazing seams is enhanced by 80MPa.

Owner:XI AN JIAOTONG UNIV

Low Silver, Low Nickel Brazing Material

ActiveUS20120207643A1Economical and easy to fabricateEconomical and easy to and useWelding/cutting media/materialsSoldering mediaWorking temperatureCopper

A homogenous brazing material essentially consisting of relatively low amounts of silver and nickel together with copper, zinc, and other constituents is provided. The brazing material has a working temperature exceeding 630° F. and is preferably between about 1250° F. and 1500° F. The brazing material preferably has about 30 percent by weight of silver, about 36 percent by weight of copper, about 32 percent by weight of zinc, and about 2 percent by weight of nickel. The addition of nickel in the above-specified amount improves resistance against interface corrosion in aqueous solutions, aids in the strength of the alloy, and provides improved wettability on ferrous and non-ferrous substrates. The brazing material may also include a flux, such as a core or a coating.

Owner:LUCAS MILHAUPT

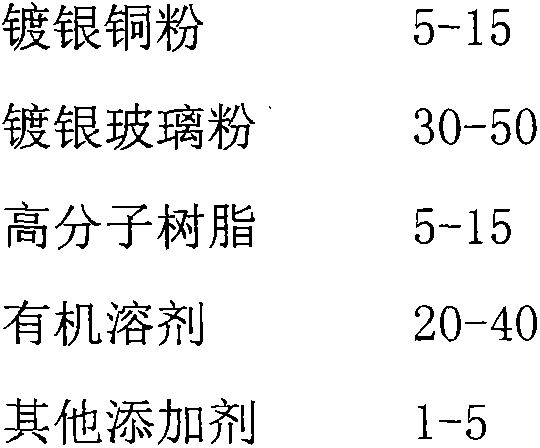

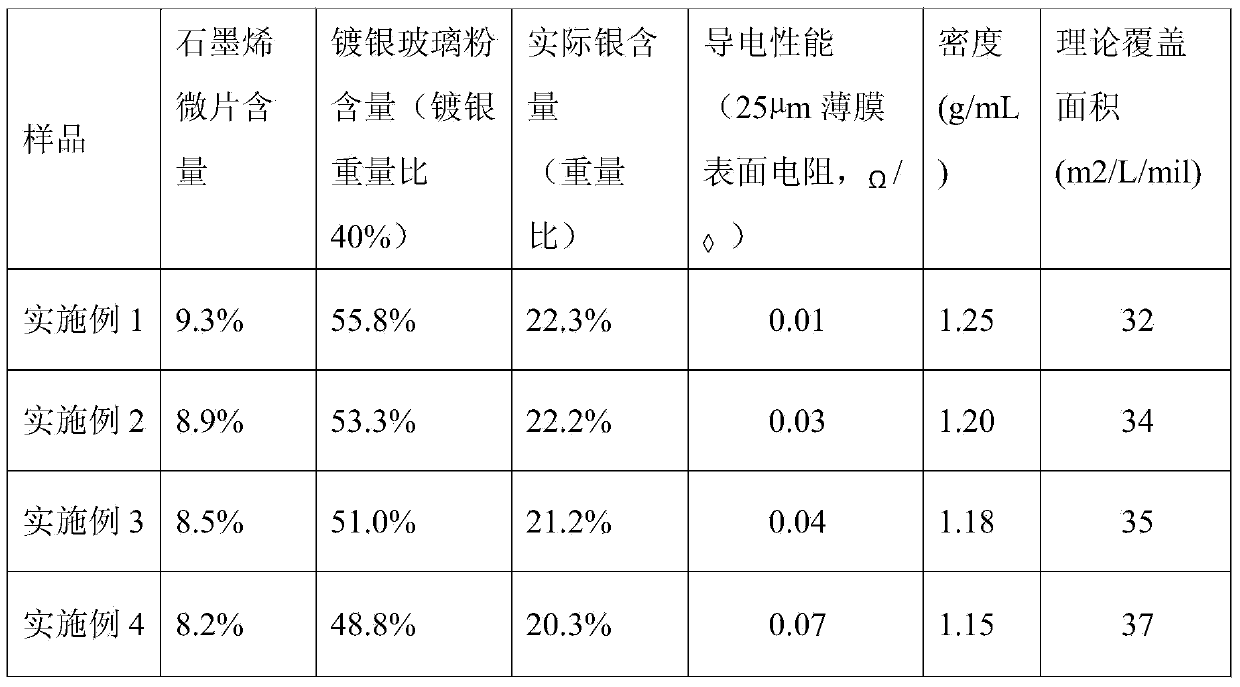

Low-silver-content graphene composite conductive silver paste and preparation method thereof

InactiveCN104200875AImprove conductivityReduce silver contentNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteOrganic solvent

The invention discloses low-silver-content graphene composite conductive silver paste. The low-silver-content graphene composite conductive silver paste is composed of, by weight, 5-15 parts of graphene microchips, 30-50 parts of silver plated glass powder, 5-15 parts of macromolecule resin, 20-40 parts of organic solvent, 1-4 parts of levelling agent and 0.1-1.5 parts of defoamer. The conductive particle graphene microchips and the silver plated glass powder adopted in the silver paste are of a sheet structure respectively, gaps among conductive particles are effectively reduced, stacking density of conductive films is increased, contact area of the particles is enlarged, contractility of the films is reduced, and conductivity of the silver pates is improved; being low in weight and only accounting for 10-20% of pure silver powder, the graphene microchips and the silver plated glass powder which are light do not easily settle in organic carriers, so that stability of the conductive silver paste is improved.

Owner:NINGBO PLUS ONE NEW MATERIAL

High temperature sintering conductive silver paste for negative temperature coefficient (NTC) thermistor and preparation method thereof

ActiveCN103165222AReduce procurement costsReduce procurement cycleNegative temperature coefficient thermistorsNon-conductive material with dispersed conductive materialSlurryThermistor

The invention relates to high temperature sintering conductive silver paste for a negative temperature coefficient (NTC) thermistor and a preparation method of the high temperature sintering conductive silver paste for the NTC thermistor. The conductive silver paste comprises the following components, by weight: 72 parts to 85 parts of metal silver powder, 1 part to 10 parts of glass powder, 10 parts to 30 parts of organic carriers and 1 part to 10 parts of solvent. The mentioned materials are fully mixed in a blender mixer, and then are dispersed at high speed through a highs-peed dispersion machine, and even slurry is obtained. The slurry is grinded on a three-roller grinder, the fineness degree of the silver paste is controlled under 15 micrometers through the fine adjustment of idler wheels, the viscosity of the silver paste is 30 Pa.S to 50 Pa.S, and lead-free welding-resistance conductive silver paste for electrothermal film quartz glass tube electrical heating elements is prepared. Compared with the prior art, the high temperature sintering conductive silver paste for the NTC thermistor has the advantages of being low in cost, low in sintering temperature, wide in sintering range, strong in adhesive force and the like.

Owner:SHANGHAI BAOYIN ELECTRONICS MATERIALS CO LTD

Tin-Silver-Zinc system lead-free solder with low silver content

InactiveCN101318269AImprove wettabilityReduce silver contentWelding/cutting media/materialsSoldering mediaRare-earth elementIndium

The invention relates to tin silver zinc series lead-free solders containing low silver, belonging to the lead-free solder technology. The components and the mass percentage of tin silver zinc series lead-free solders of the invention are as follows: tin, 85 to 99; silver, 0.01 to 3; zinc, 0.01 to 5; bismuth, 0 to 5; indium, 0 to 4; rare earth elements, 0 to 5; gallium, 0 to 2.5; and phosphorus, 0 to 3. The tin silver zinc series lead-free solders containing low silver have the advantages that under the premise of ensuring the industrial application thereof, the product cost is reduced by reducing the content of silver, and the tin silver zinc series lead-free solders containing low silver have good wetting property with a copper base plate.

Owner:TIANJIN UNIV

Isotropous conductive adhesive and preparation method thereof

InactiveCN101892026AAvoid harmEnvironmentally friendlyNon-macromolecular adhesive additivesCarboxylic acid nitrile preparationMaleopimaric acidIsotropic conductive adhesives

The invention discloses an isotropous conductive adhesive and a preparation method thereof. A raw material of the isotropous conductive adhesive is prepared by compounding a component A and a component B in a mass ratio of 100:80-100, wherein the component A comprises the following constituents in part by mass: 100 parts of epoxy resin, 5 to 20 parts of flexible diluent and 200 to 300 parts of conductive filler; and the component B comprises the following constituents in part by mass: 50 parts of rosinyl polyamide curing agent, 50 parts of modified amine curing agent and 150 to 250 parts of conductive filler. The preparation method comprises the following steps of: performing a Mannich reaction of phenol, polyamine and organic aldehyde and performing an addition reaction of a Mannich reaction product and acrylonitrile to obtain an amber low-viscosity modified amine curing agent; performing an amidation reaction of maleopimaric acid and the polyamine and performing an addition reactionof an amidation reaction product and the acrylonitrile to obtain a yellow thick rosinyl polyamide curing agent; and uniformly mixing the amber low-viscosity modified amine curing agent and the yellowthick rosinyl polyamide curing agent according to a proportion to obtain the isotropous conductive adhesive.

Owner:中国林科院林产化工研究所南京科技开发有限公司

Metal paste composition for forming electrode and silver-carbon composite electrode and silicon solar cell using the same

InactiveUS20120000523A1Reduce silver contentIncrease contentConductive materialNon-conductive material with dispersed conductive materialCarbon compositesFrit

Provided are a metal paste composition for forming an electrode, and a silver-carbon composite electrode and a silicon solar cell using the same. The metal paste composition for forming an electrode including glass frit powder, silver powder and an organic binder further includes 20 or less parts by weight, preferably 25 or less parts by weight of carbon-based material powder based on 100 parts by weight of the silver powder. Optionally, the silver powder has an average particle size of 1 μm or less. An electrode formed using the metal paste composition does not have a substantial deterioration in its electrical characteristics although the silver content is reduced.

Owner:LG CHEM LTD

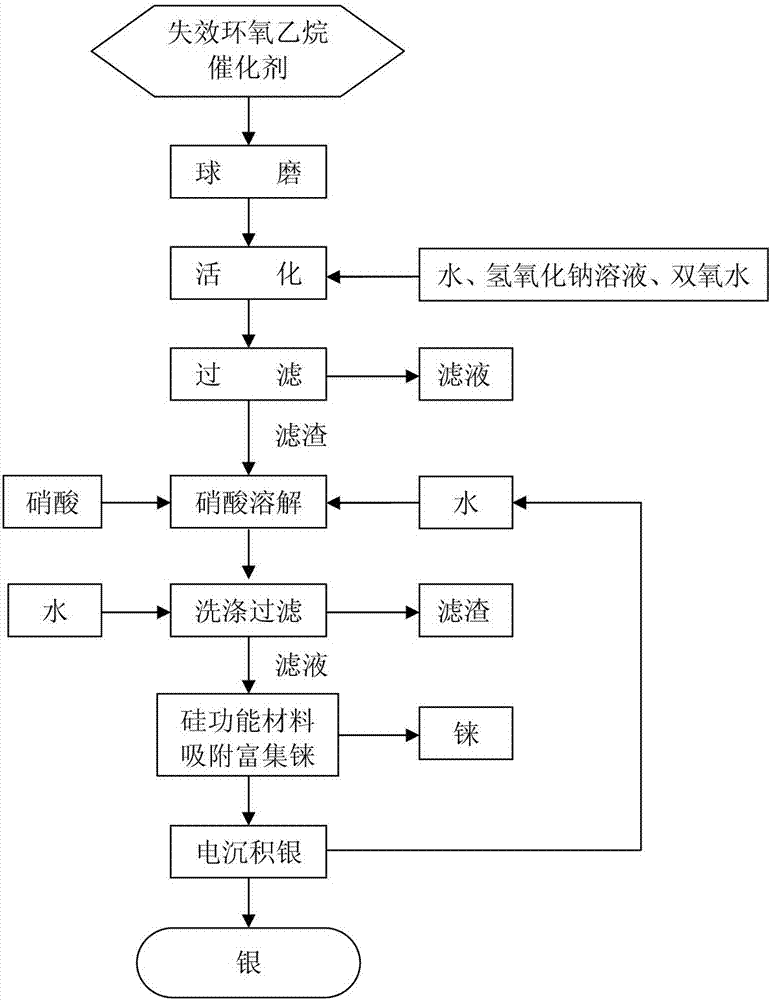

Method for recycling silver and rhenium from invalid ethylene oxide catalyst

ActiveCN107034360AHigh recovery rateImprove qualityProcess efficiency improvementRheniumEthylene oxide

The invention relates to the field of precious metal secondary resource comprehensive recovery and utilization and particularly relates to a method for recycling silver and rhenium from an invalid ethylene oxide catalyst. The method for recycling the silver and the rhenium from the invalid ethylene oxide catalyst comprises the following steps of (1), ball milling; (2), activation; (3), filtering; (4), dissolution with nitric acid; (5), washing and filtering; (6), adsorption and enrichment of rhenium with a silicon functional material; (7), electro-deposition of the silver. The recovery rate of the precious metal silver is higher than 99.6%, and the recovery rate of the silver is high; purity of a silver product reaches 99.99%, and silver quality is high; the rhenium is selectively adsorbed with the silicon functional material in a nitric acid dissolving solution and is enriched on the silicon functional material, and the recovery rate of the rhenium is higher than 85%; electro-deposition waste liquid is recycled, generated alpha-Al2O3 residues are inert residues, are poisonless and harmless and can be used as addition materials of building materials, the production process is clean, energy is saved, consumption is lowered, and the method is environmentally friendly.

Owner:GUIYAN RESOURCE YIMEN

Low-silver brazing material for dissimilar metal connecting

InactiveCN104785951AImprove processing plasticityReduce silver contentWelding/cutting media/materialsWelding/soldering/cutting articlesIndiumCerium

The invention relates to a low-silver brazing material for dissimilar metal connecting. The low-silver brazing material for dissimilar metal connecting is characterized by comprising, by weight, 13.0-18.0% of silver, 42.0-48.0% of copper, 1.0-4.0% of tin, 0.1-3.0% of indium, 0.001-0.05% of trace mixed metal, and the balance zinc; the trace mixed metal is composed of two or more of lanthanum, cerium, gallium and silicon. According to the low-silver brazing material for dissimilar metal connecting, the silver content is low, no cadmium exists, the cost performance is high, superior mechanical performance is achieved when copper and iron are brazed, quality is stable, the machining plasticity is good, and the specific resistance is small.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

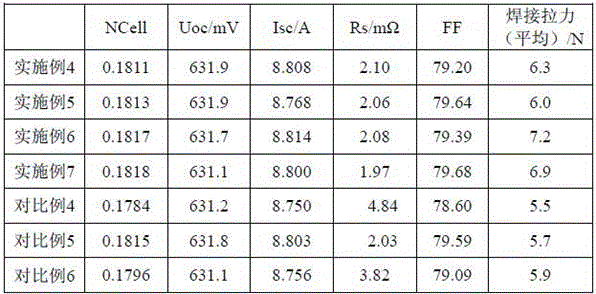

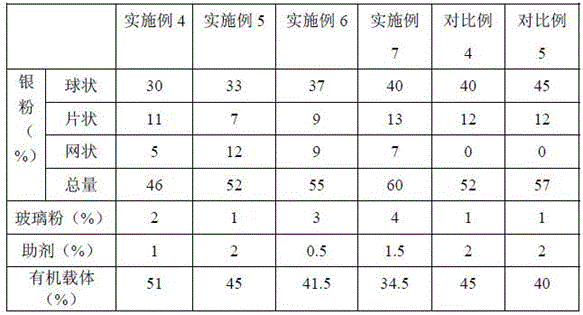

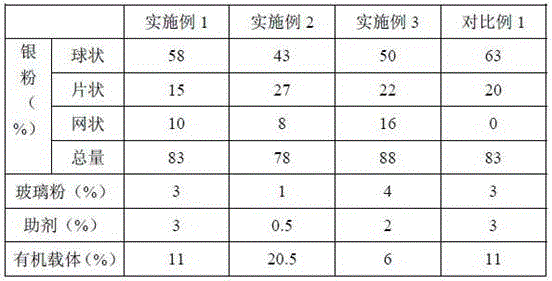

Crystalline silicon solar cell silver paste with low silver content and preparation method thereof

ActiveCN105913897AReduce meltingReduce silver contentNon-conductive material with dispersed conductive materialPhotovoltaic energy generationMicro nanoSilver paste

The invention discloses crystalline silicon solar cell silver paste with a low silver content and a preparation method thereof. The crystalline silicon solar cell silver paste is composed of: silver powder, an organic carrier and an auxiliary agent. An organic solvent and a thickening agent are mixed to form the organic carrier. Micro-nano netted silver powder, spherical silver powder and sheet-shaped silver powder are mixed to form the silver powder. With 100% of the mass of the crystalline silicon solar cell silver paste, the mass percent of the micro-nano netted silver powder is 5-16%. According to the invention, a proper amount of micro-nano netted silver powder is added to conventional silver paste, the micro-nano netted silver powder has a porous characteristic, and compared with other entity silver powder with the same particle size, the fusion speed of the micro-nano netted silver powder is low and can relatively well maintain the structure characteristic in an existing paste flash burning process, so that the purpose of lowing the silver content of the paste is achieved.

Owner:JIANGSU HOYI TECH

Multi-silver brazing filler metal containing manganese and tin and preparation method thereof

InactiveCN104923938AImprove processing plasticityReduce silver contentWelding/cutting media/materialsWelding/soldering/cutting articlesManganeseCerium

The invention relates to a multi-silver brazing filler metal containing manganese and tin, which consists of Ag, Cu, Sn, Mn, Ni and Zn, wherein the weight percentages of all the components are as follows: 19-22.5 wt% of Ag, 28-36 wt% of Zn, 36-40 wt% of Cu, 1.0-3.0 wt% of Sn, 3.5-6.5 wt% of Mn, 0.5-2.0 wt% of Ni, and 0.01-0.3 wt% of microelement R; and the microelement R is one of lanthanum, cerium and silicon, or consists of more than one of the three. The invention further comprises a preparation method of the multi-silver brazing filler metal; a medium-frequency smelting furnace is adopted to smelt and cast; all the components are added for smelting according to the sequence of Ag, Cu, Ni, Sn, Mn, Zn and Cu-R alloy; and then, the multi-silver brazing filler metal is prepared through casting, saw stripping, extrusion, drawing, molding and cleaning processes. Compared with the prior art, the multi-silver brazing filler metal has the following advantages and effects: (1) the multi-silver brazing filler metal can be used for replacing BAg45CuZnCd and Bag45CuZnCd silver brazing filler metals; the silver content is obviously reduced; the performance index parameters are approximate to that of BAg45CuZnCd and Bag45CuZnCd; and the cost performance is excellent; (2) when red copper, brass and stainless steel are brazed, the mechanical performance is excellent; (3) the brazing filler metal is better in processing plasticity; and (4) the product melting temperature is 700-770 DEG C.

Owner:HANGZHOU HUAGUANG ADVANCED WELDING MATERIALS CO LTD

Aluminum powder surface hydration processing method and application of aluminum powder in preparing Al@Ag nuclear shell composite particle conductive and electromagnetic shielding filler

The invention relates to an aluminum powder surface hydration processing method. The aluminum powder surface hydration processing method comprises the following steps that 1, the surface of aluminum powder is washed, filtered in a suction mode and dried; 2, the washed aluminum powder is placed into a solution with the volume ratio of water to ethyl alcohol being 3: 1 for hydroxylation processing; 3, a silane coupling agent is added, sulfhydrylation decoration is conducted on the aluminum powder, and filtering, washing and drying are conducted, so that the aluminum powder obtained after sulfhydrylation decoration is obtained. The invention further provides an application of the aluminum powder obtained according to the aluminum powder surface hydration processing method in preparing Al@Ag nuclear shell composite particle conductive and electromagnetic shielding filler. The aluminum powder serves as a raw material for preparing the conductive and electromagnetic shielding filler. The sulfydryl content of the surface of the processed aluminum powder is high and the processing method is simple and efficient; prepared Al@Ag nuclear shell composite particles have the advantages of being even and dense in silver shell layer, low in silver content, low in cost and the like, and have important application prospect in the fields of conductive and electromagnetic shielding composite materials and the like.

Owner:KING STRONG MATERIAL ENG LTD

Conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature

ActiveCN105131881AGood coating effectImprove stamping resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesCelluloseConductive polymer

The invention discloses a conductive silver adhesive with low solid content and capable of being rapidly cured at medium and normal temperature. The conductive silver adhesive is prepared from 1%-2% of silver nanowires, 13%-29% of flake silver powder, 20%-30% of bisphenol A epoxy resin, 5%-10% of rapid medium and normal temperature curing agents, 0.5%-1% of rapid medium and normal temperature curing accelerant, 1%-3% of thinning agents, 1%-3% of K-570 or K-550, 0.5%-1% of terephthalic acid, 20%-56.3% of cellulose, 0.5%-1% of nano-silicon dioxide, 0.1%-0.5% of antifoaming agents and 0.1%-0.5% of ICAM8401 or ICAM8402. The conductive silver adhesive can be rapidly cured at medium and normal temperature and is low in silver content and low in cost, and therefore the application range of the conductive silver adhesive is greatly extended.

Owner:上海巨尔希电子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com