Low-silver brazing material for dissimilar metal connecting

A dissimilar metal, silver brazing technology, applied in metal processing equipment, welding/welding/cutting items, welding/cutting media/materials, etc., can solve the problems of low price, environmental pollution, non-compliance, etc. Excellent performance, process performance, good cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

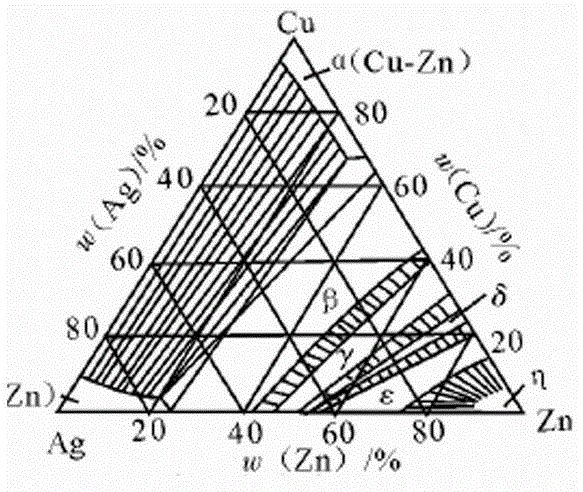

Image

Examples

Embodiment Construction

[0014] The low-silver brazing material used for the connection of dissimilar metals in the embodiment of the present invention uses 1# silver, No. 1 standard copper, national standard Zn99.995, In99.993, Sn99.95 and mixed metals. According to the above ratio, conventional intermediate frequency smelting is used The furnace is smelted and casted, and then prepared by sawing, extruding, drawing, molding, cleaning and other processes; according to Ag, Cu, Sn, In, and Zn, the smelting is added in sequence, and finally a trace of mixed metal is added, and then through casting, It is prepared by sawing, squeezing, drawing, forming, cleaning and other processes. The obtained solder has a solidus temperature range of 700-740℃ and a liquidus temperature range of 801-860℃. It has good plasticity and can be processed into various specifications and sizes of welding rods, wires, welding rings, and ribbons. , Soldering piece and other brazing materials; with FB102 (QJ102) flux, brazing on f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com