Flexible adhesive tape brazing filler metal and preparation method thereof

A technology for sticking tape and brazing filler metal, which is used in adhesives, film/flake adhesives, non-polymeric organic compound adhesives, etc. It can avoid problems such as non-densification, and achieve the effect of avoiding substandard welding seam structure and composition, reducing manufacturing costs and solving environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

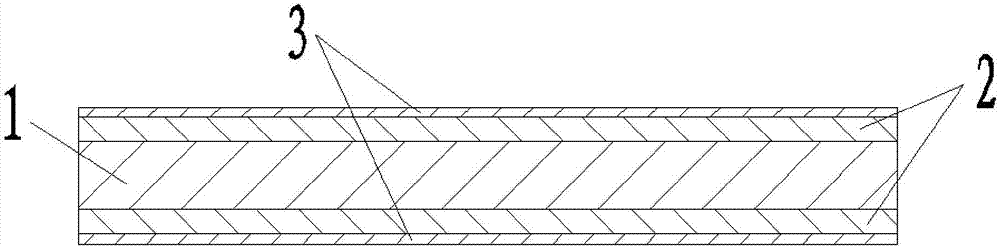

[0024] Such as figure 1 As shown, the flexible adhesive tape solder of this embodiment includes a dense metal layer 1, and both sides of the dense metal layer 1 are provided with an adhesive layer 2 formed by an adhesive, and on the adhesive layer 2 A release paper layer 3 is provided.

[0025] The dense metal layer is BNi-2 amorphous foil (BNi-2: BNi82CrSiB), the binder is ethyl cyanoacrylate, and the release paper is glassine release paper; the nickel base alloy The thickness of the amorphous strip is 0.01mm, the width is 10mm, and the length is 100mm, and the coating thickness of the adhesive is 0.001mm.

[0026] The flexible adhesive tape solder of this embodiment and the existing BNi-2 solder paste are used for the brazing of stainless steel 304 workpieces and stainless steel 316 workpieces respectively. When the flexible adhesive tape solder of this embodiment is used, first remove the release paper Layer 3 is torn off, and then the flexible sticky tape solder is attac...

Embodiment 2

[0028] The structure of the flexible adhesive tape solder in this embodiment is the same as that of the flexible adhesive tape solder in Embodiment 1. The difference is that: the dense metal layer is BNi-2 amorphous strip, the binder is ethyl cyanoacrylate, and the release paper is glassine release paper; the nickel-based alloy is amorphous The thickness of the strip is 2mm and the width is 1×10 3 mm, length 1×10 9 mm, the coating thickness of the adhesive is 1 mm.

[0029] The flexible adhesive tape solder of this embodiment and the existing BNi-2 solder paste are used for the brazing of stainless steel 304 workpieces and stainless steel 316 workpieces respectively. When the flexible adhesive tape solder of this embodiment is used, first remove the release paper Layer 3 is torn off, and then the flexible sticky tape solder is attached to the welding position for brazing, and the tensile pressure at the welded seam after brazing is 750MPa; Tensile strength is 468MPa, theref...

Embodiment 3

[0031] The structure of the flexible adhesive tape solder in this embodiment is the same as that of the flexible adhesive tape solder in Embodiment 1. The difference is that the dense metal layer is a silver-based alloy strip, the grade of the silver-based alloy is Ag-28Cu, and Ag-28Cu belongs to a crystalline alloy, the binder is ethyl cyanoacrylate, and the ion The type paper is glassine release paper; the thickness of the nickel-based alloy amorphous strip is 0.1mm, the width is 1mm, and the length is 1×10 5 mm, the coating thickness of the adhesive is 1×10 -4 mm.

[0032] The flexible adhesive tape solder of the present embodiment and the existing Ag-28Cu solder paste are used for the brazing of the copper workpiece and the brass workpiece. When the flexible adhesive tape solder of the present embodiment is used, the release paper layer 3 Tear it off, and stick the flexible sticky tape solder on the welding position for brazing. The tensile compressive strength of the we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com