Cadmium-free and low-silver filler metal containing manganese and tin and production method of cadmium-free and low-silver filler metal

A technology of silver brazing filler metal and trace elements, which is used in manufacturing tools, welding equipment, metal processing equipment, etc., can solve the problem of high silver elements, achieve stable quality, improve deep processing performance, and reduce the effect of melting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

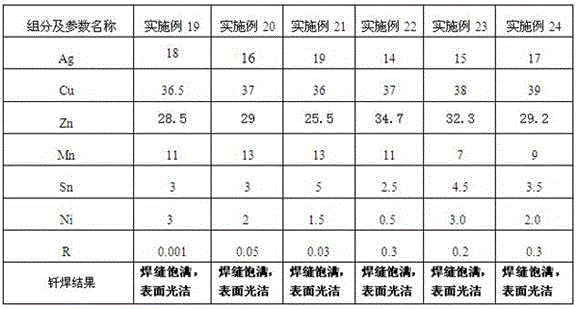

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0017] Example.

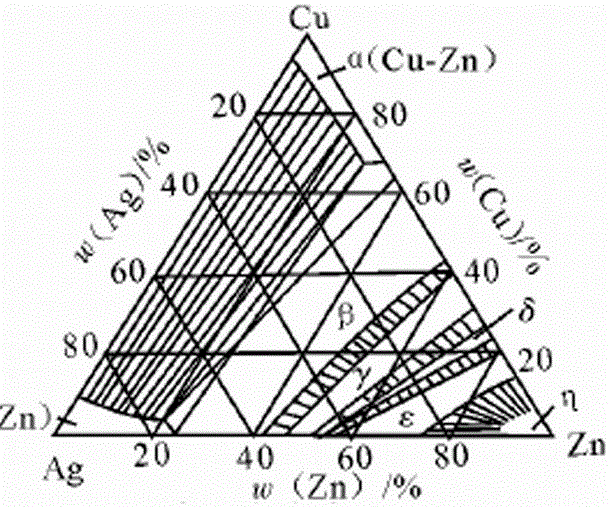

[0018] see figure 1 .

[0019] The silver solder in this example uses silver IC-Ag99.99, No. 1 standard copper, national standard Zn99.995, Cu-Mn intermediate alloy, Sn99.95AA and trace Cu-R alloy. The smelting furnace is used for smelting and casting, and then it is prepared by sawing, extruding, drawing, forming, cleaning and other processes.

[0020] The embodiment of the present invention is prepared by sequentially adding Ag, Cu, Sn, Zn, Cu-Mn, adding a small amount of Cu-R alloy, and then casting, sawing, extruding, drawing, forming, cleaning and other processes. The obtained brazing material has a melting temperature range of 685-765° C., and can be processed into brazing materials such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com