Novel tin-and-indium-containing multi-component cadmium-and-silver-free brazing filler metal

A multi-component, silver solder technology, applied in welding/cutting medium/material, welding medium, metal processing equipment, etc., can solve the problems of high cost, high silver content, unfavorable popularization and use of rare earth solder, etc. Effects of increased shear strength, reduced cost, and improved processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

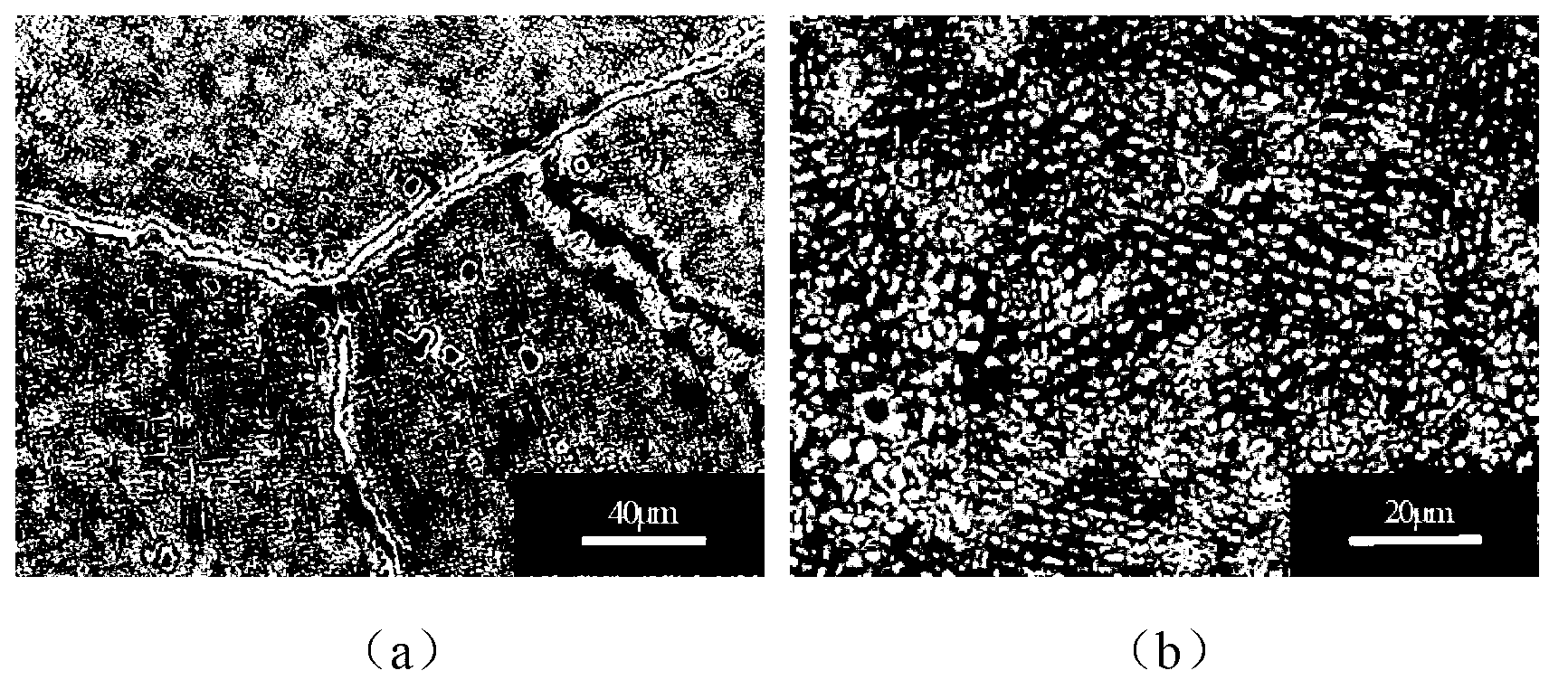

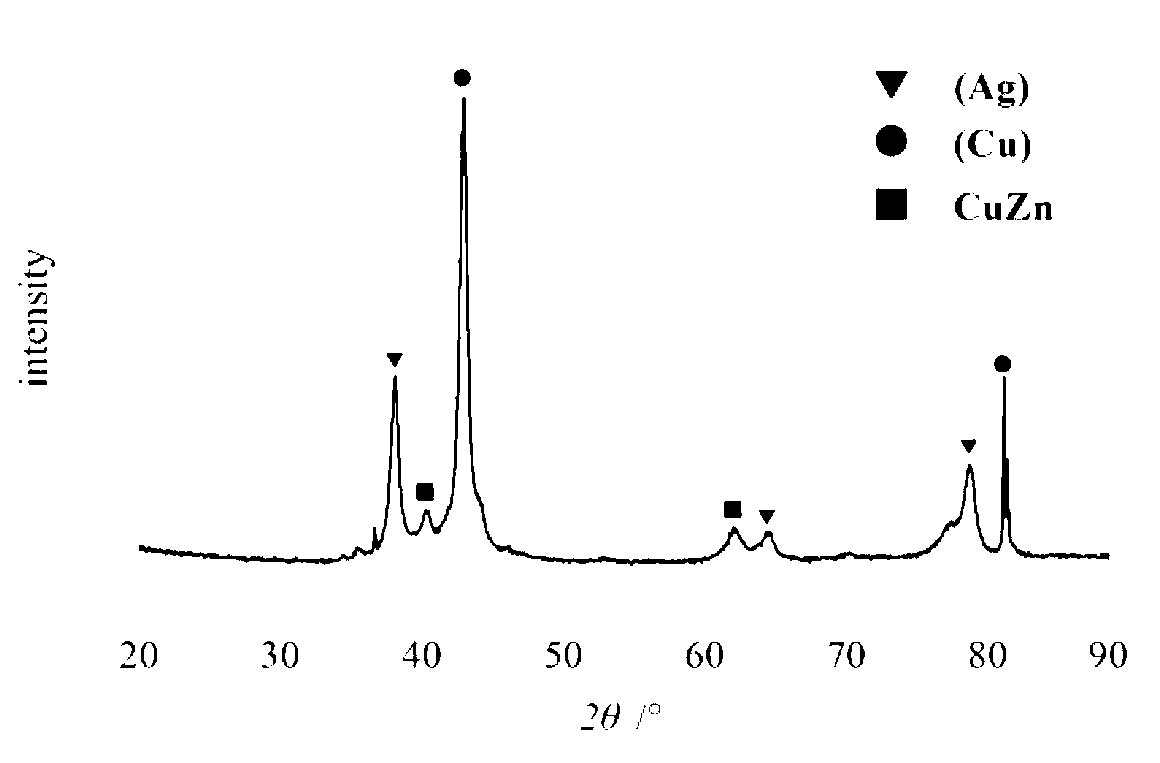

[0020] The mass percentage components of the solder in this embodiment are: Ag: 25.02%, Cu: 36.18%, Zn: 33.84%, In: 1.04%, and the remainder is Sn.

[0021] In this embodiment, the solidus temperature of the solder is 713°C, the liquidus temperature is 730°C, and the interval between the solidus and the liquidus temperature is 17°C. The wetting ratio on red copper is 2.32, the electrical conductivity is 9.6MS / m, the microhardness is 228Hv, and the shear strength of the brazed copper-red copper brazing joint is 225.49MPa.

Embodiment 2

[0023] The components of the solder in this embodiment are: Ag: 25.74%, Cu: 36.65%, Zn: 32.83%, In: 1.20%, and the remainder is Sn.

[0024] In this embodiment, the solidus temperature of the solder is 701°C, the liquidus temperature is 720°C, and the interval between the solidus and the liquidus temperature is 19°C. The wetting ratio on red copper is 2.63, the electrical conductivity is 9.5MS / m, the microhardness is 215Hv, and the shear strength of the brazed copper-red copper brazing joint is 224.62MPa.

Embodiment 3

[0026] The components of the solder in this embodiment are: Ag: 25%, Cu: 37%, Zn: 34%, In: 1%, and the remainder is Sn.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Liquidus temperature | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com