Preparation method of ultrasonic microarc oxidation silver-carrying antibiotic bioactive coating on magnesium and titanium surface

A bioactive, micro-arc oxidation technology, applied in the direction of surface reaction electrolytic coating, coating, anodic oxidation, etc., can solve the problems of hydroxyapatite decomposition, low interface bonding strength, high internal stress of the coating, etc., to achieve good anti-corrosion Corrosion, guaranteed production cost, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

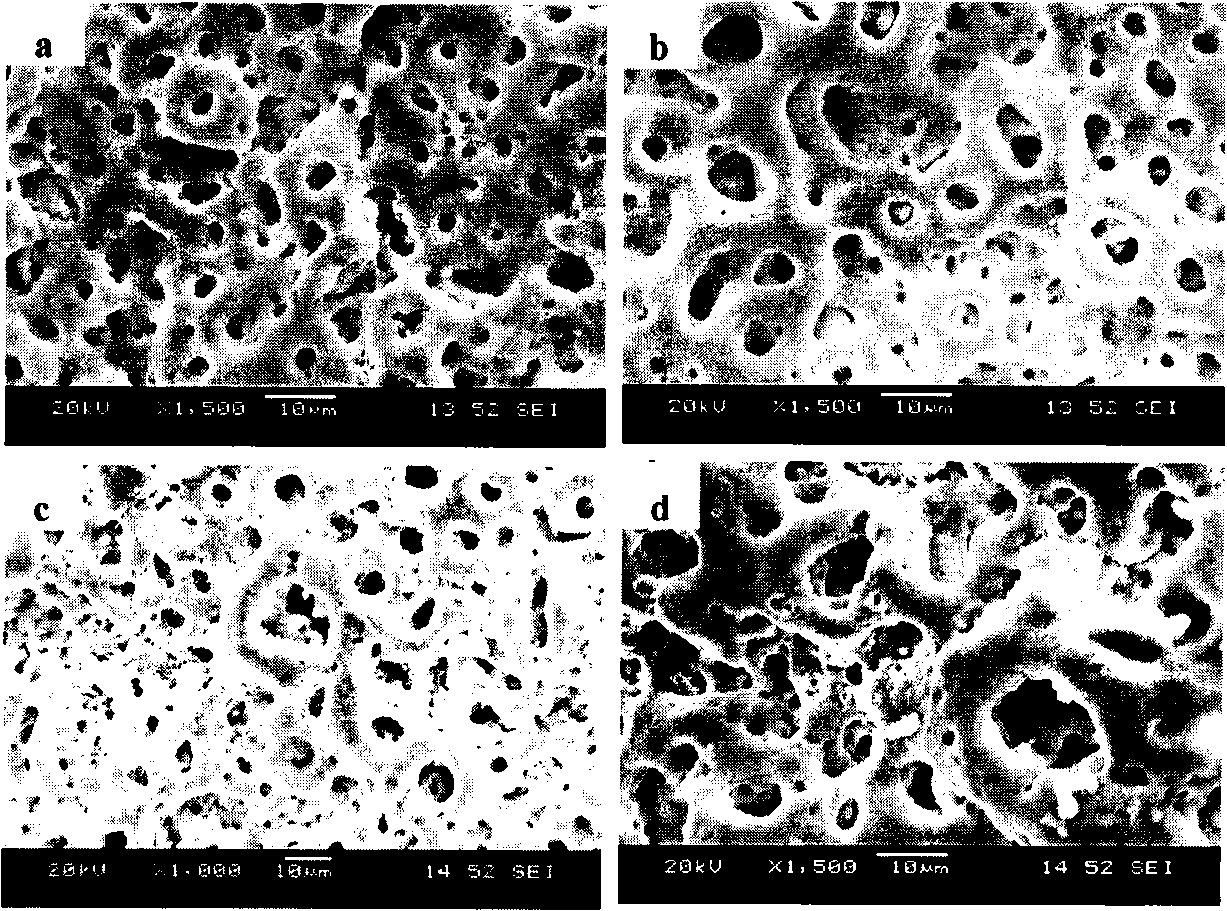

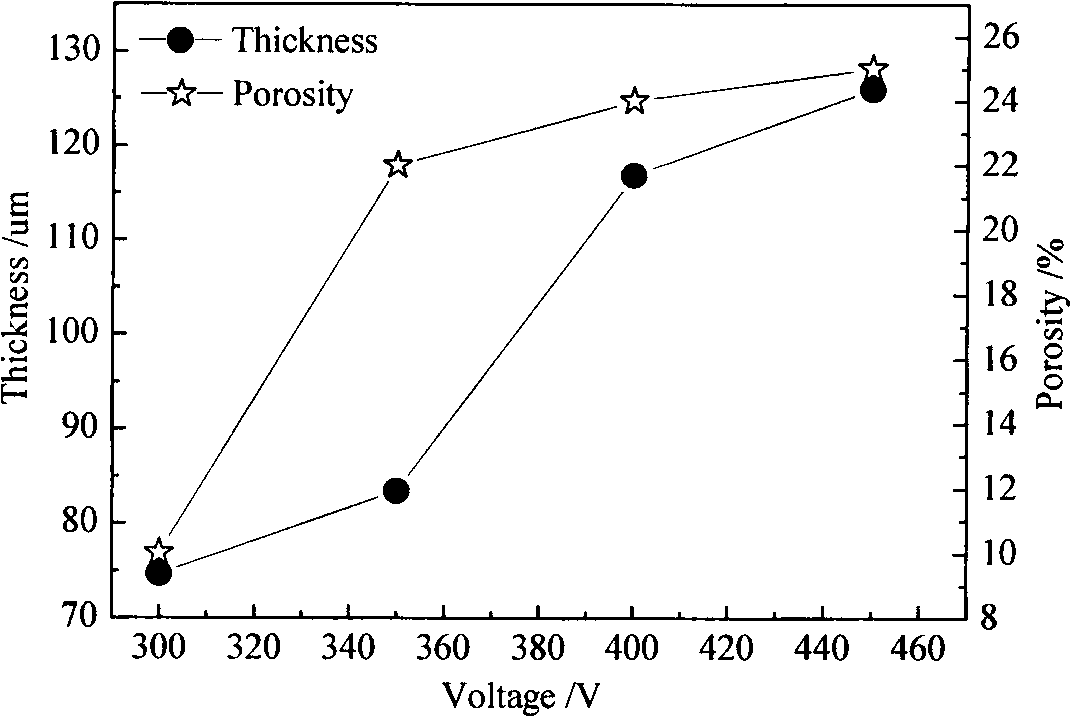

[0066] Embodiment 1: Magnesium, titanium surface supersonic micro-arc oxidation silver-carrying antibacterial bioactive coating preparation method (change oxidation voltage) at first utilize micro-drilling machine to drill a round hole at the top of titanium alloy sample, rough surface on sandpaper Grind, then ultrasonically clean with acetone and distilled water for 20 minutes each, then perform sandblasting, then ultrasonically clean with distilled water for 30 minutes, dry naturally, tie 1.3mm aluminum wire to the drilled hole, put it in a sealed bag and seal it for later use . After the magnesium and titanium alloys are pretreated, the micro-arc oxidation electrolyte is configured, and the solvent of the electrolyte is distilled water, which is deionized water. Take 1L of distilled water for later use, weigh the main electrolyte required for the experiment, 20gNH 4 h 2 PO 4 and 31gCa(CH 3 COO) 2 ·H 2 O (Ca / P ratio of 0.9), then 1 L of distilled water was placed in tw...

Embodiment 2

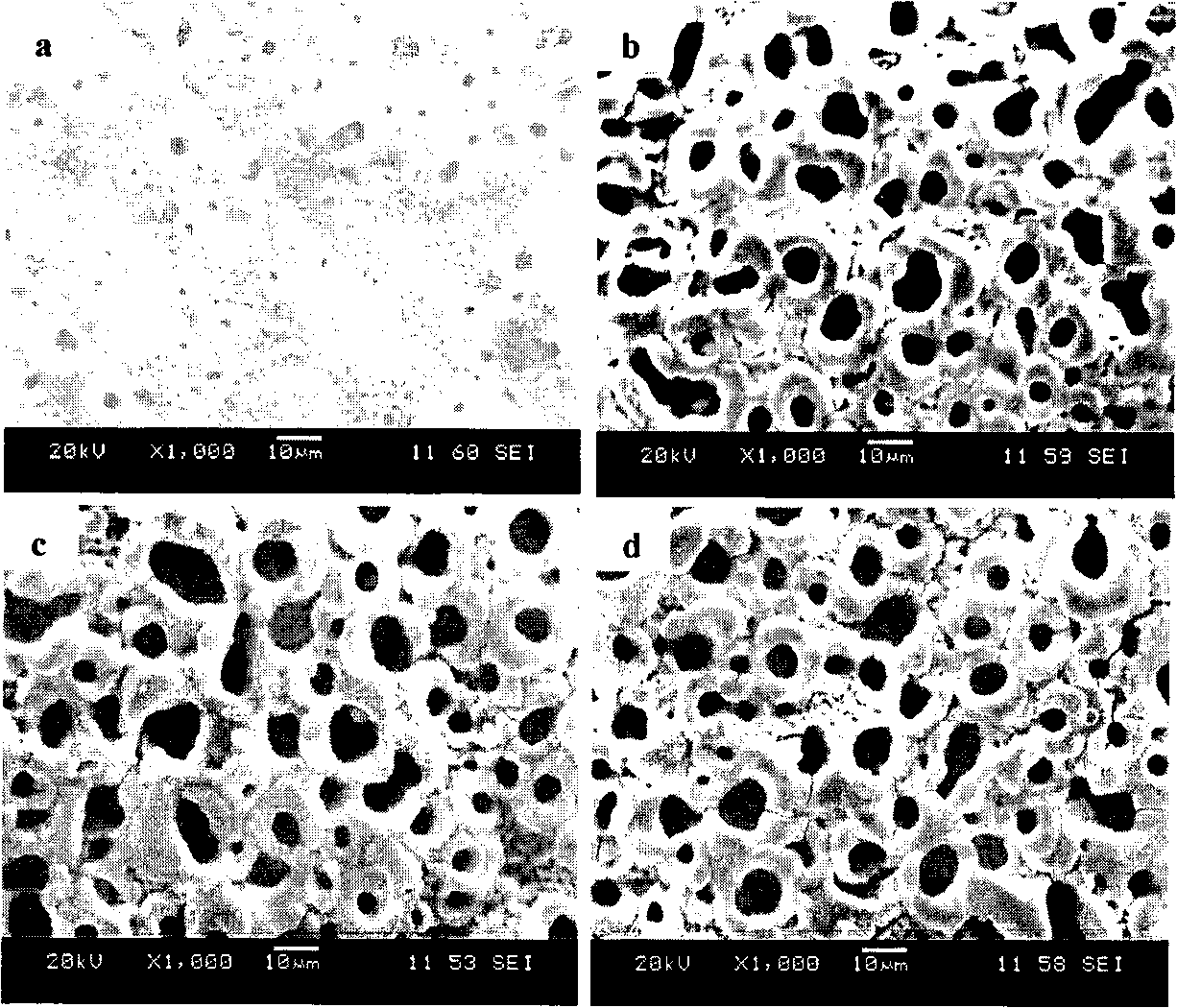

[0067] Embodiment 2: Preparation of magnesium, titanium surface ultrasonic micro-arc oxidation silver-loaded antibacterial bioactive coating (change oxidation time)

[0068] First configure the micro-arc oxidation electrolyte, and the solvent of the electrolyte is distilled water. Take 1L of distilled water for later use, and then weigh the basic electrolyte required for the experiment, 20gNH 4 h 2 PO 4 and 31gCa(CH 3 COO) 2 ·H 2 O (Ca / P ratio is 0.9), then 1 L of distilled water was placed in two beakers, one with the electrolyte Ca (CH 3 COO) 2 ·H 2 O, one added electrolyte NH 4 h 2 PO 4 , placed in a magnetic stirrer and stirred for about 1 hour, until the electrolyte was completely dissolved and dispersed evenly, and then the Ca(CH 3 COO) 2 ·H 2 The solution of O is poured into the solution containing NH 4 h 2 PO 4 solution, put it on a magnetic stirrer and stir for about 1 hour until the two solutions are fully mixed, and the order of pouring cannot be cha...

Embodiment 3

[0069] Embodiment 3: the preparation of magnesium, titanium surface ultrasonic micro-arc oxidation silver-loaded antibacterial bioactive coating (changing AgNO 3 content)

[0070] First, use a micro-drilling machine to drill a round hole on the top of each titanium alloy sample with a 1.4mm drill bit, then use sandpaper to roughly grind the surface, then use acetone ultrasonic cleaning and distilled water ultrasonic cleaning for 20 minutes each, and perform sandblasting. Afterwards, use distilled water to ultrasonically clean for 30 minutes, and after drying naturally, tie a 1.3mm aluminum wire to the drilled hole, put it in a sealed bag and seal it for later use. After the titanium alloy is pretreated, the micro-arc oxidation electrolyte is configured, and the solvent of the electrolyte is distilled water, which is deionized water. Take 1L of distilled water for later use, first weigh the main electrolyte required for the experiment on an electronic scale, 20gNH 4 h 2 PO ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com