Conducting ink and preparation method thereof

A technology of conductive ink and conductive filler, applied in inks, household appliances, applications, etc., can solve the problems of unfavorable industrialization, high production cost, high silver content, and achieve good void filling, improved electrical conductivity, and high electron mobility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A conductive ink, comprising the following components in parts by mass: 35-55 parts of conductive filler, 20-30 parts of binder, 9-21 parts of solvent, and 2-5 parts of auxiliary agent; wherein, the conductive filler It includes graphene, flake silver powder and spherical silver powder, and the graphene, flake silver powder and spherical silver powder respectively account for 0.2-2 parts, 30-40 parts and 5-15 parts of the total amount of conductive filler.

[0035] In this embodiment, the graphene is intrinsic graphene, the number of layers is 1-10, the sheet size is 1-5 μm, and the average thickness is less than 3 nm.

[0036] In this embodiment, the average particle size of the flake silver powder is 2.0-5.0 μm, and the tap density is 1.8-3.0 g / cm 3 , the bulk density is 0.8-1.4 g / cm 3 , the specific surface area is 0.7-1.4m 2 / g.

[0037] In this embodiment, the average particle diameter of the spherical silver powder is 0.4-1.2 μm, and the tap density is 4.5-5.2 ...

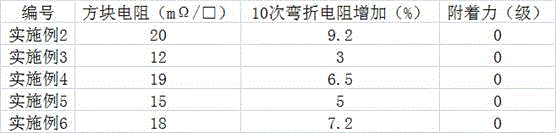

Embodiment 2

[0053] A conductive ink, comprising the following components in parts by mass: 35 parts of conductive fillers, 20 parts of binders, 21 parts of solvents, 2 parts of stabilizers; wherein, the conductive fillers include graphene, flaky silver powder and Spherical silver powder, the graphene, flaky silver powder and spherical silver powder respectively account for 0.2 parts, 30 parts and 5 parts of the total amount of conductive filler.

[0054] In this embodiment, the adhesive is obtained by stirring epoxy resin and solvent at a temperature of 90° C. for 4 hours and filtering while hot.

[0055] This embodiment also provides a preparation method of conductive ink, comprising the steps of:

[0056] (1) Preparation of binder

[0057] Take the solvent and add it to the reaction kettle, add epoxy resin in proportion while stirring at 90°C, the mass ratio of solvent to epoxy resin is 4:1, after the epoxy resin is completely soaked and dissolved, keep it warm at 80°C for 4 hours, and...

Embodiment 3

[0067] A conductive ink, comprising the following components in parts by mass: 55 parts of conductive filler, 30 parts of binder, 9 parts of solvent, 5 parts of auxiliary agent; wherein, the conductive filler includes graphene, flaky silver powder and Spherical silver powder, the graphene, flaky silver powder and spherical silver powder respectively account for 2 parts, 40 parts and 15 parts of the total amount of conductive filler.

[0068] In this embodiment, the binder is obtained by stirring a polyamide resin and a solvent at a temperature of 60° C. for 4 hours and filtering while hot.

[0069] This embodiment also provides a preparation method of conductive ink, comprising the steps of:

[0070] (1) Preparation of binder

[0071] Take the solvent and add it to the reaction kettle, and add the polyamide resin in proportion under stirring at 60°C. The mass ratio of solvent to polyamide resin is 4:1. After the polyamide resin is completely soaked and dissolved, keep it warm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com