Patents

Literature

38results about How to "Small resistance change rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Conducting ink and preparation method thereof

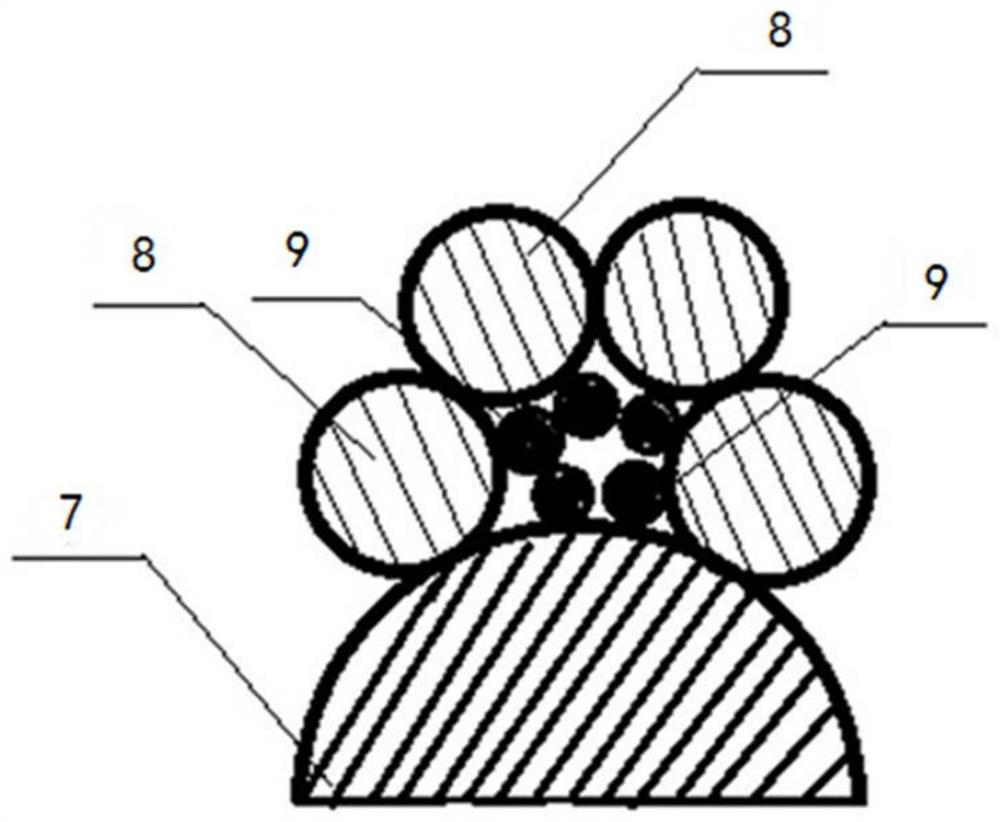

The invention discloses conducting ink, which is prepared from the following ingredients in parts by mass: 35 to 55 parts of conducting filling materials, 20 to 30 parts of bonding agents, 9 to 21 parts of solvents and 2 to 5 parts of auxiliary agents, wherein the conducting filling materials comprise grapheme, flaky silver powder and ball-shaped silver powder; the grapheme accounts for 0.2 to 2 parts of the total amount of the conducting filling materials; the flaky silver powder accounts for 30 to 40 parts of the total amount of the conducting filling materials; the ball-shaped silver powder accounts for 5 to 15 parts of the total amount of the conducting filling materials. The invention also discloses a preparation method of the conducting ink. The method comprises the following steps of (1) bonding agent preparation; (2) grapheme precursor preparation; (3) crude pulp preparation; (4) grinding and filtering; (5) finished product obtaining. The preparation method has the advantages that the conducting performance and the anti-bending performance of the ink can be obviously improved; in addition, the characteristics of wide printing applicability, low conducting ink solid content and the like are realized.

Owner:DEYANG CARBONENE TECH

Novel rapid solidification low-temperature conductive silver paste and preparation method therefor

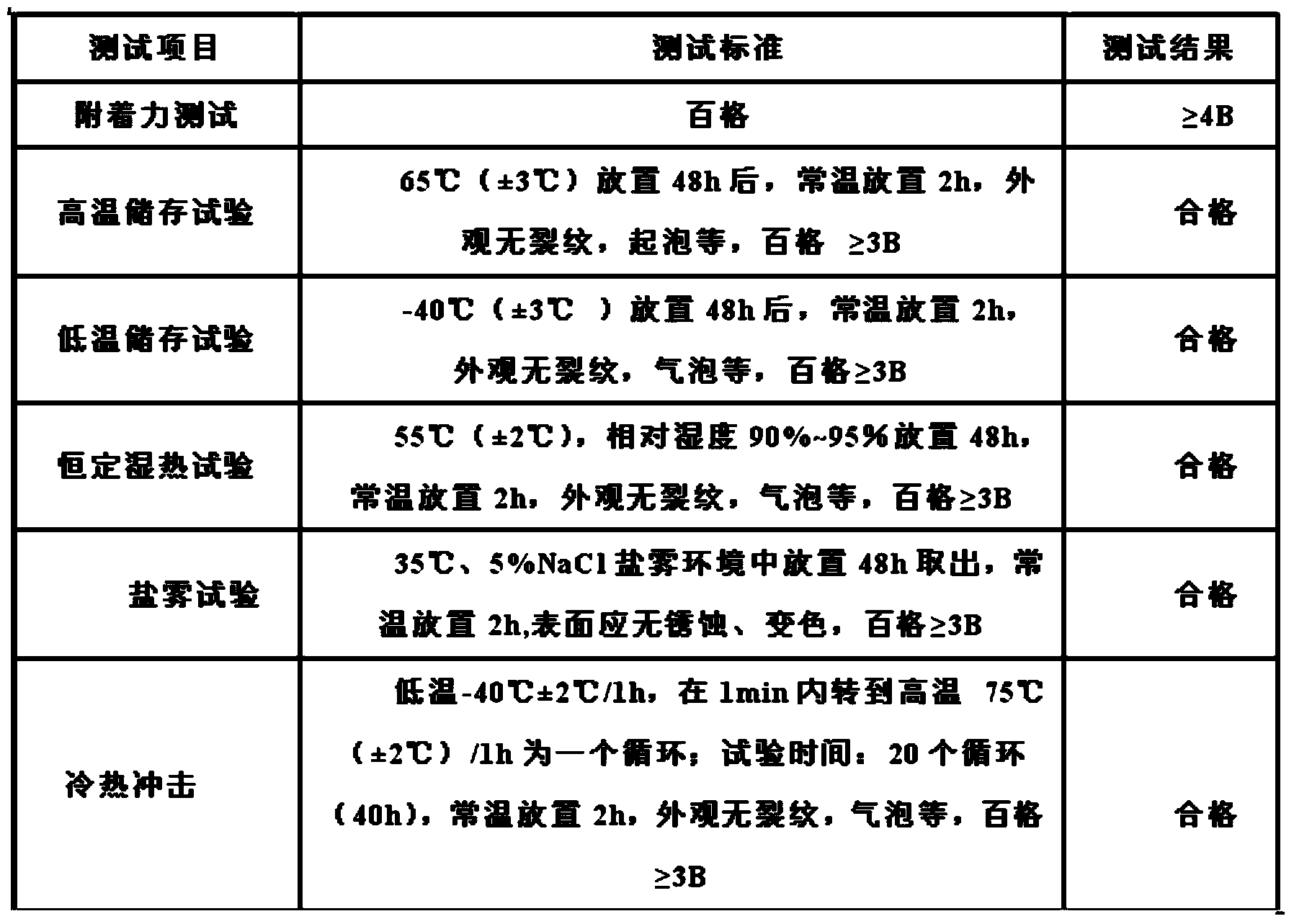

InactiveCN108447587AShort curing timeSmall resistance change rateNon-conductive material with dispersed conductive materialCable/conductor manufactureSolventImage resolution

The invention provides a novel rapid solidification low-temperature conductive silver paste and a preparation method therefor, and belongs to the field of electronic paste of information function newmaterials. The conductive silver paste contains the following components by mass percentage: 45-55% of silver powder, 5-12% of thermoplastic resin, 0.5-1% of thermosetting resin, 0.1-0.5% of heat curing agent, 1-2% of an addition agent and 30-45% of a solvent, wherein the sum of the weight percentages of the components is 100%. The prepared conductive silver paste is short in solidification time,and is completely solidified in 1-2 min under the temperature of 150 DEG C. The conductive silver paste is suitable for precise screen printing. The resolution can reach 100*100 microns, the conductive silver paste is 5B after solidification, and the hardness is greater than 2H. The printing thickness is 4-6 microns, the resistance change rate is less than 280% after 10 forwarding and reverse folding times, and the resistivity is less than 3.5*10<-5>ohm*cm.

Owner:SINO PLATINUM METALS CO LTD

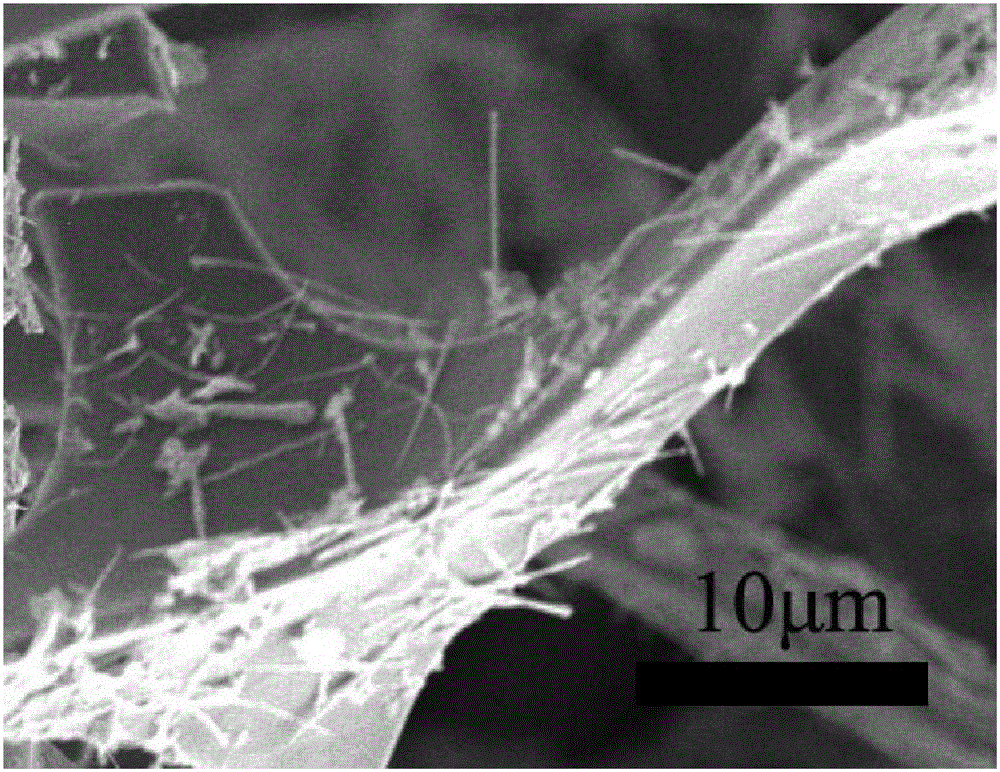

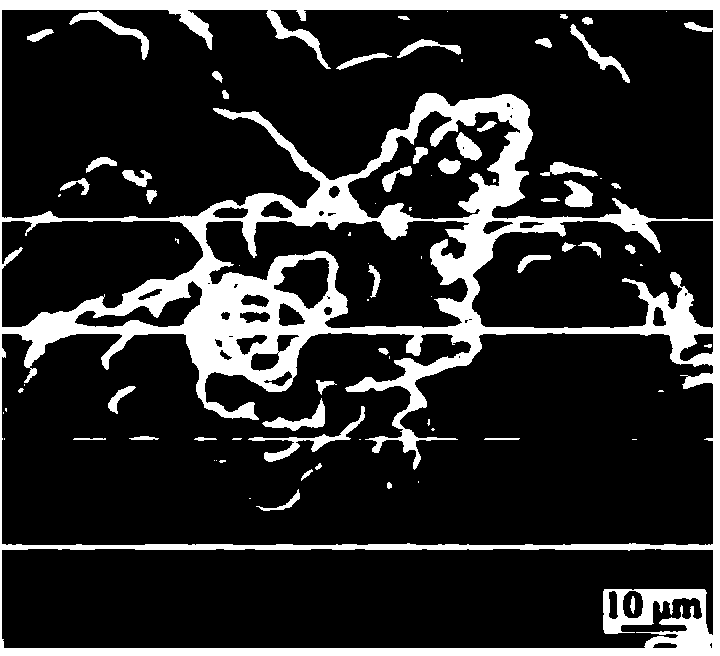

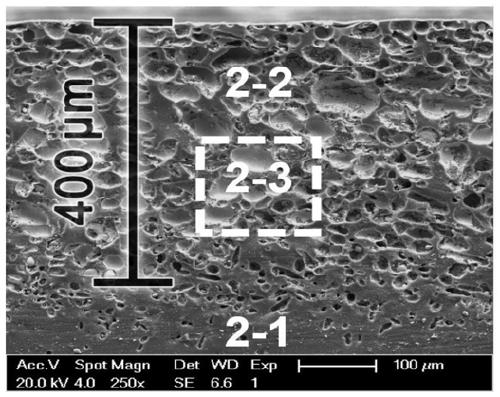

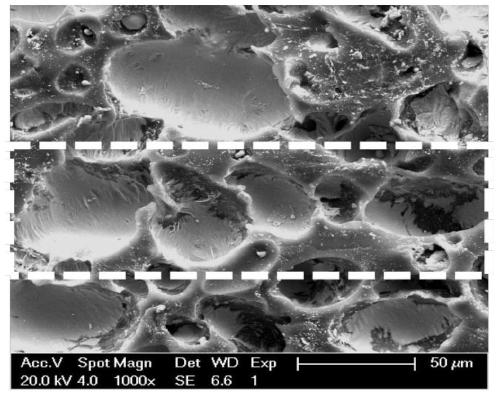

Preparation method and application for composite elastomer containing graphene coated copper nanowire

ActiveCN106653159AWide variety of sourcesLow priceMaterial nanotechnologyConductive layers on insulating-supportsElastomerCvd graphene

The invention relates to a composite elastomer containing a graphene coated copper nanowire. The composite elastomer comprises a porous material and a graphene coated metal nanowire. The graphene coated metal nanowire is grown on a skeleton of the porous material. The porous material is a rebounding porous material. The composite elastomer containing the graphene coated copper nanowire provided by the invention can rebound and recover to an original shape within 2 seconds after being pressed and released, after the composite elastomer is pressed and released for the first time, a resistance change rate is smaller than 2%, after the composite elastomer is pressed and released for 100 times, the composite elastomer can still rebound to the original shape, and the resistance change rate is smaller than 10%.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

Transparent conductive film and preparation method thereof

InactiveCN108231245AUniform diameterGood dispersionConductive layers on insulating-supportsApparatus for manufacturing conducting/semi-conducting layersComposite filmCopper wire

The invention relates to a transparent conductive film and a preparation method thereof, and belongs to the technical field of preparation of conductive films. With copper chloride as a copper source,oleic acid and oleylamine as inducers, glucose as a reducing agent and polyvinylpyrrolidone as a stabilizer, copper nanowires with high length-diameter ratio, uniform diameter, good dispersibility and regular morphology are prepared; through formation of a network with smaller linear density, a longer penetration path is provided, internal copper wire nodes are reduced, the resistivity is reduced, and a transparent metal film with low haze, high transparency, high conductivity and excellent mechanical flexibility and strength is achieved; then the copper nanowires are covered with an aqueouspoly(3,4-ethylenedioxythiophene)-polystyrene sulfonic acid solution to prepare a composite film to improve the oxidation resistance of the copper nanowires, so that the energy absorbing ability of themetal film layer during folding deformation is enhanced, the slippage degree of conductive particles is reduced, and thus the resistance change rate of a coating layer is reduced and the flexibilityand the electrical stability of a product are further improved.

Owner:常州市丰瑞电子有限公司

Solvent-free conductive silver adhesive with stable contact resistance

InactiveCN102329587AIncrease contact resistanceCompact structureNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesEpoxyOrganic solvent

The invention discloses a solvent-free conductive silver adhesive with a stable contact resistance, which relates to a conductive binding agent. The solvent-free conductive silver adhesive is a single-component conductive adhesive which is prepared by taking silver powder as a main body through adding organic carrier accessories into the main body; in the conductive adhesive, the mass percent of the main body (silver powder) is 70-75%, the mass percent of the organic carrier accessories is 25-30%, and the mass percent of a curing agent is 0.1-0.5%; the silver powder refers to flaked silver powder or branched silver powder; the organic carrier is composed of two types of epoxy resins and a kind of thermosetting phenolic resins, wherein the mass percent of the epoxy resins is 80-90%, and the mass percent of the thermosetting phenolic resins is 10-20%; and the curing agent refers to an imidazole type polymer or amine curing agent. The solvent-free conductive silver adhesive disclosed by the invention has the advantages that no organic solvent is added, the heating temperature of the conductive silver adhesive is less than that of a conductive adhesive prepared in the prior art, and the time consumption for curing is reduced; a heated / cured product is compact in structure and uneasy to have electrochemical corrosion, and the moisture absorption is reduced; and the solvent-free conductive silver adhesive has high contact resistance stability and good conductivity.

Owner:贵州振华亚太高新电子材料有限公司

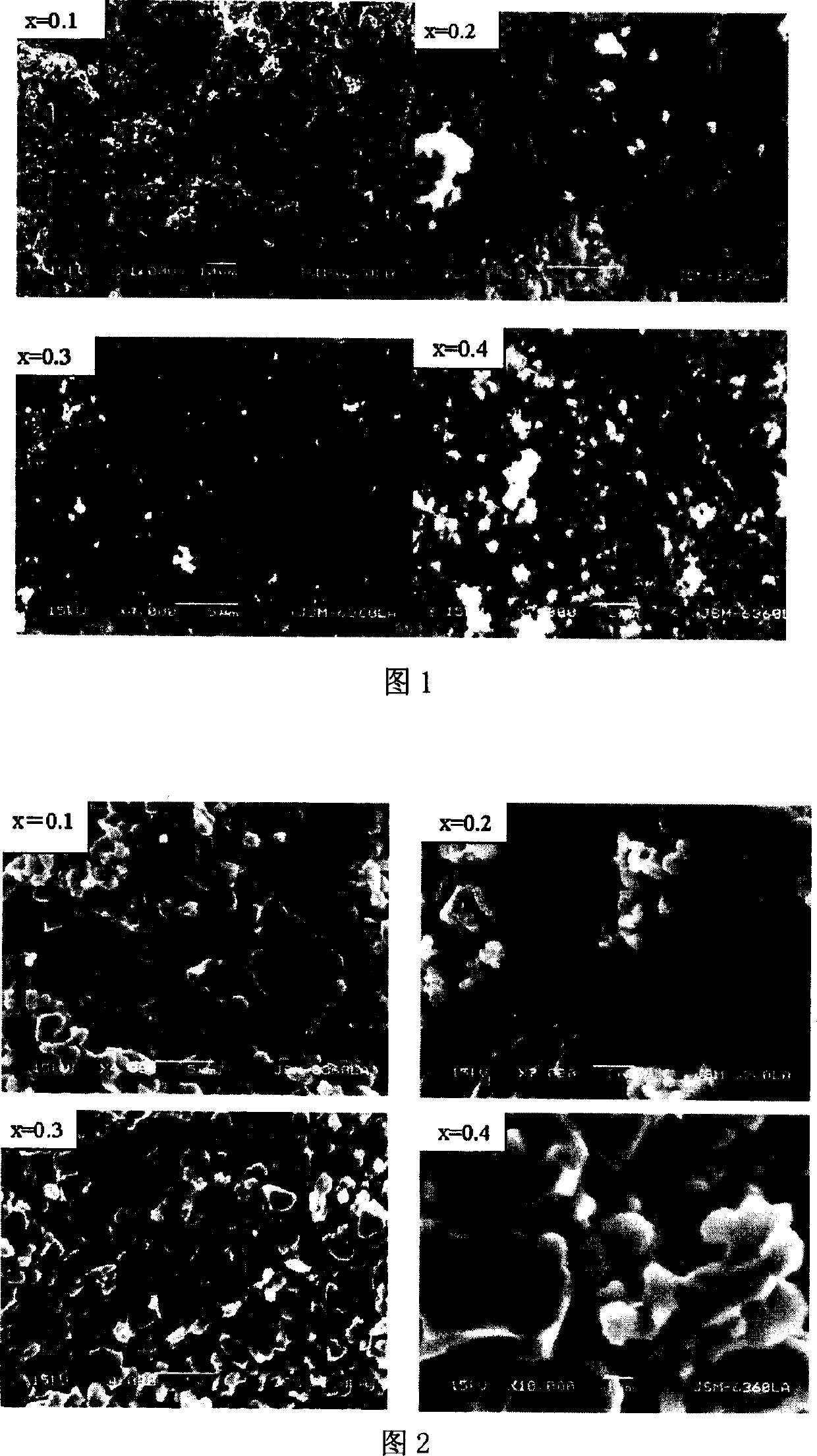

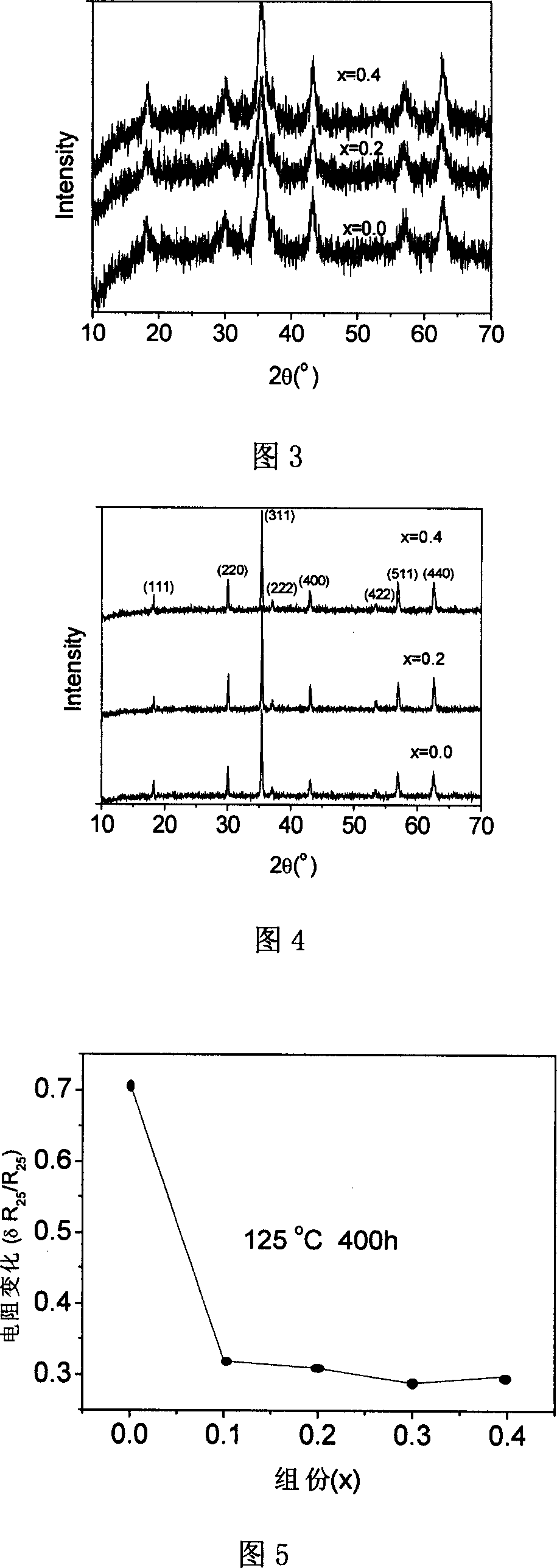

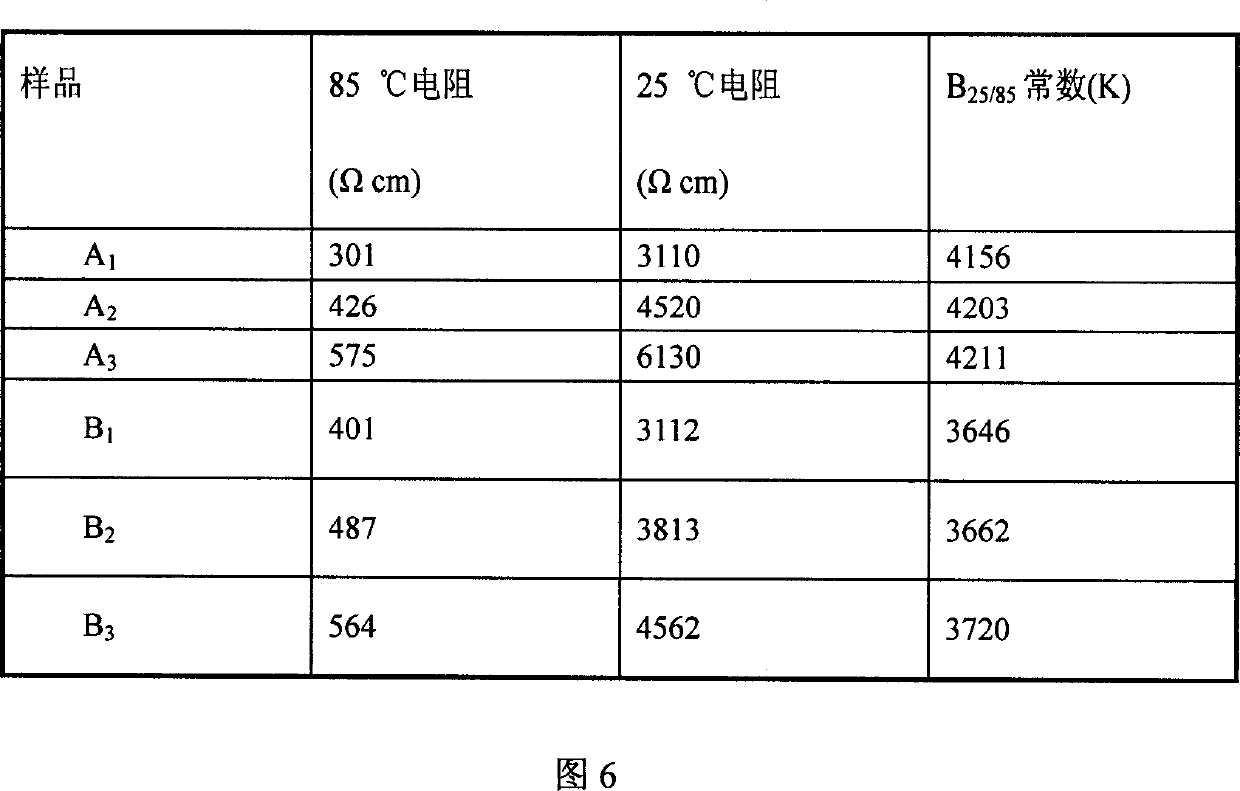

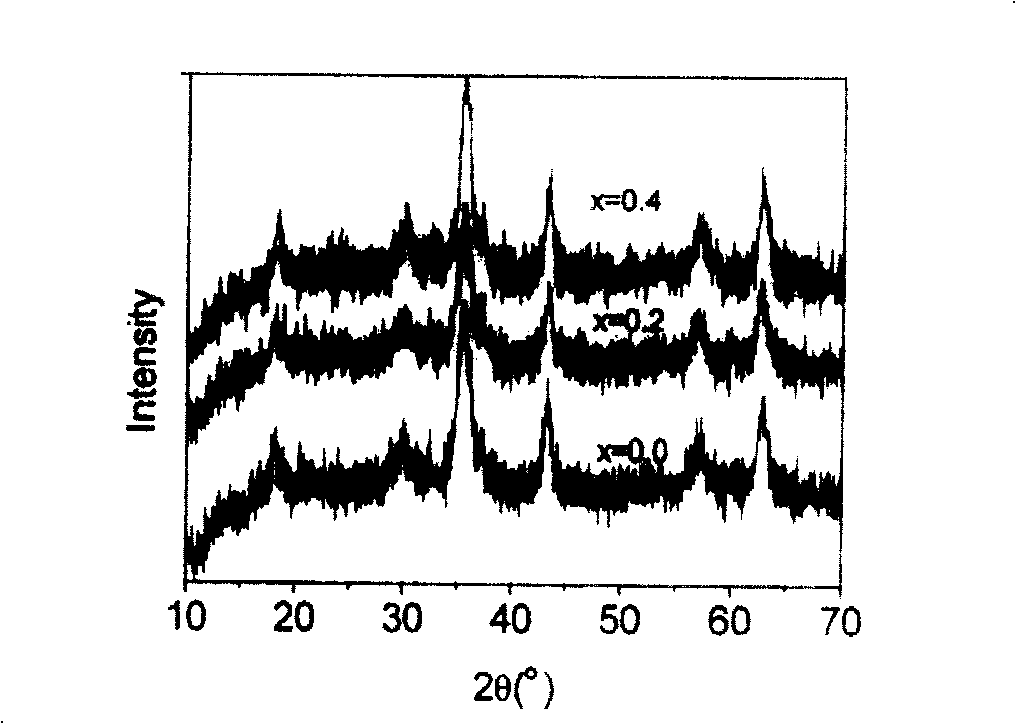

High precision thermosensitive resistor nanometer powder production method

This invention discloses a method for producing a high accuracy thermistor nanometer powder, which uses the nitrate of Cr, Ni, Mn as raw material. The method comprises the following steps: a,adding citrate, carbowax and ammonia, heating and mixing, hydrolyzing and aggregation to form transparent colloidal solution; b, drying the colloidal solution and getting dried gel, self-igniting the gel and getting the nanometer powder. By said method, the powder has good materiality, and the size of the powder paritcle can reach to 40-60 nanometer, the powder is spinel structure, after burning its size is between 1 and 2 ª–m. The powder can be used repeatedly, and the rate of finished products can reach to 80%. The powder can be used to produce the thermistor with high accuracy B value and good heat resistant property.

Owner:NINGBO UNIV

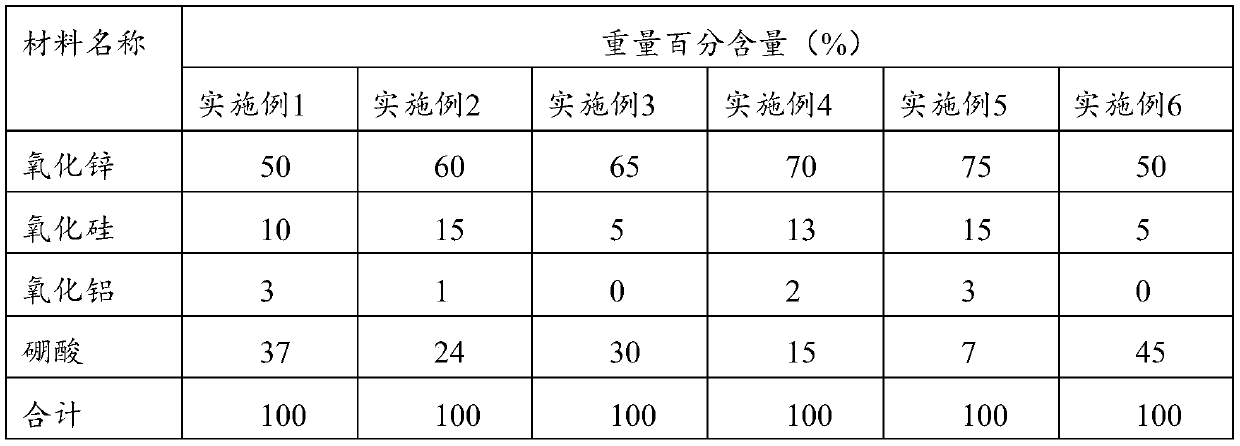

Encapsulating slurry for aluminum nitride substrate, and preparation method and application thereof

ActiveCN110642519AExpansion coefficients perfectly matchedFlat surfaceHemt circuitsPhysical chemistry

The invention provides an encapsulating slurry for an aluminum nitride substrate. The encapsulating slurry comprises 65-80 wt% of a glass powder, 0-10 wt% of an inorganic additive and 10-35 wt% of anorganic carrier; and the glass powder is prepared from 50-75 wt% of ZnO, 1-15 wt% of SiO2, 0-3 wt% of Al2O3 and 7-45 wt% of H3BO3. The encapsulating slurry for the aluminum nitride substrate is perfectly matched with the expansion coefficient of the aluminum nitride substrate, is sintered to form a smooth and flat surface, has a good binding force, and is free of toxic elements such as lead, chromium and mercury; and particularly, after the encapsulating medium slurry is sintered on a circuit on the surface of the aluminum nitride substrate, the resistance change rate of a resistance layer before and after the sintering is less than + / -5%. The invention further provides a preparation method and an application of the encapsulating slurry for the aluminum nitride substrate.

Owner:湖南利德电子浆料股份有限公司

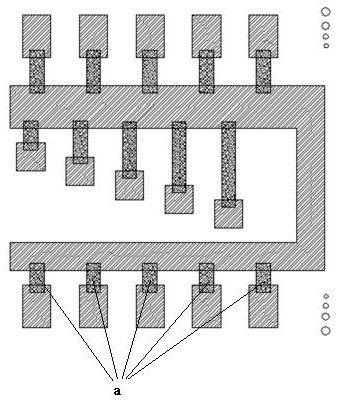

High-resistance carbon film circuit board and manufacturing method therefor

PendingCN107027240AImprove stabilityEvenly distributedLithography/patterningPrinted circuit aspectsScreen printingHigh resistance

The invention provides a manufacturing method for a high-resistance carbon film circuit board. The manufacturing method comprises the following steps of a, designing a silk screen pattern and manufacturing a silk screen; b, printing conductive metal paste on a PCB through silk screen printing by means of frictioning, and performing drying to form a conductive metal circuit; c, printing high-resistance ink on the conductive metal circuit through silk screen printing by means of frictioning, and performing drying to form a first high-resistance carbon film, wherein the first high-resistance carbon film is 7-9[mu]m in thickness; and d, paving the silk screen on the first high-resistance carbon film, printing the high-resistance ink on the first high-resistance carbon film through silk screen printing by means of frictioning, and performing drying to form a second high-resistance carbon film, wherein the second high-resistance carbon film is 7-9[mu]m in thickness. According to the manufacturing method, the original one-time printing and shaping process is divided into two times of printing, so that carbon distribution can be more uniform and resistance change rate of the formed product can be lowered; and the high-resistance carbon film is high in stability, so that the yield of the product can be effectively improved.

Owner:东莞福哥电子有限公司

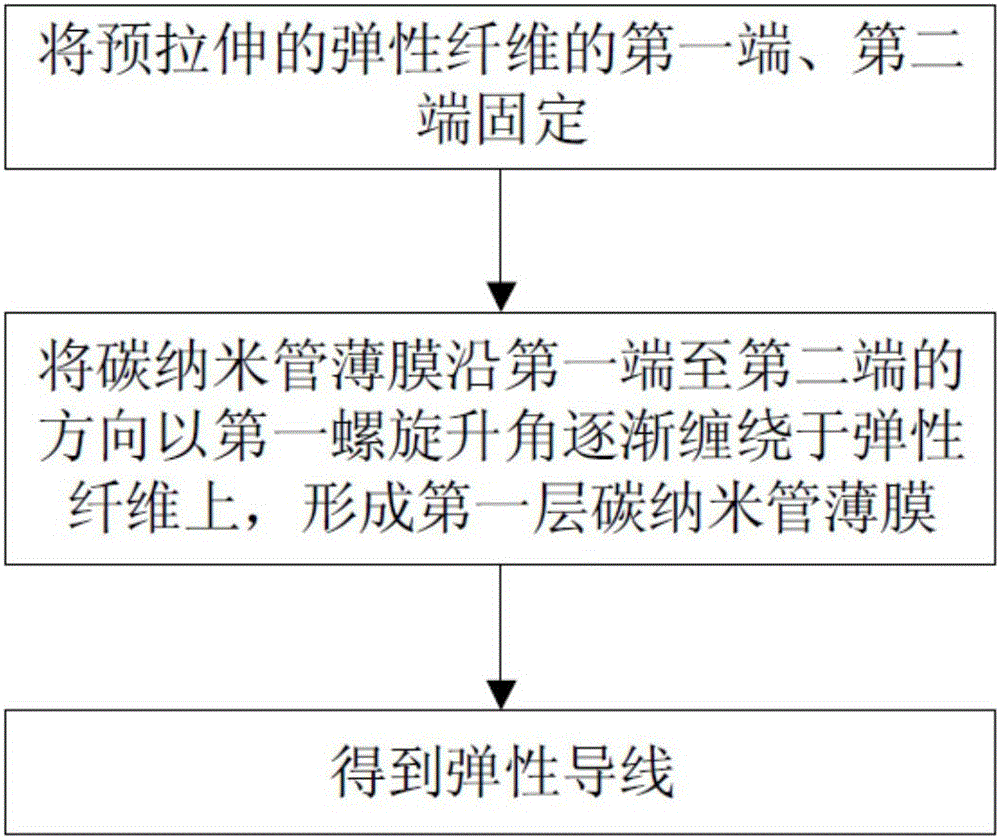

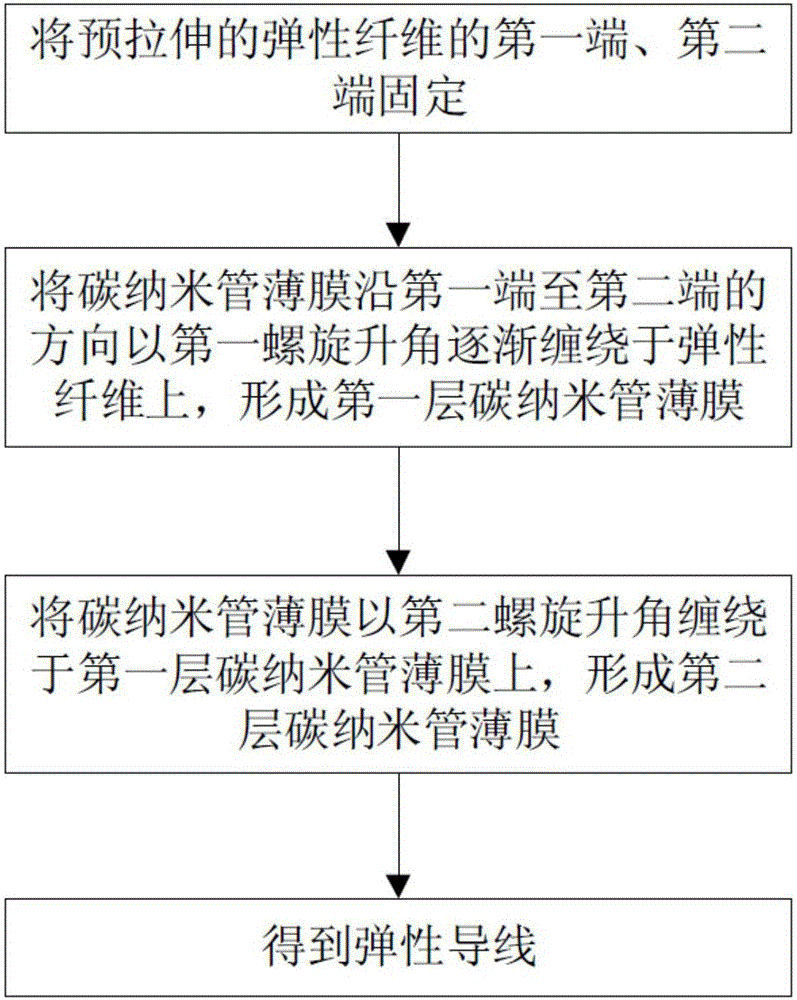

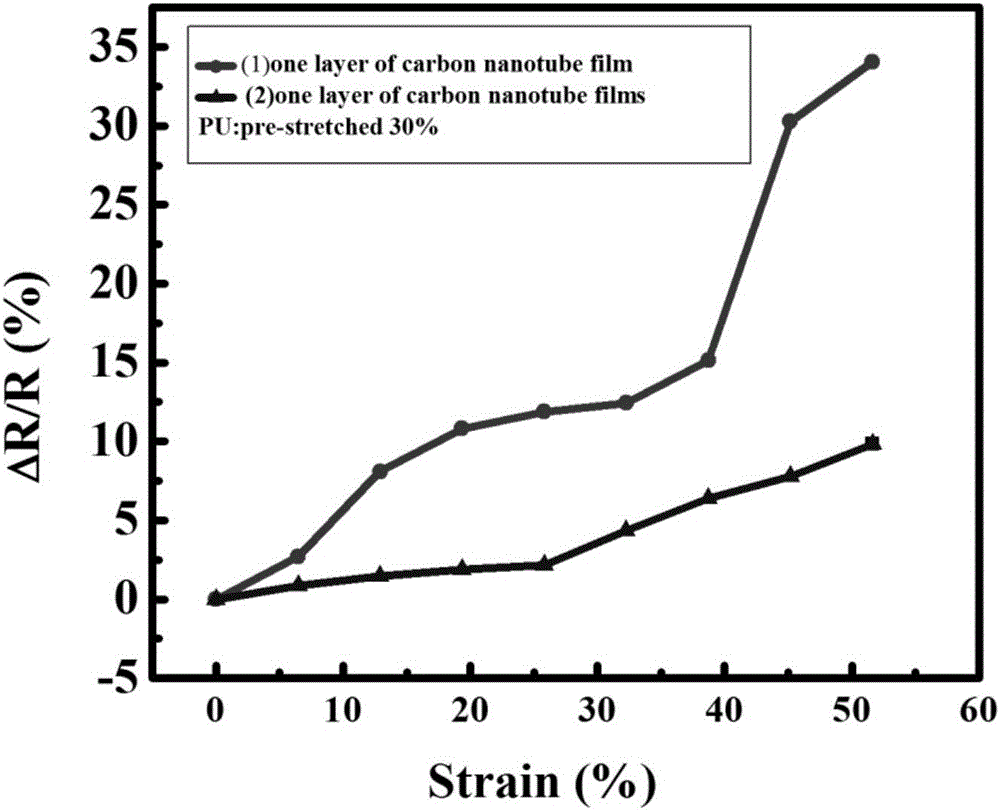

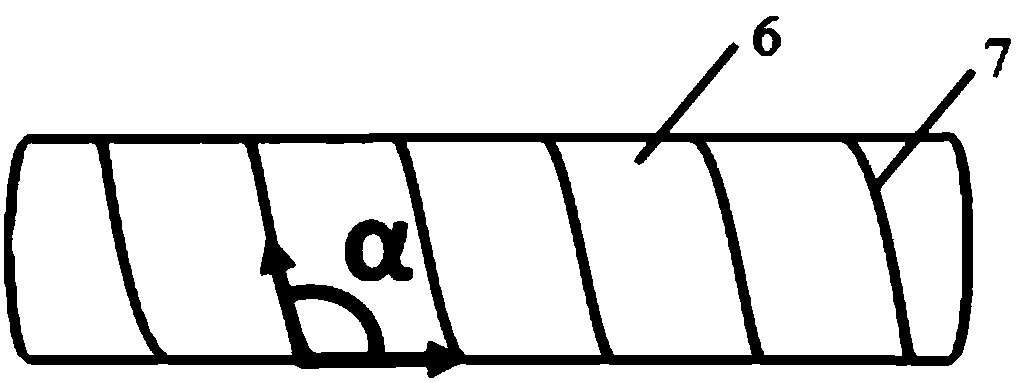

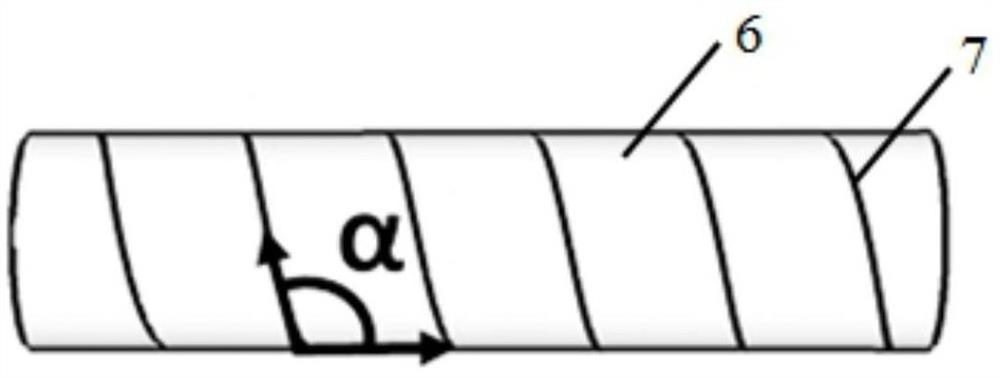

Elastic guide wire and preparation method thereof

InactiveCN106024656AHigh elongationSmall resistance change rateSemiconductor/solid-state device detailsSolid-state devicesFiberElectrical resistance and conductance

The invention discloses an elastic guide wire and a preparation method thereof. The preparation method comprises the steps of: fixing a first end and a second end of a pre-stretched elastic fiber; gradually winding a carbon nanotube thin film on the elastic fiber along the direction from the first end to the second end at a first helix angle to form a first layer of carbon nanotube thin film; and obtaining the elastic guide wire. Compared with the prior art, the preparation method has the beneficial effects that the prepared elastic guide wire has high elasticity and high stretch rate (the stretch rate can reach 300%) by pre-stretching the elastic fiber and winding the carbon nanotube thin film on the pre-stretched elastic fiber; the elastic guide wire does not greatly attenuate a contact point of the carbon nanotube thin film along with stretching to reduce the resistance change rate in the stretching process; the preparation method is simple; the cost is low; and industrialization is facilitated.

Owner:SUZHOU CREATIVE CARBON NANOTECH

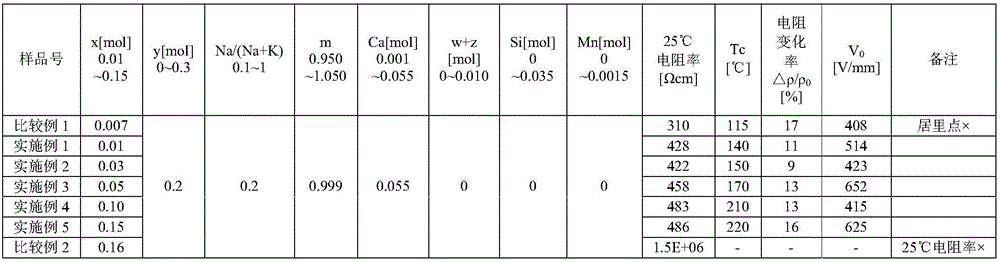

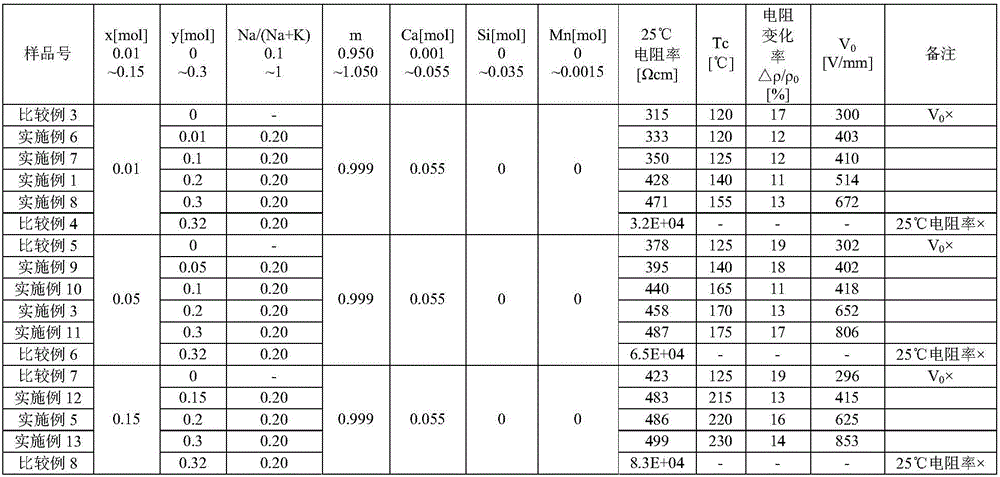

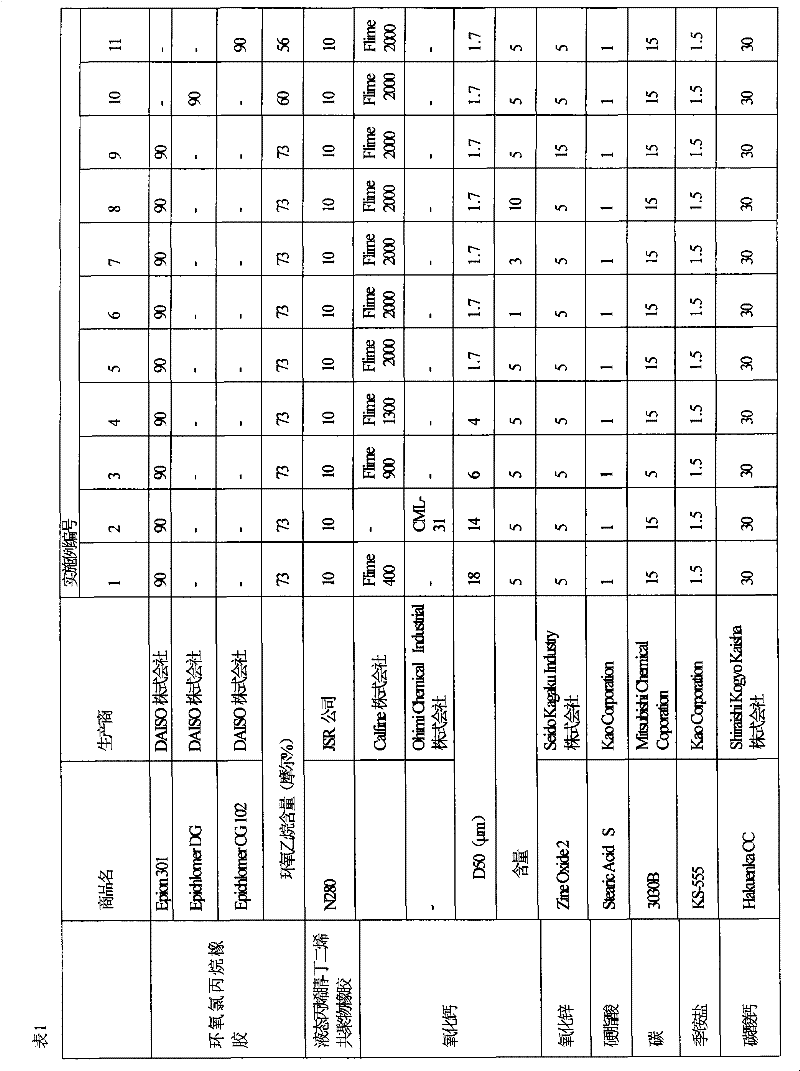

Semiconductor ceramic composition and PTC thermistor

InactiveCN106431390ASmall resistance change ratePositive temperature coefficient thermistorsThermistorsMetallurgyThermistor

The present invention provides a semiconductor ceramic composition comprising a compound represented by the following general formula (1) as a main component. (Ba<v>Bi<x>A<y>RE<w>)<m>(TiTM<z>)O<3> (wherein, A represents both elements of Na and K; RE is at least one element selected from the group consisting of Y, La, Ce, Pr, Nd, Sm, Gd, Dy and Er; and TM is at least one element selected from the group consisting of V, Nb and Ta.) 0.1=<x=<0.15 x=<y=<0.3 0=<w + z=<0.01 v + x + y + w = 1 u + z = 1 0.950=<m=<1.050 further, 0.001mol to 0.055mol of Ca is comprised and the ratio of Na / (Na+K) is 0.1 or more and less than 1.

Owner:TDK CORPARATION

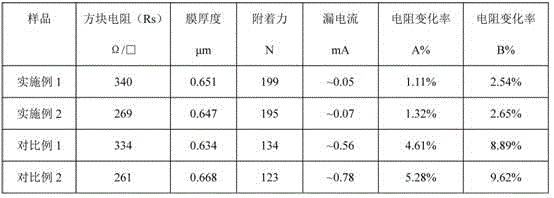

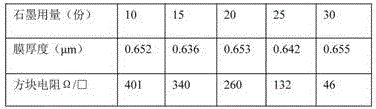

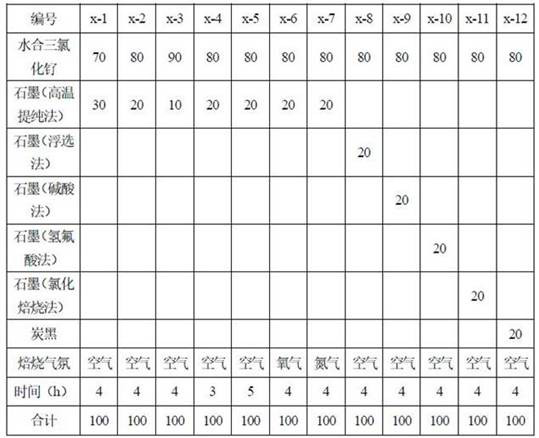

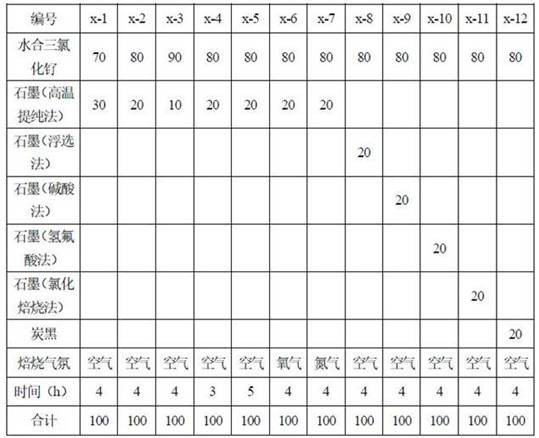

Preparation method of semiconductor electrothermal film

InactiveCN105744661AImprove electrical performanceImprove bindingHeating element materialsElectrical resistance and conductancePower flow

The invention relates to a preparation method of a semiconductor electrothermal film. The method mainly comprises the following steps: cleaning a substrate; preparing a source solution, wherein the source solution is prepared from the following components in parts by weight: 20-30 parts of stannic chloride, 10-30 parts of graphite, 10-20 parts of antimony trichloride and the like; spraying the substrate; carrying out first thermal treatment; carrying out dipping for film formation; and carrying out second thermal treatment. The semiconductor electrothermal film prepared according to the preparation method has relatively high adhesive force on the substrate and is over 190N; the leakage current is smaller than 0.10mA; the electrothermal conversion efficiency is greater than or equal to 99%; the square resistance is 45-400ohm / square; and the lifetime is over 5,000 hours.

Owner:顾伟

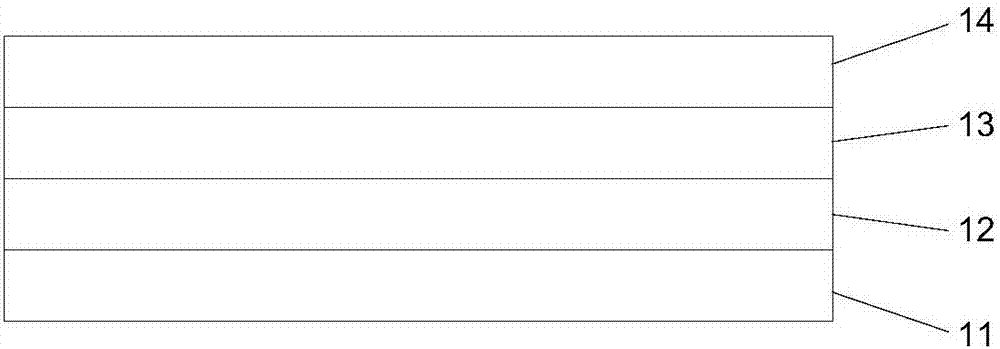

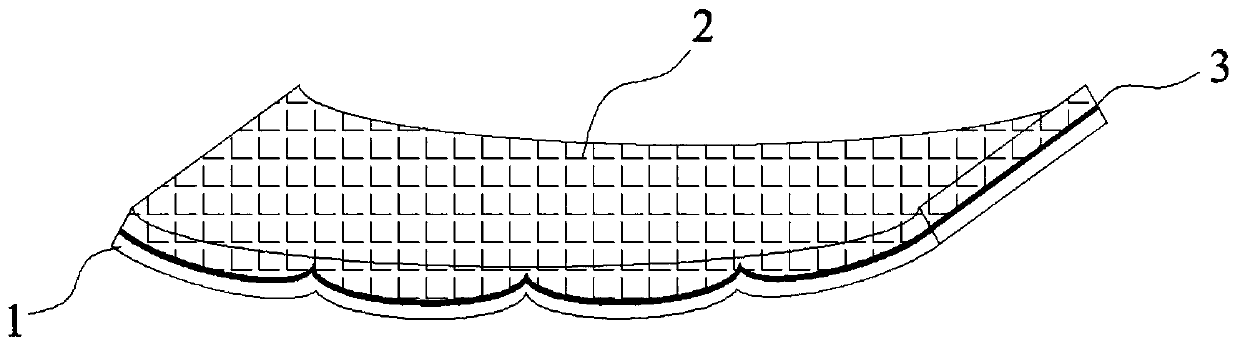

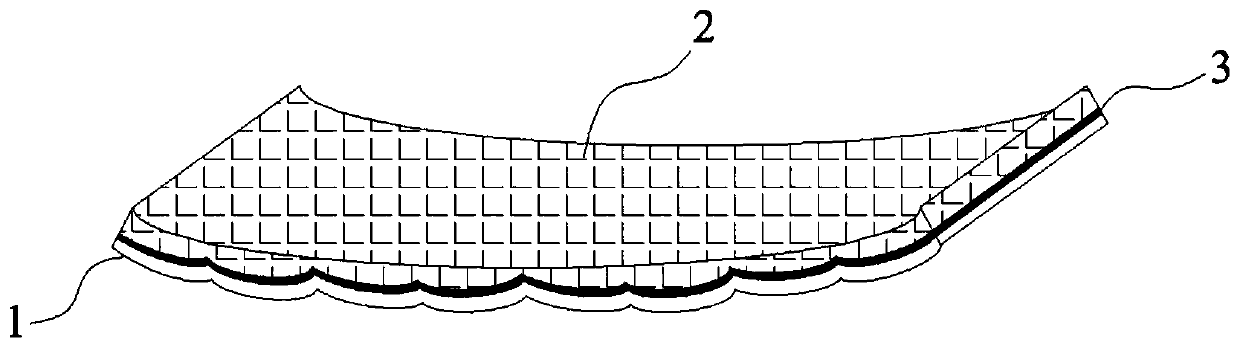

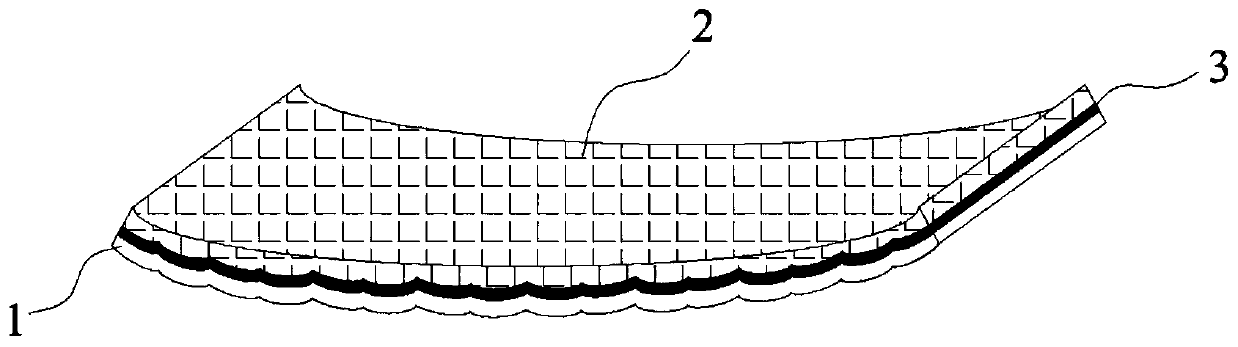

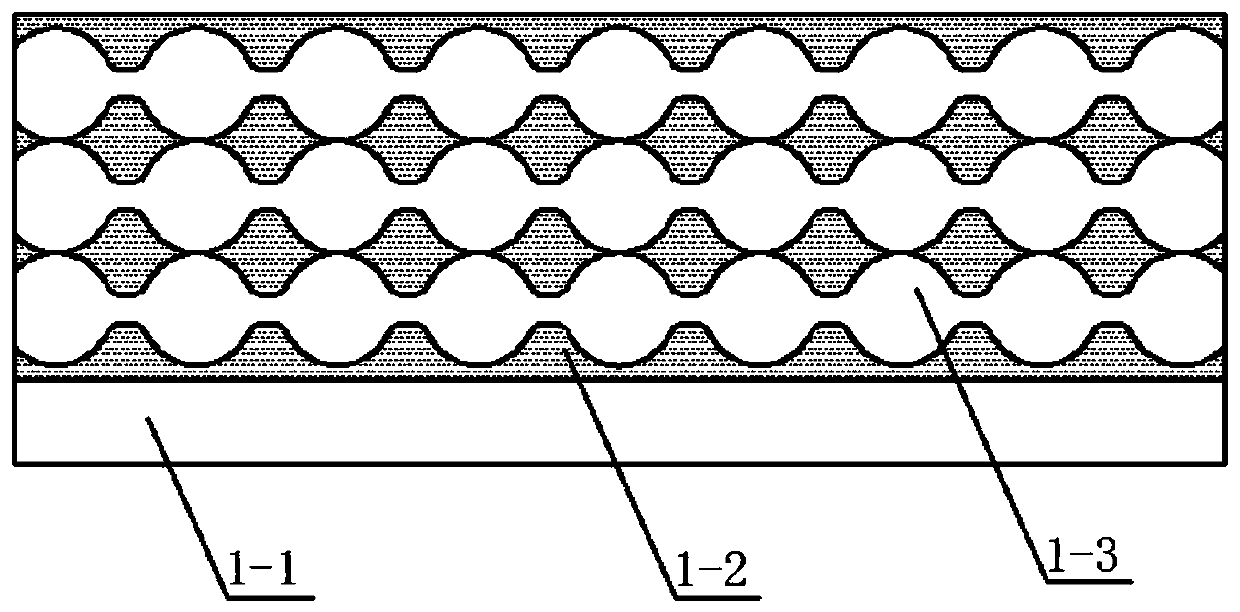

Telescopic flexible conductive film and preparation method thereof

PendingCN110379544ANo change in resistanceSmall resistance change rateMaterial nanotechnologyConductive layers on insulating-supportsEffective surfaceElastic substrate

The invention relates to a telescopic flexible conductive film. The telescopic flexible conductive film includes a first elastic substrate layer, a conductive line layer and a second elastic substratelayer, wherein the first elastic substrate layer, the conductive line layer and the second elastic substrate layer are sequentially laminated, the composite structure thus formed has a non-stretchedcurved structure as a whole, the first elastic substrate layer is selected from one of a TPU elastic film, a PET elastic film or a PI elastic film, and the second elastic substrate layer is selected from one of the TPU elastic film, rubber, silicone rubber or a TPE elastic film. The telescopic flexible conductive film is advantaged in that the first elastic substrate layer, conductive lines and the second elastic substrate layer are jointly combined into a sandwich composite structure sandwiching among the conductive lines, the first elastic substrate layer and the second elastic substrate layer can provide effective surface protection and deformation buffering for the conductive lines disposed among the two, and the conductive film is kept light and thin and has good stretchability and bendability.

Owner:GUANGDONG NANHAI ETETB TECH CO LTD

Graphene electrothermal film as well as preparation method and application thereof

The invention discloses a graphene electrothermal film as well as a preparation method and application thereof. The graphene electrothermal film is prepared from the following raw materials in parts by weight: 68-90 parts of graphene oxide, 30-40 parts of water-based fluorocarbon resin, 11-15 parts of calcium dinonylnaphthalene sulfonate, 10-15 parts of zinc lactate and 6-18 parts of 2,5-furan dioctyl phthalate. The graphene electrothermal film disclosed by the invention is prepared from the graphene oxide, the water-based fluorocarbon resin, calcium dinonylnaphthalenesulfonate, zinc lactate and the 2,5-furan dioctyl phthalate, and has excellent repeated bending resistance, electrical conductivity and heat conductivity; the graphene electrothermal film disclosed by the invention also has the advantages of high elongation at break, high strength, strong adhesive force, small leakage current, low resistance change rate and the like; and the preparation process is simple and can realize industrial production.

Owner:内蒙古石墨烯材料研究院

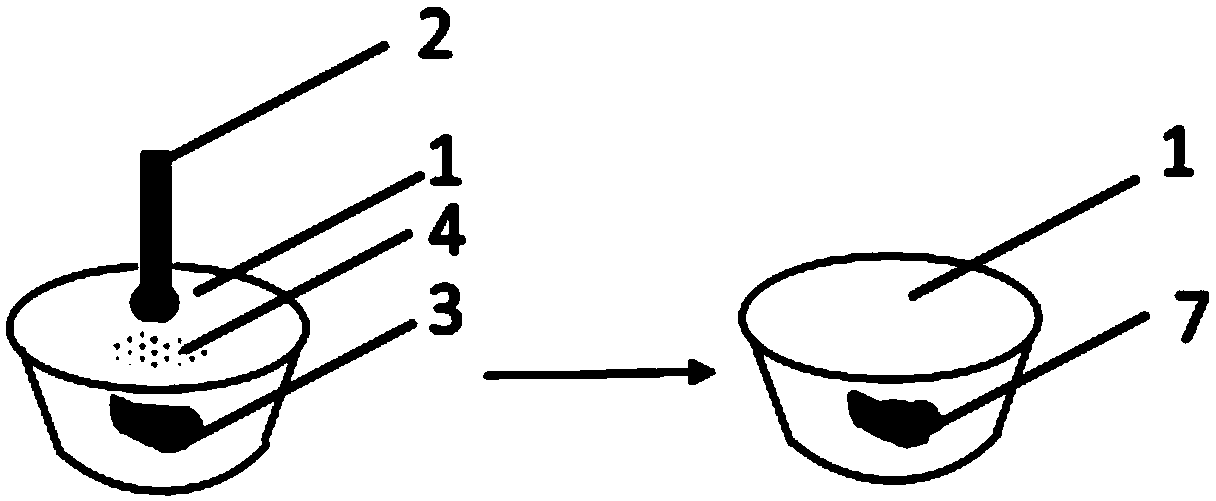

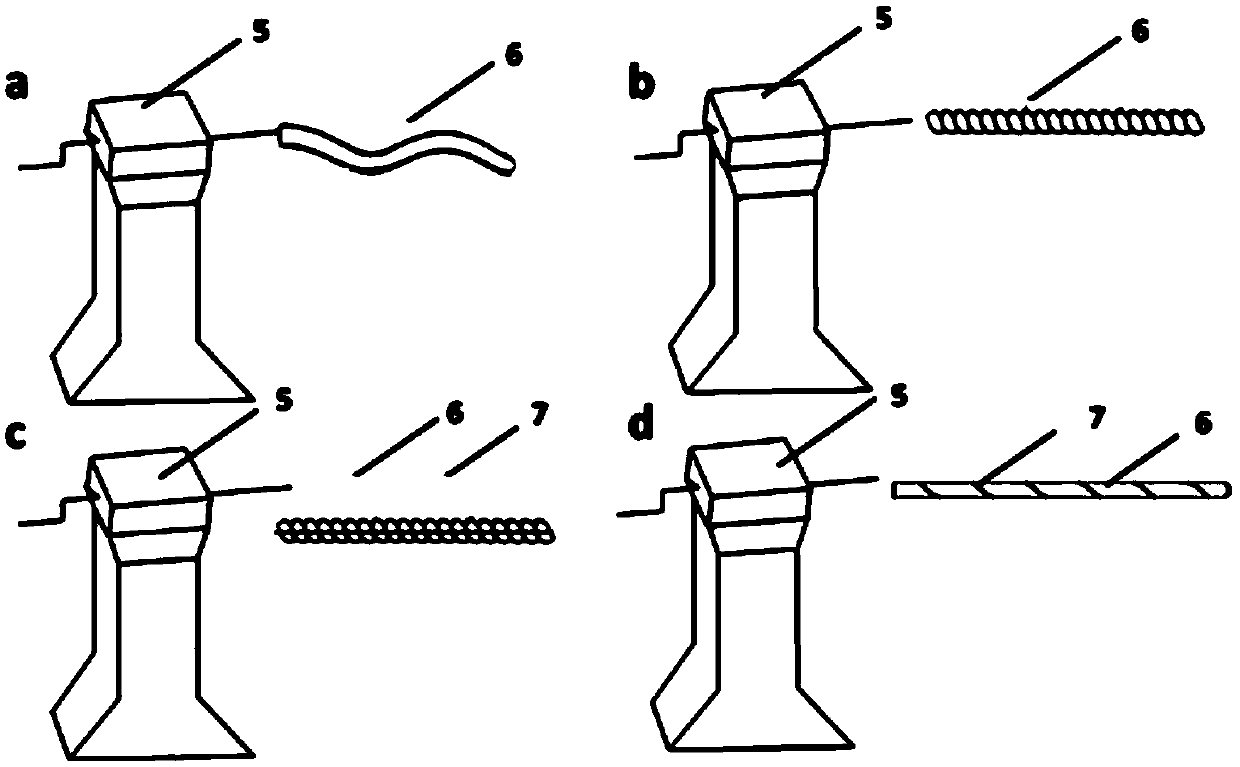

Elastic conductor and preparation method thereof

ActiveCN111415770AGood deformabilityImprove conductivityConductive layers on insulating-supportsSingle bars/rods/wires/strips conductorsElectrical resistance and conductanceLiquid metal

The invention discloses an elastic conductor and a preparation method thereof. The elastic conductor comprises an elastic base body and liquid metal, wherein the elastic base body is non-conductive, and the liquid metal is attached to the surface of the elastic base body and is in a continuous spiral winding shape on the periphery of the elastic base body. The elastic conductor is prepared by adopting a torsion forming process. When the elastic conductor is stretched and deformed, the resistance change rate is small, and the elastic conductor has potential application value in flexible electronic devices.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

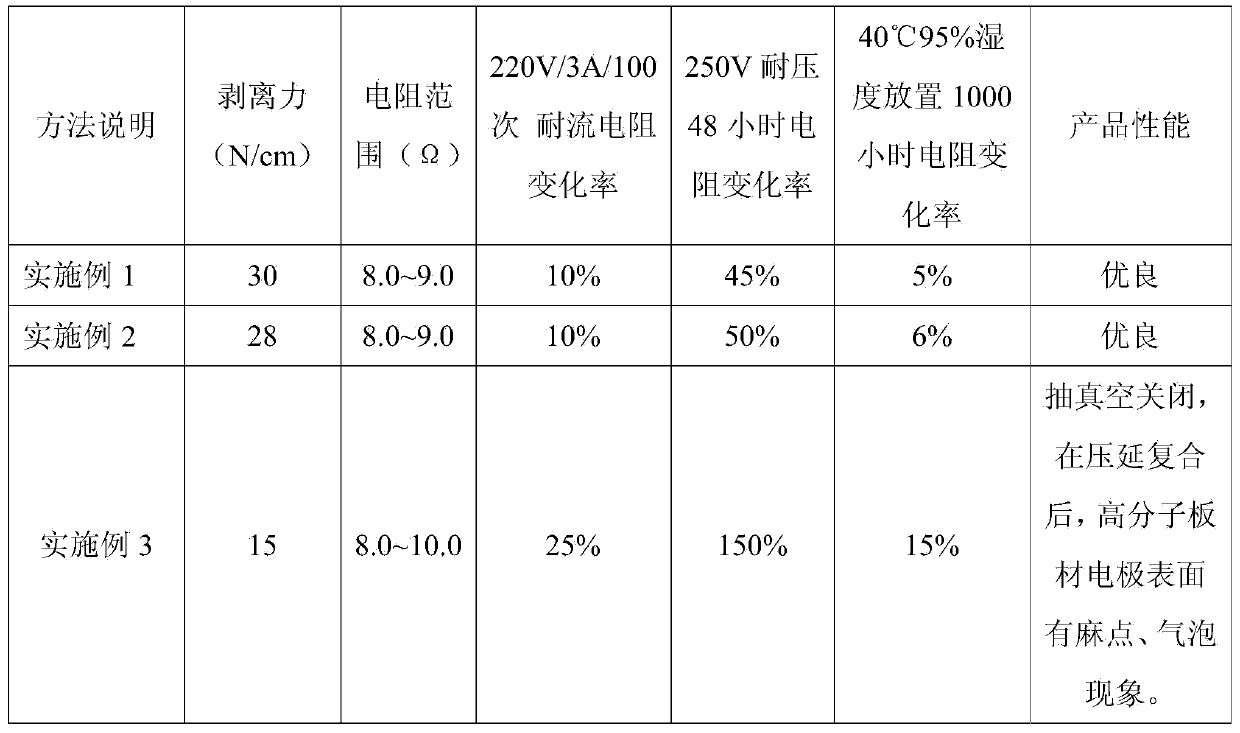

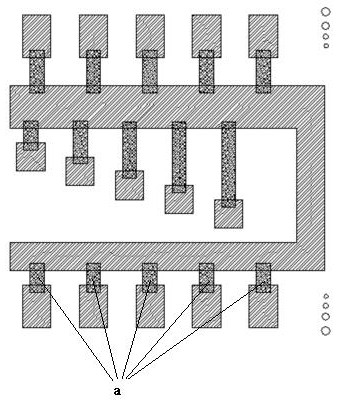

Preparation method of PPTC (Polymeric Positive Temperature Coefficient) thermistor with high electrode peeling strength and uniform resistance distribution

InactiveCN103730220AHigh electrode peeling forceImprove peel forcePositive temperature coefficient thermistorsElectrical resistance and conductanceWeather resistance

The invention discloses a preparation method of a PPTC (Polymeric Positive Temperature Coefficient) thermistor. The preparation method achieves continuous extrusion calendaring molding of the PPTC thermistor by selecting a specific technology. The preparation method provided by the invention is better in stability and high in efficiency, and the surface of a prepared macromolecule plate electrode is free from phenomena of pocking marks and bubbles; the resistance of the thermistor is good in uniformity, the electrode peeling strength is high, the inoxidizability is excellent, the resistance change rate during a durability test is small, the weather resistance is good, the product yield is higher, with the adoption of the preparation method, materials are saved, manual and energy source costs are reduced, and the preparation method has an important industrial application value.

Owner:SHANGHAI KETER POLYMER MATERIAL

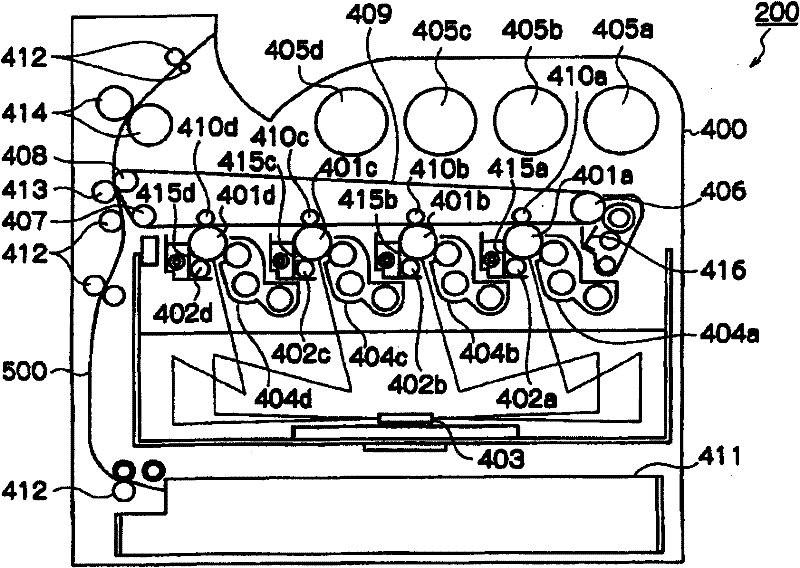

Charging member, process unit cartridge, and image forming apparatus

ActiveCN102411276AImprove surface propertiesSmall resistance change rateElectrographic process apparatusCorona dischargeRubber materialEthylene oxide

Owner:FUJIFILM BUSINESS INNOVATION CORP

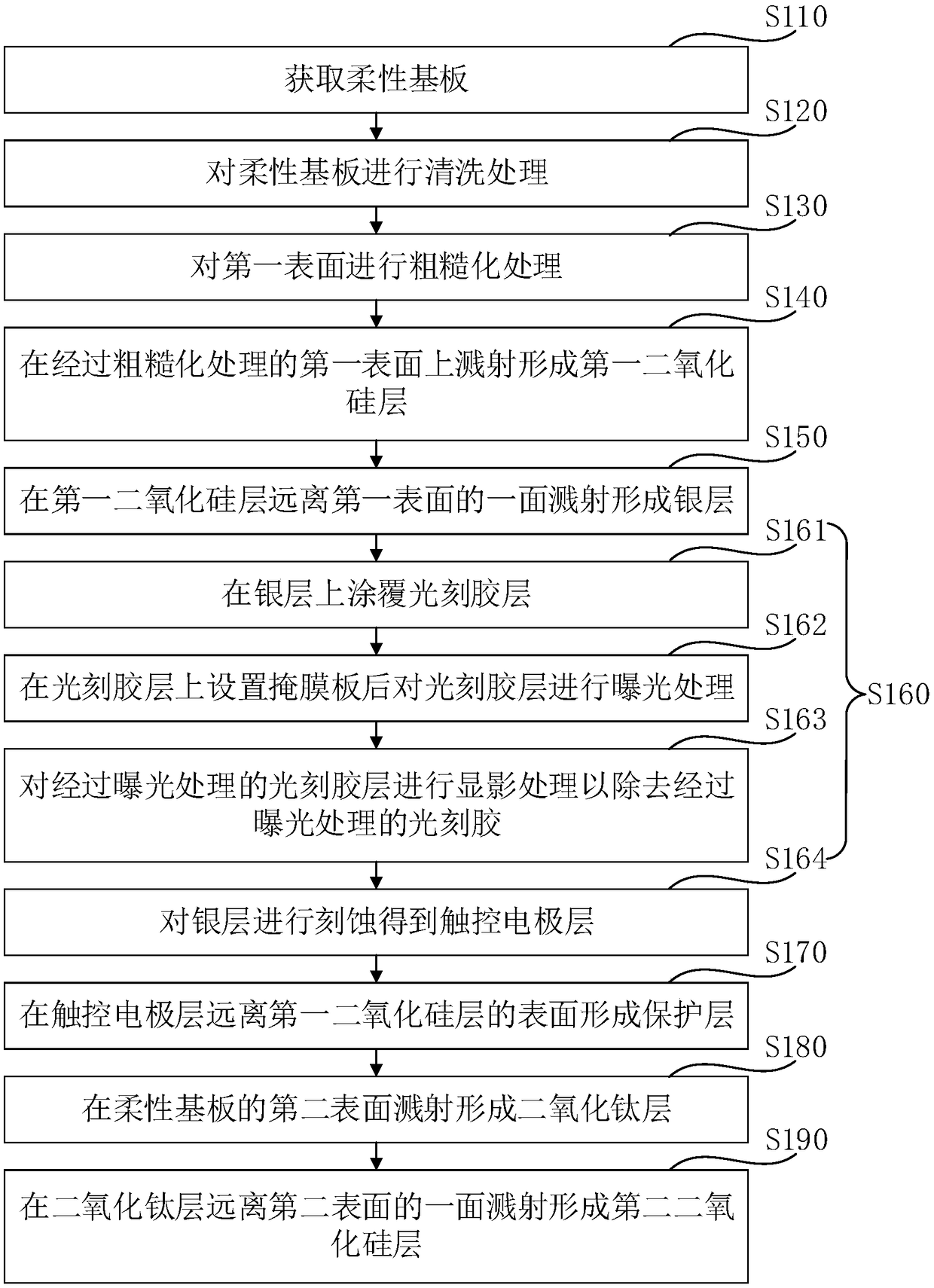

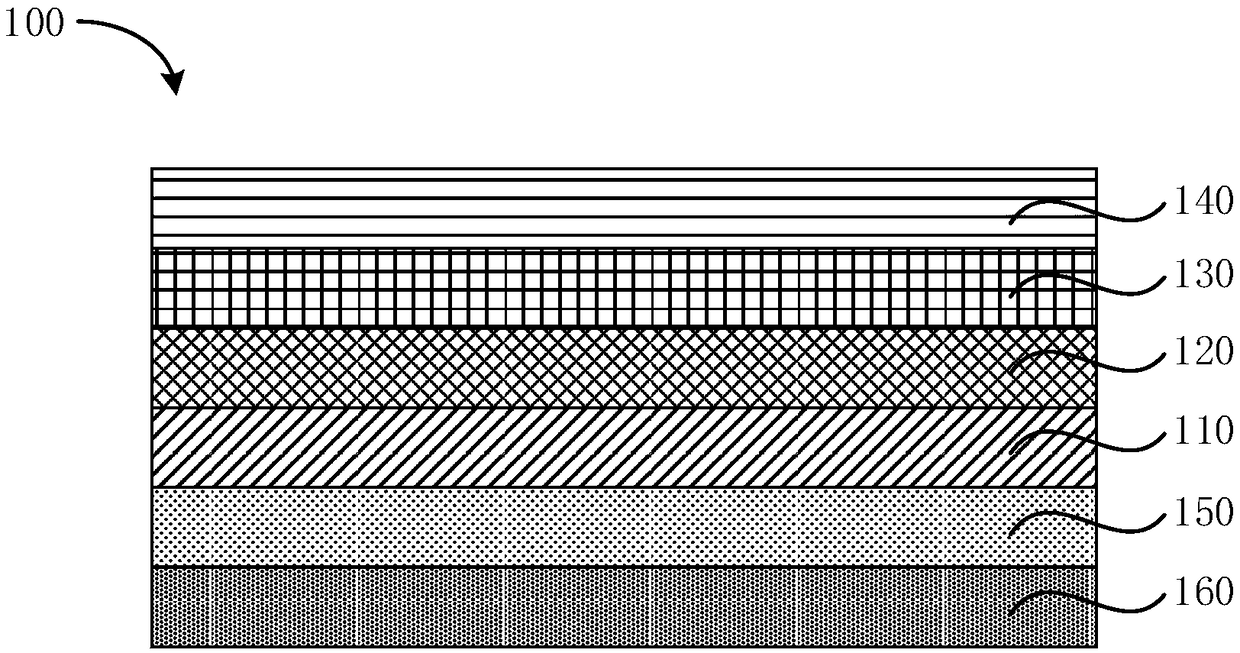

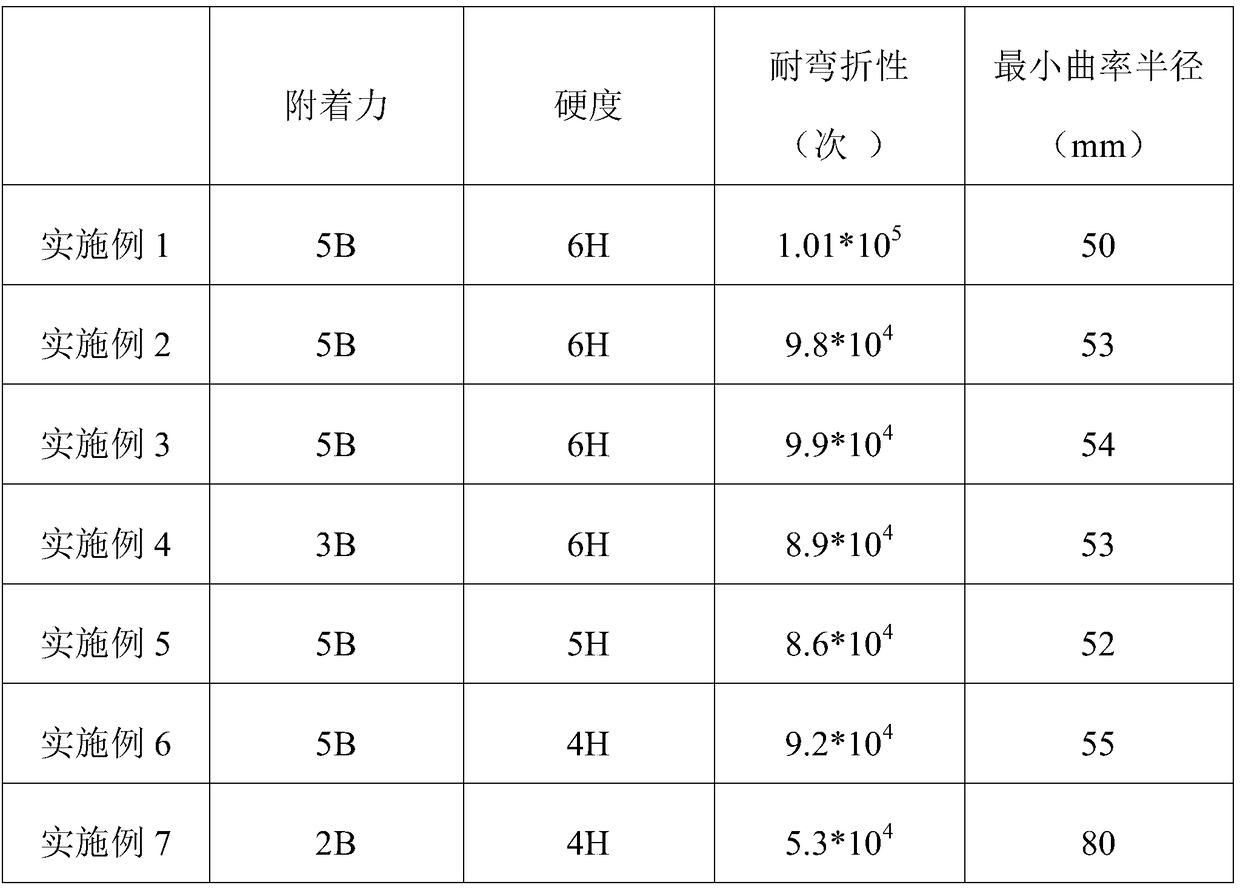

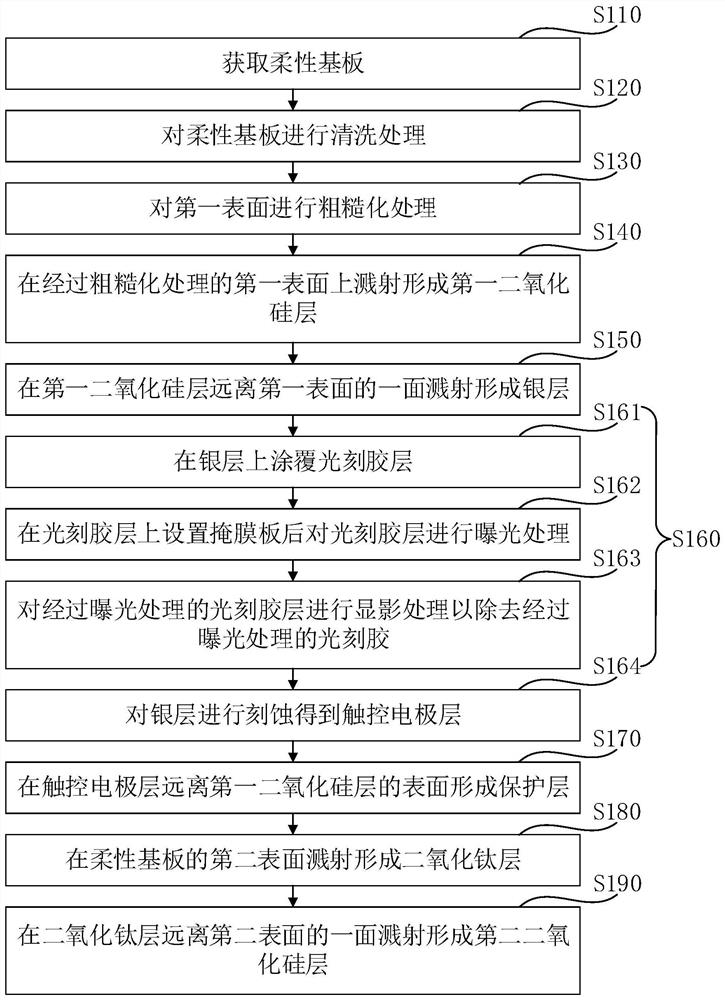

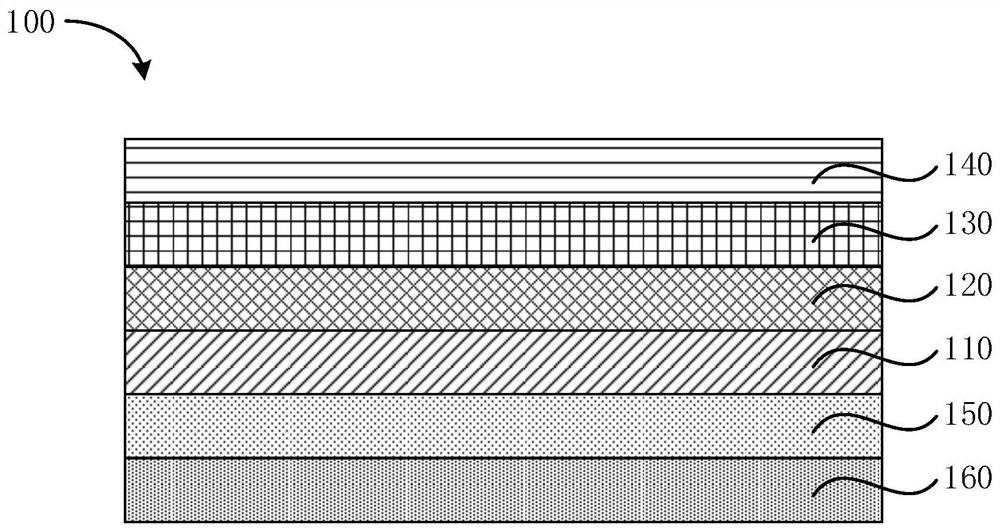

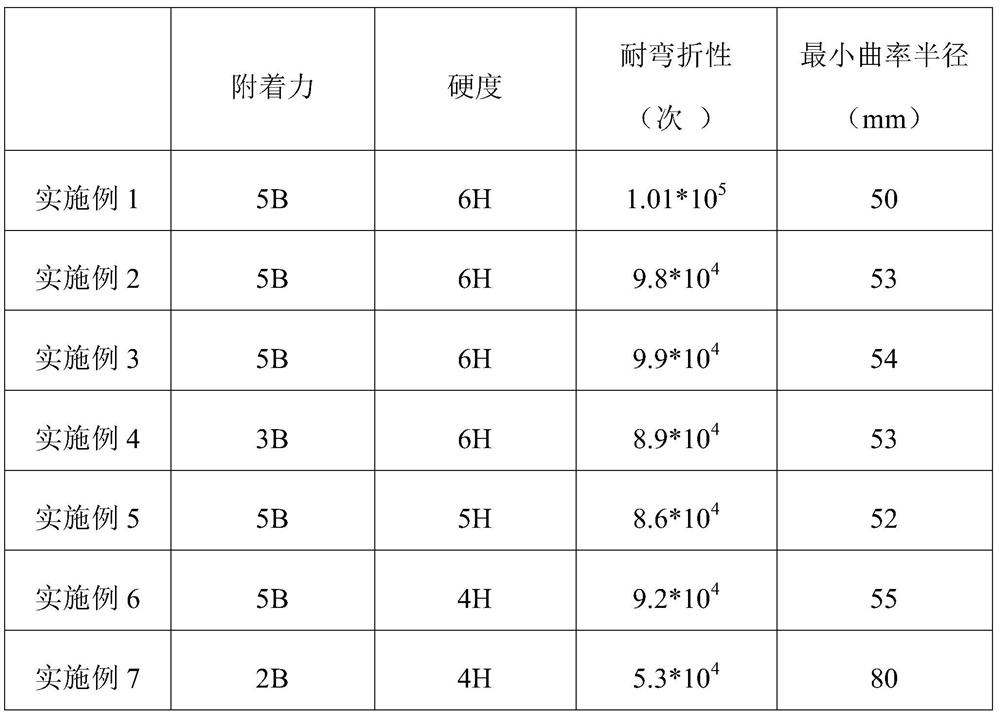

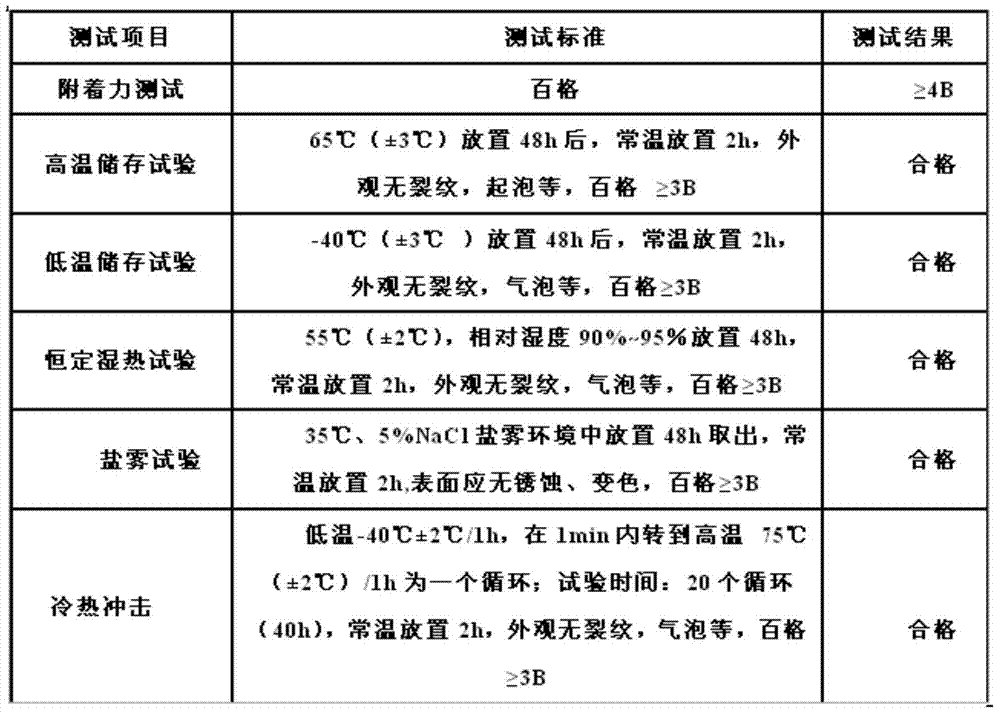

Flexible touch panel and preparation method thereof

ActiveCN109062432AImprove adhesionHigh hardnessInput/output processes for data processingSputteringHardness

The invention relates to a flexible touch panel and a preparation method thereof. A method for manufacturing a flexible touch panel comprises the following steps: obtaining a flexible substrate, wherein the flexible substrate has a first surface and a second surface opposite to the first surface; roughening the first surface; forming a first silicon dioxide layer by sputtering on the roughened first surface; forming a silver layer by sputtering on a side of the first silicon dioxide layer remote from the first surface; and performing yellow light processing on the silver layer to form a touchelectrode layer. The flexible touch panel prepared by the preparation method of the flexible touch panel has good bending resistance, the touch electrode layer still has good hardness, flexibility andadhesion after repeated bending, and the resistance change rate of the flexible touch panel is small when the flexible touch panel is bent.

Owner:WGTECH JIANGXI

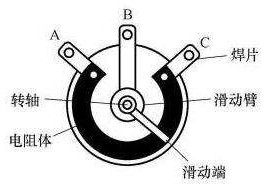

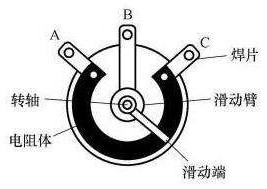

High-wear-resistance type resistance paste

ActiveCN114121336ASmall resistance change rateSimple preparation processNon-conductive material with dispersed conductive materialAdjustable resistorsWear resistanceBorosilicate glass

The invention discloses high-wear-resistance type resistance paste which comprises the following components in percentage by mass: 15%-35% of conductive powder, 25%-45% of a glass binding phase, 1%-8% of an additive and 30%-45% of an organic carrier, the conductive powder is graphite composite ruthenium dioxide, and the glass binding phase is lead borosilicate glass powder with the softening temperature of 500-600 DEG C. The resistance paste has the characteristics of stable resistance value, good temperature coefficient and good wear resistance, and can meet the use requirements of glass glaze trimmer potentiometer products.

Owner:西安宏星电子浆料科技股份有限公司

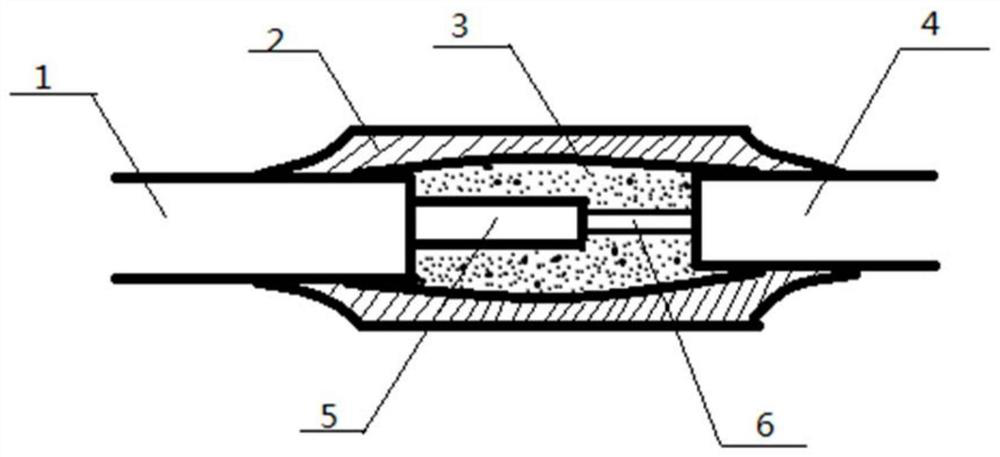

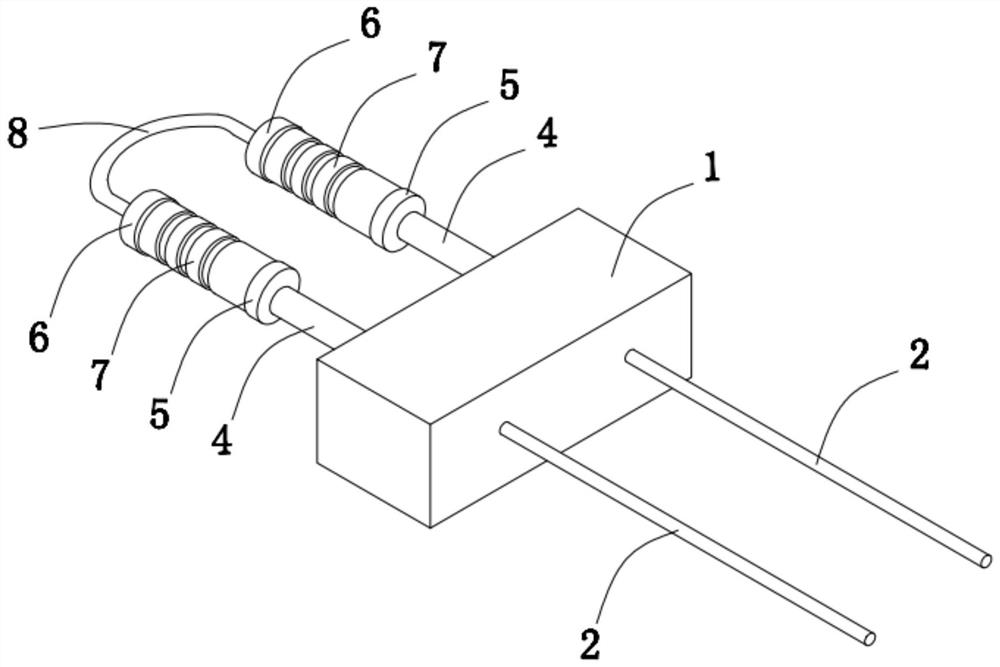

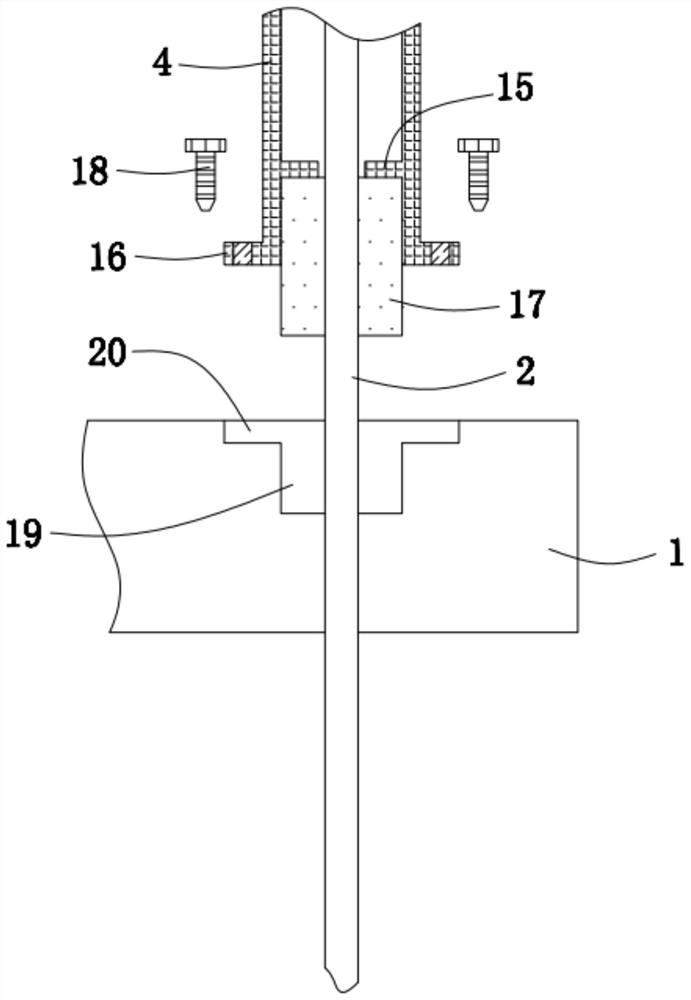

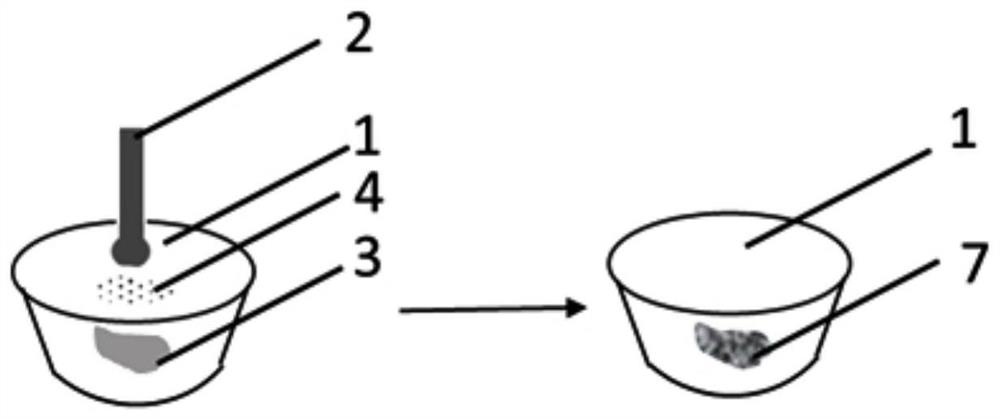

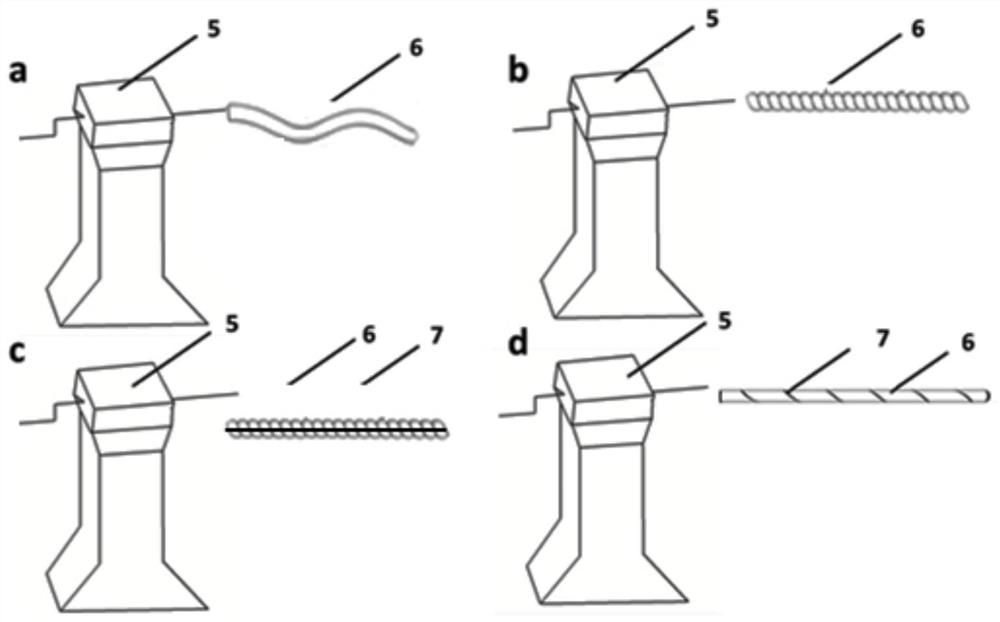

Carbon fiber and metal connecting structure and connecting method thereof

PendingCN112055434AIncrease contact areaSmall resistance change rateOhmic-resistance heating detailsHeating element shapesCarbon fibersFiber bundle

The invention discloses a carbon fiber and metal connecting structure and a connecting method thereof. The connecting structure comprises a carbon fiber wire and a metal wire which are connected witheach other, the joint of the carbon fiber wire and the metal wire is coated with a phenolic resin binder, and conductive particles are doped in the phenolic resin binder; and the joint of the carbon fiber wire and the metal wire is sleeved with an insulating heat-shrinkable sleeve. The connecting method comprises the following steps: (1) removing a silica gel outer sleeve at the joint of the carbon fiber wire to expose a carbon fiber wire bundle, and removing the outer sleeve at the joint of the metal wire to expose the metal wire; (2) inserting a metal wire into the carbon fiber bundle to enable the carbon fiber bundle to surround the periphery of the metal wire; and (3) coating the joint of the carbon fiber bundle and the metal wire with the phenolic resin binder doped with the conductive particles, completely soaking the carbon fiber bundle and the metal wire, and sleeving the joint with the insulating heat-shrinkable sleeve after the phenolic resin binder is naturally air-dried.

Owner:TIANJIN UNIV

Conductive ink for mobile phone antenna

The invention provides conductive ink for a mobile phone antenna. Based on the total weight of the conductive ink as the reference, the conductive ink is mainly composed of the following ingredients, by weight, 10-20% of modified epoxy resin, 50-70% of silver powder, 10-30% of a solvent, 0.5-2% of a dispersant, 0.5-2% of an antifoaming agent, 0.5-1% of a thixotropic agent and 2-5% of a coupling agent. Resistance value of the conductive ink provided by the invention is low and stable. The conductive ink is environmentally friendly, is safe to use, has excellent adhesive force, chemical resistance and stability, and has a good application prospect.

Owner:苏州昭奇凯虹精细化工有限公司

Laminate, composite polarizing plate and image display device

InactiveCN111867824ASmall resistance change rateLittle change in resistance valueNon-macromolecular adhesive additivesElectroluminescent light sourcesPolymer sciencePolyolefin

The purpose of the present invention is to provide a laminate in which the rate of change of resistance of a transparent conductive layer is small even in a high-temperature and high-humidity environment. In addition, another purpose of the present invention is to provide a composite polarizing plate and an image display device employing said laminate. The present invention provides a laminate characterized in that a transparent conductive layer and a pressure-sensitive adhesive layer having a moisture permeability of 100 g / (m2*day) or less, at a temperature of 40 DEG C and a relative humidityof 92%R.H., are laminated in contact with each other. It is preferable that the pressure-sensitive adhesive layer be a rubber-based adhesive or a polyolefin-based adhesive.

Owner:SUMITOMO CHEM CO LTD

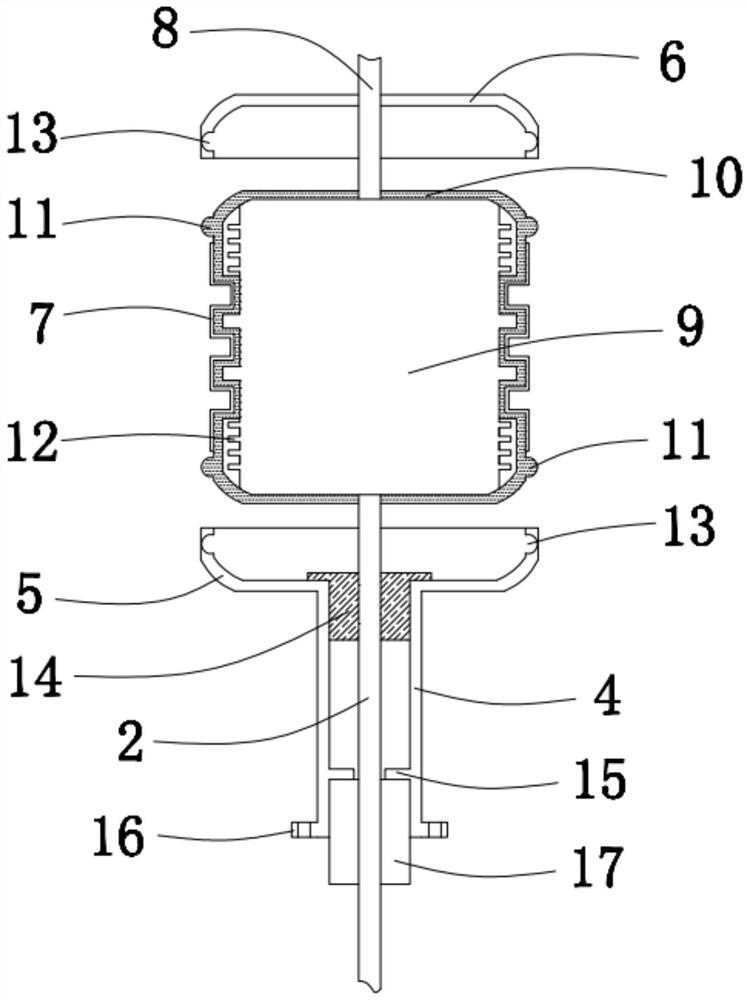

Low-temperature-coefficient metal film resistor and manufacturing process thereof

InactiveCN111816396AImprove the protective effectStable structureResistor terminals/electrodesResistors adapted for applying terminalsEpoxyElectric machine

The invention discloses a low-temperature-coefficient metal film resistor. A resistor body comprises a base body, a metal film wrapping the outer side of the base body, a first electrode cap and a second motor cap, the first electrode cap and the second motor cap are connected to the front end and the rear end of the metal film, and the outer portion of the resistor body is coated with a paint layer; the rear end of the second motor cap is connected to the epoxy resin block through a protective tube, a T-shaped fixing plug inserted into the protective tube is arranged in the second motor cap,a limiting plug is inserted into the rear end of the interior of the protective tube, and the rear end of the pin penetrates through the T-shaped fixing plug, the protective tube and the limiting plugin sequence; the rear end of the limiting plug is inserted into a positioning hole in the epoxy resin block, and a fixing ring on the outer side of the rear end of the protection pipe is fixed to a groove in the front portion of the positioning hole through a screw. According to the invention, the protection effect on the pins is improved, so that the structure is firmer; the protection tube is firmly connected with the epoxy resin block, so that the pins are effectively protected; and heat generated when the resistor body works can be dissipated quickly.

Owner:安徽怡娅通科技有限公司

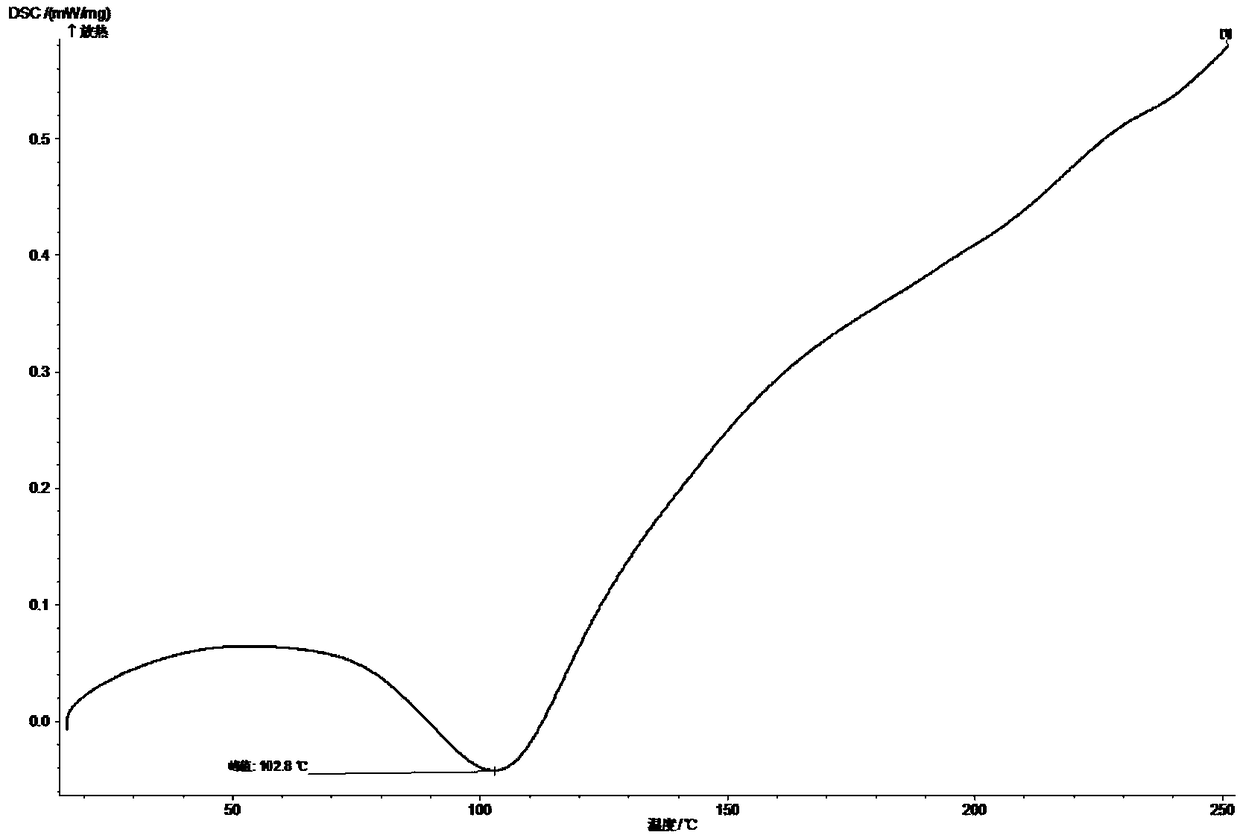

A low-temperature fast-curing organic resin carrier for printed electronics and its preparation method and application

The invention discloses a low-temperature fast curing setting organic resin carrier for printing electronics and a preparation method and application thereof. The method comprises the steps that curing can be completed at the temperature of 120-150 DEG C for 1-9 min, the room temperature storage stability is good, continuous printing can be achieved, a curing film layer has the good electrical conductivity, solvent resistance, adhesive force, surface hardness and other comprehensive performances, the braking curing time is prolonged, and the resistance changing rate is smaller than 5%. Compared with the application performance of traditional printing electronic paste, damage caused by thermal treatment to organic materials and preparation devices is effectively lowered, the production yield is improved, the prepared rare and precious metal electronic paste is stably attached to various elastic substrate materials which are high surface energy and hard to adhere, high in reliability and suitable for a large-scale continuous production technology, and the production energy consumption cost is greatly lowered. The organic resin carrier is prepared from, by mass, 30-40% of organic resin, 45-59% of mixed solvents, 8-12% of curing agents and 3-5% of rapid curing accelerators.

Owner:KUNMING INST OF PRECIOUS METALS

Flexible touch panel and preparation method thereof

ActiveCN109062432BImprove adhesionHigh hardnessInput/output processes for data processingEngineeringStructural engineering

The present invention relates to a flexible touch panel and a preparation method thereof. A preparation method of a flexible touch panel includes the following steps: obtaining a flexible substrate, the flexible substrate having a first surface and a second surface opposite to the first surface; roughening the first surface; A first silicon dioxide layer is formed by sputtering on the roughened first surface; a silver layer is formed by sputtering on the side of the first silicon dioxide layer away from the first surface; and the silver layer is formed by sputtering A yellow light process is performed to form a touch electrode layer. The flexible touch panel prepared by the above-mentioned preparation method of the flexible touch panel has good bending resistance, the touch electrode layer still has good hardness, flexibility and adhesion after repeated bending, and the above flexible touch panel The resistance change rate is small when bending.

Owner:WGTECH JIANGXI

Conductive ink for mobile phone antenna

Owner:苏州昭奇凯虹精细化工有限公司

High precision thermosensitive resistor nanometer powder

InactiveCN100415414CGood physical and chemical propertiesLow priceResistor manufacturePolyethylene glycolThermistor

This invention discloses a method for producing a high accuracy thermistor nanometer powder, which uses the nitrate of Cr, Ni, Mn as raw material. The method comprises the following steps: a,adding citrate, carbowax and ammonia, heating and mixing, hydrolyzing and aggregation to form transparent colloidal solution; b, drying the colloidal solution and getting dried gel, self-igniting the gel and getting the nanometer powder. By said method, the powder has good materiality, and the size of the powder paritcle can reach to 40-60 nanometer, the powder is spinel structure, after burning its size is between 1 and 2 mum. The powder can be used repeatedly, and the rate of finished products can reach to 80%. The powder can be used to produce the thermistor with high accuracy B value and good heat resistant property.

Owner:NINGBO UNIV

A kind of low-temperature resistance silver paste, its preparation method and application

ActiveCN109036637BImprove adhesionReduce powder lossNon-conductive material with dispersed conductive materialHeating element materialsCarbide siliconSilver paste

The invention provides a low-temperature resistance silver paste, which comprises solid powder with a mass ratio of 60 to 80 to 20 to 40 and an organic binder, and a preparation method and applicationthereof. The solid powder comprises silver powder and composite inorganic powder; The composite inorganic powder includes carbon powder, titanium dioxide and silicon carbide. The mass ratio of silverpowder, carbon powder, titanium dioxide and silicon carbide powder is 60-70: 8-3: 28-18: 4-9; The organic binder comprises a mixed dibasic ester of a type DBE with a mass ratio of 72 to 75: 10 to 11:10 to 12: 2 to 8, a polyester resin, a phenoxy resin and an adhesion promoter. The silver paste has good adhesion to the thin film substrate, and is suitable for components with high flexibility requirements, and is not easy to break wires. It also has the characteristics of high thermal efficiency, fast heating speed, heat resistance, aging resistance, chemical corrosion resistance and long service life. The silver paste can also be printed according to customer needs into any shape, suitable for different power requirements of the heater device.

Owner:湖南利德电子浆料股份有限公司

A kind of high abrasion resistance paste

ActiveCN114121336BSmall resistance change rateSimple preparation processNon-conductive material with dispersed conductive materialAdjustable resistorsSlurryHigh wear resistance

The invention discloses a high wear-resistant resistance slurry. The mass percentage of the resistance slurry is composed of: conductive powder 15%-35%, glass bonding phase 25%-45%, additive 1%-8%, 30%-45% organic carrier, the conductive powder is graphite composite ruthenium dioxide, and the glass bonding phase is lead borosilicate glass powder with a softening temperature of 500-600°C. The resistance slurry of the invention has the characteristics of stable resistance value, good temperature coefficient and good wear resistance, and can meet the use requirements of glass glaze fine-tuning potentiometer products.

Owner:西安宏星电子浆料科技股份有限公司

A kind of elastic conductor and preparation method thereof

ActiveCN111415770BGood deformabilityImprove conductivityConductive layers on insulating-supportsSingle bars/rods/wires/strips conductorsElectrical resistance and conductanceLiquid metal

The invention discloses an elastic conductor and a preparation method thereof. The elastic conductor includes an elastic matrix and liquid metal, the elastic matrix is non-conductive, the liquid metal adheres to the surface of the elastic matrix, and forms a continuous helical winding around the periphery of the elastic matrix. The invention adopts twist forming process to prepare the elastic conductor. When the elastic conductor is stretched and deformed, the resistance change rate is small, and it has potential application value in flexible electronic devices.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

A kind of preparation method of elastic conductor

ActiveCN108198665BSimple manufacturing methodLow costCable/conductor manufactureElectrical connectionLiquid metal

The invention provides a preparation method of an elastic conductor. The preparation method comprises the steps of uniformly mixing liquid metal and a melted elastic body to form a mixed body, whereinthe volume ratio of the liquid metal and the elastic body in the mixed body is 10%-70%; pouring the mixed body into a die for standing for a certain time; and curing to form the elastic conductor. The method is simple and practical and is low in cost, the prepared elastic conductor is divided into an upper layer and a lower layer, the upper layer is a pure elastic body, the lower layer is a mixedlayer of the elastic body and the liquid metal, liquid metal particles in the mixed layer fill the elastic body in a gourd string shape to form an electrical connection structure, and the elastic conductor has high conductivity, high stretchability and dynamic electrical stability.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com