Conductive ink for mobile phone antenna

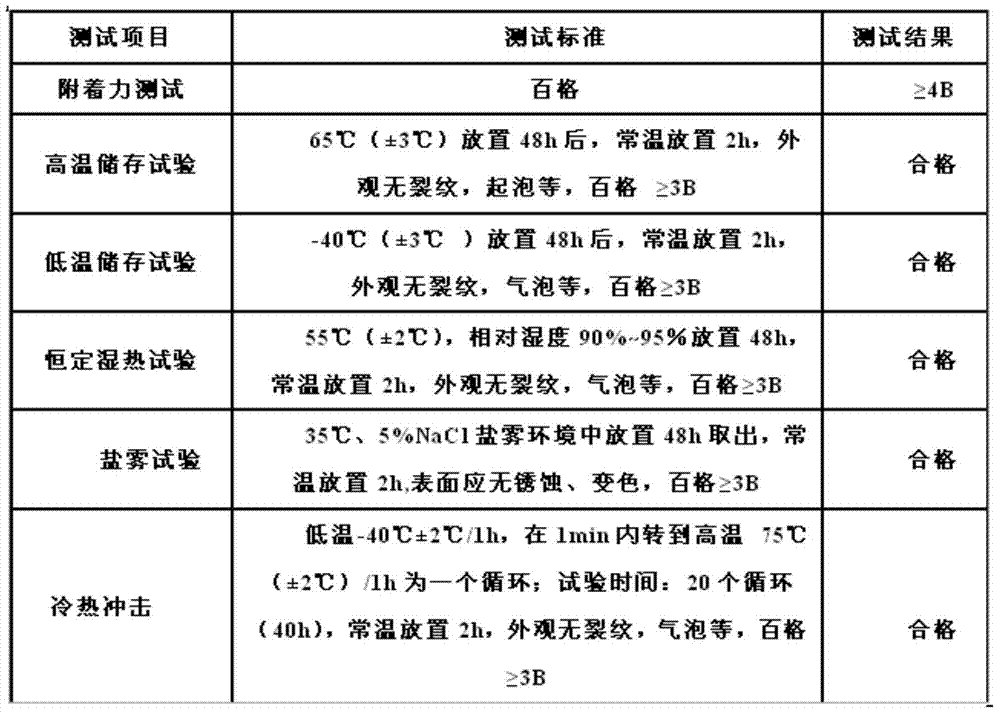

A conductive ink and mobile phone antenna technology, applied in the field of ink, can solve the problems of unguaranteed substrate adhesion, poor ink storage stability, and unstable resistance, and achieve excellent storage stability, no delamination, and small resistance changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The present embodiment provides a kind of conductive ink for mobile phone antenna, based on the total weight of the conductive ink, it is formed by mixing the following components: thermoplastic hydroxyl polyurethane epoxy resin, 10%; silver powder, 60%; cyclohexanone , 22%; dispersant (alkanol ammonium salt of block copolymer of acidic groups), 1.5%; polyether modified silicone defoamer, 1.5%; thixotropic agent (fumed silica), 1 %; Silane coupling agent, 4%.

Embodiment 2

[0028] The present embodiment provides a kind of conductive ink for mobile phone antenna, based on the total weight of the conductive ink, it is mixed with the following components: thermoplastic hydroxyl polyurethane modified bisphenol A epoxy resin, 20%; silver powder, 55%; isophorone, 19%; dispersant (alkanol ammonium salt of block copolymer of acidic groups), 1%; polyether modified silicone defoamer, 1%; thixotropic agent ( fumed silica), 1%; silane coupling agent, 3%.

Embodiment 3

[0030] The present embodiment provides a kind of conductive ink for mobile phone antenna, based on the total weight of the conductive ink, it is mixed with the following components: thermoplastic hydroxyl polyurethane modified bisphenol A epoxy resin, 10%; silver powder, 70%; Ethylene glycol ether acetate, 10%; Dispersant (alkanol ammonium salt of block copolymer of acidic groups), 2%; Polyether modified silicone defoamer, 2%; Thixotropic agent (fumed silica), 1%; silane coupling agent, 5%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com