Preparation method and application for composite elastomer containing graphene coated copper nanowire

A technology of graphene coating and elastomer, applied in the direction of nanotechnology, nanotechnology, metal/alloy conductors, etc., can solve the problems of performance change, cumbersome steps, easy to fall off, etc., and achieve mild conditions, simple process, and wide sources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 10 mL of Cu(NO with a concentration of 0.1 mol / L 3 ) 2 The solution was mixed evenly with 5 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL. Then add 2mL of 99% ethylenediamine solution, stir for 25min, then add 200mL of 10mol / L NaOH solution and keep stirring for 50min, then add 0.2mL of 35% hydrazine hydrate solution, and sonicate for 15min, then deionized water Sponge cleaned ultrasonically for 10 minutes and dried at 60°C was added to the reaction solution, and continued to be ultrasonically treated for 20 minutes. Finally, the reaction system was reacted in a water bath at 70°C for 80 minutes, and the obtained product was dried in a vacuum oven at room temperature for 24 hours. Finally, a graphene-coated copper nanowire foam can be obtained with a conductivity of 9×10 -2 S / m.

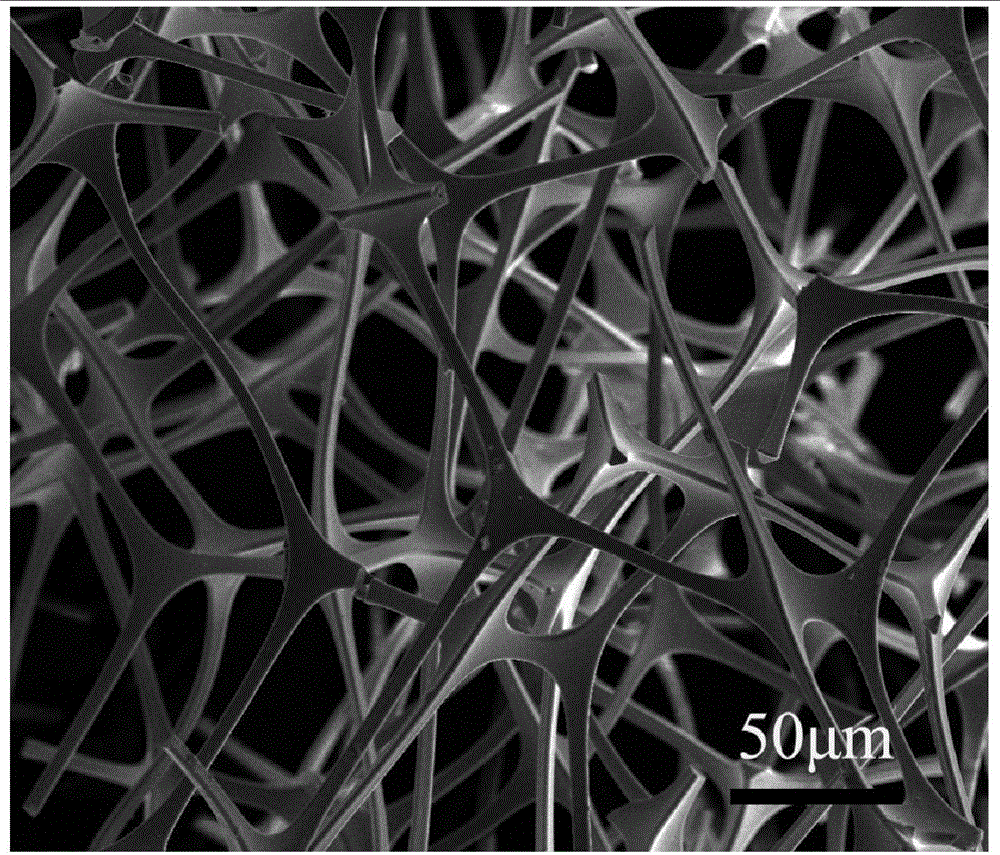

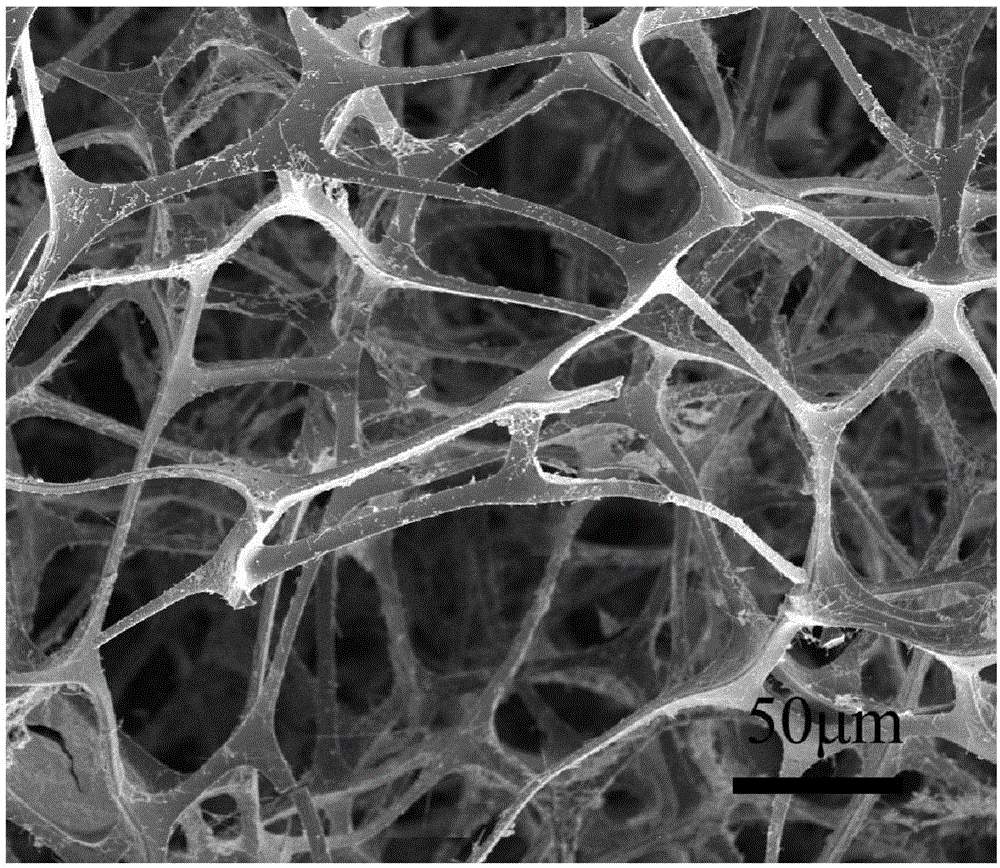

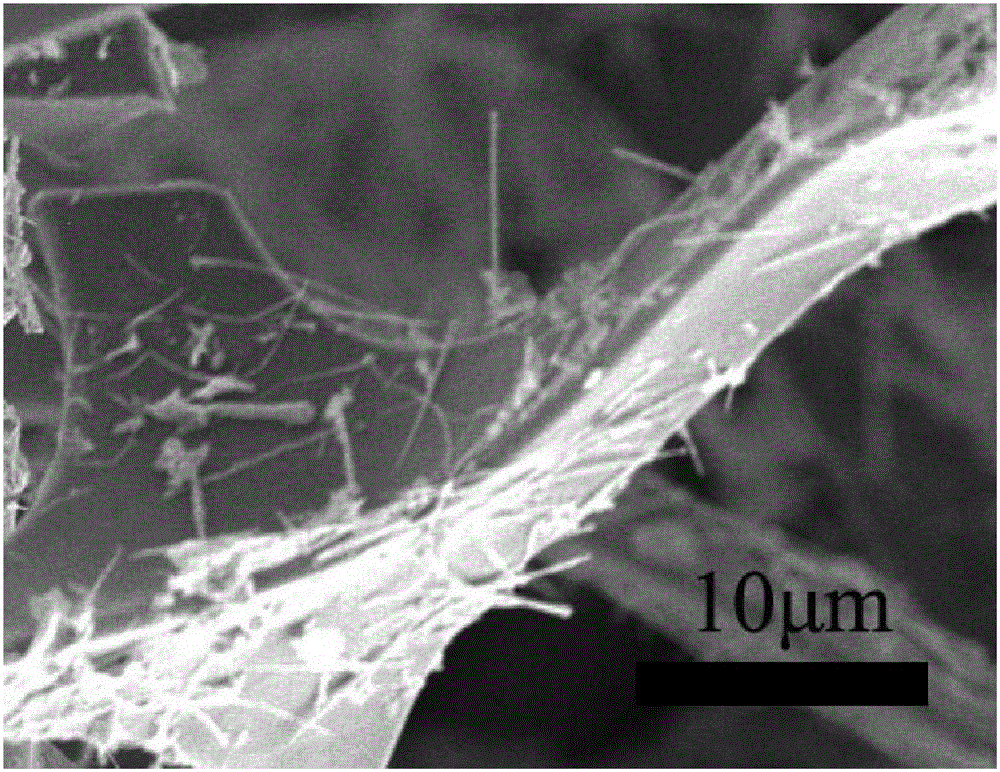

[0052] figure 1 It is the scanning electron micrograph of the sponge after drying in embodiment 1. from figure 1 It can be seen that the dried sponge itself has a...

Embodiment 2

[0062] 15 mL of Cu(NO with a concentration of 0.05 mol / L 3 ) 2 The solution was mixed evenly with 5 mL of graphene oxide aqueous solution with a concentration of 1 mg / mL. Then add 3mL of 80% ethylenediamine solution, stir for 20min, then add 250mL of 5mol / L NaOH solution and continue stirring for 45min, then add 0.3mL of 35% hydrazine hydrate solution, and ultrasonic for 25min, then deionized water Sponge cleaned ultrasonically for 10 minutes and dried at 60°C was added to the reaction solution, and continued to be ultrasonically treated for 15 minutes. Finally, the reaction system was reacted in a water bath at 60°C for 90 minutes, and the obtained product was dried in a vacuum oven at room temperature for 12 hours. Finally, graphene-coated copper nanowire foam can be obtained. Its conductivity is 5×10 -2 S / m, after being pressed and released, it can rebound and return to its original shape within 1.5 seconds. After the first press and release, its resistance change rate i...

Embodiment 3

[0064] 20 mL of Cu(NO with a concentration of 0.1 mol / L 3 ) 2 The solution was mixed evenly with 5 mL of graphene oxide aqueous solution with a concentration of 2 mg / mL. Then add 4 mL of 60% ethylenediamine solution, stir for 30 min, then add 400 mL of 15 mol / L NaOH solution and continue stirring for 60 min. Finally, 0.4 mL of 80% hydrazine hydrate solution was added, and ultrasonicated for 25 minutes, then the sponge that was ultrasonically cleaned with deionized water for 10 minutes and dried at 60°C was added to the reaction solution, and ultrasonic treatment was continued for 15 minutes. Finally, the reaction system was placed in React in a water bath at 90°C for 50 minutes, and dry the obtained product in a vacuum oven at room temperature for 20 hours to finally obtain a graphene-coated copper nanowire foam.

[0065] Its conductivity is 7×10 -2 S / m, after being pressed and released, it can rebound and return to its original shape within 1.5 seconds. After the first pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com