Elastic guide wire and preparation method thereof

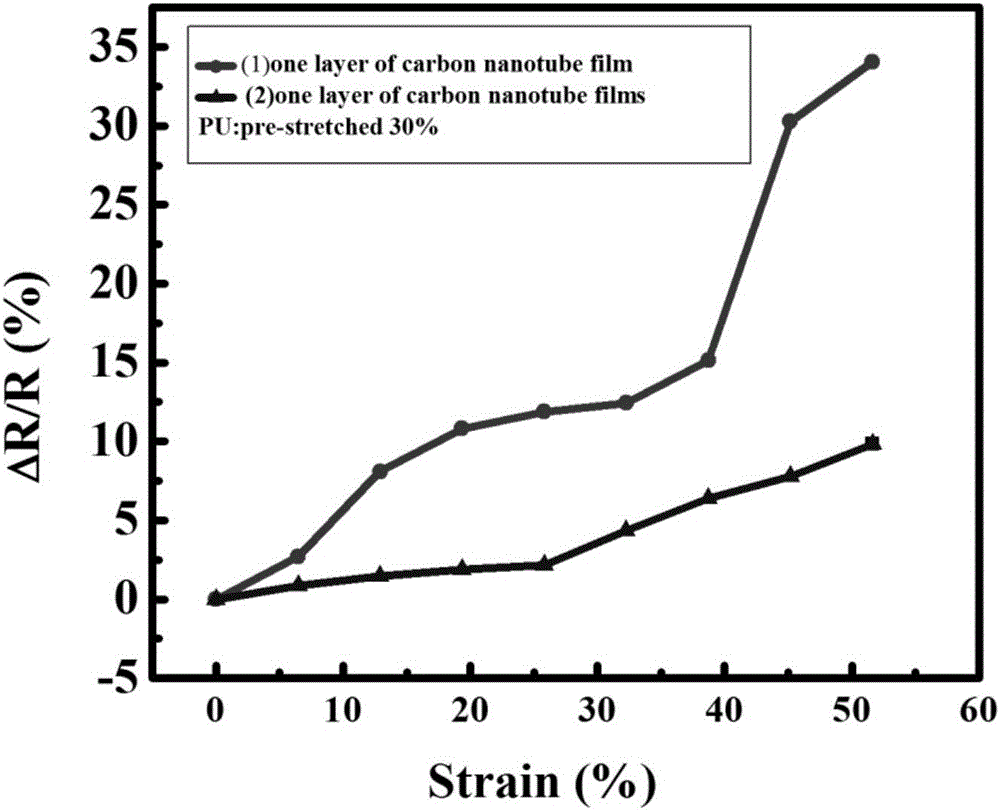

An elastic and wire technology, applied in the field of elastic wire and its preparation, can solve the problems of large resistance change rate, small fracture length, poor conductivity, etc., and achieve strong conductivity, high elongation, electrical stability and fatigue resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

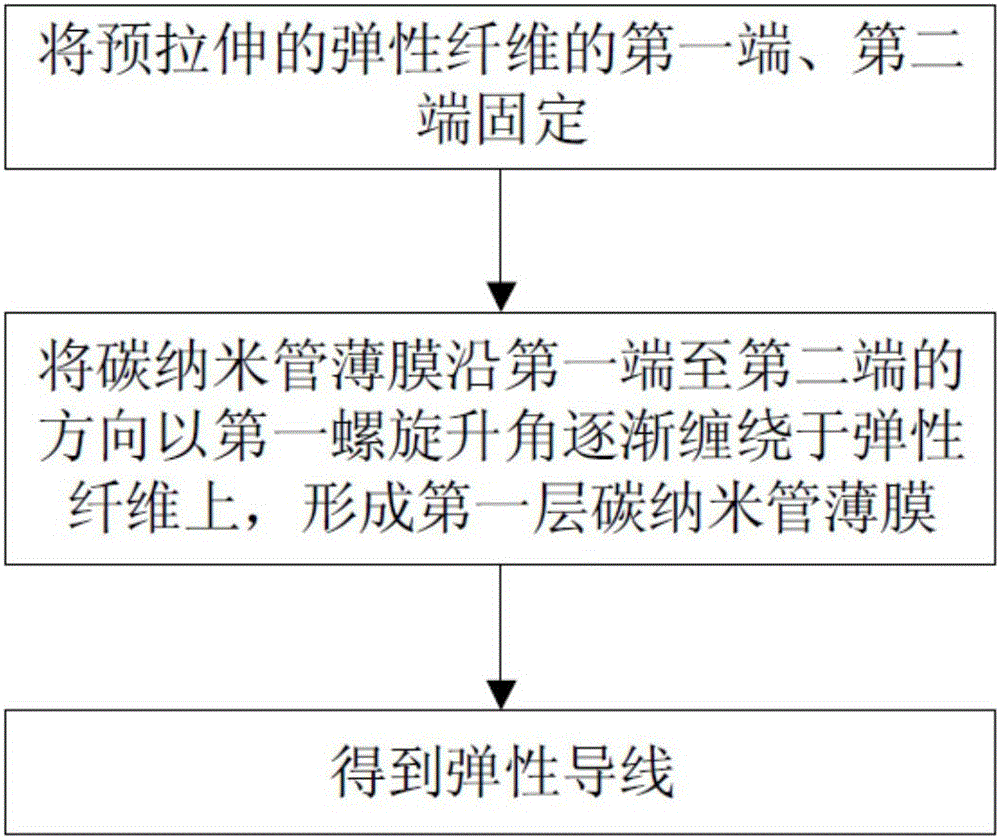

[0036] see figure 1 , figure 1 It is a flowchart of a method for preparing an elastic wire according to an embodiment of the present invention. The preparation method comprises steps:

[0037] fixing the first end and the second end of the pre-stretched elastic fibers;

[0038] gradually winding the carbon nanotube film on the elastic fiber at a first helix angle along the direction from the first end to the second end to form a first layer of carbon nanotube film;

[0039] Obtain the elastic wire.

[0040] The preparation method of the elastic wire according to one embodiment of the present invention, by pre-stretching the elastic fiber, and then winding the carbon nanotube film on the pre-stretched elastic fiber, the elastic wire can be made to have high elasticity and at the same time , and the contact point of the carbon nanotube film will not be greatly attenuated along with the stretching, thereby reducing the resistance change rate during the stretching process; and...

Embodiment 1

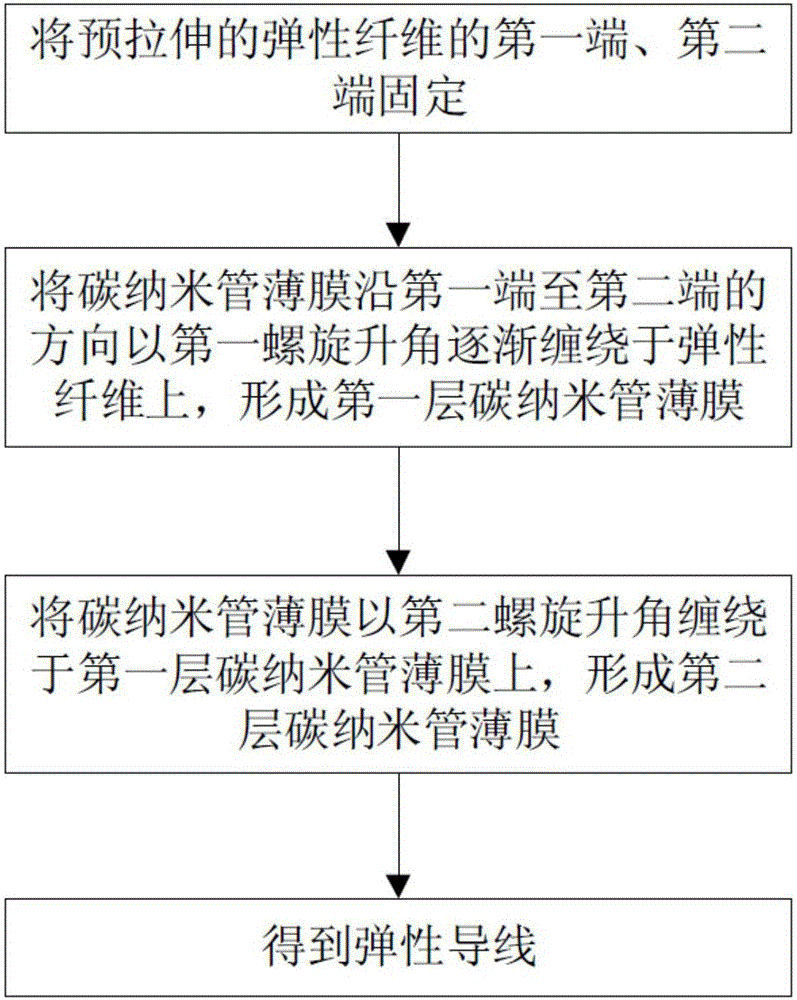

[0081] see figure 2 , figure 2 It is a flowchart of the preparation method of the elastic wire according to the first embodiment of the present invention, and the preparation method includes steps:

[0082] Fixing the first end and the second end of the pre-stretched elastic fiber, wherein the pre-stretch rate of the elastic fiber is about 30%;

[0083] gradually winding the carbon nanotube film on the elastic fiber at a first helix angle along the direction from the first end to the second end to form a first layer of carbon nanotube film;

[0084] Winding the carbon nanotube film on the first layer of carbon nanotube film with a second helix angle to form a second layer of carbon nanotube film; wherein, in the direction from the first end to the second end, The helical direction of the second layer of carbon nanotube film is opposite to the helical direction of the first layer of carbon nanotube film, and the second helix angle is the same as the first helix angle and is...

Embodiment 2

[0089] see Figure 4 , Figure 4 It is a flow chart of the preparation method of the elastic wire according to the second embodiment of the present invention, and the preparation method includes steps:

[0090] Fixing the first end and the second end of the pre-stretched elastic fiber, wherein the pre-stretch rate of the elastic fiber is about 30%;

[0091] gradually winding the carbon nanotube film on the elastic fiber at a first helix angle along the direction from the first end to the second end to form a first layer of carbon nanotube film;

[0092] Coating an organic solvent on the surface of the first layer of carbon nanotube film, heating after maintaining for a period of time;

[0093] Winding the carbon nanotube film on the first layer of carbon nanotube film with a second helix angle; wherein, in the direction from the first end to the second end, the second layer of carbon nanotube film The helical direction of the carbon nanotube film is opposite to the helical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com