High precision thermosensitive resistor nanometer powder

A nano-powder, thermistor technology, applied in resistors, resistor manufacturing, circuits, etc., can solve the problems of low uniformity of powder chemical composition, low yield, poor repeatability, etc., to improve thermal aging resistance. performance, improved thermal aging resistance, and the effect of good thermal aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

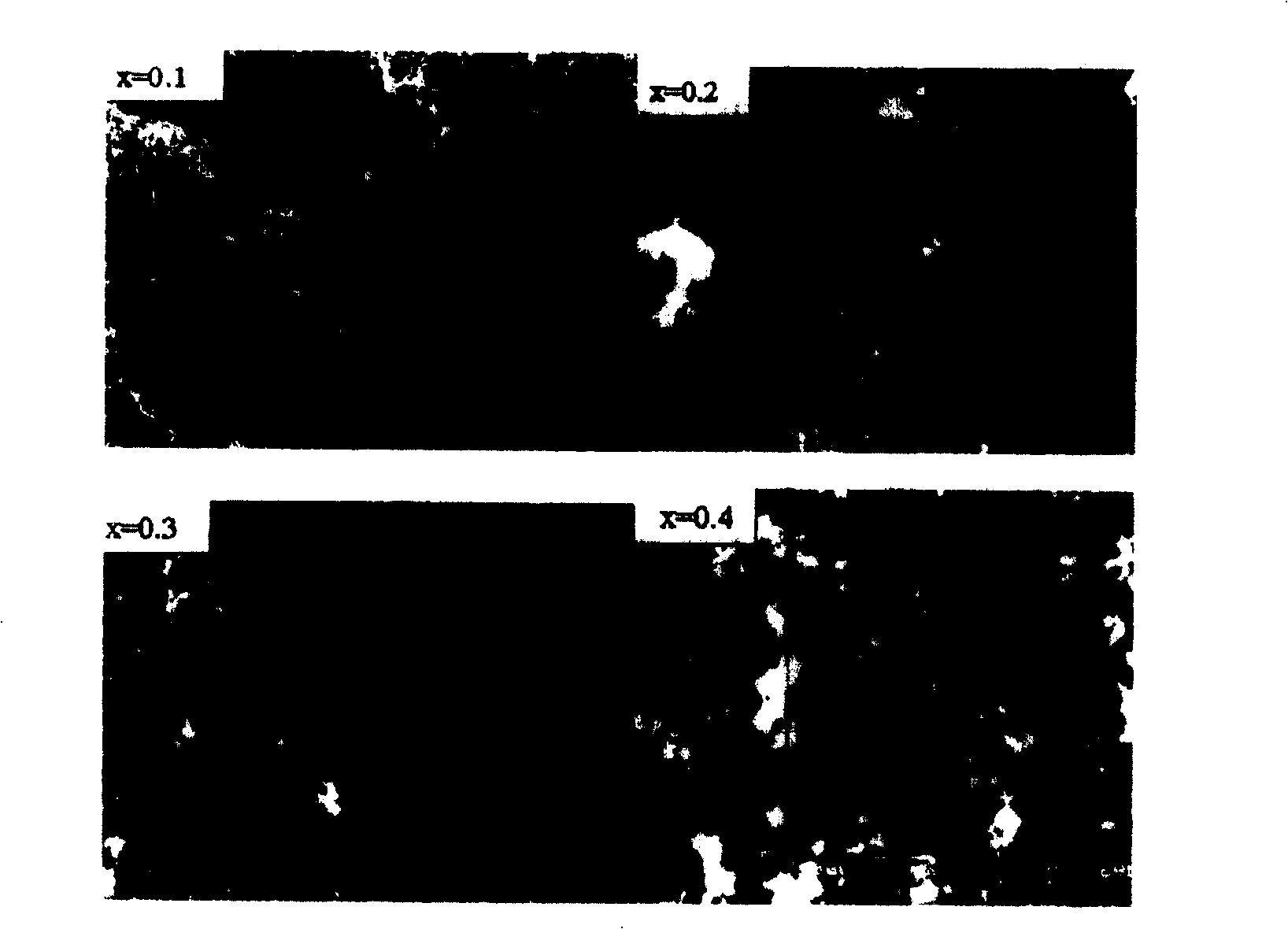

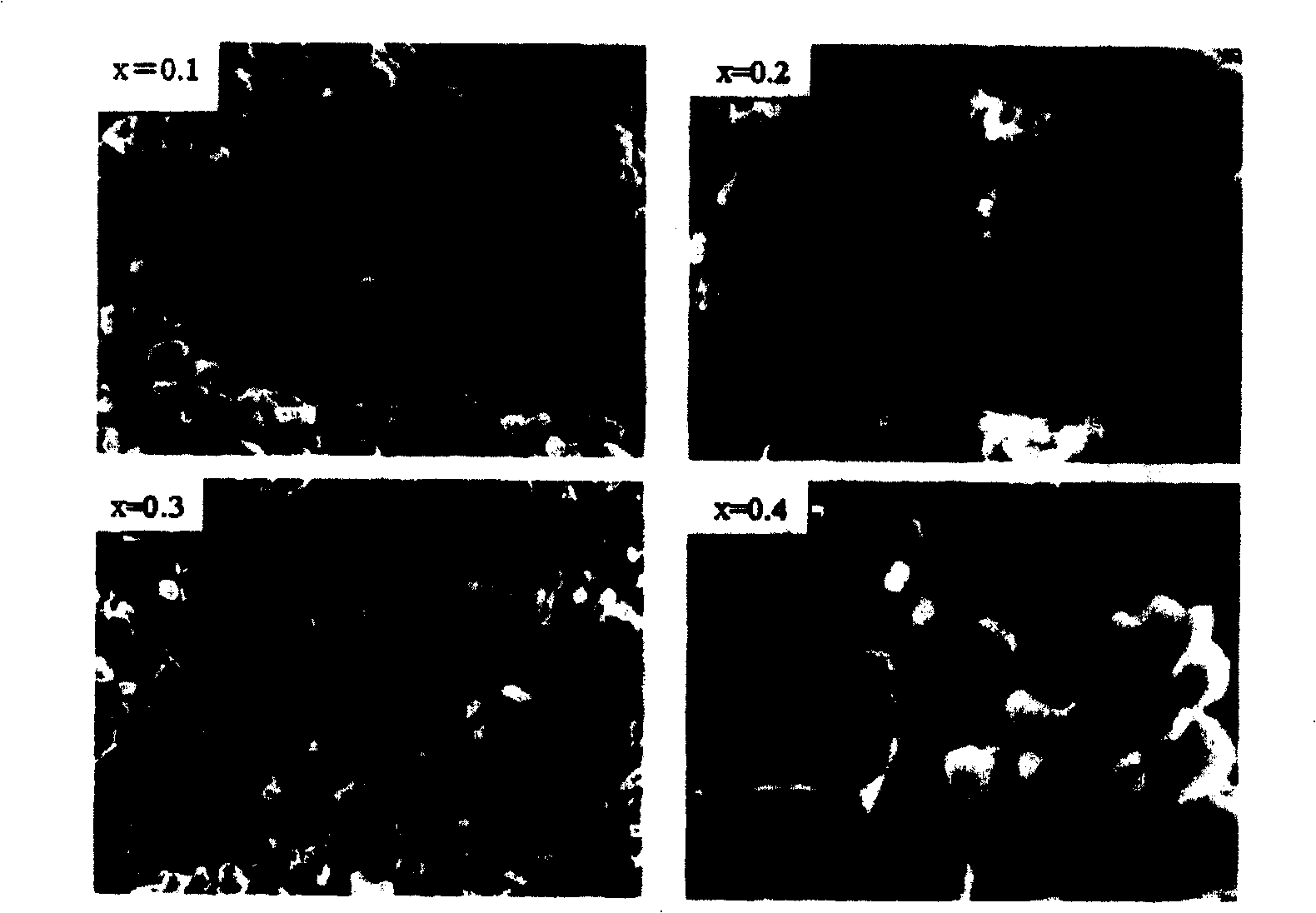

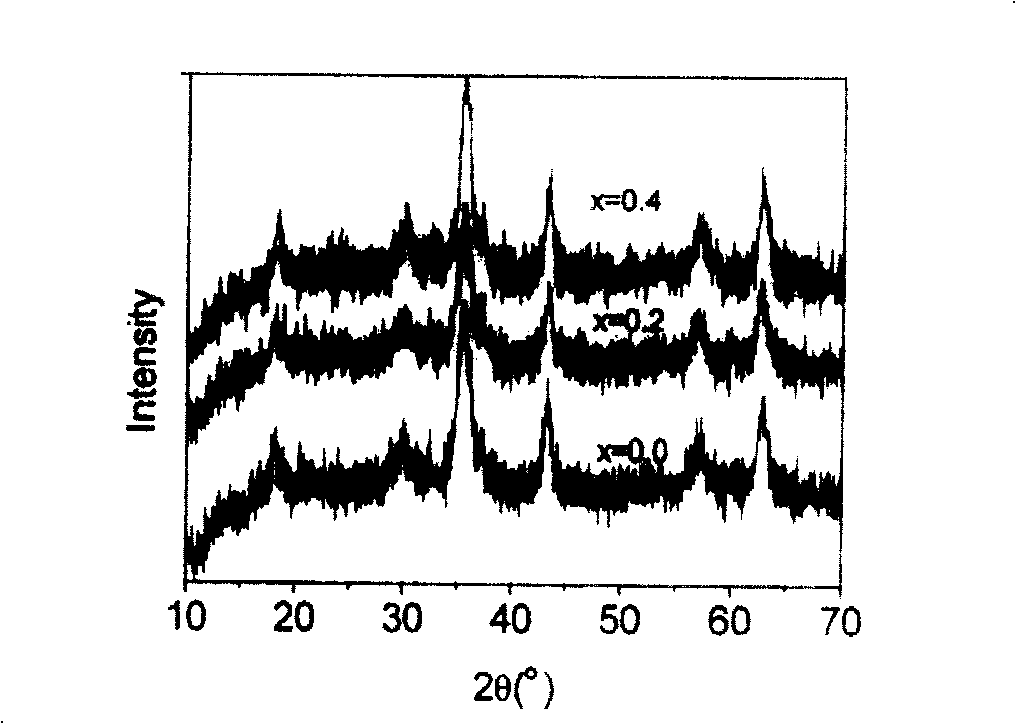

[0019] Example 1: First, the molar ratio is: Cr:Ni:Mn=5:30:65, respectively weigh 0.0005 moles, 0.003 moles, 0.0065 moles of Cr, Ni, and Mn nitrates as raw materials, mix and dissolve them in 67 mL of deionized In water, the molar concentration of metal ions is controlled to be 0.15mol / L, and it is configured as a main component solution; 3.89g of citric acid and 9g of polyethylene glycol (PEG) are added to the prepared solution to make a mixed solution, which is adjusted with ammonia water The pH of the mixed solution is 3, and the ratio of the total number of moles of metal ions in the mixed solution to citric acid is 1:1.6; the mixed solution is heated and stirred for 0.5 hours, and a brown transparent sol is formed as the hydrolysis and polymerization reactions proceed. , put the sol liquid in a drying oven at 120°C to obtain a dry brown gel; put the obtained dry brown gel into a muffle furnace, heat it at a temperature of 450°C for 2 hours, and then carry out spontaneous c...

Embodiment 2

[0020] Embodiment 2: First, the molar ratio is: Cr:Ni:Mn=10:30:60, respectively weigh 0.001 mole, 0.003 mole, 0.006 mole of Cr, Ni, Mn nitrate as raw material, mix and dissolve into 40mL deionized In water, control the molar concentration of metal ions: 0.25mol / L, and configure it as the main component solution; add 4.86g of citric acid and 10g of polyethylene glycol (PEG) to the prepared solution to make a mixed solution, and use ammonia water to Adjust the pH of the mixed solution to 4, and the ratio of the total number of moles of metal ions in the mixed solution to citric acid is 1:2.0; the mixed solution is heated and stirred for 0.7 hours, and as the hydrolysis and polymerization reactions proceed, a brown sol is formed , put the sol liquid in a drying oven at 120°C to obtain a dry dark brown gel; put the obtained dry dark brown gel into a muffle furnace, heat it at a temperature of 470°C for 2.5 hours, and then carry out spontaneous combustion treatment. To remove the o...

Embodiment 3

[0021] Embodiment Three: First, the molar ratio is: Cr:Ni:Mn=15:30:55, respectively weigh 0.0015 moles, 0.003 moles, 0.0055 moles of Cr, Ni, Mn nitrates as raw materials. Mix and dissolve into 25mL deionized In water, the molar concentration of metal ions is controlled to be: 0.4mol / L, configured as a main component solution; 583g of citric acid and 12g of polyethylene glycol (PEG) are added to the prepared solution to make a mixed solution, and the mixed solution is adjusted with ammonia water The pH of the solution=5, the ratio of the molar sum of the metal ions in the mixed solution to citric acid is 1:2.4; the mixed solution was heated and stirred for 1 hour, and as the hydrolysis and polymerization proceeded, a black sol was formed. The sol liquid is placed in a drying oven at 120°C to obtain a dry black gel; the obtained dry black gel is placed in a muffle furnace, and is kept at a temperature of 500°C for 3 hours before spontaneous combustion to remove the organic compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com