Preparation method of semiconductor electrothermal film

An electrothermal film and semiconductor technology, which is applied in the field of semiconductor electrothermal film preparation, can solve the problems of insufficient bonding between the electrothermal film and the substrate, insufficient stability of the electrothermal film, and difficulty in controlling the sheet resistance, so as to achieve stable electrothermal conversion performance and low leakage current Small, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

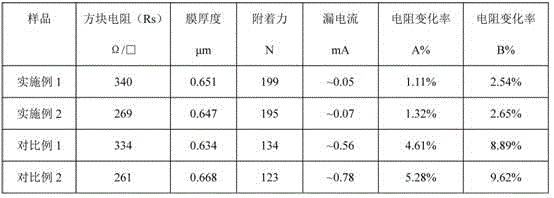

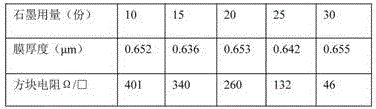

Embodiment 1

[0030] (1) Cleaning the substrate: Clean the substrate with distilled water and dry it for later use;

[0031] (2) Prepare the source solution: weigh the following components by weight, mix them, heat to 50°C, and stir for 1-2 hours to obtain the source solution of the semiconductor electric heating film: 22 parts of tin tetrachloride, 15 parts of graphite, trichloride 10 parts of antimony, 6 parts of titanium tetrachloride, 1.0 part of fluoroboric acid, 0.4 part of fullerene, 0.5 part of sodium chloride, 1 part of water, 4 parts of toluene, 45 parts of ethanol;

[0032] (3) Spray the substrate: place the substrate in step (1) in the heating chamber, control the temperature of the heating chamber in the range of 450-500°C, and start to spray the semiconductor obtained in step (2) when the surface temperature of the substrate reaches about 350°C The electrothermal film source solution is atomized and sprayed onto the surface of the substrate;

[0033] (4) The first heat treatm...

Embodiment 2

[0037] (1) Cleaning the substrate: Clean the substrate with distilled water and dry it for later use;

[0038] (2) Prepare the source solution: weigh the following components by weight, mix them, heat to 75°C, and stir for 2 hours to obtain the source solution of the semiconductor electric heating film: 25 parts of tin tetrachloride, 20 parts of graphite, and 13 parts of antimony trichloride 4 parts of titanium tetrachloride, 0.9 part of fluoboric acid, 0.6 part of fullerene, 0.3 part of sodium chloride, 3 parts of water, 2 parts of toluene, 35 parts of ethanol;

[0039] (3) Spray the substrate: place the substrate in step (1) in the heating chamber, control the temperature of the heating chamber in the range of 500-550°C, and start to spray the semiconductor obtained in step (2) when the surface temperature of the substrate reaches about 400°C The electrothermal film source solution is atomized and sprayed onto the surface of the substrate;

[0040] (4) The first heat treatm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Leakage current | aaaaa | aaaaa |

| Adhesion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com