Encapsulating slurry for aluminum nitride substrate, and preparation method and application thereof

A technology of aluminum nitride substrate and encapsulation slurry, which is applied in the field of slurry, can solve the problems that cannot meet the application requirements of aluminum nitride substrate high-power chip components, high thermal conductivity, small expansion coefficient, etc., and achieve expansion The coefficients are perfectly matched, the binding force is good, and the surface is smooth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

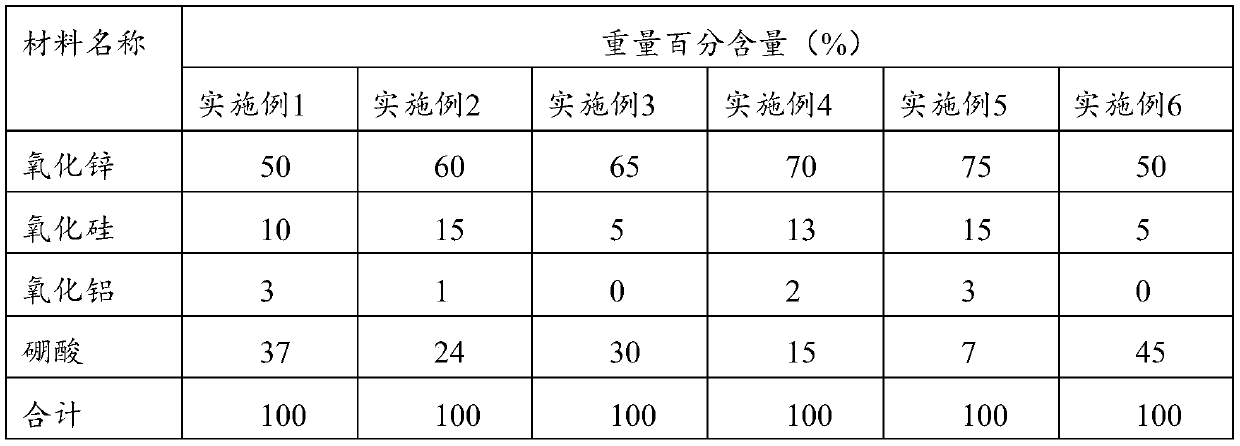

[0065] Carry out the preparation of glass powder according to each raw material in table 1 and raw material content:

[0066] Raw materials for preparing glass powder and the content of each raw material in Table 1 embodiment 1~6

[0067]

[0068] Preparation method of glass powder:

[0069] By weight percentage in Table 1, ZnO, SiO 2 、Al 2 o 3 、H 3 BO 3 After weighing, use a vertical powderer to mix thoroughly, then put it into a corundum crucible, without preheating or slowly heating up, directly put it into a high-temperature furnace at a high temperature of 1100-1200 ° C, keep it warm for 30 minutes, and then pour the molten glass It is poured into deionized water for water quenching, and finally the glass slag after water quenching is ball milled, dried and pulverized with a zirconia tank and zirconia balls to obtain a finished glass powder with a particle size of 1-3.5 μm.

[0070] Prepare the organic vehicle according to the composition and composition content ...

Embodiment 7~12

[0091] The encapsulation slurry is prepared according to the method of Example 3 and Example 4. The difference from Example 3 and Example 4 is that different inorganic additives are used to replace the additives in Example 3 and Example 4. The inorganic additives are listed in Table 4. Ingredient and ingredient content used.

[0092] Inorganic additive components and slurry performance test results in Table 4 Examples 7-12

[0093]

[0094]

[0095] The performance detection methods in Table 4 are the same as those in Table 3. The results show that after adding the inorganic additives used in the present invention, the prepared encapsulation slurry has little influence on resistance, and the resistance change rate is less than ±5%. , the number of bubbles on the surface is less than 5, and the bonding force with the aluminum nitride substrate is good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com