A kind of preparation method of elastic conductor

An elastomer and elastic technology, applied in cable/conductor manufacturing, electrical components, circuits, etc., can solve the problems of complex preparation methods and difficult actual preparation of flexible wires, and achieve enhanced dynamic electrical stability, good dynamic electrical stability, Good effect of resistance recovery performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the liquid metal is GaInSn, which is an alloy whose mass ratio is Ga:In:Sn=68.2:21.8:10. The liquid metal is liquid at room temperature and has high conductivity; the elastomer is polydimethyl Silicone (PDMS), a thermosetting polymer.

[0028] In this example, the preparation method of the elastic conductor is as follows:

[0029] (1) Mechanically stir the GaInSn alloy, PDMS, and curing agent evenly, so that the liquid metal droplets are evenly dispersed in the PDMS to obtain a mixture, wherein the volume ratio of the GaInSn alloy to PDMS is 20:80, that is, the volume ratio is 25%;

[0030] (2) Pour the mixture into a mold with a depth of 2mm. Let the mold containing the mixture stand for 1 hour to remove the air bubbles in the mixture and deposit the liquid metal, then put it into a drying oven at 60°C and heat it for 3h-4h to solidify the PDMS in the mixture, and take out the sample after cooling to obtain elastic conductor.

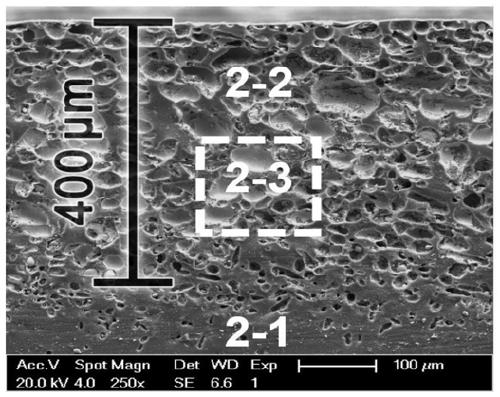

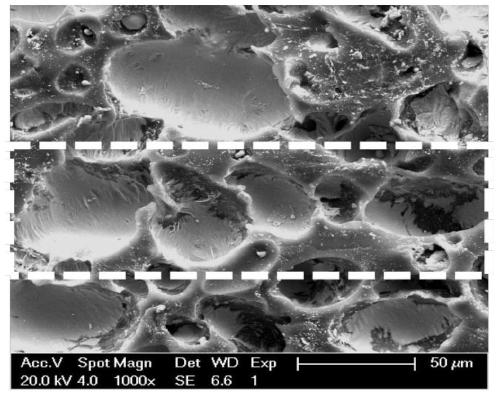

[0031] The scannin...

Embodiment 2

[0036] In this embodiment, the liquid metal is the same as that in Embodiment 1, the elastomer is the same as that in Embodiment 1, and the curing agent is the same as that in Embodiment 1.

[0037] In this example, the preparation method of the elastic conductor is basically the same as that in Example 1, except that in step (1), the volume ratio of GaInSn alloy to PDMS is 5%.

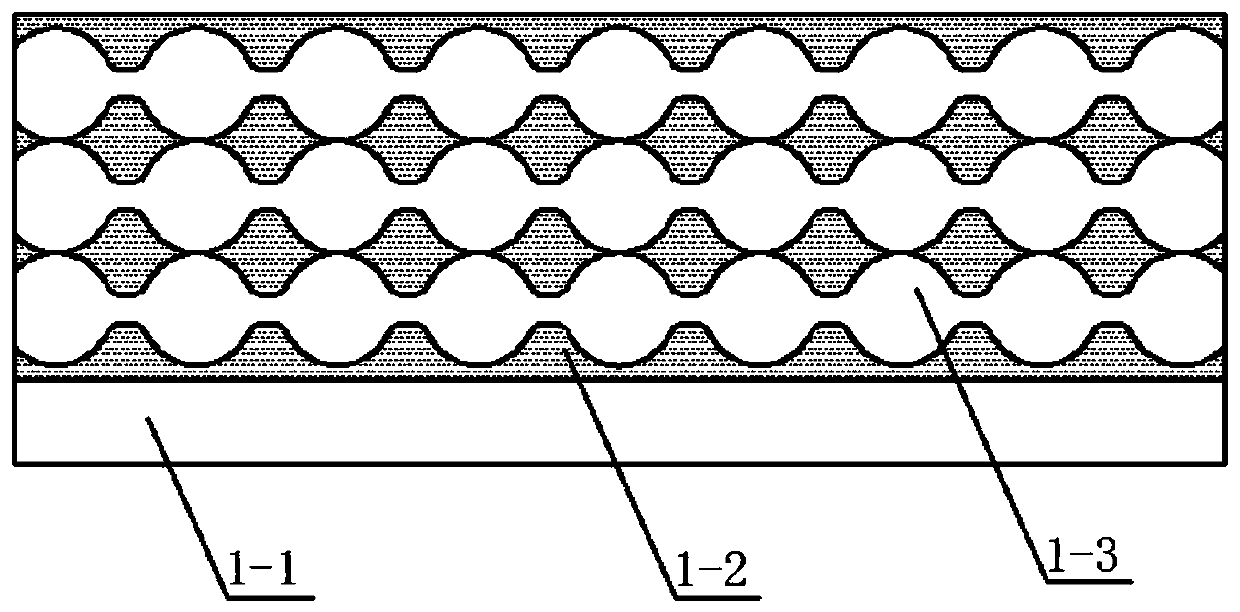

[0038]The scanning electron micrographs of the above-mentioned elastic conductors are similar to figure 2 As shown, the elastic conductor has a two-layer structure, the lower layer is the support layer, and the upper layer is the conductive layer. In the conductive layer, the special structure of liquid metal in the shape of gourd strings is filled in the elastic body to form a connected conductive channel.

[0039] Detect the resistance change of the elastic conductor prepared above when the tensile stress is loaded and unloaded, and the results show that:

[0040] (1) The elastic conductor has goo...

Embodiment 3

[0043] In this embodiment, the liquid metal is the same as that in Embodiment 1, the elastomer is the same as that in Embodiment 1, and the curing agent is the same as that in Embodiment 1.

[0044] In this example, the preparation method of the elastic conductor is basically the same as that in Example 1, except that in step (1), the volume ratio of GaInSn alloy to PDMS is 10%.

[0045] The scanning electron micrographs of the above-mentioned elastic conductors are similar to figure 2 As shown, the elastic conductor has a two-layer structure, the lower layer is the support layer, and the upper layer is the conductive layer. In the conductive layer, the special structure of liquid metal in the shape of gourd strings is filled in the elastic body to form a connected conductive channel.

[0046] Detect the resistance change of the elastic conductor prepared above when the tensile stress is loaded and unloaded, and the results show that:

[0047] (1) The elastic conductor has g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| rate of change | aaaaa | aaaaa |

| rate of change | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com