High-wear-resistance type resistance paste

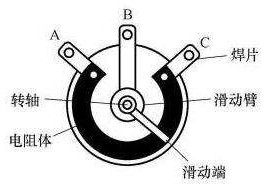

A resistance paste, high wear resistance technology, applied in the direction of resistors, adjustable resistors, circuits, etc., can solve the problems of surface wear of resistors, large changes in resistance value, failure of potentiometers, etc., to achieve stable resistance, The effect of small resistance change rate and wide resistance range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

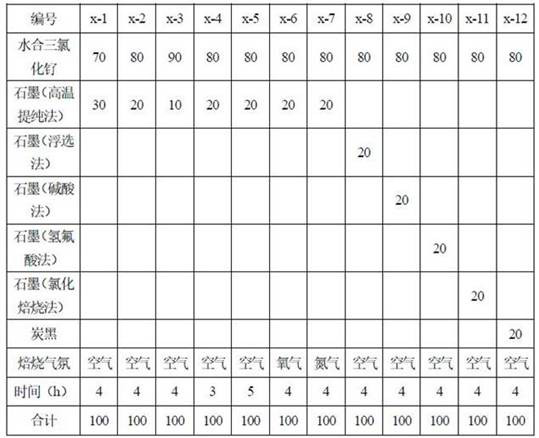

[0016] 1. Preparation of conductive powder: After dissolving ruthenium trichloride hydrate with deionized water, add graphite or carbon black with a particle size of less than 1.0 μm according to the ratio in Table 1, mix evenly, and then add triethanolamine to adjust the pH value to 7~ 8. Continue to stir for 30 minutes, filter the precipitate and dry it at 80°C, then roast it in a muffle furnace at 570°C, and mill it with broken balls until the particle size is 0.7-1.3 μm. Among them, graphite is graphite powder with a purity greater than 99.9% prepared by high-temperature purification method, flotation method, alkali-acid method, hydrofluoric acid method, and chlorination roasting method.

[0017] Table 1 Ingredients ratio and preparation method of conductive powder

[0018]

[0019] At the same time, conduct comparative tests with conductive powders x-13, x-14, and x-15. The preparation methods of conductive powders x-13, x-14, and x-15 are as follows:

[0020] Mix rut...

Embodiment 2

[0037]Embodiment 2 is compared with comparative examples 1 and 2, and the length of the roasting time that illustrates graphite composite ruthenium dioxide can affect the temperature coefficient of resistance, and the 4h roasting that the present invention selects can make resistance paste obtain better temperature coefficient characteristic.

[0038] The comparison between Example 2 and Comparative Examples 3 and 4 shows that the baking atmosphere of graphite composite ruthenium dioxide will change the properties of the conductive phase material, resulting in a significant deterioration in the wear resistance of the resistor paste.

[0039] Embodiment 2 is compared with Comparative Examples 5~8, illustrates that graphite composite ruthenium dioxide must adopt the graphite that high-temperature purification process prepares, and the graphite that other methods prepare is used for composite ruthenium dioxide and is applied in resistance slurry, can not make resistance slurry Ha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com