Semiconductor ceramic composition and PTC thermistor

A ceramic composition and semiconductor technology, applied in thermistors, resistors, resistor parts, etc., can solve the problem of high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~73、 comparative example 1~27

[0077] Preparation of BaCO as starting material 3 、TiO 2 、 Bi 2 o 3 、Na 2 CO 3 、K 2 CO 3 , CaCO 3 , SiO 2 , MnCO 3 , oxides of RE (such as Y 2 o 3 ) and TM oxides (such as Nb 2 o 5 ), each raw material was weighed in such a manner that the composition after sintering was Table 1-9, and then wet-mixed in ethanol using a ball mill, then dried, and calcined at 800° C. for 2 hours.

[0078] The above calcined body was wet pulverized in pure water using a ball mill, and then dehydrated and dried. This is granulated using a binder such as PVA to obtain a granulated powder. This was molded into a cylindrical shape (diameter 17 mm×thickness 1.0 mm) by a single-screw extruder, and sintered at 1200° C. for 2 hours in an air atmosphere to obtain a sintered body.

[0079] Ag-Zn paste was applied to both sides of the sintered body by screen printing, and after sintering in the air at 500-800°C to form electrodes, the temperature characteristics of resistivity were measured a...

Embodiment 74

[0082] A semiconductor ceramic composition was prepared in the same manner as in Example 1 except that the atmosphere during sintering was set to a nitrogen atmosphere and further heat-treated in an atmosphere of 800° C., and the same evaluations as in Examples 1 to 73 were performed. The results are shown in Table 9.

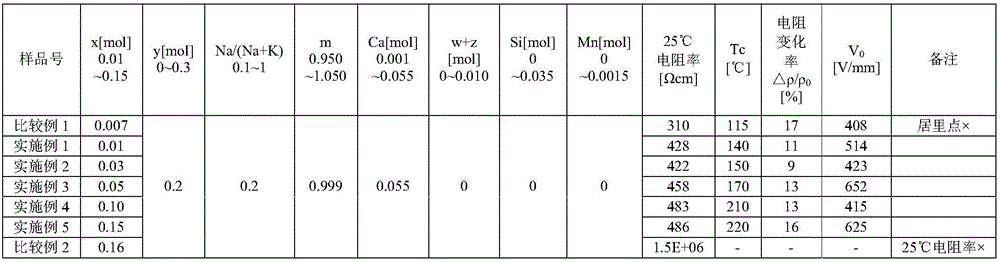

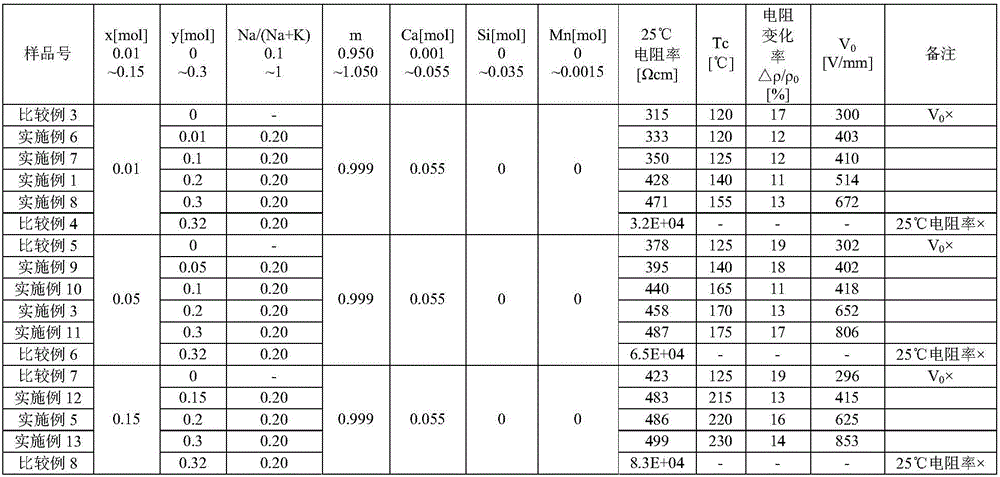

[0083] According to Table 1, it can be seen that the composition range x of the Bi element is related to the Curie point. According to Examples 1-5, if the composition range of Bi element is 0.01≤x≤0.15, the Curie point is higher than that of BaTiO 3 The Curie point, that is, the high temperature side of 120°C moves, and the resistivity at room temperature is below 500Ωcm, the withstand voltage is above 400V / mm, and the resistance change rate △ρ / ρ 0 Keep it under 20%. In addition, it can be seen that the higher the content of x, the more the Curie point shifts to the high temperature side, and the room temperature resistivity tends to slightly increase. In C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Curie point | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com