Low-temperature-coefficient metal film resistor and manufacturing process thereof

A technology of metal film resistors and low temperature coefficient, applied in the direction of non-adjustable metal resistors, resistors, resistor parts, etc. Firmness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

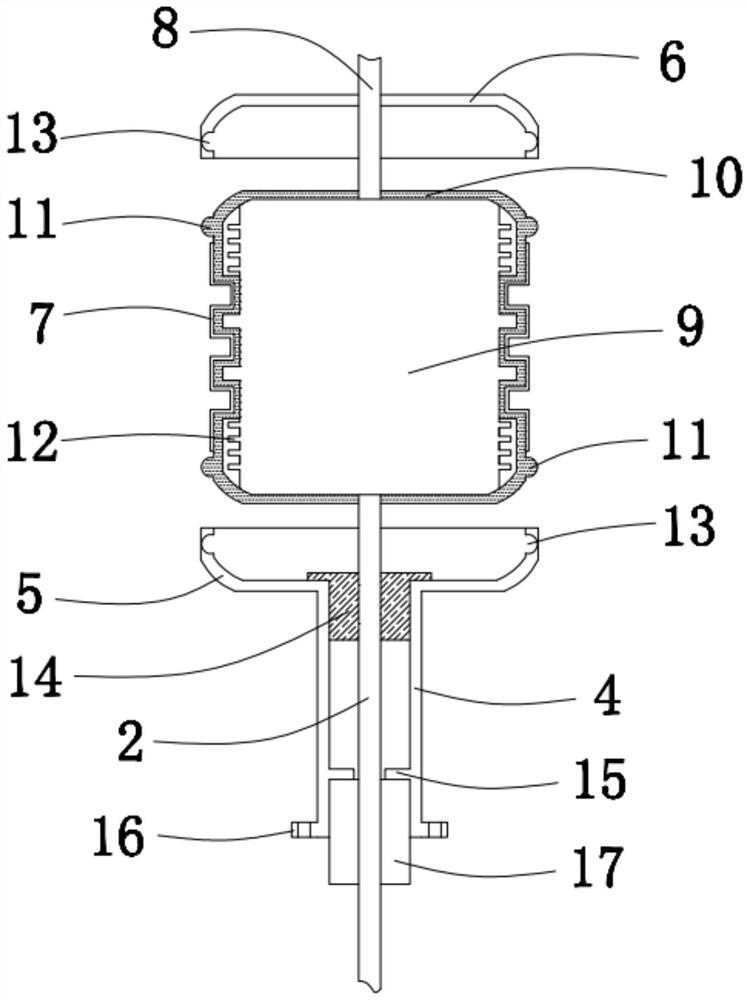

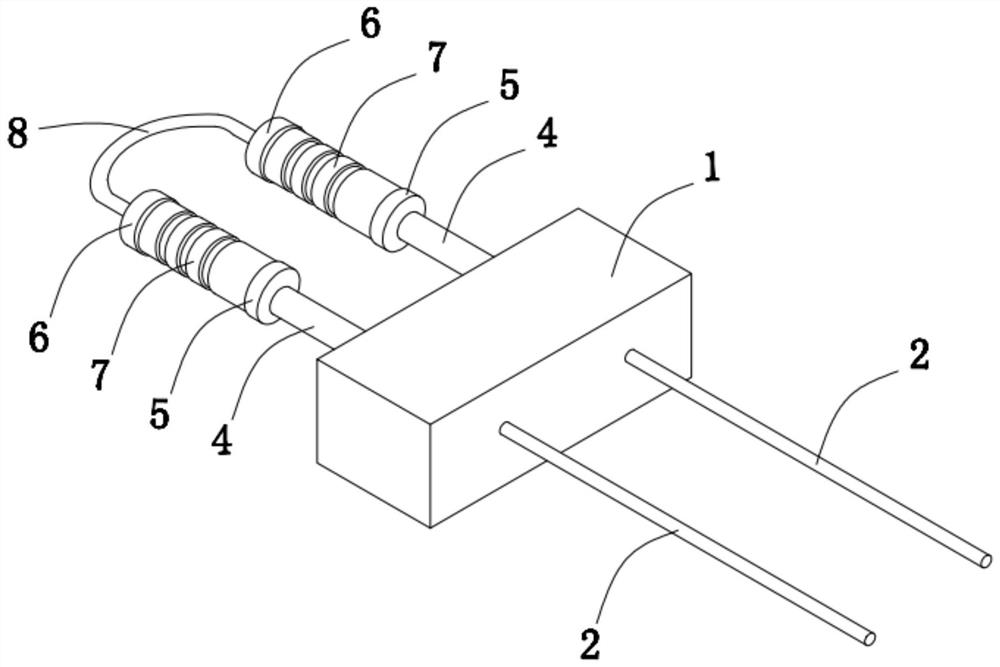

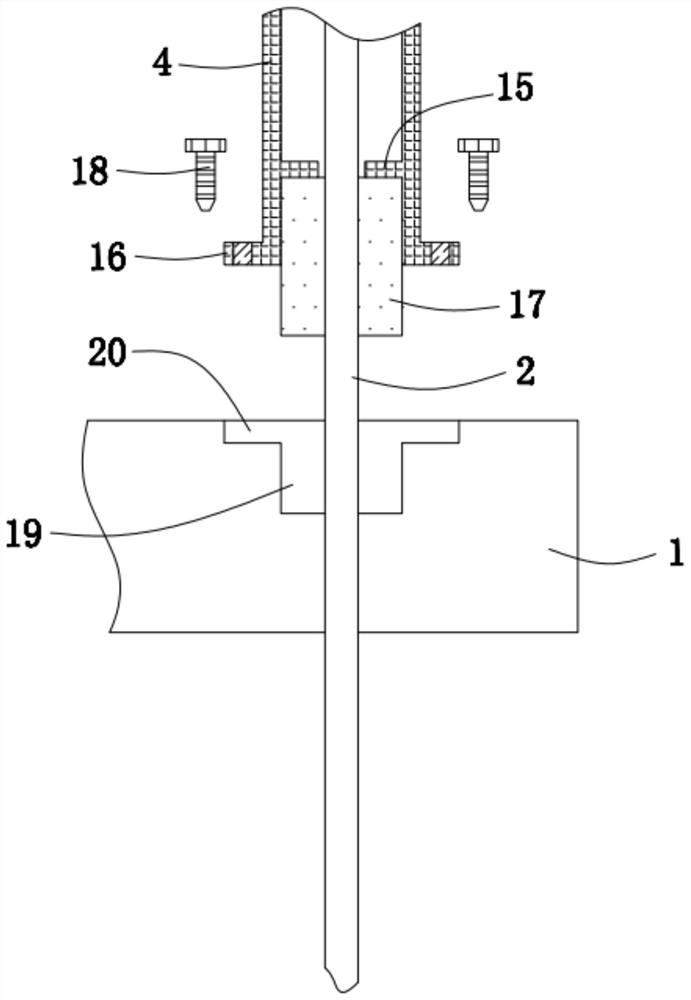

[0024] The present invention provides such as Figure 1-3 A metal film resistor with a low temperature coefficient, including an epoxy resin block 1 and two resistor bodies with pins 2, one end of the two resistor bodies is connected in series with each other through a connecting pin 8, and the other end of the resistor body The outer side of the pin 2 is poured into an epoxy resin block 1 through epoxy resin, and the resistor body includes a base body 9, a metal film 10 wrapped on the outside of the base body 9, a first electrode cap 6 and a second electrode cap connected to the front and rear ends of the metal film 10. Motor cap 5, the exterior of the resistor body is coated with a paint layer 7, the connecting pin 8 is connected to the front end of the metal film 10 after penetrating the first electrode cap 6, and the pin 2 is penetrating the back of the second motor cap 5 connected to the back end of the metal film 10;

[0025] The rear end of the second motor cap 5 is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com