Elastic conductor and preparation method thereof

A technology of elastic substrate and conductor, applied in cable/conductor manufacturing, rod/rod/wire/strip conductor, and equipment for manufacturing conductive/semiconductor layers, etc., can solve the problems of low production efficiency and stretchable conductors And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

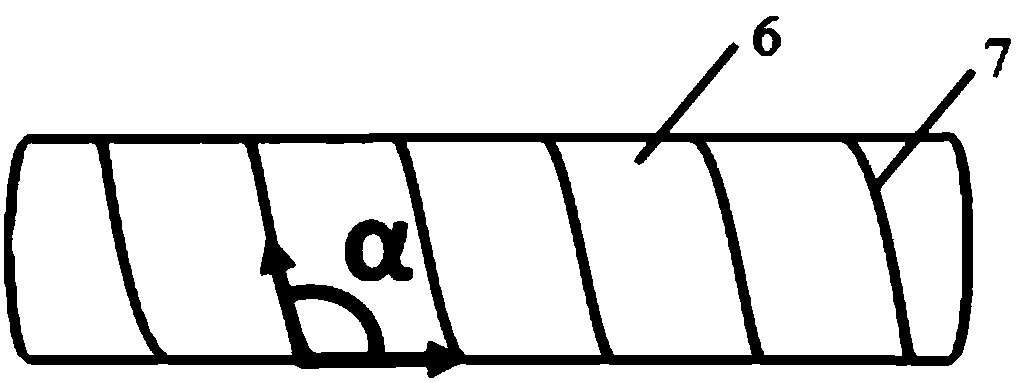

[0033] In this embodiment, the elastic conductor structure is as figure 1 As shown, an elastic matrix 6 and liquid metal 7 are included. The elastic substrate 6 is a thermoplastic rubber tube (TPE), and the liquid metal 7 is a gallium indium tin alloy doped with copper powder. The liquid metal 7 is attached to the surface of the elastic base 6 and is in a continuous spiral winding shape around the periphery of the elastic base 6. The included angle α between the liquid metal and the reference line parallel to the central axis of the spiral winding is 120°.

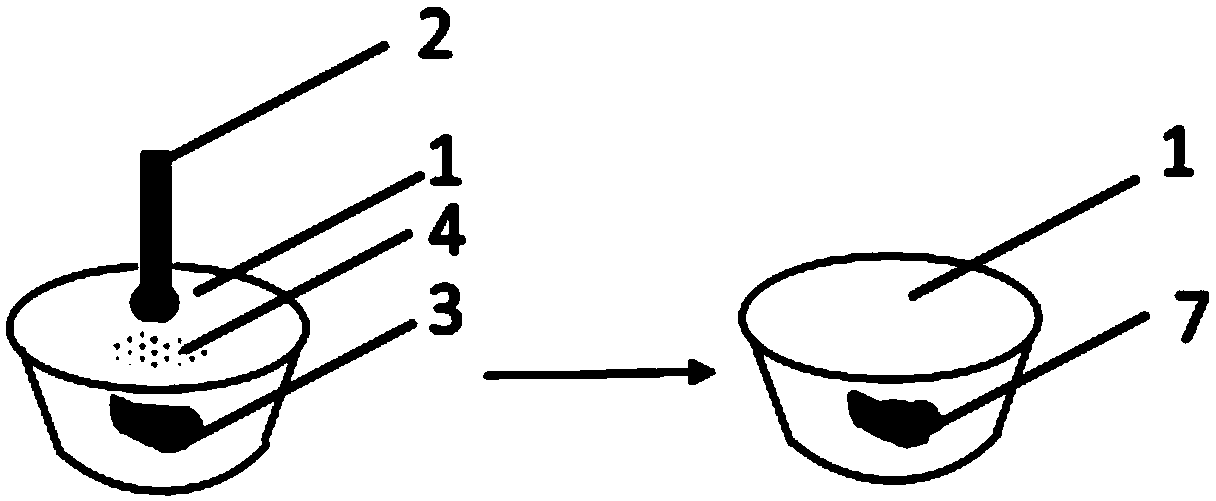

[0034] The preparation process of the elastic conductor is as figure 2 As shown, including the following steps:

[0035] Step 1: Such as figure 2 As shown, the liquid metal 3 and copper powder 4 are placed in a mortar 1 and ground with a pestle 2 for one hour. The mass ratio of the liquid metal to the copper powder is 9:1 to obtain the liquid metal doped with copper powder. Vacuum with a vacuum pump until there are no pores ...

Embodiment 2

[0040] In this embodiment, the structure of the elastic conductor is basically the same as that in Embodiment 1, except that the included angle α between the liquid metal and the reference line parallel to the central axis of the spiral is 110°.

[0041] The preparation process of the elastic conductor is basically the same as that of Example 1, except that steps 3 and 4 are as follows:

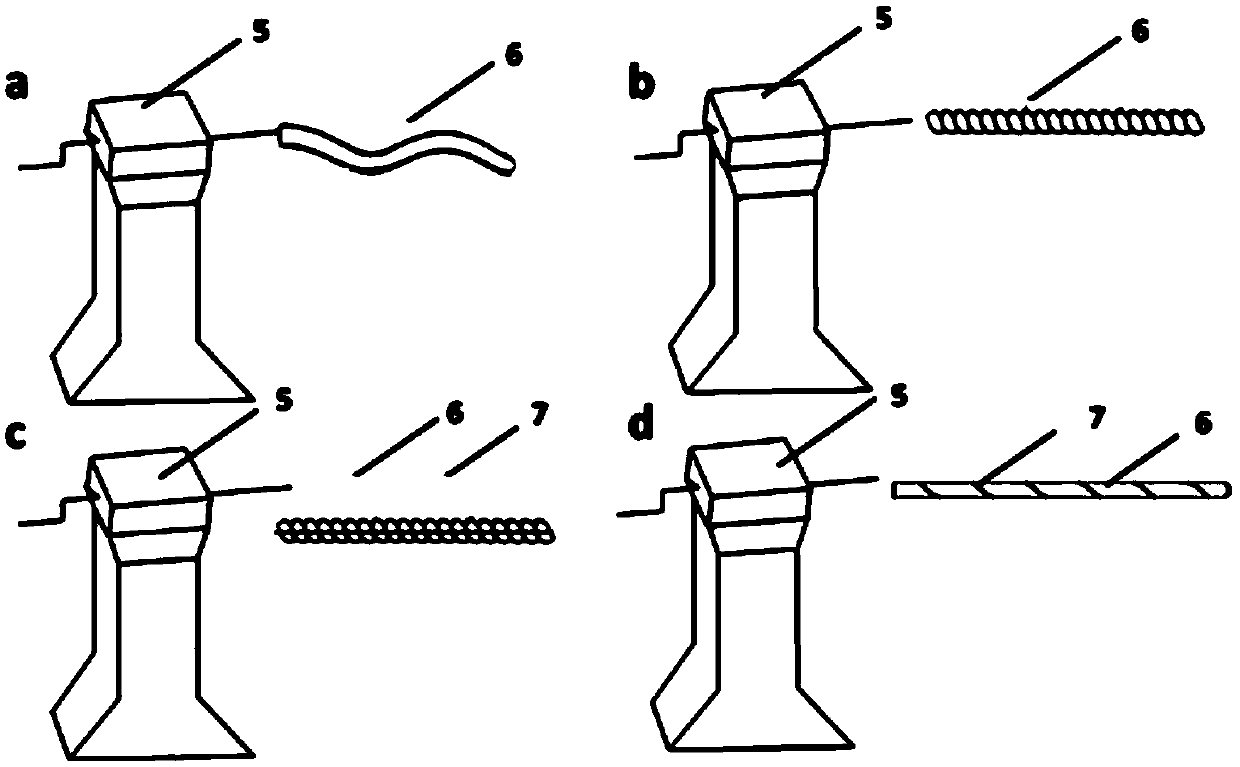

[0042] Step 3: Rotate the winding machine 60 times clockwise to obtain a threaded TPE rubber tube; coat the threaded TPE rubber tube with the liquid metal doped with copper powder prepared in step 1, and the liquid metal adheres to the surface of the elastic substrate. Linear.

[0043] Step 4: Fix the threaded TPE rubber tube with liquid metal doped with copper powder on the winding machine 5 obtained in Step 3, and the winding machine rotates 60 times counterclockwise to obtain a continuous liquid metal around the elastic substrate. Spiral orbit, and the angle between the liquid metal and the refe...

Embodiment 3

[0045] In this embodiment, the structure of the elastic conductor is basically the same as that in Embodiment 1, except that the included angle α between the liquid metal and the reference line parallel to the central axis of the spiral is 100°.

[0046] The preparation process of the elastic conductor is basically the same as that of Example 1, except that steps 3 and 4 are as follows:

[0047] Step 3: Rotate the winding machine 90 times clockwise to obtain a threaded TPE rubber tube; coat the threaded TPE rubber tube with the liquid metal doped with copper powder prepared in step 1, and the liquid metal adheres to the surface of the elastic substrate. Linear.

[0048] Step 4: Fix the threaded TPE rubber tube with liquid metal doped with copper powder on the winding machine 5 obtained in Step 3, and the winding machine rotates 90 times counterclockwise to obtain a continuous liquid metal around the elastic substrate. Spiral winding, and the included angle between the liquid metal a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com