Preparation method of PPTC (Polymeric Positive Temperature Coefficient) thermistor with high electrode peeling strength and uniform resistance distribution

A technology with high peeling strength and thermistor, applied in the direction of resistors with positive temperature coefficient, etc., can solve the problems of long-term storage, small electrode peeling force, discrete resistance distribution, etc., to save materials, good resistance consistency, Effect of small resistance change rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

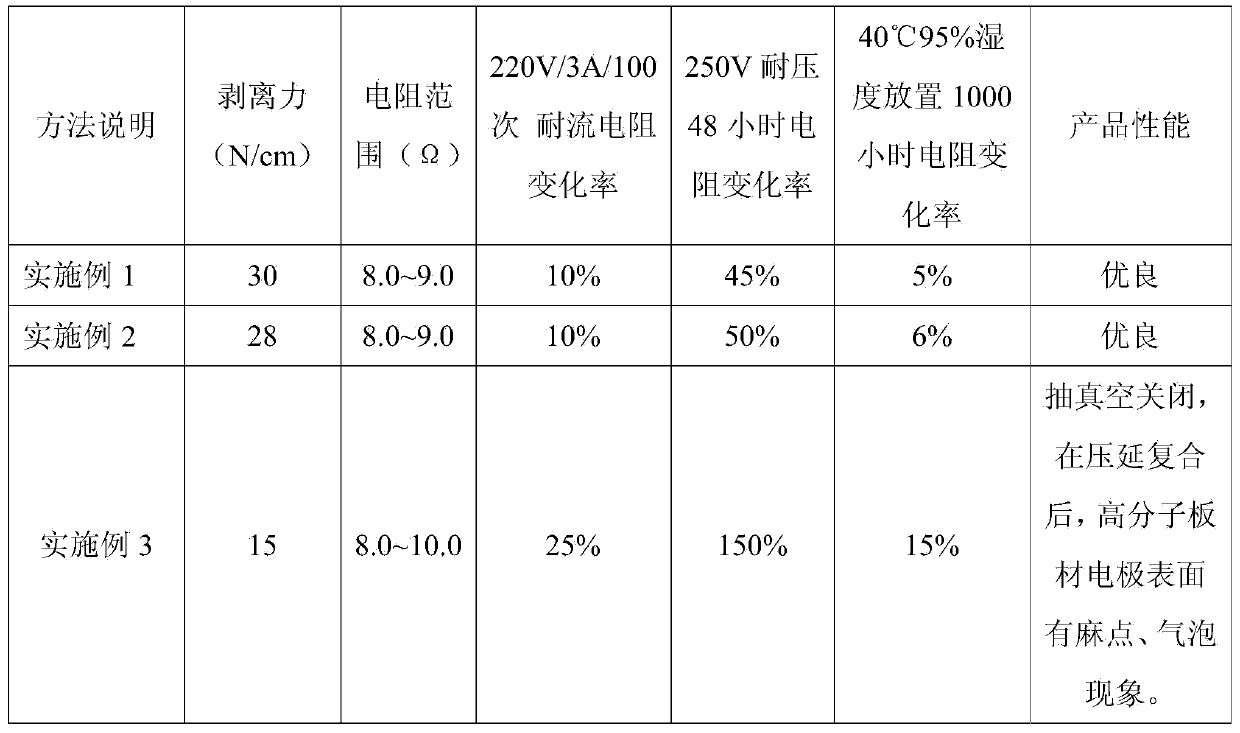

Embodiment 1

[0047] In this embodiment, the base material is: 4400 g of high-density polyethylene, 4000 g of carbon black, and 4200 g of magnesium hydroxide.

[0048] Concrete process step is in the present embodiment:

[0049] 1) Base material treatment: mix the base material according to the above components, then pour the base material into the mixer and mix evenly;

[0050] 2) Twin-screw extruder extrusion: After mixing in step 1), the base material is vacuum-extruded by the twin-screw extruder; the twin-screw extruder

[0051] The extrusion temperature of the rod extruder is 190-200°C;

[0052] 3) Extrusion and calendering: extruded by a single-screw extruder at 190-195°C, and then rolled on a calender to obtain a shaped sheet, which is automatically rewound by a rewinding device; a 110mm wide mushroom-shaped coarse screen is used for calendering Nickel-plated copper foil is used as an electrode, and the electrode is automatically unwound by an unwinding device with tension. The tem...

Embodiment 2

[0061] In this embodiment, the base material is: 4400 g of high-density polyethylene, 4000 g of carbon black, and 4200 g of magnesium hydroxide.

[0062] Concrete process step is in the present embodiment:

[0063] 1) Base material treatment: mix the base material according to the above components, then pour the base material into the mixer and mix evenly;

[0064] 2) Extrusion by twin-screw extruder: After mixing in step 1), the base material is vacuum-extruded by the twin-screw extruder; the extrusion temperature of the twin-screw extruder is 190-200°C;

[0065] 3) Extrusion and calendering: extruded by a single-screw extruder at 190-195°C, and then rolled on a calender to obtain a shaped sheet, which is automatically rewound by a winding device; 110mm wide dendritic nickel plating is used for calendering Copper foil is used as an electrode, and the electrode is automatically unrolled by an unwinding device with tension. The head temperature of the single-screw extruder is ...

Embodiment 3

[0074] This embodiment is a comparative test of Examples 1 and 2. Under the condition that other process conditions remain unchanged, vacuum extrusion is not used and common roughened copper foil is used as the electrode when the twin-screw extruder is extruded to obtain the final high Molecular PTC thermistor. The common roughened copper foil is selected from Shanghai Jinbao roughened copper foil with a thickness of 35um.

[0075] In this embodiment, the base material is: 4400 g of high-density polyethylene, 4000 g of carbon black, and 4200 g of magnesium hydroxide.

[0076] Concrete process step is in the present embodiment:

[0077] 1) Base material treatment: mix the base material according to the above components, then pour the base material into the mixer and mix evenly;

[0078] 2) Twin-screw extruder extrusion: the base material mixed in step 1) is extruded through a twin-screw extruder; the extrusion temperature of the twin-screw extruder is 190-200°C;

[0079] 3) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com