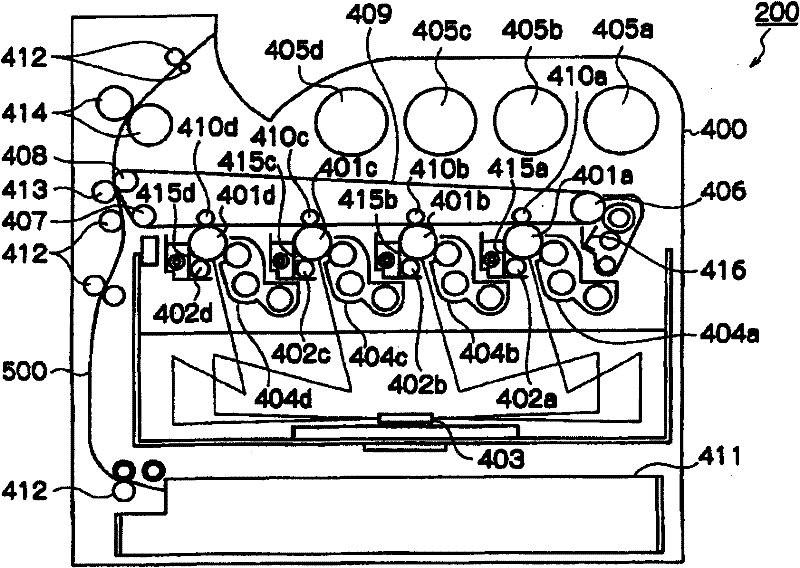

Charging member, process unit cartridge, and image forming apparatus

一种充电部件、导电性的技术,应用在电晕放电装置、电气元件、电路等方向,达到电阻变化率降低、图像品质优、表面性质改善的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

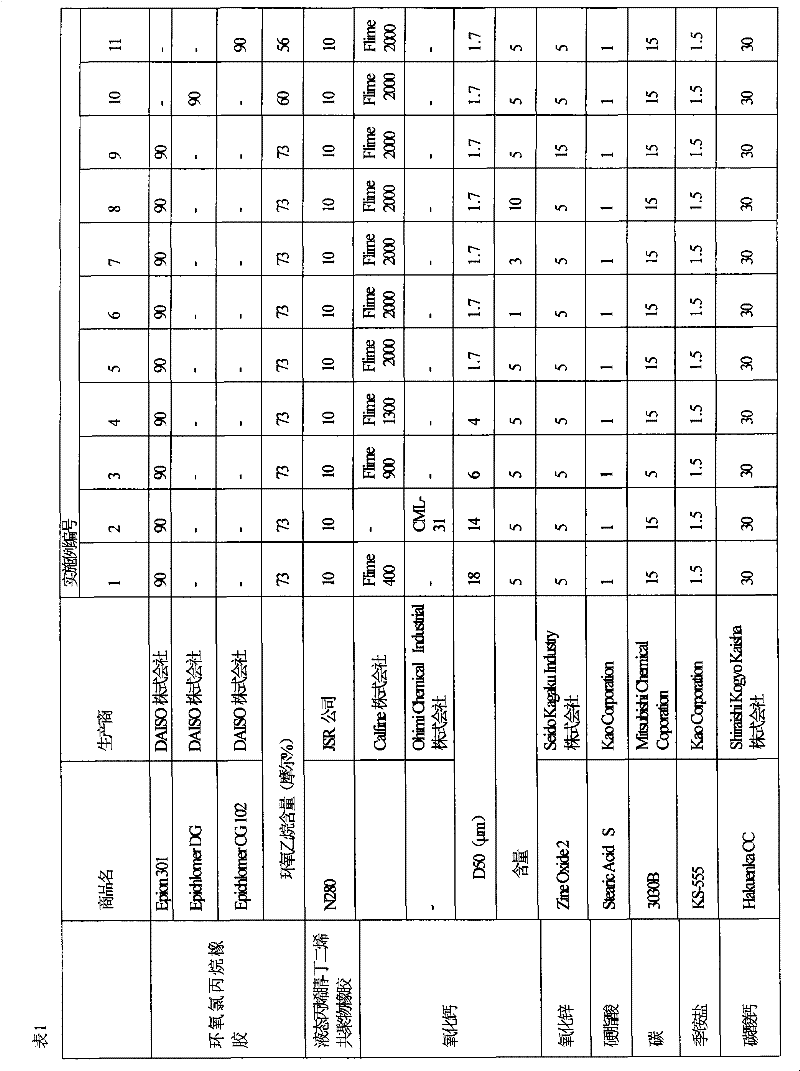

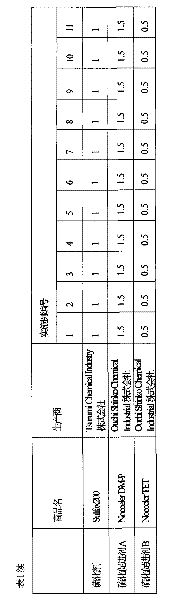

Embodiment 1 to 11 and comparative example 1 to 3

[0062] 1. Make the charging roller

[0063] 1-1. Making a metal shaft

[0064] A drawn metal tube having an outer diameter of 8 mm was cut to a length of 330 mm and subjected to electroless nickel plating to produce a metal shaft.

[0065] 1-2 Formation of conductive elastic layer

[0066]The ingredients shown in the following Tables 1 and 2 (units are weight ratios) were kneaded in a tangential pressure kneader (available from Moriyama Co., Ltd.) with a net chamber capacity of 75 liters, and then kneaded in a 22-inch open mill Kneading in to obtain unvulcanized rubber flakes. The unvulcanized rubber sheet is extruded by a single-screw rubber extruder (cylinder inner diameter: 60mm; L / D: 20) with a crosshead die (inner diameter: 12mm, die mouth diameter: 8mm), while the metal shaft is continuously Through this crosshead die, the extruded unvulcanized rubber is thus coated on the metal shaft. The rotation speed of the screw was 15 rpm, and the temperatures at the barrel, sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com