Carbon fiber and metal connecting structure and connecting method thereof

A connection structure, carbon fiber technology, applied in the direction of ohmic resistance heating parts, heating element shapes, etc., can solve problems such as unfavorable production and rapid installation, large longitudinal stress at the contact point, large damage to carbon fiber filaments, etc., to improve heating life and Effect of heat supply quality, indirect contact area increase, and contact resistivity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

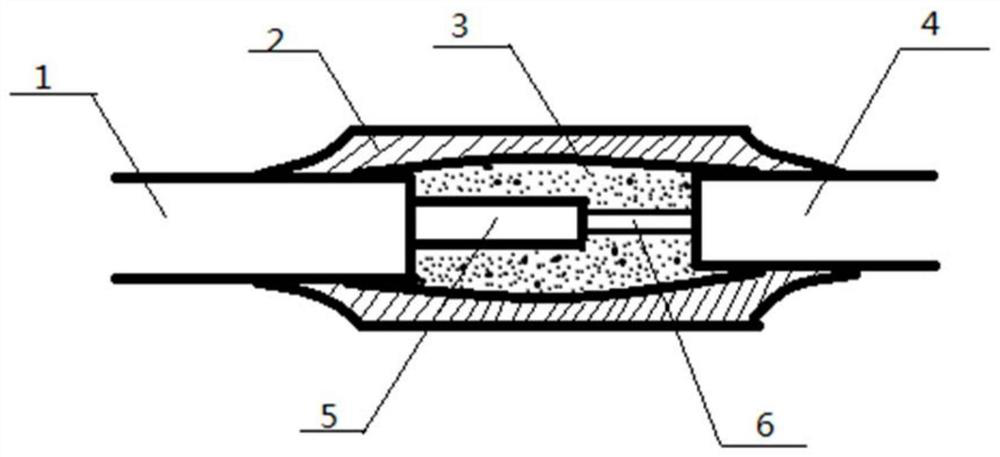

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0020] The resistance stability of the heating element is an important index to evaluate the quality of the element, and the resistance change rate under a certain temperature rise is used To represent,

[0021]

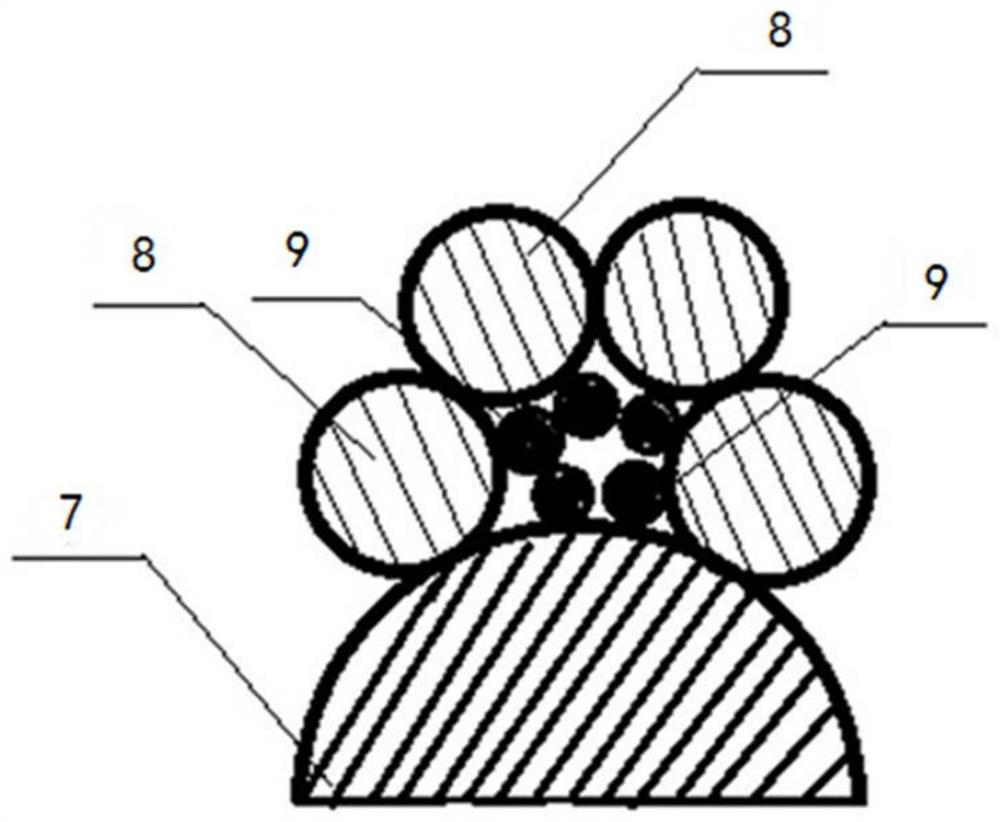

[0022] where R 0 is the cold resistance of the carbon fiber heating element, and R is the dynamic resistance of the carbon fiber heating element. Let the monofilament length of carbon fiber be L, the diameter of monofilament be d, and the total number of monofilaments be n cf , the cold resistivity of carbon fiber material ρ cf , n c The number of fiber overlapping points between carbon fiber monofilaments is equivalent to increasing the parallel connection between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com