Crystalline silicon solar cell silver paste with low silver content and preparation method thereof

A technology for solar cells and crystalline silicon, which is applied in the field of low silver content crystalline silicon solar cell silver paste and its preparation, can solve the problems of easy sintering, difficult oxidation and high conductivity of silver powder, and achieves the reduction of silver content, less ash residue, The effect of high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

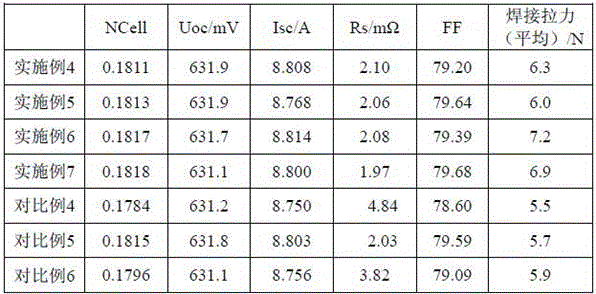

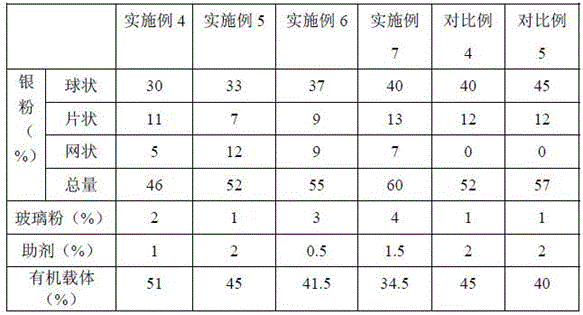

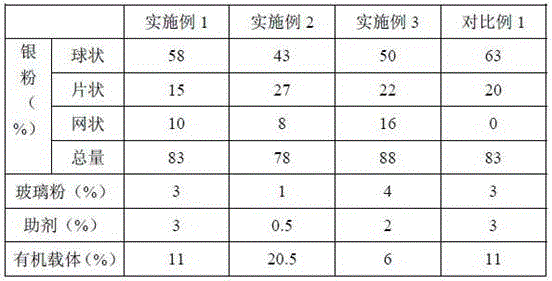

[0035] In Examples 1-3, the average particle size of the spherical silver powder is 0.2~3μm, and the tap density is 4.5~5.5 g / cm 3 ; The average particle size of flake silver powder is 2~6μm, and the tap density is 4.0~4.5 g / cm 3 In Example 1 and Example 3, the micro-nano reticulated silver powder has a two-dimensional structure, with a size range of 0.1~10μm, a porosity of 20~60%, and a pore size <100nm; in Example 2 the micro-nano reticulated silver powder is Three-dimensional structure, other specifications are the same as above.

[0036] The glass powder system in Examples 1 to 3 and Comparative Examples 1 to 3 is lead-free glass powder, the formula of lead-free glass powder and its mass percentage composition are: Bi 2 O 3 40~60%, B 2 O 3 10~20%, SiO 2 8~15%, ZnO 10~30%, Al 2 O 3 0.5~5%, BaO 0.1~2%, TeO 2 10~25%, ZrO 2 0~3% and TiO 2 1~5%. The glass powder composition selected in the embodiment is: Bi 2 O 3 43%, B 2 O 3 15%, SiO 2 10%, ZnO 12%, Al 2 O 3 3%, BaO 1%, ...

Embodiment 2

[0038] The mass percentages of the components of the organic vehicle in Example 2 are: 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 35%, and diethylene glycol butyl ether 30% , 3-hydroxy-3-carboxyl tributyl glutarate 12%, dimethyl adipate 5%, cellulose acetate butyrate 2%, ethyl cellulose 8%, rosin resin 8%.

Embodiment 3

[0039] The mass percentage content of each component of the organic carrier in Example 3 is preferably: 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate 30%, and diethylene glycol butyl ether 35%. Tributyl 3-hydroxy-3-carboxyglutarate 10%, dimethyl adipate 5%, cellulose acetate butyrate 5%, ethyl cellulose 5%, rosin resin 10%.

[0040] Additives: Example 1 adds thixotropic agent 1.5%, defoamer 0.3%, dispersant 0.2%, leveling agent 0.7% and wetting agent 0.3%; Example 2 only adds thixotropic agent, example 3 Add thixotropic agent 1.5%, defoamer 0.3%, and dispersant 0.2%.

[0041] Taking Example 1 as a reference sample, in Comparative Example 1, no micro-nano reticulated silver powder was added, and the mass percentage of spherical silver powder and flake silver powder was increased, and the content of other components was the same as that of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com