Silver solder for connecting brass and stainless steel

A silver brazing material and stainless steel technology, applied in welding/cutting medium/material, welding medium, welding equipment, etc., can solve the problems of high welding cost, low welding cost and high silver content, and achieve good processing performance and welding cost. Low, low silver content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Manufacture of brazing filler metals: according to the ratio of ingredients, the wires and strips of brazing filler metals are manufactured by melting, casting, extrusion, drawing or rolling processes. Among them, the rare earth is smelted into a copper-rare earth master alloy in advance and then proportioned, and the raw materials of other components are pure metals.

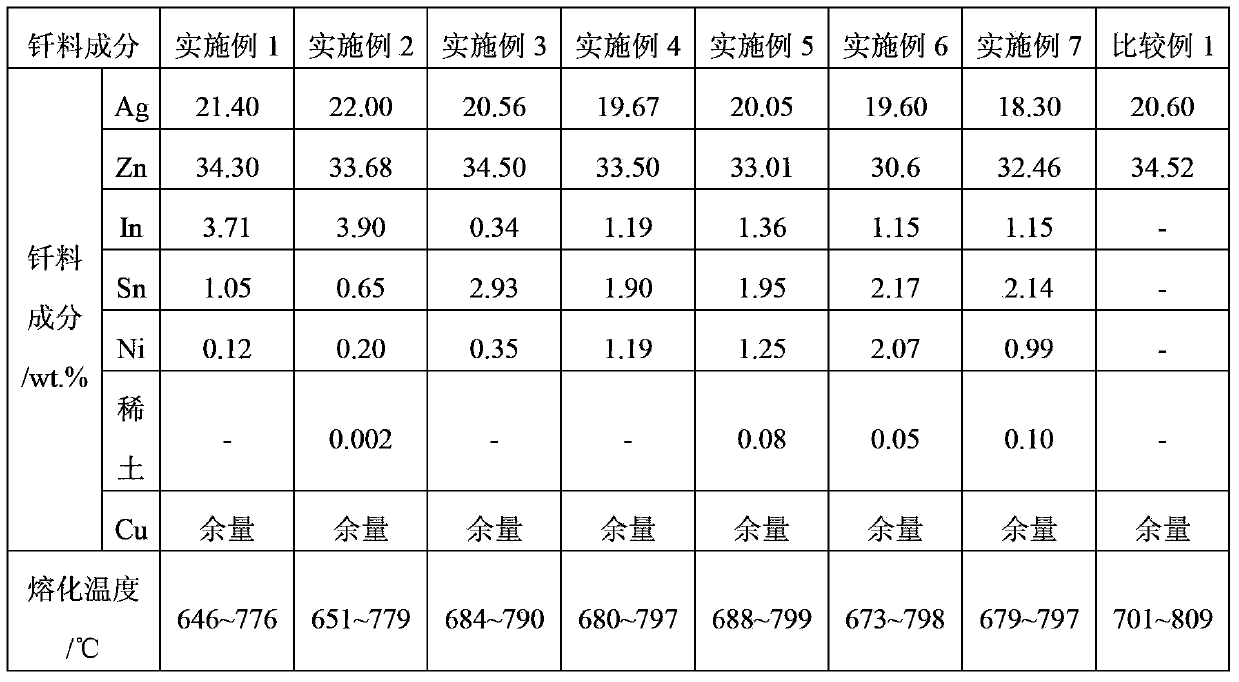

[0026] The embodiment of solder of the present invention and the performance comparison with existing BAg20CuZn solder are shown in Table 1. The melting temperature of the solder is measured by a differential thermal analyzer, the heating rate is 15°C / min, and the protective gas is N 2 , using a high-purity alumina crucible.

[0027] Table 1: The embodiment of brazing filler metal of the present invention and the performance comparison with existing silver brazing filler metal

[0028]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com