Mixed metal powder, preparation method, conductive silver pulp and use

A mixed metal and metal silver technology, which is applied in the field of metal powder processing, can solve the problems of unstable silver-plated copper powder, decreased powder conductivity, and easy oxidation of copper elements, so as to achieve difficult migration, no decrease in electrical conductivity, and excellent comprehensive performance. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

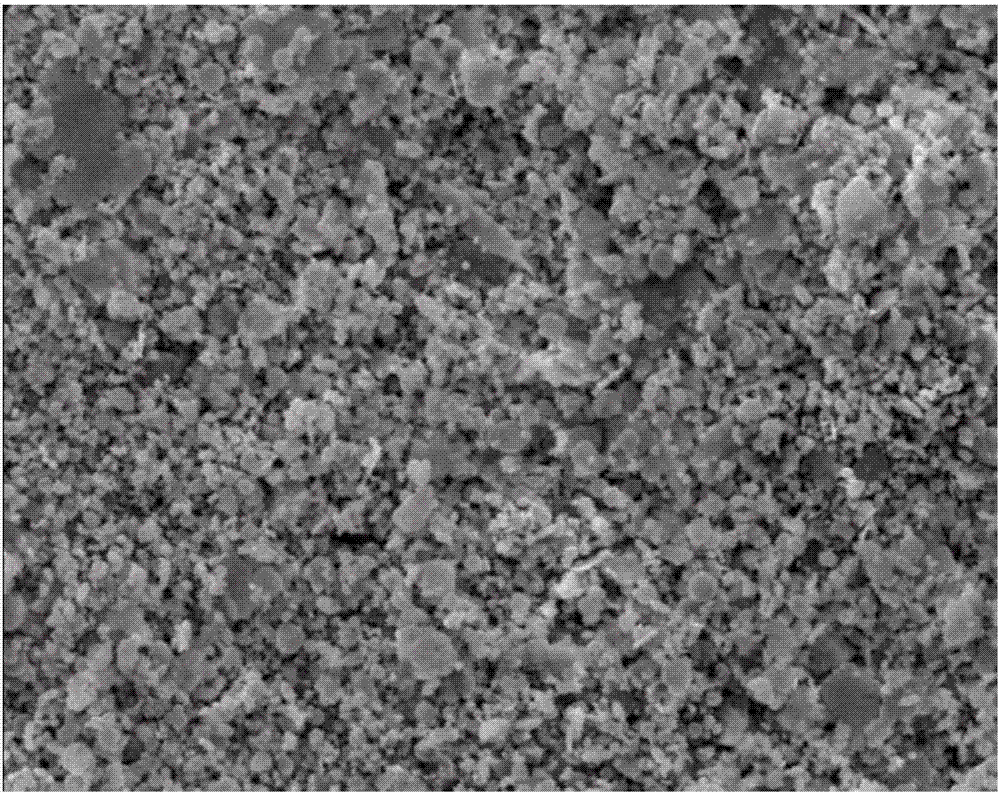

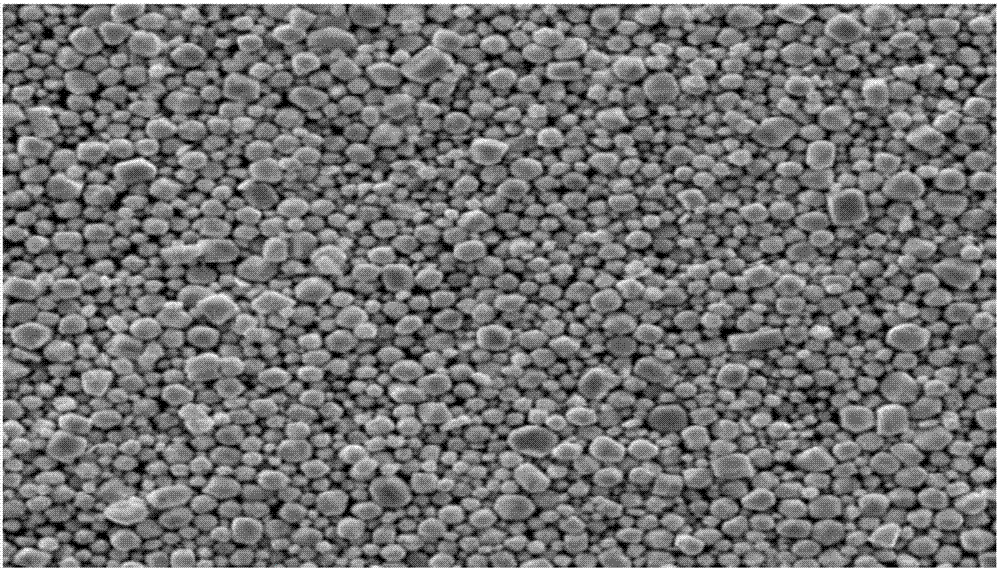

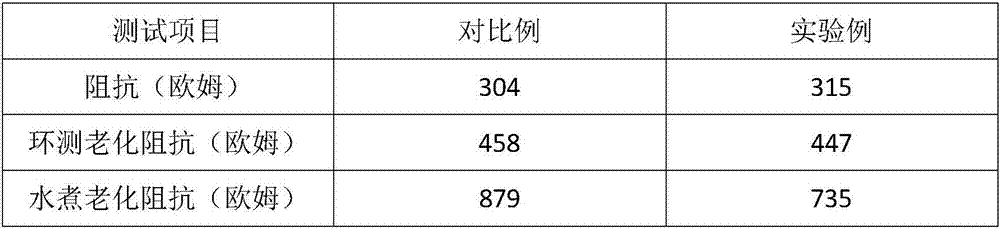

Image

Examples

Embodiment 1

[0024] A kind of preparation method step of mixed metal powder is:

[0025] (1) first add oleic acid and cetyl alcohol in deionized water;

[0026] (2) Adding zirconium hydride powder and silver nitrate with an average particle diameter of 1.5 microns successively, then heating to 50 degrees, and insulated for 0.5 hours;

[0027] (3) add sodium carbonate then, insulation 0.5 hour;

[0028] (4) Finally add glucose and glycerol and keep warm for 2 hours to obtain a mixed metal powder suspension;

[0029] (5) The obtained mixed metal powder suspension is cleaned with de-distilled water, and the washing solution reaches about 7 to a pH value;

[0030] (6) Remove part of the moisture from the mixed metal powder suspension to obtain a ratio of 1:1 between the mixed metal powder and water;

[0031] (7) Finally, zirconium balls are added for ball milling to obtain a mixed metal powder with an average particle size of 1.8 microns. The silver content in the test analysis is 20%, the ...

Embodiment 2

[0033] A kind of preparation method step of mixed metal powder is:

[0034] (1) first add oleic acid and myristyl alcohol in deionized water;

[0035] (2) Add tungsten hydride powder and silver nitrate with an average particle size of 1.1 microns in turn, then heat to 50 degrees and keep warm for 0.5 hours;

[0036] (3) add sodium carbonate then, insulation 0.5 hour;

[0037] (4) After finally adding dodecanal and glycerin, it was incubated for 2 hours to obtain a mixed metal powder suspension;

[0038] (5) The obtained mixed metal powder suspension is cleaned with de-distilled water, and the washing solution reaches about 7 to a pH value;

[0039] (6) Remove part of the moisture from the mixed metal powder suspension to obtain a ratio of 1:1 between the mixed metal powder and water;

[0040] (7) Finally, zirconium balls are added for ball milling to obtain a mixed metal powder with an average particle size of 2.0 microns. The silver content in the test analysis is 17%, the...

Embodiment 3

[0042] A kind of preparation method step of mixed metal powder is:

[0043] (1) add oleic acid and stearic acid in deionized water earlier;

[0044](2) Add titanium hydride powder and silver nitrate with an average particle size of 1.2 microns in turn, then heat to 45°C and keep warm for 1 hour;

[0045] (3) Add sodium carbonate then, keep warm for 1 hour;

[0046] (4) After finally adding dodecanal and glycerin, it was incubated for 2 hours to obtain a mixed metal powder suspension;

[0047] (5) The obtained mixed metal powder suspension is cleaned with de-distilled water, and the washing solution reaches about 7 to a pH value;

[0048] (6) Remove part of the moisture from the mixed metal powder suspension to obtain a ratio of 1:1 between the mixed metal powder and water;

[0049] (7) Finally, zirconium balls are added for ball milling to obtain a mixed metal powder with an average particle size of 1.2 microns. The silver content in the test analysis is 19%, the titanium c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com