Multi-silver brazing filler metal containing manganese and tin and preparation method thereof

A silver solder and multi-component technology, applied in the field of multi-component silver solder and its preparation, can solve problems such as unfavorable operator health, insufficient solder strength, environmental pollution, etc., achieve excellent mechanical properties, improve deep processing performance, reduce solid-liquid The effect of phase temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

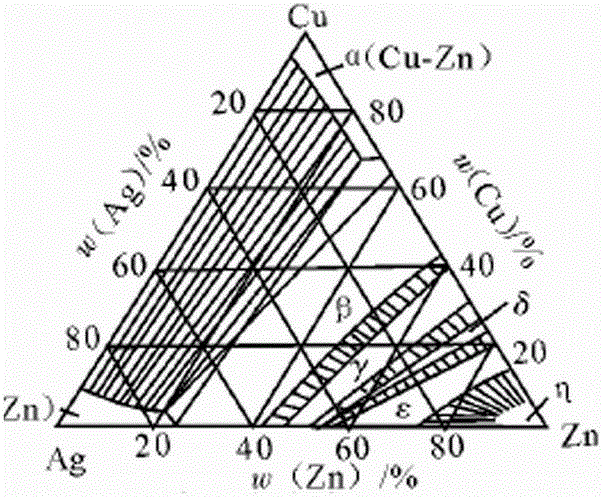

Image

Examples

Embodiment Construction

[0014] 1) The silver solder in the present invention uses silver IC-Ag99.99, No. 1 standard copper, national standard Zn99.995, DJMnD, Sn99.95AA, Ni99.96 and Cu-R alloy, according to the above ratio, using conventional intermediate frequency The smelting furnace is used for smelting and casting. During smelting, each component is sequentially added and smelted according to the order of Ag, Cu, Ni, Sn, Mn, Zn, and Cu-R alloys, and then through casting, sawing, extrusion, drawing, forming, and cleaning. prepared by other processes. Copper-trace element alloy (Cu-R alloy) is prepared according to the existing technology according to the ratio before smelting and added at the end. Since the trace element R is added through Cu-R alloy, the loss of trace element R after smelting is greatly The content of the trace element R is relatively stable, which improves the quality of the product. The obtained brazing material has a melting temperature range of 700~770°C, and can be processe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com