Silver nanowire doped conductive silver colloid and preparation method thereof

A technology of silver nanowires and conductive silver glue, which is applied in the direction of conductive adhesives, circuits, adhesives, etc., can solve the problems that conductive colloids cannot obtain good conductive effects, cannot reduce the cost of conductive glue, and the contact area of silver powder particles is small. High industrial application value, good aging resistance, good conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

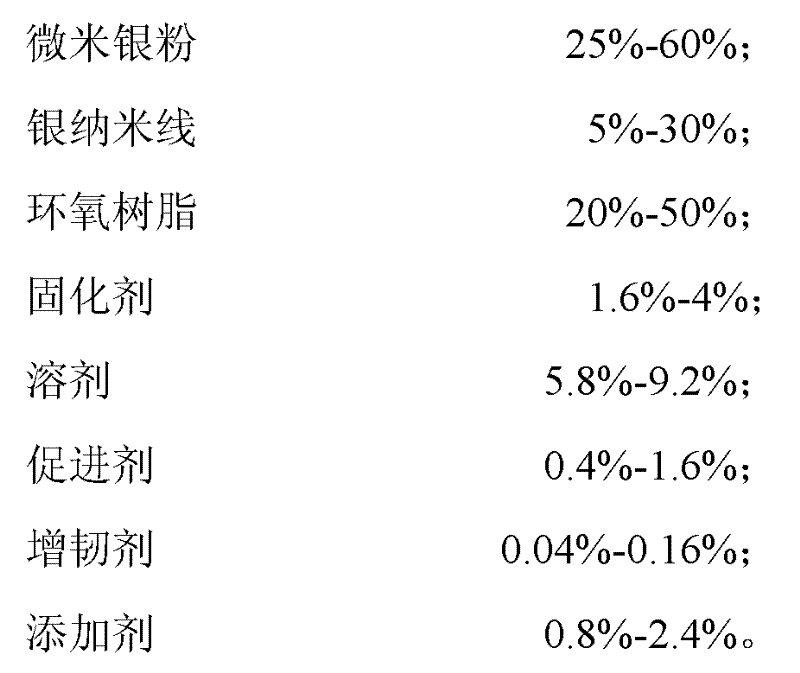

[0027] A silver nanowire-doped conductive silver glue, its raw material includes the following components in weight percentage:

[0028]

[0029] The shape of the micron silver powder is flake, with a diameter of 1-8 μm and a specific surface area of 0.9-1.6 μm 2 / g; the silver nanowire is a single crystal silver nanowire with a length of 20-200 μm, a diameter of 20-100 nm, and a volume resistivity of 0.3×10 5 -0.35x10 5 S / cm; described epoxy resin is made up of E-51 epoxy resin and bisphenol epoxy resin, and described bisphenol epoxy resin is bisphenol S epoxy resin, and epoxy equivalent (g / mol) is 185~ 195 (Blue Star New Material Wuxi Resin Factory); The curing agent is triethanolamine; The solvent is made up of ethylene glycol and acetone; The accelerator is imidazole; The toughening agent is polyurethane, and the polyurethane is AFCONA- 4000 type polyurethane (Lanya Trading Co., Ltd.); said additive includes defoamer, coupling agent, thixotropic agent, anti-aging ag...

Embodiment 2

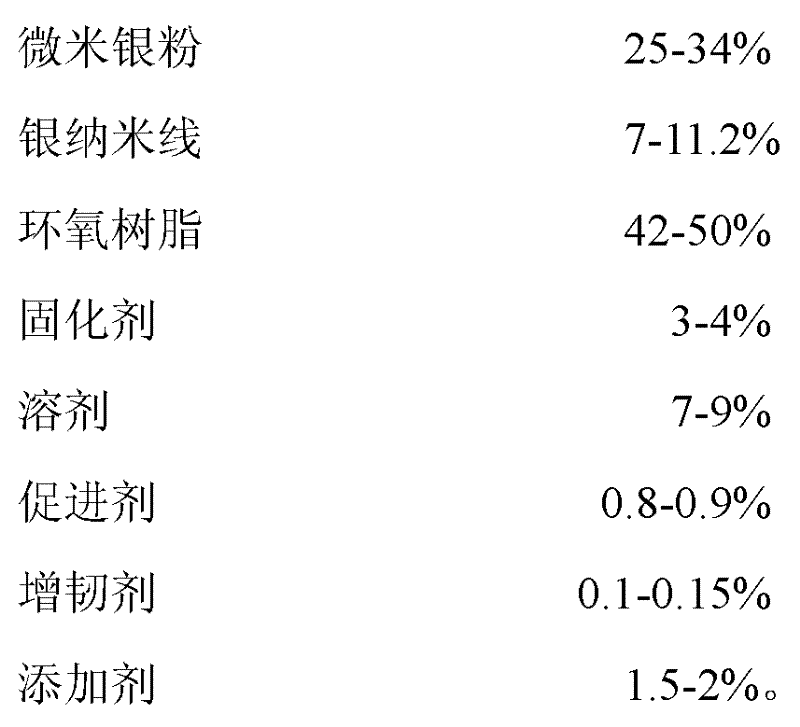

[0035] A silver nanowire-doped conductive silver glue, its raw material includes the following components in weight percentage:

[0036]

[0037]

[0038] The shape of the micron silver powder is flake, with a diameter of 1-8 μm and a specific surface area of 0.9-1.6 μm 2 / g; the silver nanowire is a single crystal silver nanowire with a length of 20-200 μm, a diameter of 20-100 nm, and a volume resistivity of 0.3×10 5 -0.35x10 5 S / cm; the epoxy resin is composed of bisphenol epoxy resin and glyceryl ether epoxy resin, wherein the bisphenol epoxy resin is bisphenol S epoxy resin, and the epoxy equivalent (g / mol) is 185~195 (Blue Star New Material Wuxi Resin Factory), glyceryl ether epoxy resin is glycidyl ether epoxy resin, and epoxy value is 0.78~0.85 (Shanghai Xinhua Resin Factory); Described curing agent is triethanolamine; Described solvent is It is composed of ethylene glycol, acetone and dimethyl phthalate; the accelerator is tertiary amines, and the tertiary a...

Embodiment 3

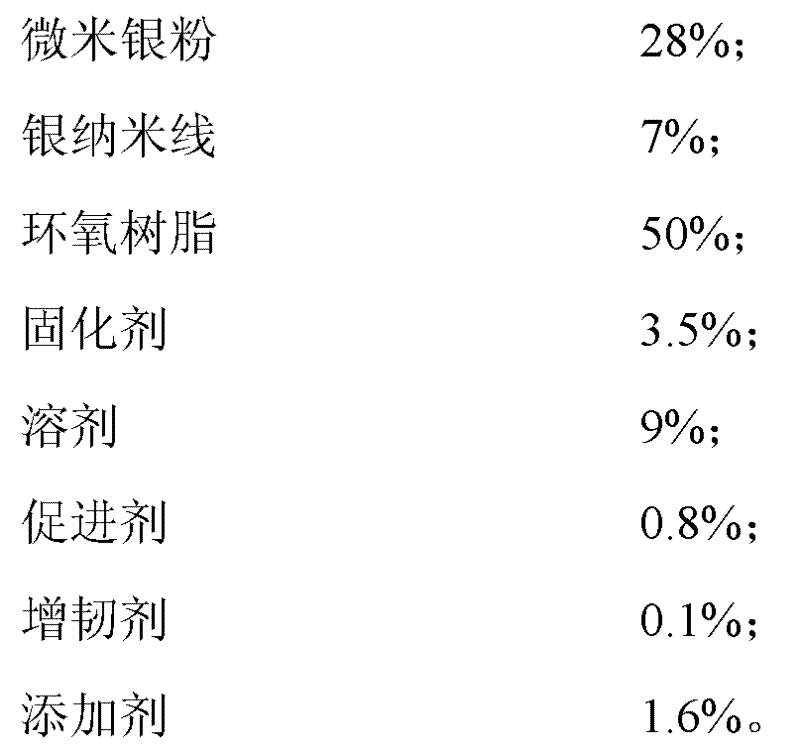

[0044] A silver nanowire-doped conductive silver glue, its raw material includes the following components in weight percentage:

[0045]

[0046]

[0047] The shape of the micron silver powder is flake, with a diameter of 1-8 μm and a specific surface area of 0.9-1.6 μm 2 / g; the silver nanowire is a single crystal silver nanowire with a length of 20-200 μm, a diameter of 20-100 nm, and a volume resistivity of 0.3×10 5 -0.35x10 5 S / cm; the epoxy resin is composed of E-51 epoxy resin and glyceryl ether epoxy resin, wherein the glyceryl ether epoxy resin is glycidyl ether epoxy resin, and the epoxy value is 0.78~0.85; the said The curing agent is composed of dicyandiamide and organic acid hydrazide, the organic acid hydrazide is adipic acid dihydrazide; the solvent is composed of acetone and dimethyl phthalate; the accelerator is imidazole The toughening agent is a silicone resin, and the silicone resin is a SH-1053 silicone resin; the additive includes a defoamer, a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com