High temperature sintering conductive silver paste for negative temperature coefficient (NTC) thermistor and preparation method thereof

A technology of high-temperature sintering and conductive silver paste, which is applied in the manufacture of cables/conductors, resistors with negative temperature coefficients, and conductive materials dispersed in non-conductive inorganic materials. Problems such as high sintering temperature and narrow sintering range can achieve the effect of reducing procurement cost and cycle, improving electrical conductivity, and being easy to eutectic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A preparation method of conductive silver paste for NTC thermistor, the method may further comprise the steps:

[0030] (1) Preparation of organic carrier: Prepare 50Kg of organic carrier, weigh 8Kg of polymer resin, 22Kg of butyl ether and 20Kg of terpineol, then heat it up to 80°C and keep the temperature constant until the resin dissolves at a constant temperature to 25000-35000cps, then filtering the resin on a mesh cloth of 300-400 mesh to remove impurities to obtain an organic carrier;

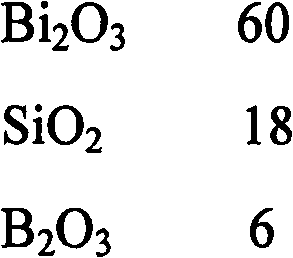

[0031] (2) Prepare materials, prepare materials according to the following components and contents:

[0032]

[0033] Among the metal silver powders used, the ball powder is 75Kg, the flake powder is 10Kg, the particle size of the ball powder is 2.5 μm, and the tap density is 3.4 g / ml; the particle size of the flake powder is 0.9 μm, and the tap density is 1.9 g / ml;

[0034] The glass powder used is lead-free glass powder, the sintering temperature is 700-850 DEG C, and its co...

Embodiment 2

[0042] A preparation method of conductive silver paste for NTC thermistor, the method may further comprise the steps:

[0043] (1) Preparation of organic carrier: Prepare 50Kg of organic carrier, weigh 10Kg of polymer resin, 20Kg of butyl ether and 20Kg of terpineol, then heat it up to 80°C and keep the temperature constant until the resin dissolves at a constant temperature to 25000-35000cps, then filtering the resin on a mesh cloth of 300-400 mesh to remove impurities to obtain an organic carrier;

[0044] (2) Prepare materials, prepare materials according to the following components and contents:

[0045]

[0046] Among the metal silver powders used, the ball powder is 70Kg, the flake powder is 10Kg, the particle size of the ball powder is 2.2 μm, and the tap density is 3.0 g / ml; the particle size of the flake powder is 0.9 μm, and the tap density is 1.9 g / ml;

[0047] The glass powder used is lead-free glass powder, the sintering temperature is 700-850 DEG C, and its c...

Embodiment 3

[0054] A preparation method of conductive silver paste for NTC thermistor, the method may further comprise the steps:

[0055](1) Preparation of carrier: Prepare 50Kg of carrier, weigh 12.5Kg of polymer resin, 17.5Kg of butyl ether and 20Kg of terpineol, then heat it up to 80°C and keep the temperature constant until the resin dissolves at a constant temperature to 25000-35000cps, then filtering the resin on a mesh cloth of 300-400 mesh to obtain a carrier;

[0056] (2) Prepare materials, prepare materials according to the following components and contents:

[0057]

[0058] Among the metal silver powders used, the ball powder is 70Kg, the flake powder is 8Kg, the particle size of the ball powder is 2.2 μm, and the tap density is 3.0 g / ml; the particle size of the flake powder is 0.9 μm, and the tap density is 1.9 g / ml;

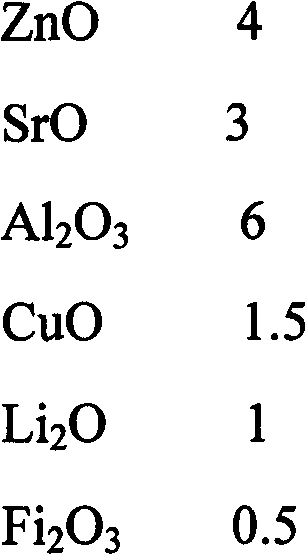

[0059] The glass powder used is lead-free glass powder, the sintering temperature is 700-850 DEG C, and its composition and content (wt%) are:

[0060] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com