High-temperature creep-resistant ceramic material and preparation method thereof

A technology of creep resistance and ceramic materials, which is applied in the field of high-temperature ceramic materials, can solve problems such as poor high-temperature creep resistance, poor corrosion resistance, and easy fracture, and achieve improved bridge support, increased powder bulk density, and reduced sintering The effect of temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

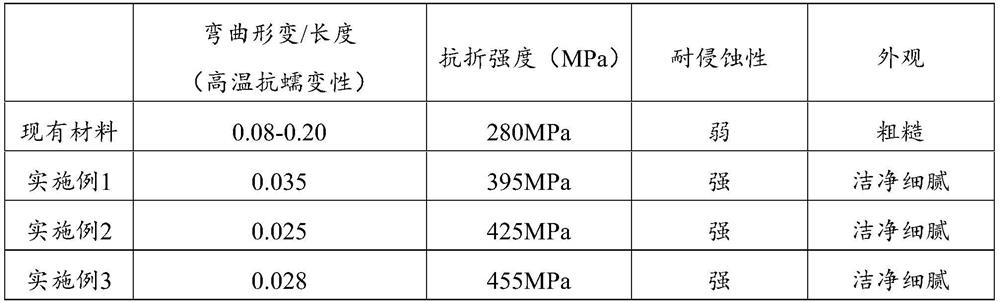

Examples

preparation example Construction

[0030] The invention provides a method for preparing a high-temperature creep-resistant ceramic material, comprising the following steps:

[0031] S1. In parts by weight, weigh 50-90 parts of high-purity α-Al 2 o 3 powder, 25-50 parts of tabular corundum powder, 1-3 parts of zirconia powder and 0.5-1 part of sintering aid, put them into a ball mill, use water as a solvent, add a water-soluble dispersant, grind and mix, and set the ball milling time It takes 15-24 hours to obtain a ceramic slurry with high solid content, good fluidity and uniform suspension; wherein, the pH value of the ceramic slurry is preferably slightly alkaline, for example, the pH value is 8-10.

[0032] S2. After sieving the ceramic slurry obtained in S1, vacuum defoaming, put it into a ceramic slurry bucket, add a catalyst and an initiator, after stirring evenly, inject the evenly stirred slurry into a mold, and demould after curing, to obtain ceramic body;

[0033] S3, drying the ceramic green body ...

Embodiment 1

[0045] This embodiment provides a method for preparing a high-temperature creep-resistant ceramic material, comprising the following steps:

[0046] S1. In parts by weight, weigh 50 parts of high-purity α-Al 2 o 3 powder, 48.5 parts of tabular corundum powder, 1 part of zirconia powder and 0.5 part of sintering aid, put them into a ball mill, use water as a solvent, add a water-soluble dispersant, grind and mix, and set the ball milling time to 15h to obtain a high-solid A ceramic slurry with uniform phase content, good fluidity and uniform suspension; wherein, the pH value of the ceramic slurry is preferably slightly alkaline, for example, the pH value is 8.

[0047] S2. After sieving the ceramic slurry obtained in S1, vacuum defoaming, put it into a ceramic slurry bucket, add a catalyst and an initiator, after stirring evenly, inject the evenly stirred slurry into a mold, and demould after curing, to obtain ceramic body;

[0048] S3, drying the ceramic green body obtained...

Embodiment 2

[0060] This embodiment provides a method for preparing a high-temperature creep-resistant ceramic material, comprising the following steps:

[0061] S1. In parts by weight, weigh 65 parts of high-purity α-Al 2 o 3 powder, 33.5 parts of platy corundum powder, 1.5 parts of zirconia powder and 0.65 parts of sintering aid, put them into a ball mill, use water as solvent, add water-soluble dispersant, grind and mix, set the ball milling time to 18h, and get high solid A ceramic slurry with uniform phase content, good fluidity and uniform suspension; wherein, the pH value of the ceramic slurry is preferably slightly alkaline, for example, the pH value is 9.

[0062] S2. After sieving the ceramic slurry obtained in S1, vacuum defoaming, put it into a ceramic slurry bucket, add a catalyst and an initiator, after stirring evenly, inject the evenly stirred slurry into a mold, and demould after curing, to obtain ceramic body;

[0063] S3, drying the ceramic green body obtained in S2, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com