Patents

Literature

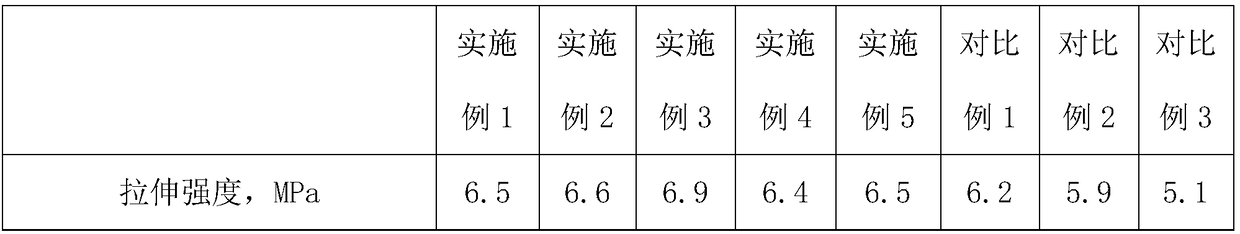

49results about How to "Strong light transmittance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof computer bag for bathing

ActiveCN104490057AIngenious designEasy to installOther accessoriesMetallic materialsPersonal computer

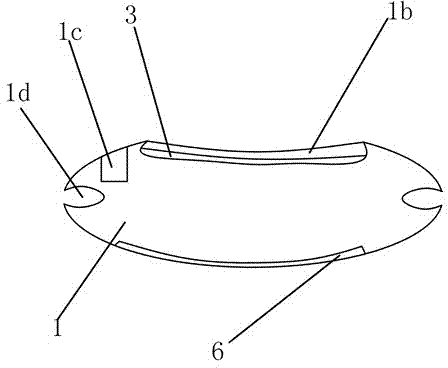

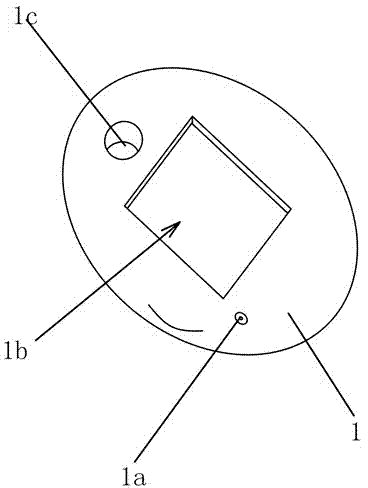

The invention provides a waterproof computer bag for bathing and belongs to the field of daily necessities. The waterproof computer bag comprises an ellipsoidal air bag, wherein a unidirectional inflation hole is formed in the air bag, a square placing groove is formed in the upper end of the air bag, a square independent bag is arranged in the placing groove and consists of a bag body I and a bag body II, the independent bag is less than the placing groove, the bag body I is communicated with the bag body II, the bottom of the placing groove is fixedly connected with a metal plate made of a metal material, one sides of the bag body I and the bag body II are both fixedly connected with a soft magnetic sheet and are respectively provided with a zipper mechanism, the bag body I and the bag body II are connected to each other by virtue of the zipper mechanisms, the other sides of the bag body I and the bag body II are used as operation surfaces, each operation surface is made from PET and a silica gel material, and a stable board is arranged at and fixedly connected to the bottom in the air bag. The waterproof computer bag for the bathing is capable of sealing a panel personal computer in a bathroom and has diversified functions.

Owner:HAIMEN DADE INTPROP SERVICE CO LTD

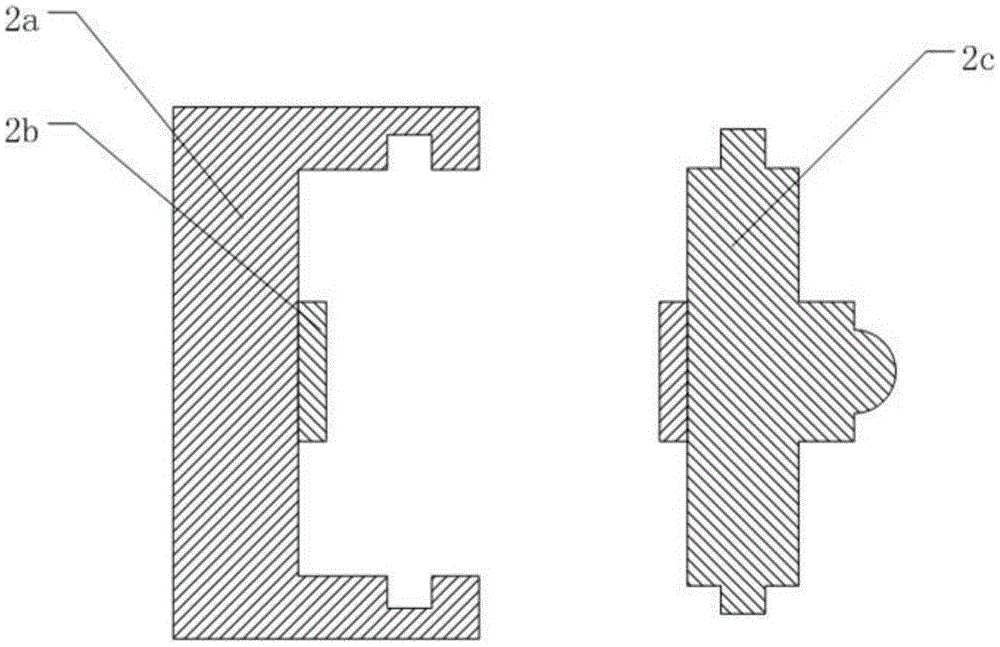

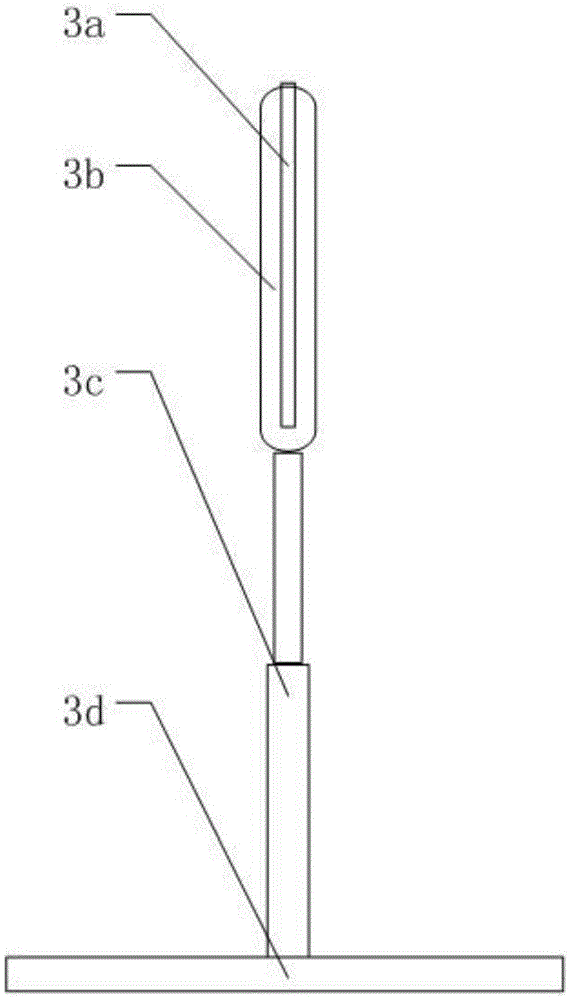

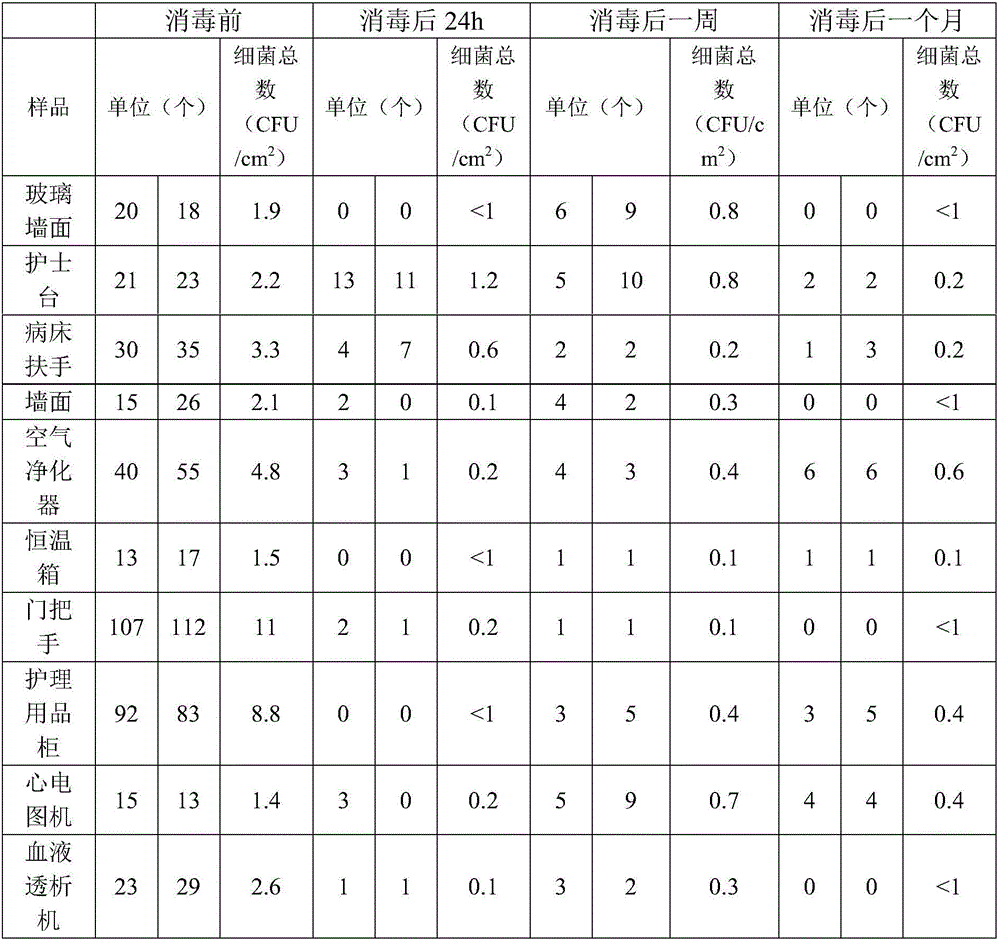

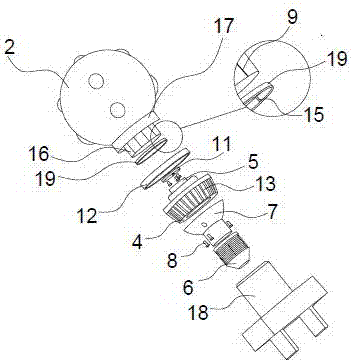

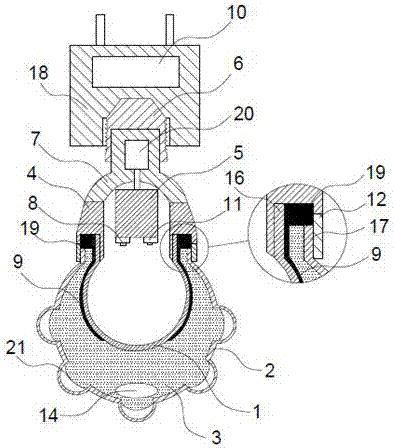

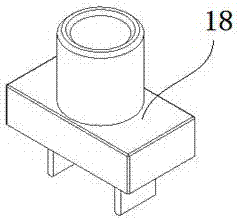

Laser measurement device for simply measuring mechanical vibration amplitude

InactiveCN105527012AStrong light transmittanceLow costSubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansPhysicsMeasurement device

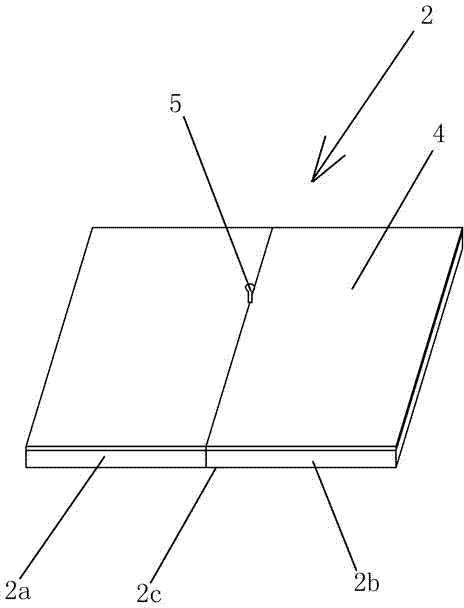

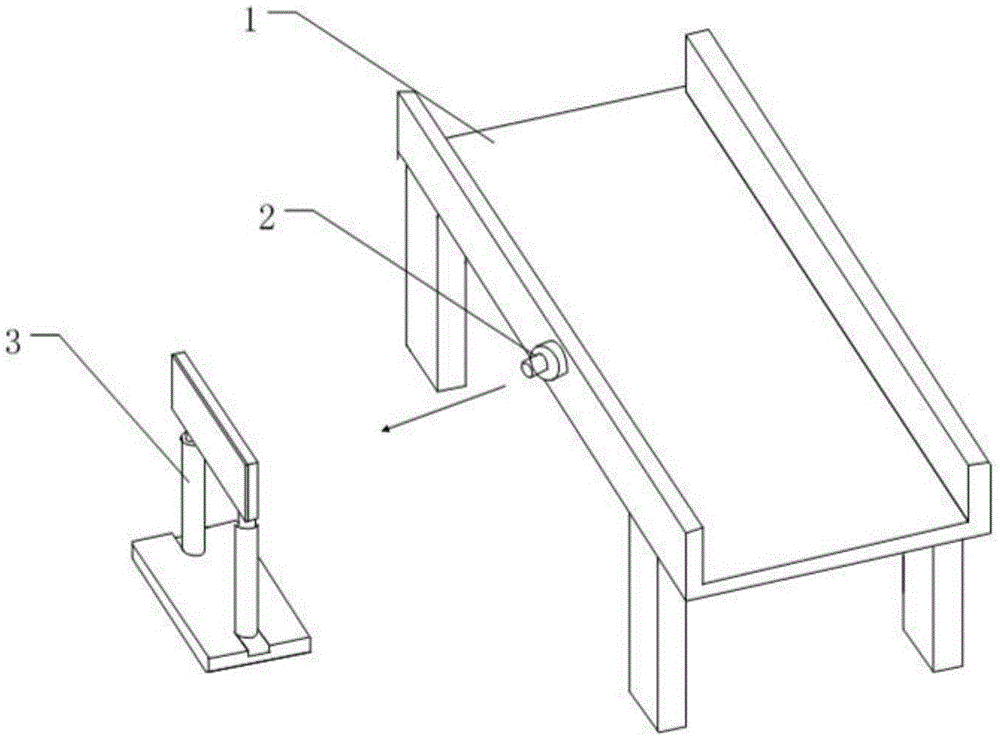

The invention discloses a simple vibration amplitude measurement device, and particularly relates to a device for measuring the vibration amplitude of a vibrating machine in the industrial production process. When the machine vibrates, a laser transmitter (2c) fixedly connected to the side of the vibrating machine is driven to vibrate and displace, beams emitted by the laser transmitter (2c) vibrate along with the machine, then vibrating patterns are formed on a receiving plate (3b) on a light spot receiving assembly (3), and the vibration amplitude is read according to coordinate paper on the receiving plate (3b). The vibration amplitude of a vibrating screen can be directly measured by the device; the device is low in cost, easy to manufacture and simple in use, can be reused, is not limited by the production condition, can be observed remotely, and is intuitive and high in efficiency. The device can also be used for remotely observing and judging whether some dangerous machines work normally nor not.

Owner:HONGTA TOBACCO GRP

Preparation method of kieselguhr-PVC composite material

InactiveCN104945789AImprove impact resistanceStrong light transmittancePolyvinyl chlorideBoron nitride

The invention discloses a preparation method of a kieselguhr-PVC composite material. The method is characterized by comprising the following steps: (1), grinding kieselguhr, enabling ground kieselguhr to pass through a 500-600-mesh sieve, so as to obtain kieselguhr powder; (2), adding the kieselguhr powder obtained in the step (1) into water, adding a titanate coupling agent into the water, stirring for reaction for 10-15 h at the room temperature, drying and grinding, so as to obtain modified kieselguhr powder; (3), weighing the following components according to weight ratio: polyvinyl chloride resin, the modified kieselguhr powder obtained in the step (2), zinc oxide, polybutylene terephthalate, oxidized polyethylene wax, an ACR processing agent, lead stearate and boron nitride, uniformly mixing, and adding the mixture into a double-screw extruder to be granulated, so as to obtain the kieselguhr-PVC composite material. The kieselguhr-PVC composite material prepared by the invention has better impact resistance, higher light transmittance, and good obdurability.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

New-type electric fireplace flame board and its making process

InactiveCN101020358AGood toughnessStrong light transmittanceDomestic stoves or rangesLighting and heating apparatusElectricityFireplace

The present invention discloses one new type electric fireplace flame board and its making process. The flame board is made through mixing transparent unsaturated polyester resin, curing agent and hardening agent; vacu micron deairing and dewatering of the mixture inside a vacu micron machine; molding; demolding; washing and surface smoothness treatment. The flame board is tough and transparent, and can form vivid flame.

Owner:匡小军

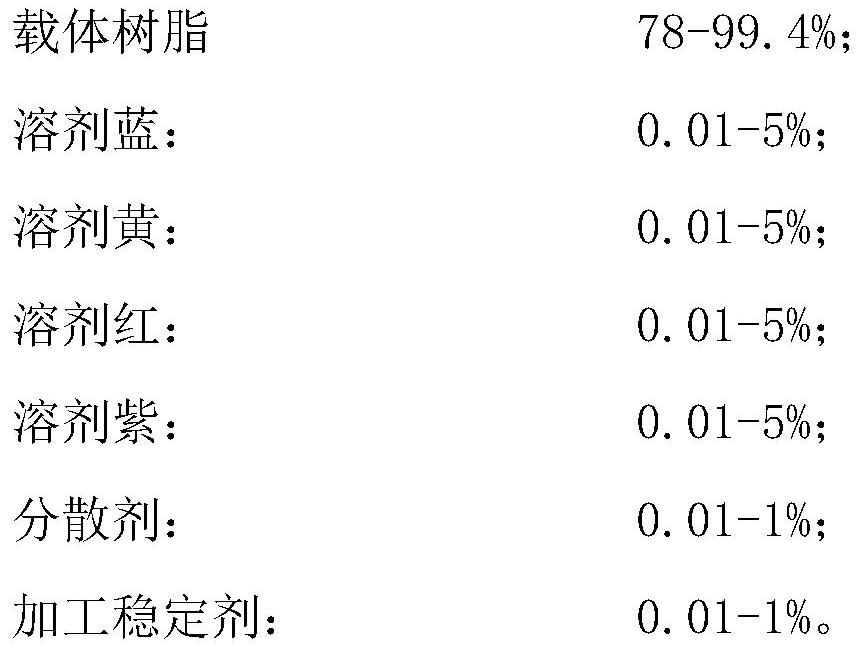

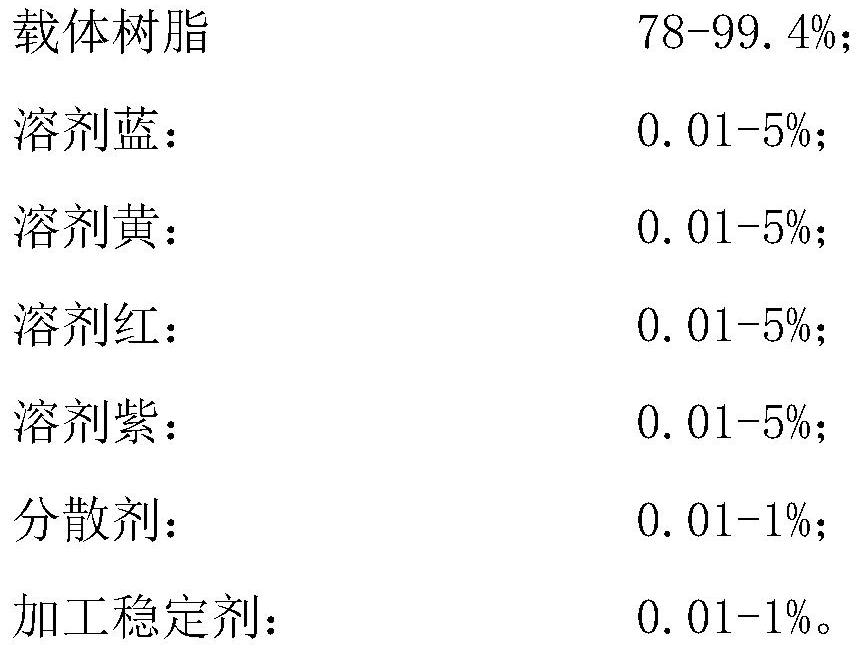

Multi-color-selection and multi-base-material laser welding light-transmitting color master batch and preparation method thereof

The invention discloses a multi-color-selection and multi-base-material laser welding light-transmitting color master batch and a preparation method thereof. The multi-color-selection and multi-base-material laser welding light-transmitting color master batch is prepared from the following raw materials in parts by weight: 78-99.4% of carrier resin, 0.01-5% of solvent blue, 0.01-5% of solvent yellow, 0.01-5% of solvent red, 0.01-5% of solvent violet, 0.01-1% of a dispersant, and 0.01-1% of a processing stabilizer. According to the invention, various colors including black are adjusted on the premise that the laser transmittance is guaranteed through combination of the toner, the defect that a conventional laser welding light-transmitting master batch is limited to be black is overcome, the compatibility of a carrier and a dispersing agent of the color master batch with various base materials such as PC, ABS, PA and PBT is improved through a pretreatment process, the application range of the laser welding light-transmitting color master batch is widened, when a resin base material changes, the component proportion can be adjusted to eliminate the influence caused by the change of the base material, and the color stability is improved, which cannot be achieved by conventional single dye black, and the processing stabilizer improves the color stability of the laser welding light-transmitting color master batch under a high-temperature condition in the processing process.

Owner:SHANGHAI PRET COMPOSITES +3

Preparation method of aqueous transparent heat-insulating glass coating

ActiveCN108912871AStrong light transmittanceLow critical surface tensionAntifouling/underwater paintsPaints with biocidesCarbon dioxidePolytetrafluoroethylene

The invention relates to a preparation method of an aqueous transparent heat-insulating glass coating, and belongs to the technical field of preparation of architectural coatings. Modified polytetrafluoroethylene resin is creatively used as a matrix, and nano titanium dioxide is used as filler so as to prepare the glass coating, wherein the polytetrafluoroethylene resin which is modified by an adhesion promoter has ultra-high adhesion so that the performance of the aqueous transparent heat-insulating glass coating is more comprehensive, and organic pollutants adsorbed on the surface of the nano titanium dioxide are decomposed into carbon dioxide and oxygen through selection of the nano titanium dioxide as the filler, so that the original brightness of glass is maintained, and a good heat insulating effect is achieved without influence on the transparency of the glass. The aqueous transparent heat-insulating glass coating has the advantages of strong adhesion, long service life, good water resistance, strong viscosity resistance, strong anti-staining performance, strong UV resistance, high transparency and a good thermal insulation effect, formaldehyde and other indoor harmful organic compounds can be decomposed, and therefore the coating has a very broad application prospect and advantage.

Owner:上海金泰子建筑装饰工程有限公司

Method for manufacturing OGS (one glass solution) touch screen by means of electroplating BM (black matrix) on front surface thereof

InactiveCN103713790AThe overall thickness is thinReduce weightInput/output processes for data processingMetallurgyIndium tin oxide

The invention discloses a method for manufacturing an OGS (one glass solution) touch screen by means of electroplating a BM (black matrix) on the front surface thereof. The method includes steps of (1), manufacturing a glass substrate and chemically enhancing and treating the glass substrate to improve the strength of the glass substrate; (2), plating a single-point touch ITO (indium tin oxide) film layer on the lower surface of the glass substrate; (3), electroplating BM layers on one side of the upper surface of the glass substrate; (4), coating a transparent layer on one side of the upper surface of each BM layer. The method has the advantages of high yield, low cost and simplicity in process.

Owner:JIANGXI HOLITECH TECH

Novel hollow glass microballoon filled modified plastic and manufacturing method thereof

InactiveCN104725698AGood heat resistanceIncreased tensile strength and impact strengthPlant protective coveringsMaleic anhydrideIsophorone

The invention discloses a novel hollow glass microballoon filled modified plastic which is prepared from the following raw materials in parts by weight: 50-60 parts of linear polyethylene, 35-45 parts of high-density polyethylene, 4.3-6.2 parts of nano antimony tin oxide, 0.6-1.4 parts of nano titanium white, 0.5-0.8 part of stearic acid, 0.1-0.3 part of potassium persulfate, 0.2-0.4 part of isophorone, 2-3 parts of hollow glass microballoon, 1-2 parts of maleic anhydride grafted polypropylene, 0.02-0.04 part of antioxidant 1010, 0.02-0.04 part of UV-327, 1-3 parts of oxidized polyethylene wax and a right amount of anhydrous ethanol. The manufacturing method comprises the following steps: adding the nano materials into the coupling agent, uniformly mixing with the linear polyethylene, high-density polyethylene, hollow glass microballoon, isophorone and the like, and carrying out melt extrusion granulation with a double screw extruder. The prepared plastic has the advantages of favorable ultraviolet cracking resistance, favorable mold resistance, favorable heat resistance, higher tensile strength and higher shock strength.

Owner:WUHU ZHONGLI PARTS

Polycarbonate flame retardant endurance plate and preparation method thereof

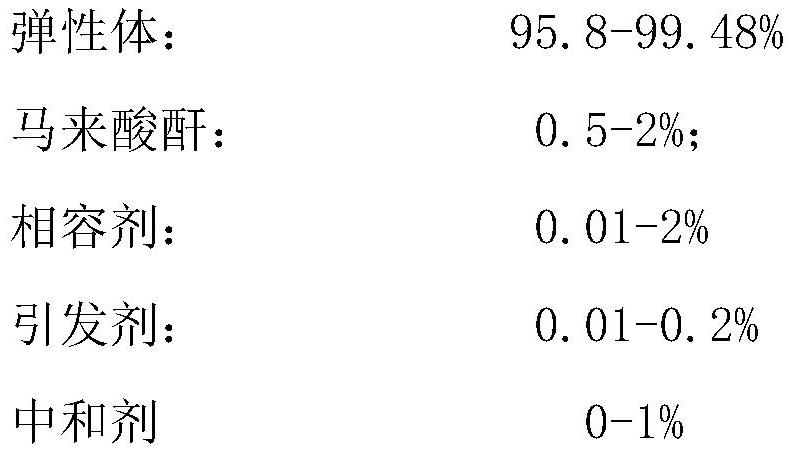

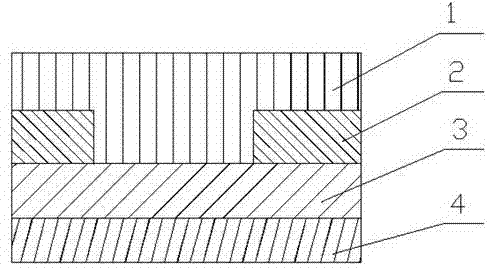

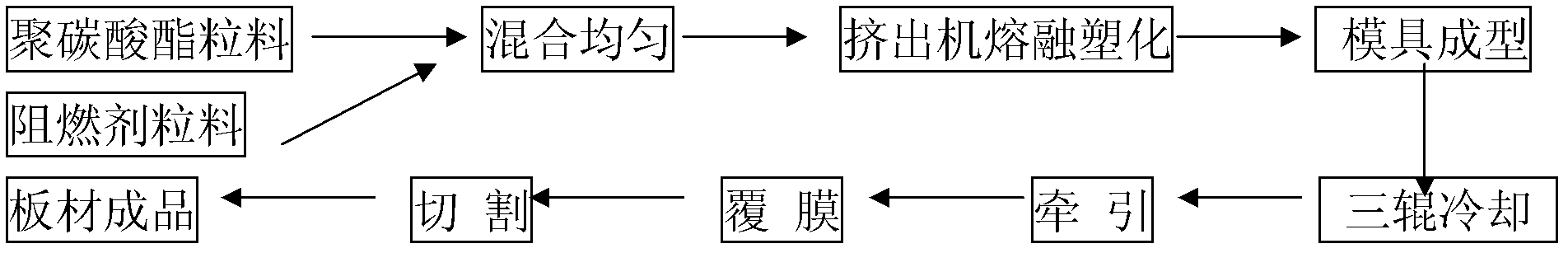

InactiveCN103183948AHigh strengthHigh toughness, high light transmittancePotassium perfluorobutanesulfonateNon toxicity

The invention relates to a polycarbonate flame retardant endurance plate. The flame retardant endurance plate is composed of the following components, by weight, 95%-99.5% of polycarbonate and 0.5%-5% of a flame retardant, wherein the flame retardant is modified potassium perfluorobutanesulfonate. A preparation method of the flame retardant endurance plate comprises the steps of (1) mixing carbonate particles and flame retardant particles uniformly, melting and plasticizing the mixture in an extruder; (2) shaping the plasticized material in a mold and cooling by a three-roller method; and (3) drawing, coating and cutting the cooled model. The polycarbonate flame retardant endurance plate provided by the invention has the advantages of thin thickness, high strength, strong toughness, high transparency, non-toxicity and harmlessness, etc. The polycarbonate flame retardant endurance plate can not release toxic and harmful gas to the environment, and fits ROHS environment-protecting directives.

Owner:SHANGHAI HUILI TUVGAL SHEETAB

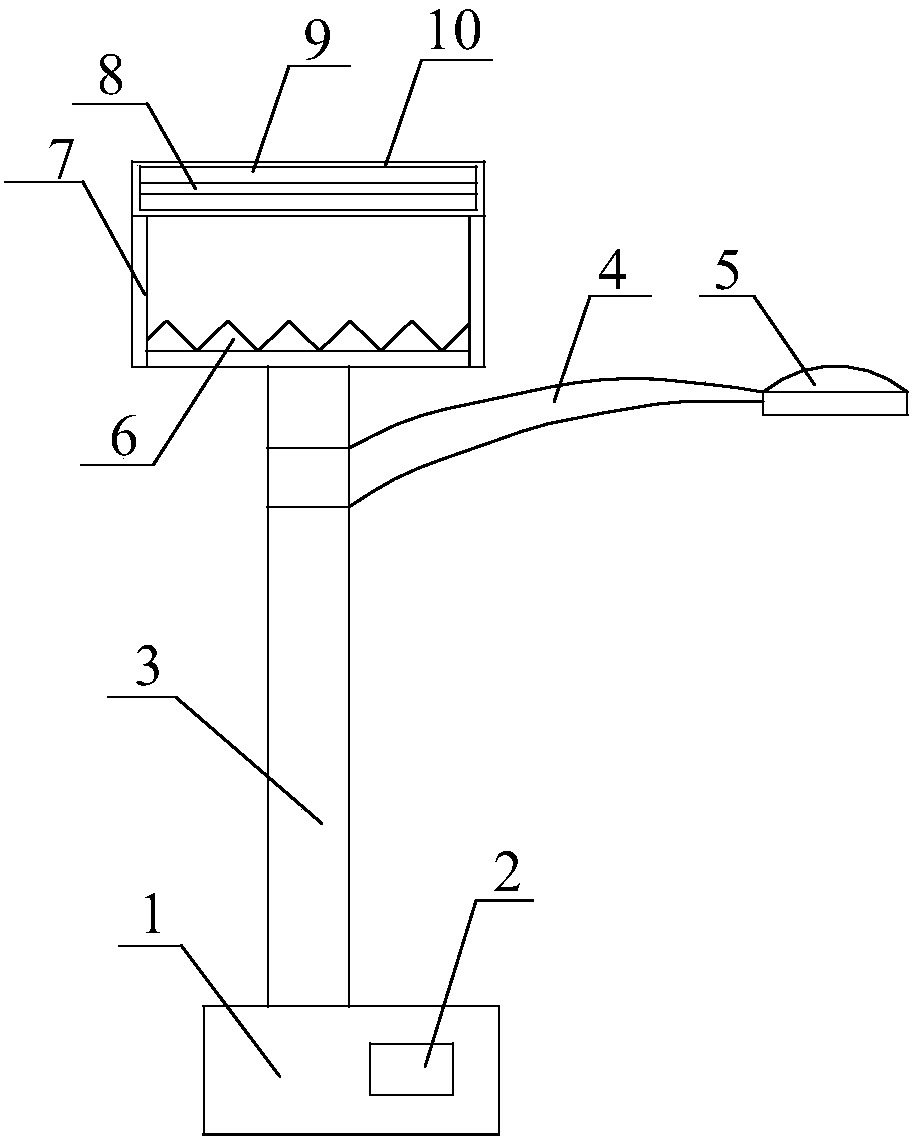

Double-sided solar power generation street lamp

InactiveCN107859957AEfficient use ofMeet power demandMechanical apparatusPhotovoltaicsElectricityEngineering

The invention discloses a double-sided solar power generation street lamp. The double-sided solar power generation street lamp is characterized by comprising a base (1), a lamp post (3) arranged on the base (1), a lamp pole (4) arranged on the lamp post (3), a lamp cap (5) with a light source and arranged on the lamp pole (4), and a double-sided solar power generation device arranged on the lamp post (3), wherein the double-sided solar power generation device comprises a support (7) arranged on the lamp post (3), a double-sided solar power generation structure arranged on the support (7), anda reflecting plate (6) arranged on the support (7) and positioned below the double-sided solar power generation structure; and a storage battery (2) in electric connection with each of the double-sided solar power generation structure and the light source is further arranged on the base (1). The double-sided solar power generation street lamp has the benefits as follows: not only is the structuresimple, but also the cost is low, the solar energy is utilized more efficiently by adopting the double-sided solar power generation device, the electric energy requirements of the street lamp are met,and the popularization and application are facilitated.

Owner:CHENGDU SAIPUQI TECH CO LTD

Boron-carbide-filled modified plastic and manufacturing method thereof

The invention discloses a boron-carbide-filled modified plastic which is prepared from the following raw materials in parts by weight: 100 parts of low density polyethylene, 4.5-6.8 parts of nano antimony tin oxide, 1-2 parts of nano titanium white, 2-3 parts of epoxy soybean oil, 1-3 parts of straw ash, 0.4-0.8 part of nano silicon dioxide, 0.1-0.3 part of trimethoprim lactate, 0.2-0.4 part of barium chromate, 0.4-0.5 part of boron carbide, 1.2-1.6 parts of maleic anhydride graft compatilizer and a right amount of anhydrous ethanol. The manufacturing method comprises the following steps: adding the nano materials into the coupling agent, activating by stirring, uniformly mixing with the linear polyethylene, nano silicon dioxide, boron carbide and the like, and carrying out melt extrusion granulation with a double screw extruder. The prepared plastic has the characteristics of favorable wear resistance, favorable heat stability, ultraviolet irradiation resistance, aging resistance, high strength and higher chemical resistance. When the modified plastic is subjected to deep processing into a plastic film for vegetable greenhouses, the plastic film has the advantages of short degradation period, favorable low-temperature resistance, obvious heat insulation effect, self-cleaning function, bacteria resistance and high light transmittance.

Owner:WUHU ZHONGLI PARTS

Sunshine-resistant and ageing-resistant modified plastic and preparation method thereof

The invention discloses sunshine-resistant and ageing-resistant modified plastic, which is prepared from the following raw materials in parts by weight: 35-45 parts of polystyrene, 55-65 parts of polyvinyl chloride, 4.9-6.8 parts of nano antimony tin oxide, 1-2 parts of nanometer titanium dioxide, 2-4 parts of polyethylene glycol 200, 1-2 parts of aluminic acid ester, 0.2-0.4 part of cadmium sulfate, 1.1-2.3 parts of polyoxyethylated castor oil, 0.1-0.3 part of bromotriazine, 0.4-0.7 part of lead stearate and a proper amount of absolute ethyl alcohol. The method comprises the following steps: firstly, adding a nano material to a coupling agent, stirring, activating, grafting and mixing with polystyrene, polyvinyl chloride, bromotriazine, polyoxyethylated castor oil and the like evenly; and fusing, extruding and pelletizing through a twin-screw extruder. The sunshine resistance, the ageing-resistance, the tensile strength and the shock strength of the prepared plastic are significantly improved; the service life is certainly prolonged; and the heat resistance is also certainly improved.

Owner:WUHU ZHONGLI PARTS

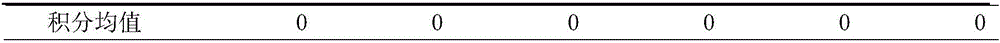

Long-acting broad-spectrum bacterium resisting and corrosion preventing nano spraying foam agent as well as preparation method and application thereof

InactiveCN106280980AStrong light transmittanceFireproof paintsAntifouling/underwater paintsMedical equipmentDisinfectant

The invention discloses a long-acting broad-spectrum bacterium resisting and corrosion preventing nano spraying foam agent. The nano spraying foam agent contains the following components by weight percent: 0.1-5% of bacterium resisting drugs, 2-25% of organosilane resin, 1-5% of dispersing agent, 1-8% of preservatives, 0.1-4% of stabilizing agents, 10-95% of solvents and 0.5-5% of disinfectants. The nano spraying foam agent has the characteristics and advantages that the use thickness of the long-acting broad-spectrum bacterium resisting and corrosion preventing nano spraying foam agent product is 10-50mu m; the product has the advantages of friction resistance, heat resistance, aging resistance, radiation resistance, no embrittlement at low temperature, hydrophobicity, moisture resistance, no toxicity, strong light transmittance, capability of resisting bacteria and preventing corrosion for 0.5-6 years, and the like and is widely applied to bacterium resistance, corrosion prevention and disinfection in the fields of medical equipment, household appliances, hospitals, schools, automobiles, families, etc.

Owner:江苏微特克纳米科技有限公司

Method for preparing diatomite modified PVC (Polyvinyl Chloride) plastics

InactiveCN105153574AImprove impact resistanceStrong light transmittanceHydroxystearic AcidPolyvinyl chloride

The invention discloses a method for preparing diatomite modified PVC (Polyvinyl Chloride) plastics. The method is characterized by comprising the following steps: (1) grinding diatomite into powder with the grain size of 10-100nm; (2) adding the diatomite powder obtained in the step (1) into water, adding light calcium carbonate and glycerol trihydroxy stearate into the diatomite powder added water, carrying out stirring reaction for 2-3 hours at room temperature, and carrying out drying, so as to obtain modified diatomite powder; and (3) weighing the following substances in parts by weight: 100 parts of PVC resin, 20-30 parts of the modified diatomite powder obtained in the step (2), 5-6 parts of simethicone, 3-6 parts of magnesium hydroxide, 3-8 parts of MBS processing aid and 0.1-1 part of stabilizer, uniformly mixing the substances, adding the mixture into a twin-screw extruder, carrying out stirring for 10-15 minutes at the temperature of 180-260 DEG C while the host revolution rate is 50-100rpm, carrying out extruding, then, carrying out cooling and drawing, and carrying out air-drying and pelleting. The diatomite modified PVC plastics prepared by the method have relatively good impact resistance and good toughness and are suitable for being extensively used.

Owner:SUZHOU RONGCHANG COMPOUND MATERIAL

Liquid-cooling heat dissipation LED lamp

InactiveCN107270138APrevent burstIncrease the brightness of the irradiationLighting heating/cooling arrangementsProtective devices for lightingCooling effectEngineering

The invention provides a liquid-cooling heat dissipation LED lamp which comprises a lamp holder and a lampshade. The lamp holder comprises a radiator and a lamp cap connected to one end of the radiator through a connecting piece. An LED base plate is connected to the lamp holder. The lampshade is connected to one end of the lamp holder. The lampshade comprises an inner lampshade body and an outer lampshade body which are in two layers, and a liquid storage cavity where cooling liquid is poured is formed between the two lampshade bodies. A heat conduction part connected with the lamp holder in a heat conduction manner is attached to the outer surface of the side wall of the inner lampshade body and is soaked in the cooling liquid. The lamp holder is in threaded connection with the lampshade, and the inner lampshade body and the outer lampshade body are connected with the lamp holder. An expansion ring is embedded between an inner connecting ring and an outer connecting ring and is tightly attached to the bottom face of an annular groove. A bar-shaped groove matched with the heat conduction part is formed in the inner wall of the expansion ring. By means of the LED lamp, the cooling liquid is used for heat dissipation, the cooling effect is good, the radiation range is large, the service life of the LED lamp can be better and effectively prolonged, the volume of the liquid storage cavity is slightly adjusted through the expansion ring, and safety of the LED lamp is facilitated.

Owner:海盐派特普科技有限公司

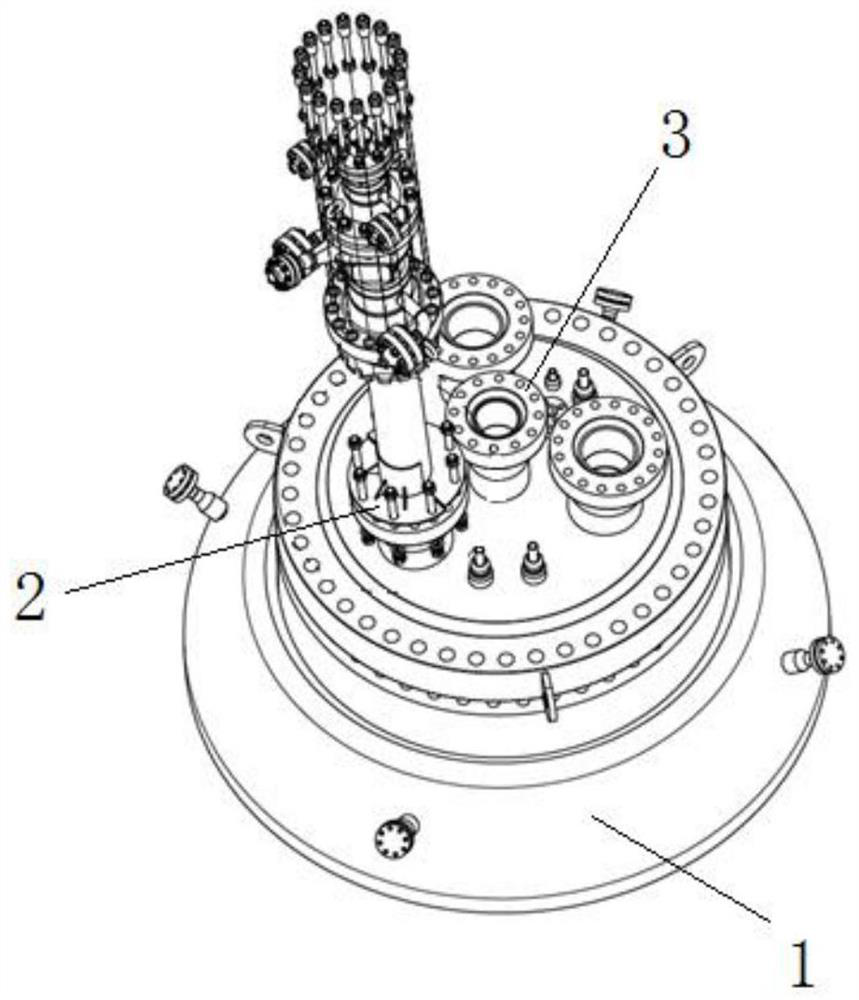

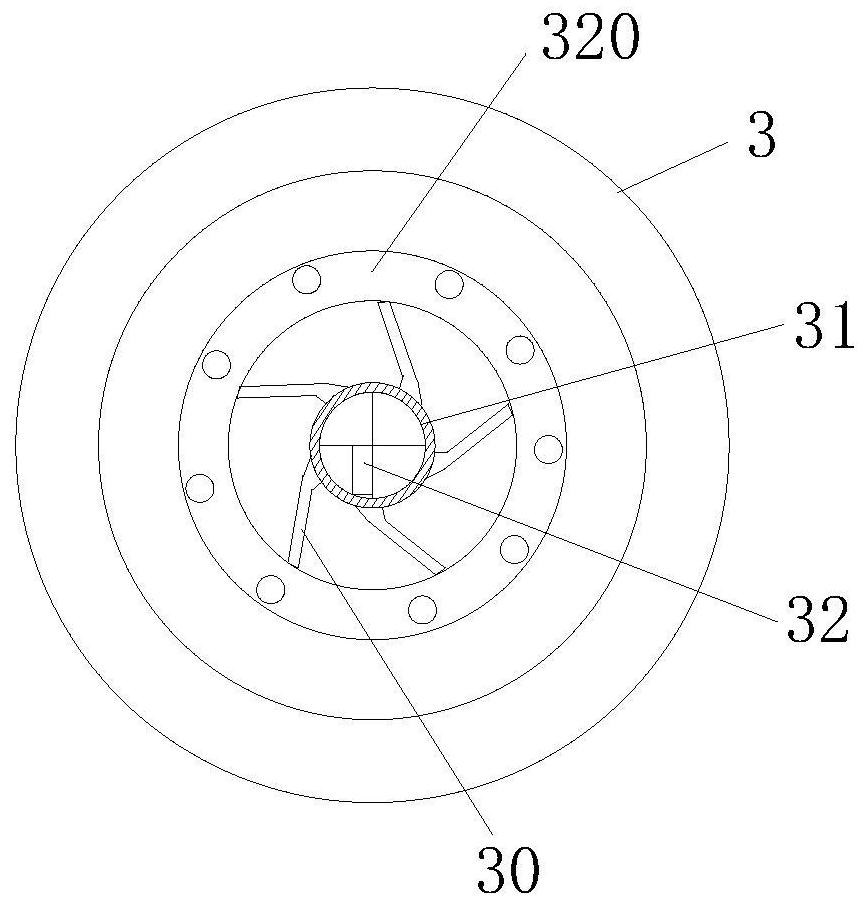

Combined gasification furnace burner

PendingCN112239679AIncreased coal inputSolve the problem of small coal inputGranular/pulverulent flues gasificationThermodynamicsProcess engineering

The invention discloses a combined type gasification furnace burner which comprises a burner base; the burner base is vertically installed at the top of a gasification furnace, an ignition starting burner is arranged on the burner base, at least two pulverized coal burners are arranged on the outer side of the ignition starting burner, and the pulverized coal burners are evenly distributed on thesame virtual circle, so that the complex operation procedure of switching ignition start-up burners during start-up of the gasification furnace is omitted. On one hand, the coal feeding amount of thegasification furnace can be increased, the defects that the coal feeding amount of the gasification furnace is small and the productivity is low when a single burner is arranged are overcome, on the other hand, pulverized coal and oxygen can be sprayed into the gasification furnace more evenly through multi-nozzle arrangement, temperature deviation in a hearth of the gasification furnace can be eliminated, and an accurate basis is provided for judging the temperature in the gasification furnace. The influence on the process operation is reduced, the influence on the productivity of the gasification device caused by frequent startup and shutdown is reduced, the economic loss of enterprises is reduced, the economic benefit is improved, and meanwhile, the heating and boosting speed and the accuracy of remote operation during normal operation of the gasification furnace are improved.

Owner:陕西宏远燃烧设备有限公司

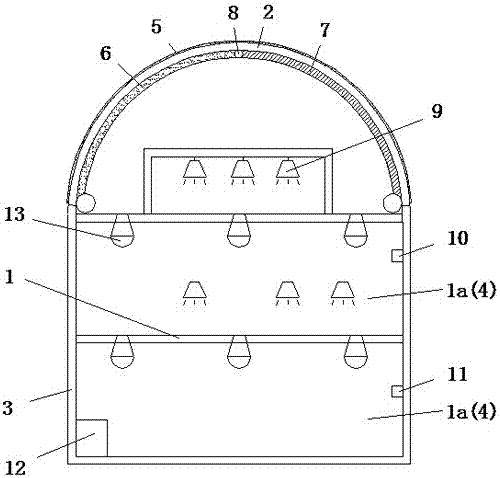

Horticultural greenhouse system

InactiveCN107231977AAvoid enteringStrong light transmittanceClimate change adaptationGreenhouse cultivationGreenhouseTransmittance

The invention relates to a horticultural greenhouse system. The horticultural greenhouse system comprises a framework, a light-transmitting glass and a heat preservation surrounding plate, the framework forms the structure of a greenhouse, a heat ray shielding sheet is arranged outside the light transmitting glass, and is made of a tungsten material, a transparent heat preservation layer and a non-transparent heat preservation layer are arranged inside the light-transmitting glass, are in alternating use through a driving piece, and are both provided with roller shutter structures, one end of the transparent heat preservation layer is fixedly connected with the other end of the light transmitting glass, one end of the non-transparent heat preservation layer is fixedly connected with one of the transparent light transmitting glass, the other end of the transparent heat preservation layer is connected with the other end of the non-transparent heat preservation layer through a connecting rod, a set of slide rails are arranged along the inner wall of the transparent glass, slide blocks are arranged at both ends of the connecting rod, and the connecting rod can drive the transparent light transmitting layer and the non-transparent light transmitting layer to move back and forth driven by the coordination of the slide blocks and the slide rails. According to the horticultural greenhouse system, harmful light rays in light rays can be lowered, and the greenhouse in which heat is preserved at night and the light transmittance is increased in the day can be achieved.

Owner:苏州星川园艺绿化有限公司

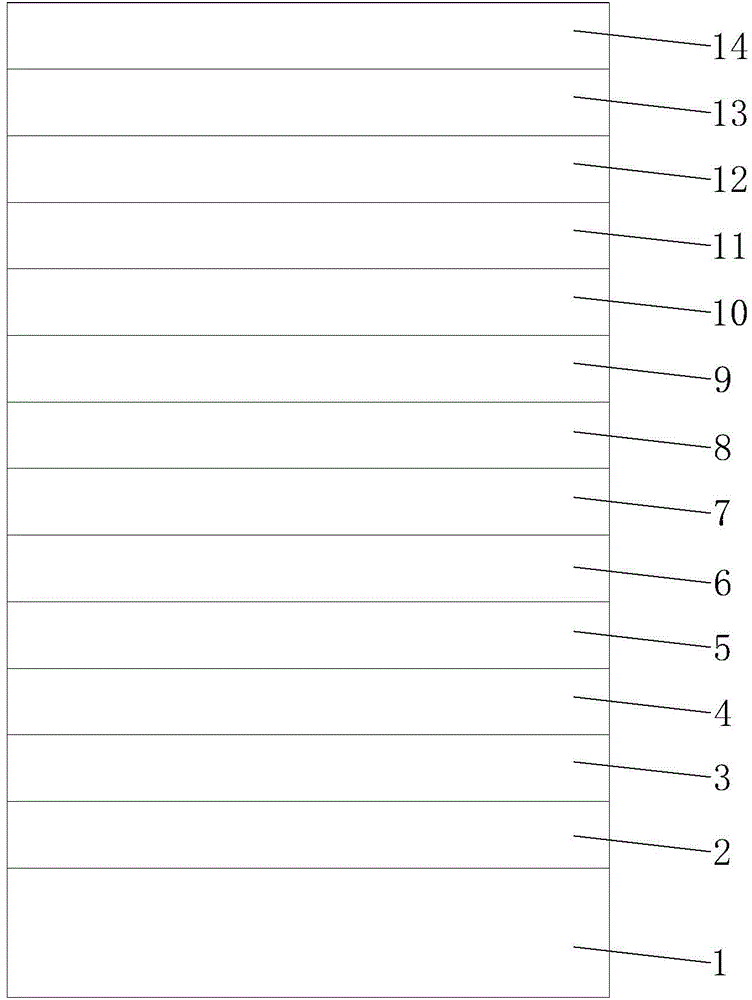

Novel double-silver LOW-E coated glass

InactiveCN104355551AGood adhesionStrong adhesionGlass/slag layered productsOptoelectronicsBond properties

A piece of novel double-silver LOW-E coated glass comprises a glass base material, wherein a SixNy base film layer, a first TiOx film layer, a first AZO barrier layer, a first Ag layer, a first NiCr barrier layer, a second AZO barrier layer, a second TiOx film layer, a third AZO barrier layer, a second Ag layer, a second NiCr barrier layer, a fourth AZO barrier layer, a third TiOx film layer and a SixNy top film layer are arranged on the upper surface of the glass base material from bottom to top in sequence. The novel double-silver LOW-E coated glass has better bonding property and higher mechanical strength, and the storage life can be prolonged.

Owner:中山市亨立达机械有限公司

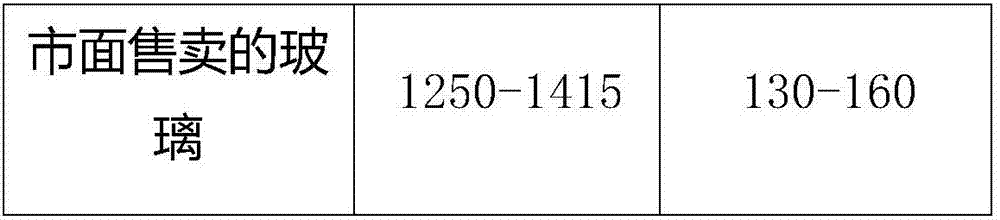

Low-reflection and high-transmittance glass and coating process thereof

The invention belongs to the technical field of material preparation, and in particular relates to a low-reflection, high-transmittance glass and its coating process; a low-reflection, high-transparency glass and its coating process proposed by the present invention include the following steps: cleaning, coating and other processes , the coated glass prepared by it can well improve the problems of glass reflection, low light transmittance, high cost, etc., and its coated glass can be widely used in military, national defense and other fields.

Owner:ZHONGSHAN CHUANGKE RES TECH SERVICE

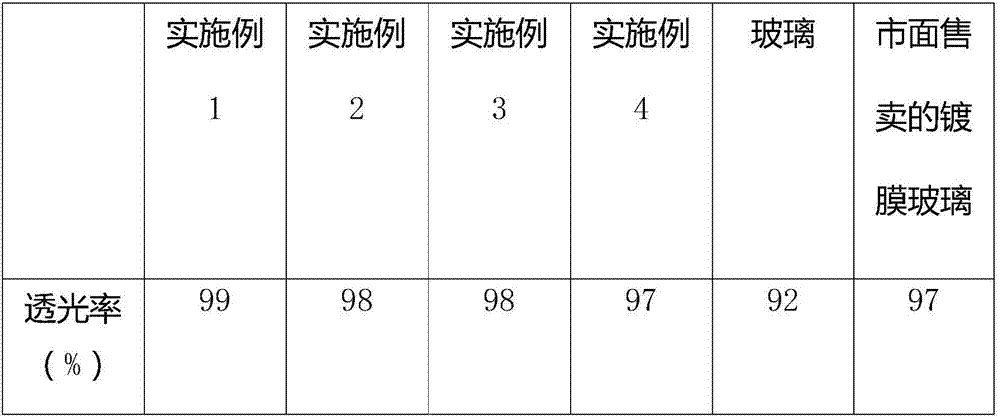

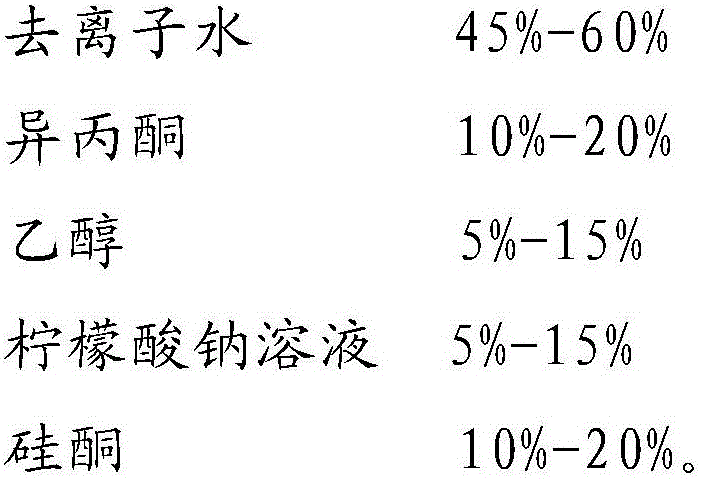

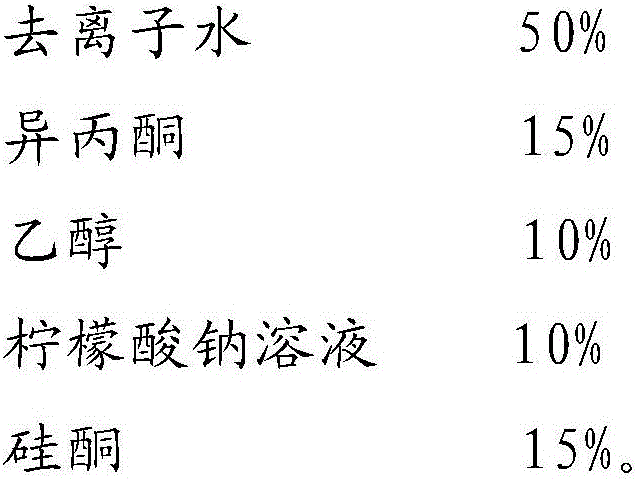

Glass cleaning liquid with automatic cleaning function and high light transmittance

InactiveCN106544182ASelf-cleaningStrong light transmittanceOrganic non-surface-active detergent compositionsTransmittanceKetone

The invention discloses glass cleaning liquid with an automatic cleaning function and high light transmittance. The cleaning liquid comprises, by mass, 45%-60% of deionized water, 10%-20% of isopropyl-ketone, 5%-15% of ethanol, 5%-15% of sodium citrate solutions and 10%-20% of silicone. The glass cleaning liquid has the beneficial effects that the cleaning effect is good, and the transparency of glass can be increased.

Owner:天津天翔电子科技有限公司

UV-resistant anti-crack modified plastic and production method thereof

The invention discloses a type of UV-resistant anti-crack modified plastic. The UV-resistant anti-crack modified plastic comprises, by weight, 50 parts to 60 parts of polyethylene, 30 parts to 40 parts of EVA resin, 5 parts to 8 parts of nanometer tin antimony oxide, 1 part to 3 parts of nanometer titanium dioxide, 2 parts to 4 parts of China hemp fiber powder, 1.1 parts to 2.3 parts of zinc stearate, 1 part to 2 parts of nanometer organic montmorillonite, 0.2 part to 0.4 part of antimony oxide, 0.1 part to 0.3 part of 2-Dihydroxy-4-methoxybenzophenone, 0.5 part to 1.2 parts of polydimethylsiloxane, and the appropriate amount of absolute ethyl alcohol. The produced plastic is resistant to UV light and cracking, is remarkably improved in tensile strength and impact strength, and is improved to some extent in chemical resistance and heat resistance; when the plastic is deeply processed to form film which is used for vegetable greenhouses, the plastic has the advantages of being high in low temperature resistance, obvious in heat insulation, self-cleaning, antibacterial, high in light transmittance and the like.

Owner:WUHU ZHONGLI PARTS

Preparation and application method of high whiteness, high light transmittance and high plasticity ceramic green mud

The invention relates to a preparation and application method of high whiteness, high light transmittance and high plasticity ceramic blank mud, which uses Linchuan talc, phlogopite, orthoclase and American fairy water as raw materials, and undergoes raw material pretreatment, batching, ball milling, Aged, sieved, iron-removed, dehydrated, and smelted to obtain a ceramic body slime with a plasticity index greater than 20, and the ceramic body mud has a whiteness greater than 84 after molding, drying, biscuit firing, water replenishment, glazing, and high-temperature firing. Ceramic products with light transmittance greater than 7.5% / 2mm. The invention adopts common mineral raw materials and chemical raw materials for specific proportioning, and modifies the Linchuan talc, so that the green body has high whiteness, strong light transmittance, good plasticity and wide sintering range, and can also make The green body will not be deformed when it is fired at a high temperature of 1240-1310°C. It solves the shortcomings of high difficulty in production, complex molding process and narrow firing temperature range of high-whiteness and high-transparency ceramics, so it has broad market prospects.

Owner:JINGDEZHEN CERAMIC UNIV

High-strength thin film and preparation method thereof

The invention discloses a high-strength thin film. The high-strength thin film is prepared from the following raw materials in parts by weight: 80 to 100 parts of polyvinyl chloride resin, 20 to 30 parts of nitrile rubber, 15 to 20 parts of o-cresol formaldehyde epoxy resin, 4 to 8 parts of glass fibres, 2 to 6 parts of cotton pulp, 3 to 7 parts of acorus gramineus, 5 to 10 parts of polyethylene terephthalate, 2 to 5 parts of methylenediphenyl diisocyanate, 5 to 10 parts of polyoxyethylene nonyl phenyl ether, 4 to 8 parts of sodium carboxymethylcellulose, 2 to 5 parts of aminophenyl sulfone, 5to 10 parts of a plasticizer, 2 to 4 parts of a leveling agent, 1 to 3 parts of a curing agent and 0.5 to 1 part of an antioxidant. The invention also discloses a preparation method of the high-strength thin film. The thin film prepared by the preparation method has high strength, high aging resistance and high light transmittance under the cooperative action of various raw materials.

Owner:赵丽敏

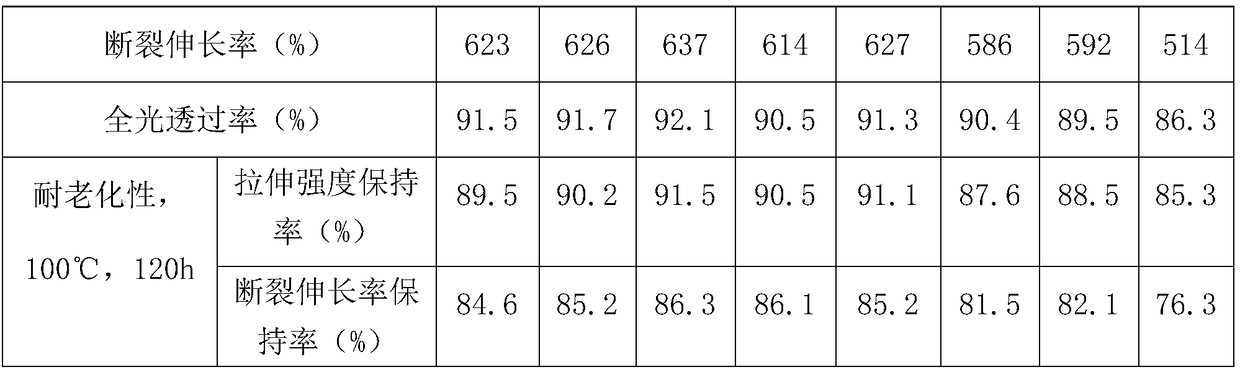

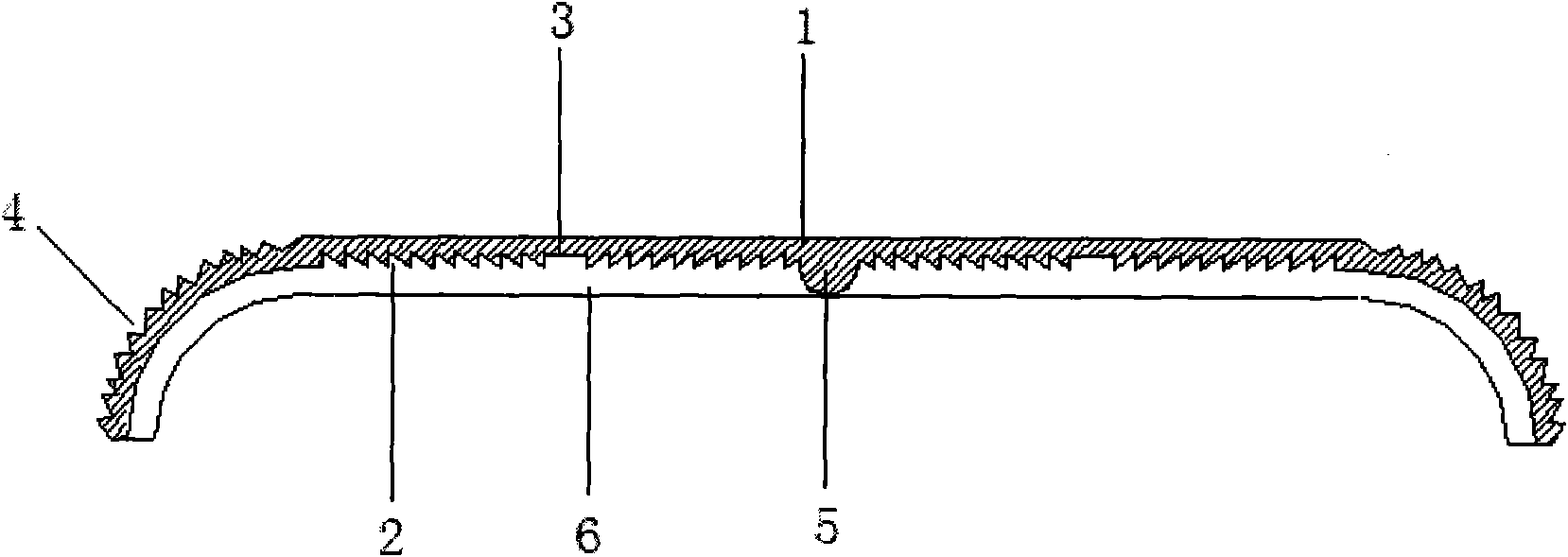

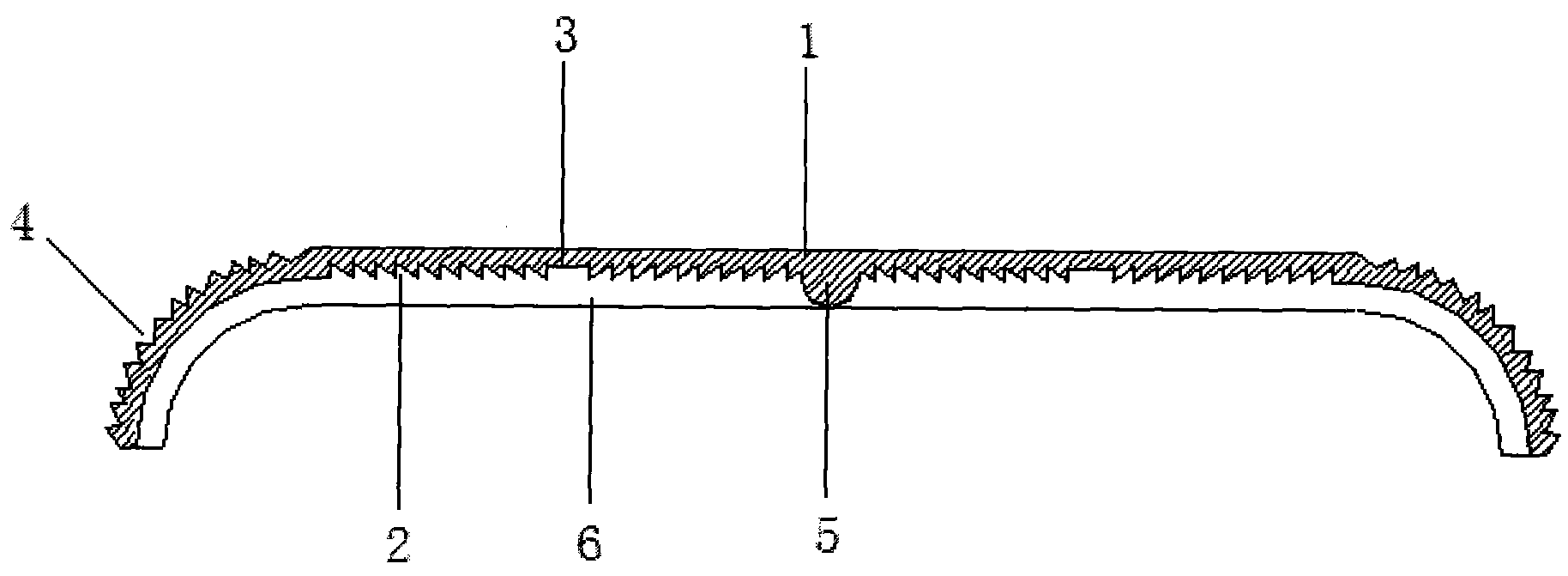

Extra-high-expansion lens for solar power heat-collecting device

InactiveCN101840940AIncrease sunlight penetrationStrong light transmittanceSolar heating energySolar heat devicesUltrasound attenuationSupporting system

The invention discloses an extra-high-expansion lens for a solar power heat-collecting device, which comprises a lens body. The upper surface of the lens body is provided with a film layer; the lens body is provided with a supporting structure; and the lower surface of the lens body is provided with a linear micro-groove. The extra-high-expansion lens for the solar power heat-collecting device has the advantages of simple structure, delicate design, light transmittance of over 92 percent, resistance to the high temperature of more than 130 DEG C, yellowing resistance and attenuation-free property; the surface of the lens has a self-cleaning function and is kept away from sundries, such as dust, sand and stone which affect light transmittance; and a well-shaped supporting system with extremely high light transmittance is arranged in the lens, so the lens does not deform in a large area after being used for a long time and the condensing effect is not affected.

Owner:袁长胜

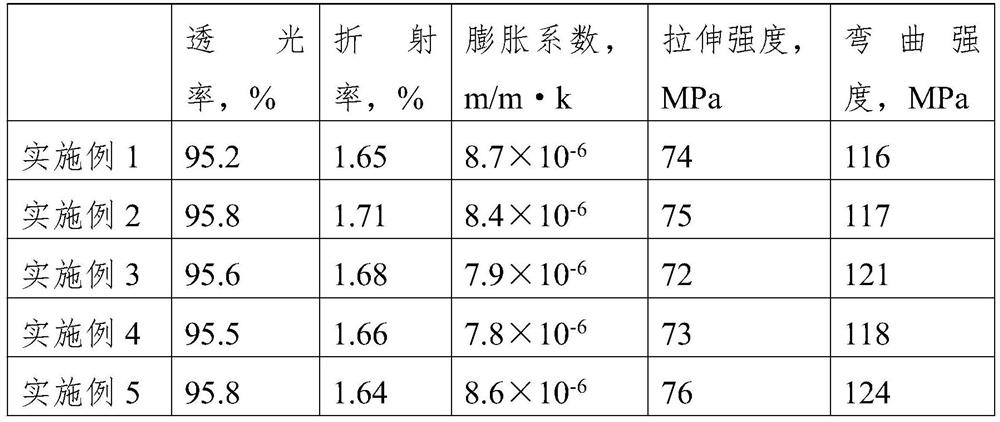

A light guide plate with high light transmittance and its preparation method

The invention provides a high-transparency light guide plate and a preparation method thereof. The light guide plate comprises, in weight percent, 15-20% of PC (polycarbonate), 2-3.5% of silane coupling agents, 2-10% of modified silicon dioxide, 0.4-1% of light stabilizers, 0.5-1.2% of compatilizers, 0.5-3% of organic tin compounds, the balance PMMA (polymethyl methacrylate), 2-5% of silicone and3-8% of cellulose triacetate. By the aid of reasonable raw material selecting and blending and process improvement, the prepared light guide plate has excellent transparency, refractivity and toughness and is low in service deformation rate, and the service life of the light guide plate is remarkably prolonged.

Owner:苏州亿光源光电科技股份有限公司

A kind of processing technology of automobile transparent lampshade

The invention discloses a processing technology for a transparent lampshade for an automobile, which relates to the field of processing lamps and lanterns for automobiles, including six steps of processing and molding, ultrasonic cleaning, static electricity elimination, spraying treatment on the outer surface, anti-fog coating on the inner surface, and edge grinding. As a raw material for lampshade processing, methyl methacrylate has strong impact resistance, high light transmittance, strong wear resistance and flame resistance. A layer of anti-fog film is coated on the inner surface of the lampshade blank to prevent water from forming in the lampshade. Fog is conducive to the safe driving of the car. The frosting treatment on the edge of the lampshade blank can increase the roughness of the outer surface of the lampshade blank edge and make the installation of the lampshade more secure.

Owner:DANYANG ZHONGYUAN AUTOMOBILE LIGHT

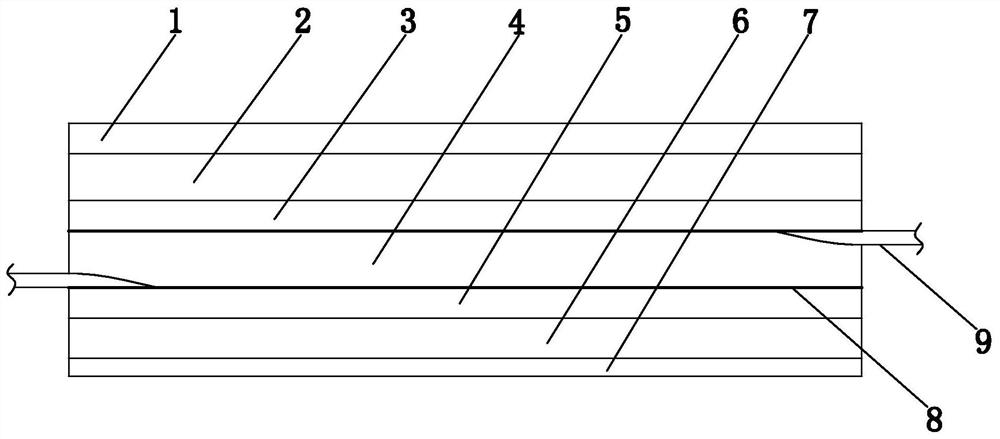

Self-adhesive dimming film

PendingCN111999930AImprove toughnessGood toughness, high transparencyFilm/foil adhesivesOrganic non-macromolecular adhesiveThin membraneProtection layer

The invention discloses a self-adhesion type dimming film. An outer protective layer, a first adhesive layer, a first conductive film layer, a polymer dispersed liquid crystal layer, a second conductive film layer, a second adhesive layer and a release layer are sequentially arranged from top to bottom. Multiple innovations in structure, material taking and formula are carried out; the film has the advantages of stability in operation, difficulty in damage, high transparency after being electrified and capability of being applied to curved surfaces; the dimming film can be installed by a useraccording to the requirements of the user, transformation of traditional glass is achieved, new and old replacement of the dimming film and modification of DIY decoration such as patterns are facilitated, material waste is avoided, time and labor are saved, the operation difficulty is low, the cost is low, comfort and convenience are brought to life of people, the application range is wide, and the market competitiveness is high.

Owner:UPASS MATERIAL TECH JIANGSU

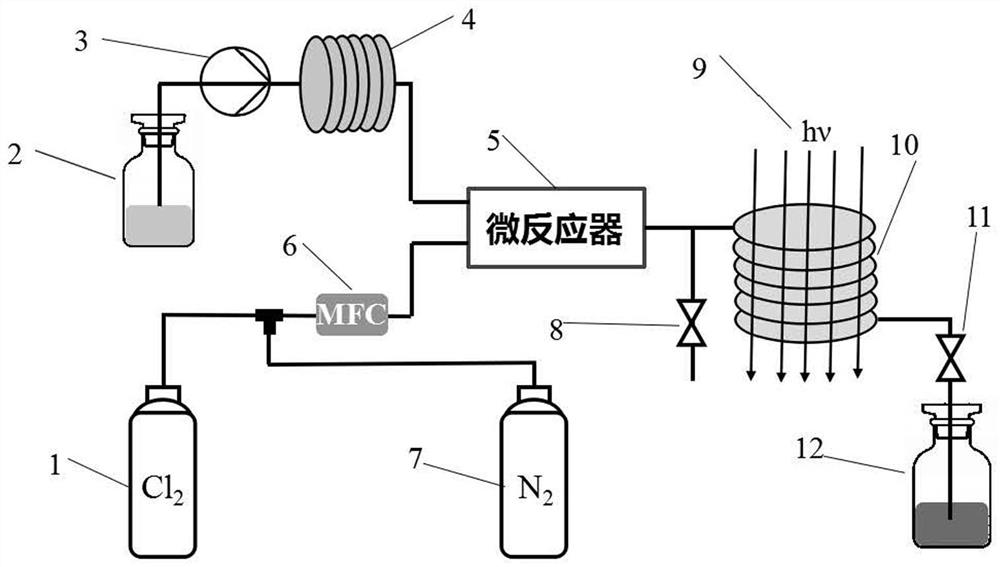

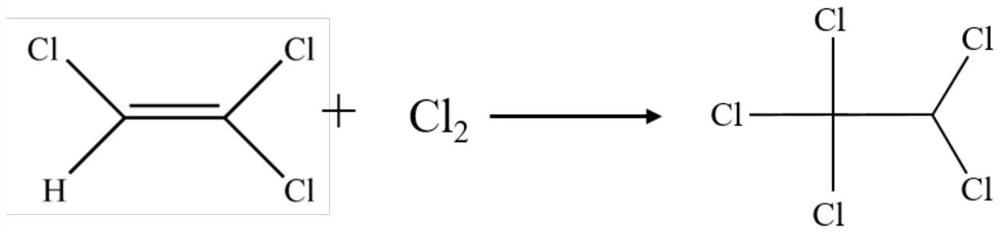

Method and device for continuously synthesizing pentachloroethane by taking trichloroethylene as raw material

PendingCN114452915ALess side effectsMake up for insufficient reaction mixingChemical/physical/physico-chemical microreactorsEnergy based chemical/physical/physico-chemical processesWater chlorinationNitrogen gas

The invention belongs to the technical field of chemical engineering, and relates to a method and a device for continuously synthesizing pentachloroethane by taking trichloroethylene as a raw material. The method comprises the following steps: firstly, introducing dried nitrogen into a microchannel reactor in the device; removing water from the chlorine gas through a mass flow controller and a dryer, and introducing the chlorine gas into a reactor system; the method comprises the following steps: introducing chlorine into a micro-channel reactor, pumping a raw material solution containing trichloroethylene into the micro-channel reactor, fully and uniformly mixing the raw material solution with the introduced chlorine in the micro-channel reactor in a gas-liquid two-phase manner, and continuously carrying out a continuous chlorination addition reaction on the mixed gas-liquid mixture in a delay pipeline under the action of illumination, and treating a liquid-phase product after the reaction to obtain high-yield pentachloroethane. According to the invention, a continuous process is adopted to replace a traditional intermittent mode to carry out a chlorination reaction to synthesize pentachloroethane, the mass transfer capacity of a gas-liquid reaction is enhanced, the reaction time is greatly shortened, the reaction efficiency is improved, and the defect of insufficient mixing of gas-phase and homogeneous-phase reactions is overcome.

Owner:SHENYANG RES INST OF CHEM IND

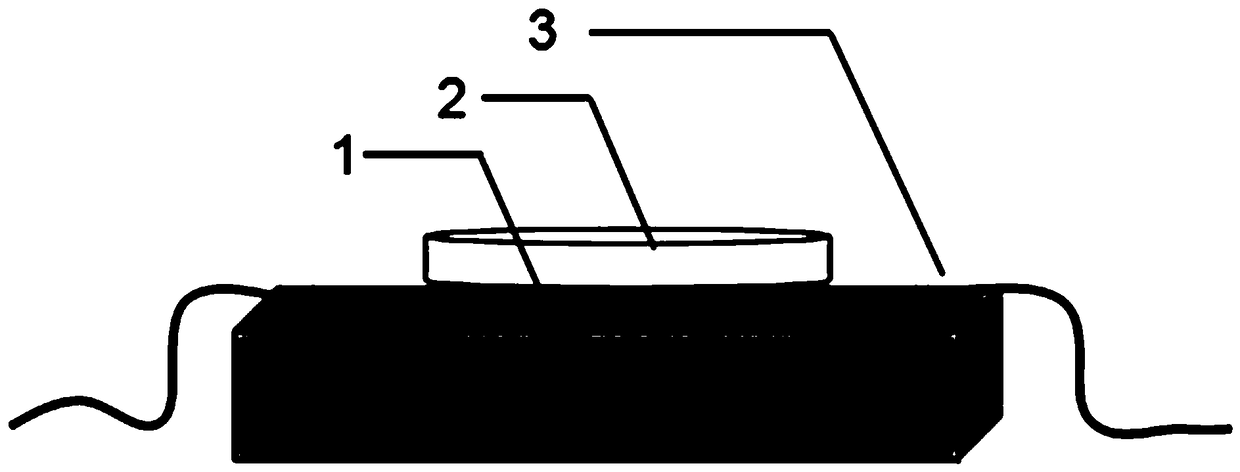

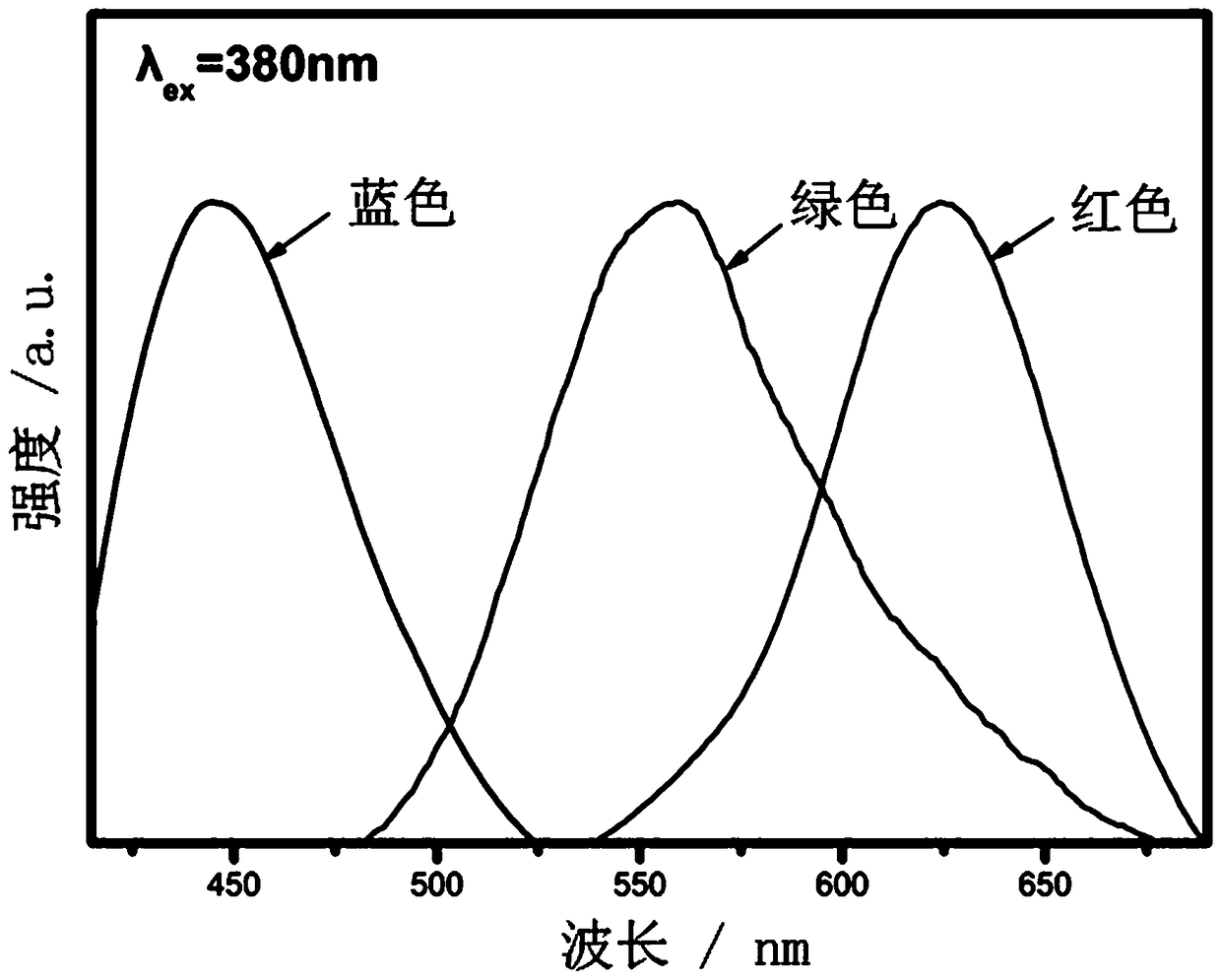

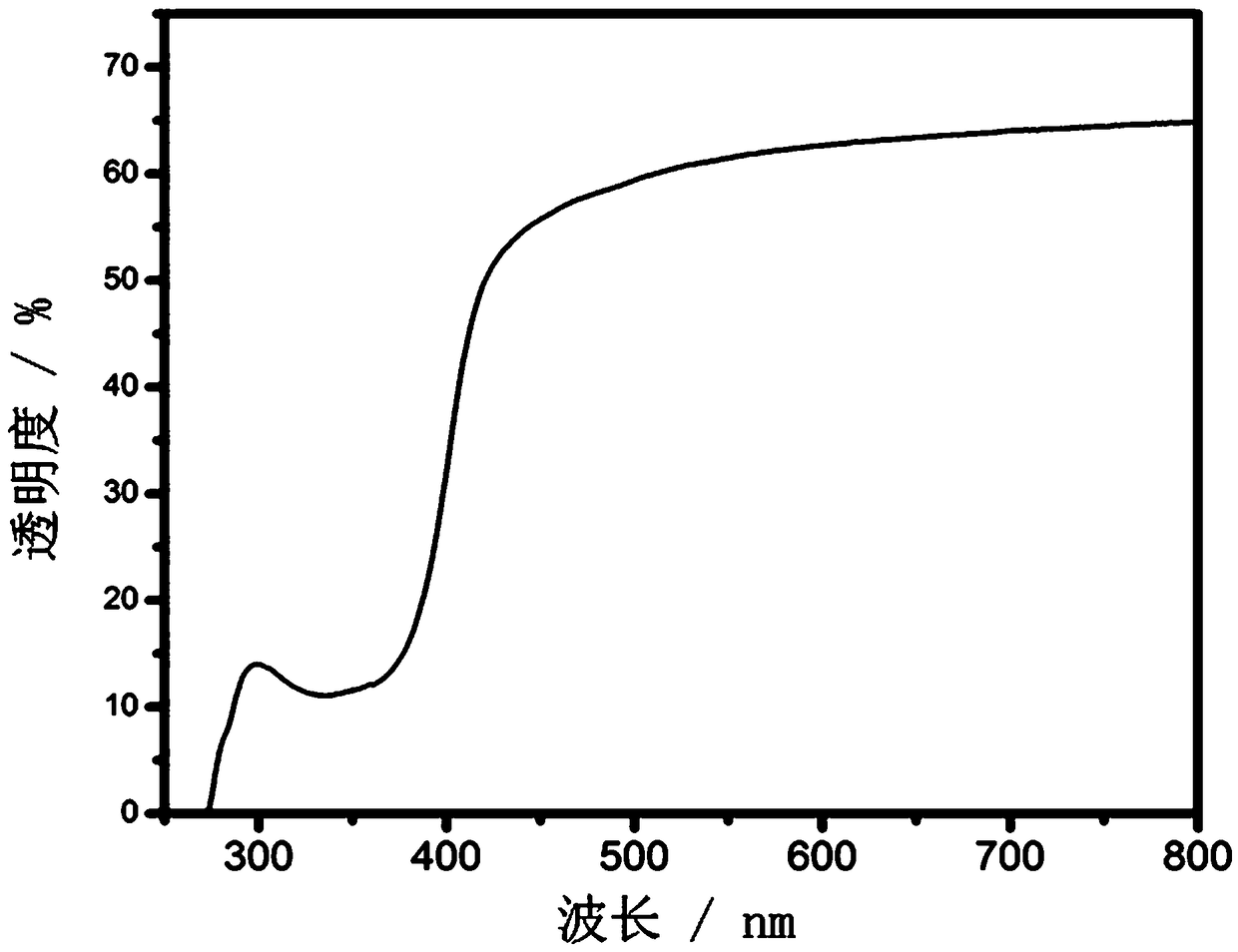

A kind of white light led fluorescent film and LED based on fluorescent film

The invention discloses a novel white light LED fluorescent film excited by ultraviolet light. The LED based on the fluorescent film and its preparation method comprises mixing and curing two-component organic silica gel, fluorescent carbon dot solution and red fluorescent powder, vacuumizing and removing bubbles, and slowly Pour it into a mold, put it in an oven to cure at 75°C, remove the mold and then cure it at 130°C to obtain a fluorescent film. The above fluorescent film is packaged on the ultraviolet LED chip by "chip type". The fluorescent film of the present invention greatly reduces the amount of fluorescent powder used, has the advantages of simple preparation process, controllable shape and thickness, uniform material dispersion, low cost, etc. "type" package on the ultraviolet LED chip, has considerable application prospects.

Owner:WUYI UNIV

A kind of preparation method of crystal jade porcelain raw material

The invention belongs to the field of ceramic and discloses a Jingyu porcelain raw material preparation method. The preparation method utilizes 25-35% by mass of kaolin, 20-30% by mass of Longyan washing mud, 20-30% by mass of Qingyuan mud, 2.5-7.5% by mass of a clinker, 7-13% by mass of feldspar powder and 2.5-7.5% by mass of large plagiopematite weathering residue balls. A Jingyu porcelain finished product prepared from the Jingyu porcelain raw material contains fewer impurities, has a wide sintering temperature range and has whiteness of 88%, transparency of 41% and glossiness of 91.9%.

Owner:醴陵市瓷艺堂有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com