A kind of white light led fluorescent film and LED based on fluorescent film

A fluorescent film and LED chip technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve problems such as poor uniformity, poor consistency of light emission and color temperature of devices, and lower price, and achieve strong light transmittance and stability , Avoid the rise of working temperature, the effect of controllable shape and thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

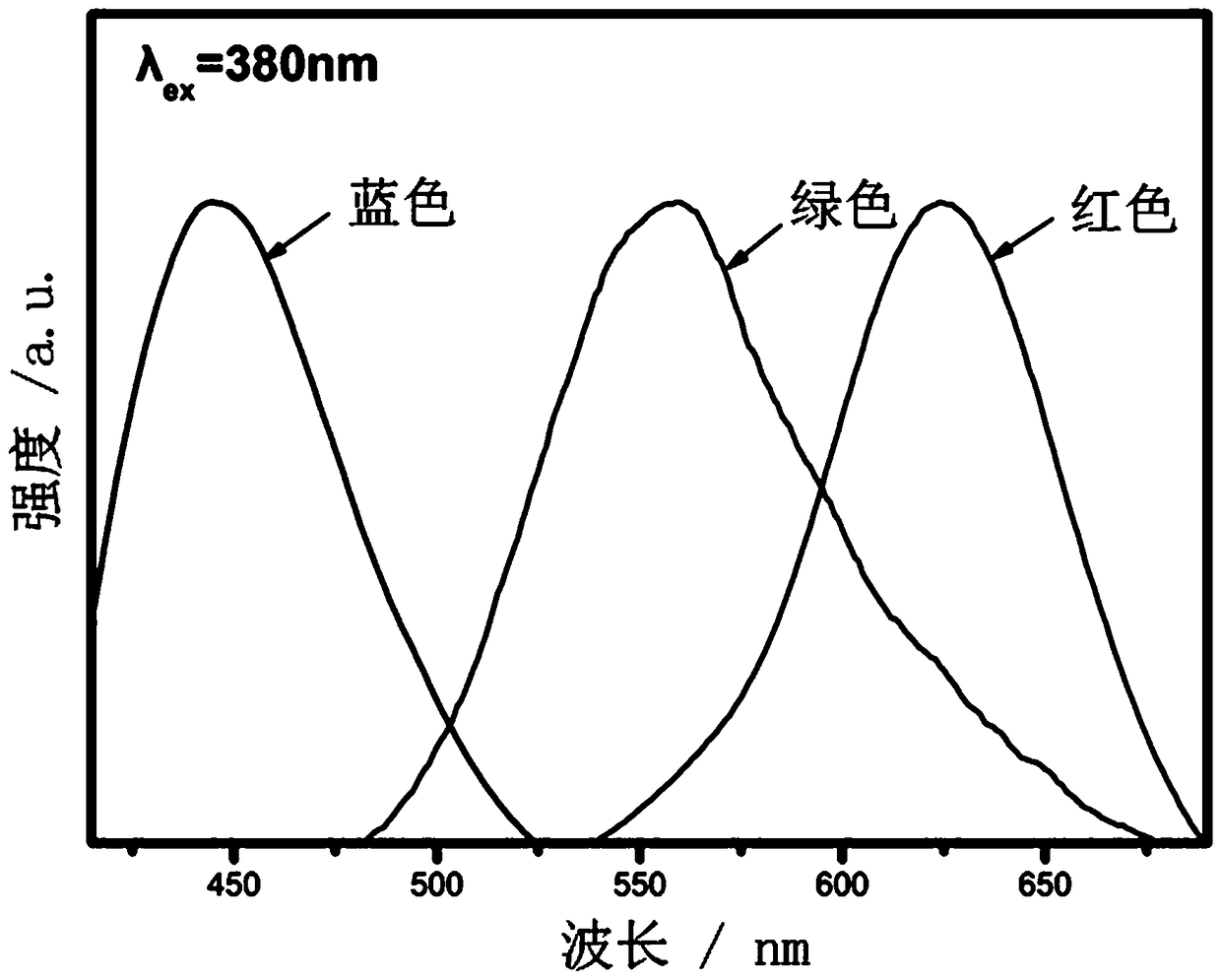

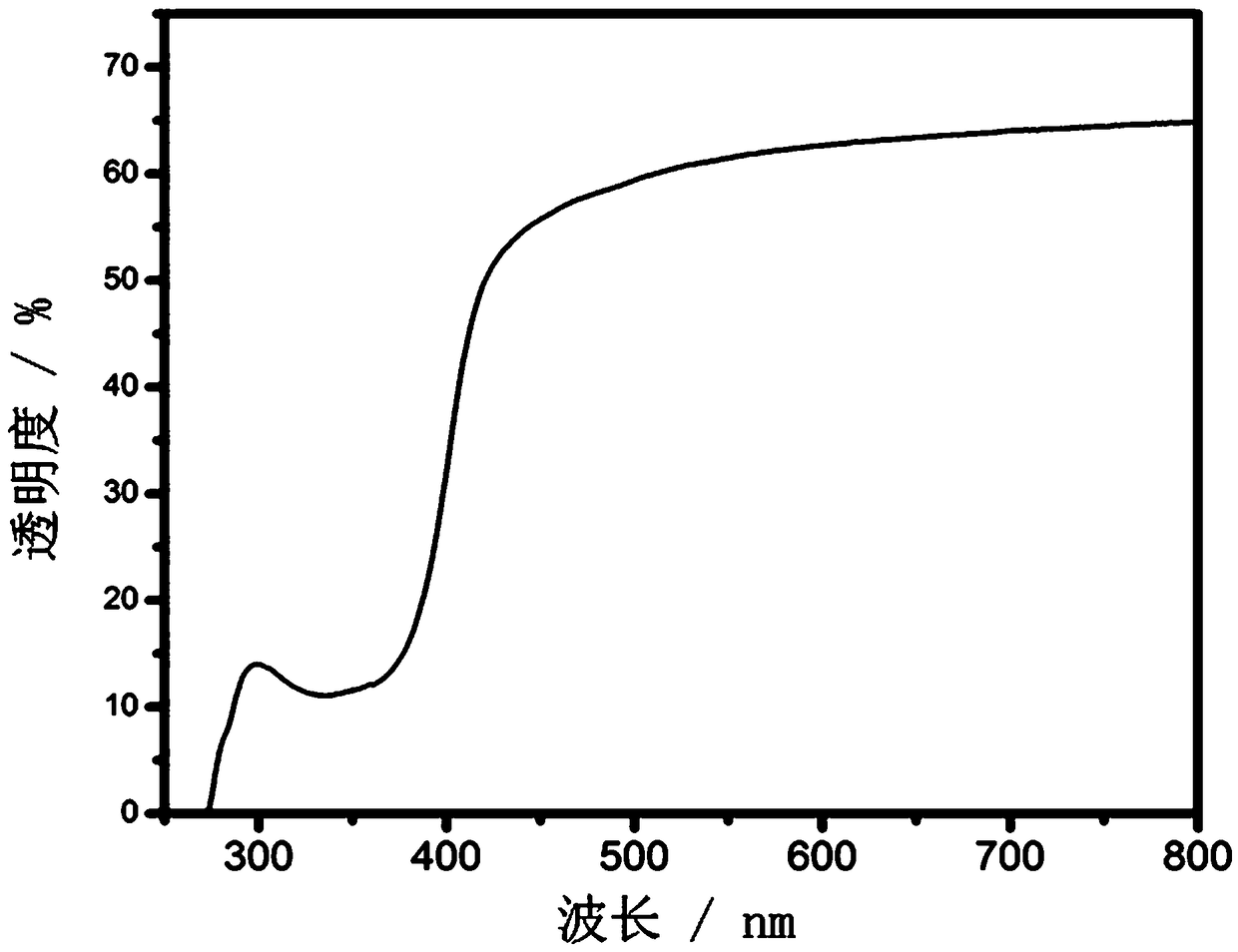

[0034] A new type of white LED fluorescent film excited by ultraviolet light is formed by mixing and curing two-component organic silica gel, fluorescent carbon dot solution and red phosphor powder.

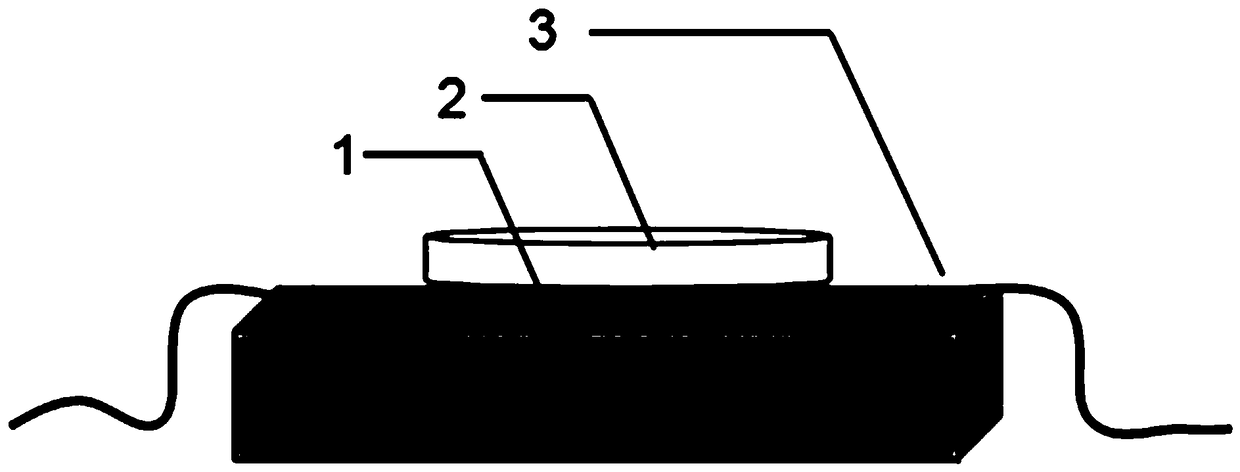

[0035] A new type of white light LED based on the above-mentioned fluorescent film, which mainly includes: an ultraviolet LED chip 1, a fluorescent film 2 and a wire 3. The positive and negative electrodes are drawn out from the ultraviolet LED chip 1 through the wire 3 to prepare for electrification. Chip type" packaging method is directly packaged on the ultraviolet LED chip 1 to form an LED that emits white light under ultraviolet excitation.

[0036] The preparation method of the above-mentioned novel white light LED comprises the following steps:

[0037] (1) Preparation of carbon dot fluorescent materials

[0038] During the stirring process, 0.05 mL of ethylenediamine (AR, content ≥ 99 (%)) was added dropwise to 20 mL of citric acid aqueous solution with a concentration o...

Embodiment 2

[0046] (1) Preparation of carbon dot fluorescent materials

[0047] The preparation process of the carbon dot fluorescent material in this example is the same as that in Example 1.

[0048] (2) Pretreatment of carbon dot fluorescent materials

[0049] The pretreatment process of the carbon dot fluorescent material in this example is the same as the pretreatment process in Example 1.

[0050] (3) Preparation of fluorescent film

[0051] Measure 10 ml of the solution outside the bag after the above dialysis treatment in a beaker, and evaporate to remove 90% of the water. At the same time, weigh 2.500g of type A integrated silica gel, 2.500g of type B integrated silica gel, and 0.002g of R6733 commercial red powder and mix them evenly. The first curing is carried out in a drying oven, wherein the first curing condition is 75°C for 90 minutes, and the second curing is carried out after the mold is removed, and the condition is 130°C for 6 hours to obtain a fluorescent film. Th...

Embodiment 3

[0055] (1) Preparation of carbon dot fluorescent materials

[0056] The preparation process of the carbon dot fluorescent material in this example is the same as that in Example 1.

[0057] (2) Pretreatment of carbon dot fluorescent materials

[0058] The pretreatment process of the carbon dot fluorescent material in this example is the same as the pretreatment process in Example 1.

[0059] (3) Preparation of fluorescent film

[0060] Measure 10 ml of the solution outside the bag after the above dialysis treatment in a beaker, and evaporate to remove 90% of the water. At the same time, weigh 2.500g of type A integrated silica gel, 2.500g of type B integrated silica gel, and 0.002g of R6733 commercial red powder and mix them evenly. The first curing is carried out in a drying oven, wherein the first curing condition is 75°C for 90 minutes, and the second curing is carried out after the mold is removed, and the condition is 130°C for 6 hours to obtain a fluorescent film. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com