A light guide plate with high light transmittance and its preparation method

A high light transmittance, light guide plate technology, applied in the field of light guide plates, can solve the problems of not meeting the needs of display technology, affecting product efficacy and quality, and prone to expansion changes in volume, achieving excellent light transmittance, improving refraction, Use effects with small deformation rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

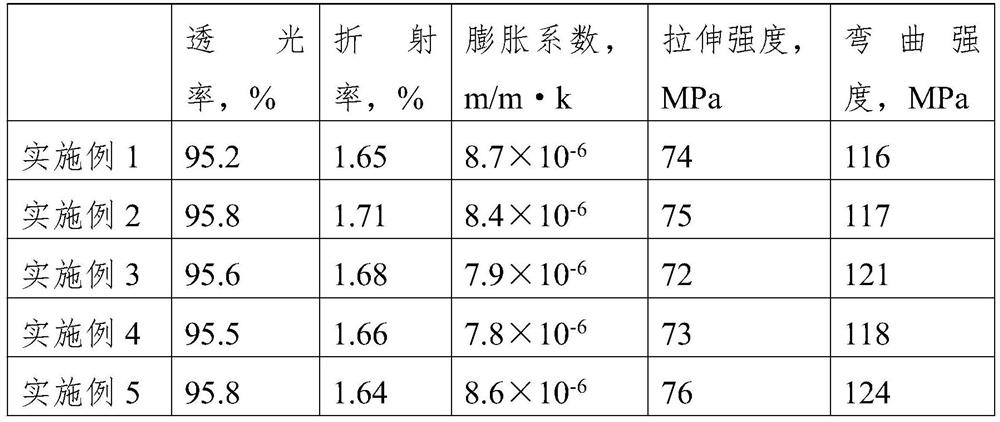

Examples

Embodiment 1

[0018] A light guide plate with high light transmittance, comprising the following components in mass percentage: PC 15%, silane coupling agent 3.2%, modified silicon dioxide 6%, light stabilizer 0.5%, compatibilizer 0.8%, organic Tin compound 0.8%, PMMA balance.

[0019] The silane coupling agent is a combination of vinyltriethoxysilane and aminosilane coupling agent, the mass ratio of which is 1:0.5, wherein the aminosilane coupling agent is γ-aminopropyltrimethoxysilane.

[0020] The organotin compound is a composition of dimethyltin and dibutyltin with a mass ratio of 1:1.

[0021] The modified silicon dioxide is metal-containing modified silicon dioxide, the metal is a combination of Cu and Ag, and the metal doping amount is 0.5% of the total mass of the modified silicon dioxide. The preparation steps of the modified silicon dioxide are as follows: Fused spherical silica micropowder with a particle size distribution of 50-60μm, add it to polyvinyl alcohol aqueous solutio...

Embodiment 2

[0024] A light guide plate with high light transmittance, comprising the following components in mass percentage: PC 20%, silane coupling agent 3.5%, modified silicon dioxide 2%, light stabilizer 0.8%, compatibilizer 1.2%, organic Tin compound 2.4%, PMMA balance; also includes silicone 4%, cellulose triacetate 6%.

[0025] The silane coupling agent is a combination of vinyltriethoxysilane and aminosilane coupling agent, the mass ratio of which is 1:0.6, wherein the aminosilane coupling agent is selected from γ-aminopropyltrimethoxysilane.

[0026] The organic tin compound is a composition of dimethyl tin and dibutyl tin with a mass ratio of 1:0.6.

[0027] The modified silicon dioxide is metal-containing modified silicon dioxide, the metal is a composition of Cu and Al, and the metal doping amount is 1% of the total mass of the modified silicon dioxide. The preparation steps of the modified silicon dioxide are as follows: Fused spherical silica micropowder with a particle siz...

Embodiment 3

[0030] A light guide plate with high light transmittance, comprising the following components in mass percentage: PC 18%, silane coupling agent 3%, modified silicon dioxide 4%, light stabilizer 1%, compatibilizer 1%, organic Tin compound 3%, PMMA balance; also includes silicone 3%, cellulose triacetate 4%.

[0031] The silane coupling agent is a combination of vinyltriethoxysilane and aminosilane coupling agent, the mass ratio of which is 1:0.8, wherein the aminosilane coupling agent is anilinomethyltrimethoxysilane.

[0032] The organic tin compound is a composition of dimethyl tin and dibutyl tin with a mass ratio of 1:0.5.

[0033]The modified silicon dioxide is metal-containing modified silicon dioxide, the metal is a composition of Ag and Al, and the metal doping amount is 1.5% of the total mass of the modified silicon dioxide. The preparation steps of the modified silicon dioxide are as follows: Fused spherical silica micropowder with a particle size distribution of 50-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com