Method and device for continuously synthesizing pentachloroethane by taking trichloroethylene as raw material

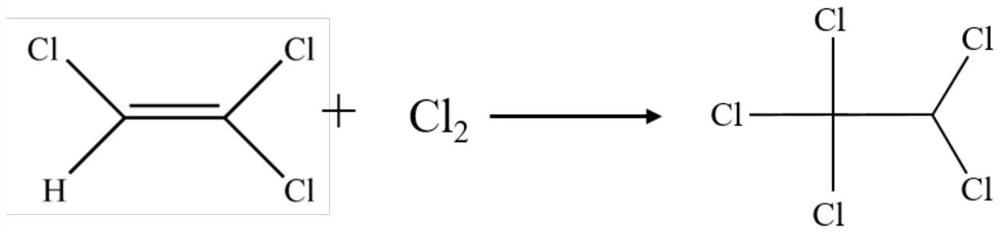

A technology of trichlorethylene and pentachloroethane, which is applied in the field of microchannel continuous technology to synthesize pentachloroethane, can solve the problems of complex reaction equipment, low safety and controllability, and slow reaction rate, and achieve controllable reaction process , Improve the reaction efficiency, the effect of strong light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

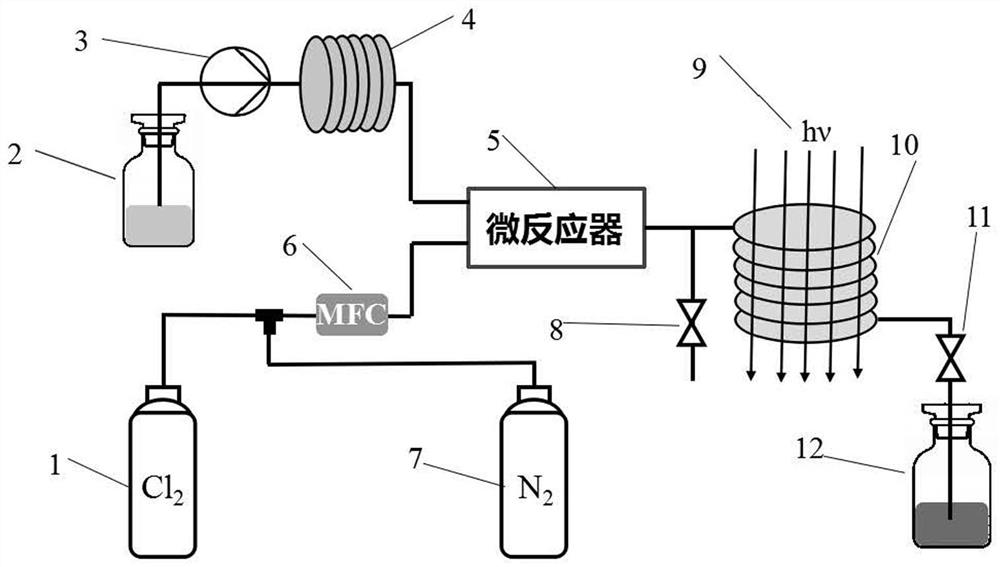

[0030] device such as figure 1 As shown, a device for continuously synthesizing pentachloroethane using dichloroethane as a raw material, the device includes a chlorine gas cylinder 1, a raw material tank 2, a metering pump 3, a preheating pipeline 4, a microchannel reactor 5, and a gas mass flow rate Meter 6, nitrogen cylinder 7, sampling valve 8, light source 9, time-delay pipeline 10, back pressure valve 11 and storage tank 12; Described microreactor 5 has two material inlets and a material outlet, and described Raw material tank 2 links to each other with a feed inlet of described microchannel reactor 5 by first pipeline; Described chlorine cylinder 1 links to each other with another feed inlet of described microchannel reactor 5 by second pipeline; The outlet of the microchannel reactor 5, the delay pipeline 10, the back pressure valve 11 and the storage tank 12 are connected in series through pipelines.

[0031] The first pipeline between the raw material tank 2 and the...

Embodiment 2

[0036] The configuration of the raw material liquid: use dry nitrogen to remove the dissolved oxygen in the raw material trichlorethylene and the solvent methylene chloride, then dissolve the trichlorethylene in the solvent, and then add the polymerization inhibitor (2,6-dichloromethane tert-butyl-p-cresol), promptly obtain raw material liquid, contain 0.1%wt polymerization inhibitor in the raw material liquid, and mass concentration is the trichlorethylene solution of 20%.

[0037] Then each material is passed into the device, first, use N 2 Purge the experimental device to eliminate water vapor and impurities in the reaction system. The raw material liquid prepared above is input into the raw material tank, and nitrogen protection is passed through the head space of the raw material tank at the same time, and is ready for use. Under ultraviolet light, open the gas valve of the chlorine gas cylinder, let the chlorine gas pass through the dryer to remove the residual trace mo...

Embodiment 3

[0039] The configuration of the raw material liquid: use dry nitrogen to remove the dissolved oxygen in the raw material trichlorethylene and the solvent methylene chloride, then dissolve the trichlorethylene in the solvent, and then add the polymerization inhibitor (2,6-dichloromethane tert-butyl-p-cresol), promptly obtain raw material liquid, contain 0.1%wt polymerization inhibitor in the raw material liquid, and mass concentration is the trichlorethylene solution of 20%.

[0040] Then feed each material into the device. First, use N2 to purge the experimental device to eliminate water vapor and impurities in the reaction system. The raw material liquid prepared above is input into the raw material tank, and nitrogen protection is passed through the head space of the raw material tank at the same time, and is ready for use. Under ultraviolet light, open the gas valve of the chlorine gas cylinder, let the chlorine gas pass through the chlorine gas drier, to remove the trace m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com