Multi-color-selection and multi-base-material laser welding light-transmitting color master batch and preparation method thereof

A laser welding, multi-color technology, applied in the multi-substrate application of laser welding light-transmitting color masterbatch and its preparation, multi-color selection field, can solve the problem of increasing the application of laser welding molding technology, less research on color masterbatch, color masterbatch Lack of in-depth research, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-14

[0054] The preparation method of embodiment 1-14 and comparative example 1-6:

[0055] Preparation of laser welding transparent masterbatch:

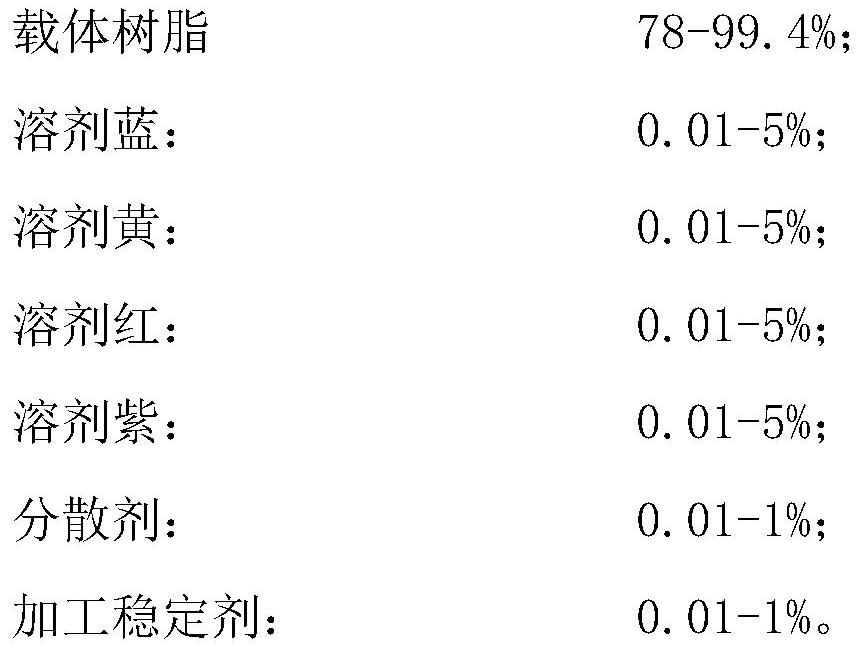

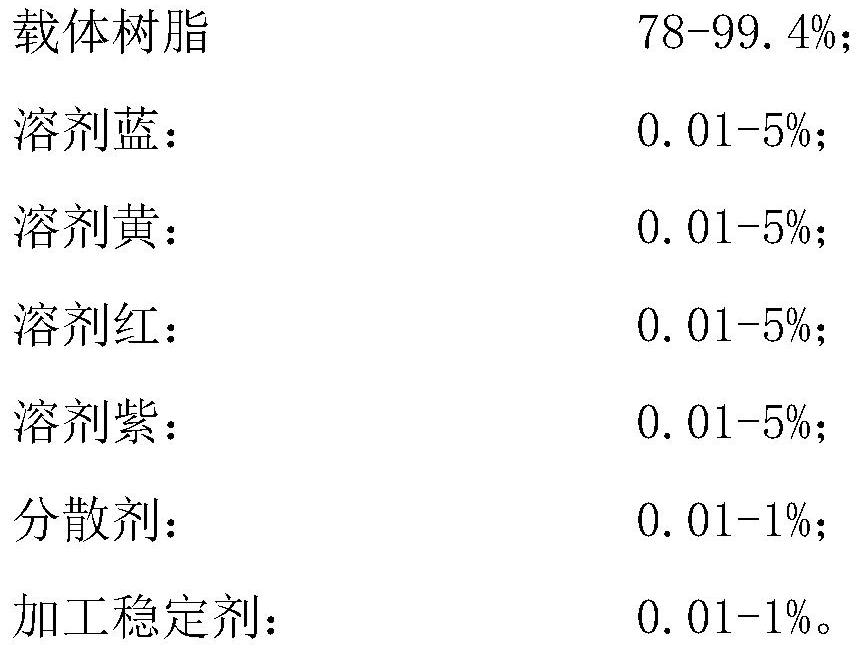

[0056] The raw materials are weighed according to the formula ratio; the carrier resin, solvent blue, solvent yellow, solvent red, solvent violet, dispersant and processing stabilizer are mixed uniformly through a high-speed mixer. The above-mentioned carrier resin and auxiliary agent mixed raw materials are added through the main feeding port of the twin-screw extruder, and the laser welding penetration is obtained after the processes of melting extrusion, granulation, and drying at a temperature of 200-260 ° C. Optical masterbatch.

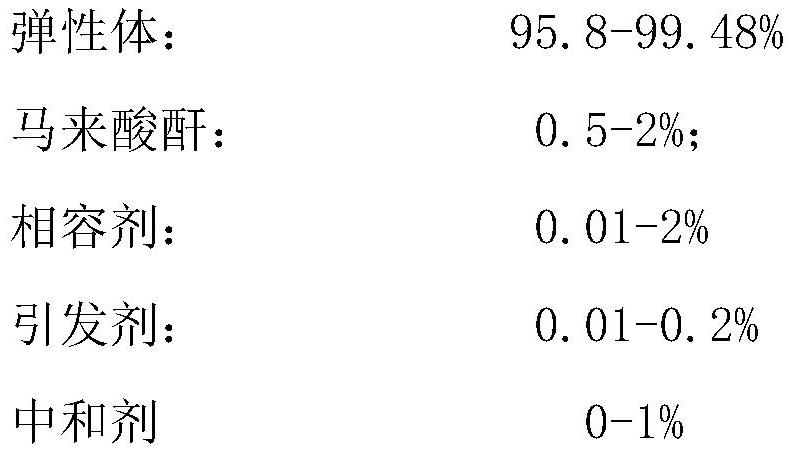

[0057] Preparation method of the transparent layer:

[0058] Weigh the dried raw materials according to the formula ratio; mix the resin and laser welding light-transmitting masterbatch through a high-speed mixer. The above-mentioned resin mixed raw materials are fed into the twin-screw extruder throug...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com