Polycarbonate flame retardant endurance plate and preparation method thereof

A polycarbonate and endurance board technology, applied in the field of flame retardant materials, can solve the problems of low decomposition temperature, easy leakage, high cost, etc., and achieve the effects of high light transmittance, high solubility, and strong toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw material formula:

[0023] PC 3117: 99kg,

[0024] Potassium modified perfluorobutane sulfonate: 1kg.

[0025] Preparation:

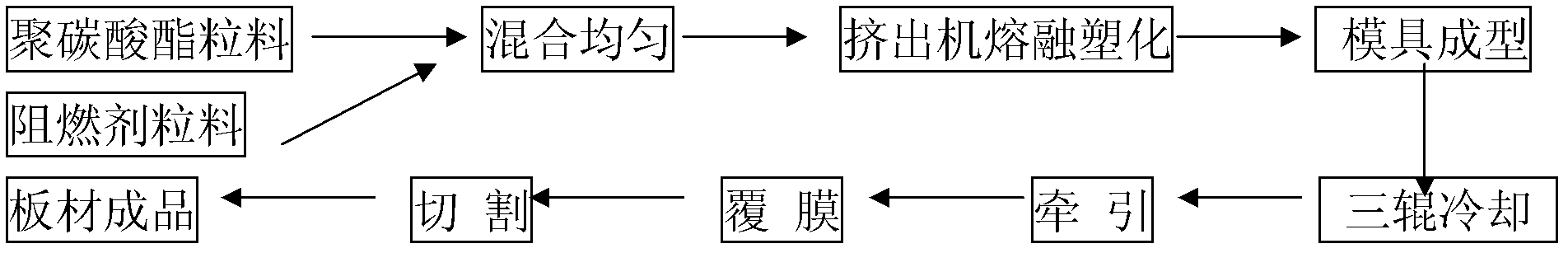

[0026] (1) After the carbonate granules and flame retardant granules are mixed uniformly by the above weight, they are melted and plasticized in the extruder;

[0027] (2) After the plastic compound is molded in the mold, it is cooled by three sticks;

[0028] (3) The cooled model is sequentially drawn, coated and cut to obtain a 2mm polycarbonate endurance board.

Embodiment 2

[0030] Raw material formula:

[0031] PC3117 99kg,

[0032] Modified potassium perfluorobutane sulfonate 1kg.

[0033] Preparation:

[0034] The same preparation method as in Example 1 can be used to produce a 3mm polycarbonate endurance board.

Embodiment 3

[0036] Raw material formula:

[0037] PC3117 98kg,

[0038] Modified potassium perfluorobutane sulfonate 2kg.

[0039] Preparation:

[0040] The same preparation method as in Example 1 can be used to produce a 2mm polycarbonate endurance board.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com